Contact

Cutting-edge technology to meet every requirement

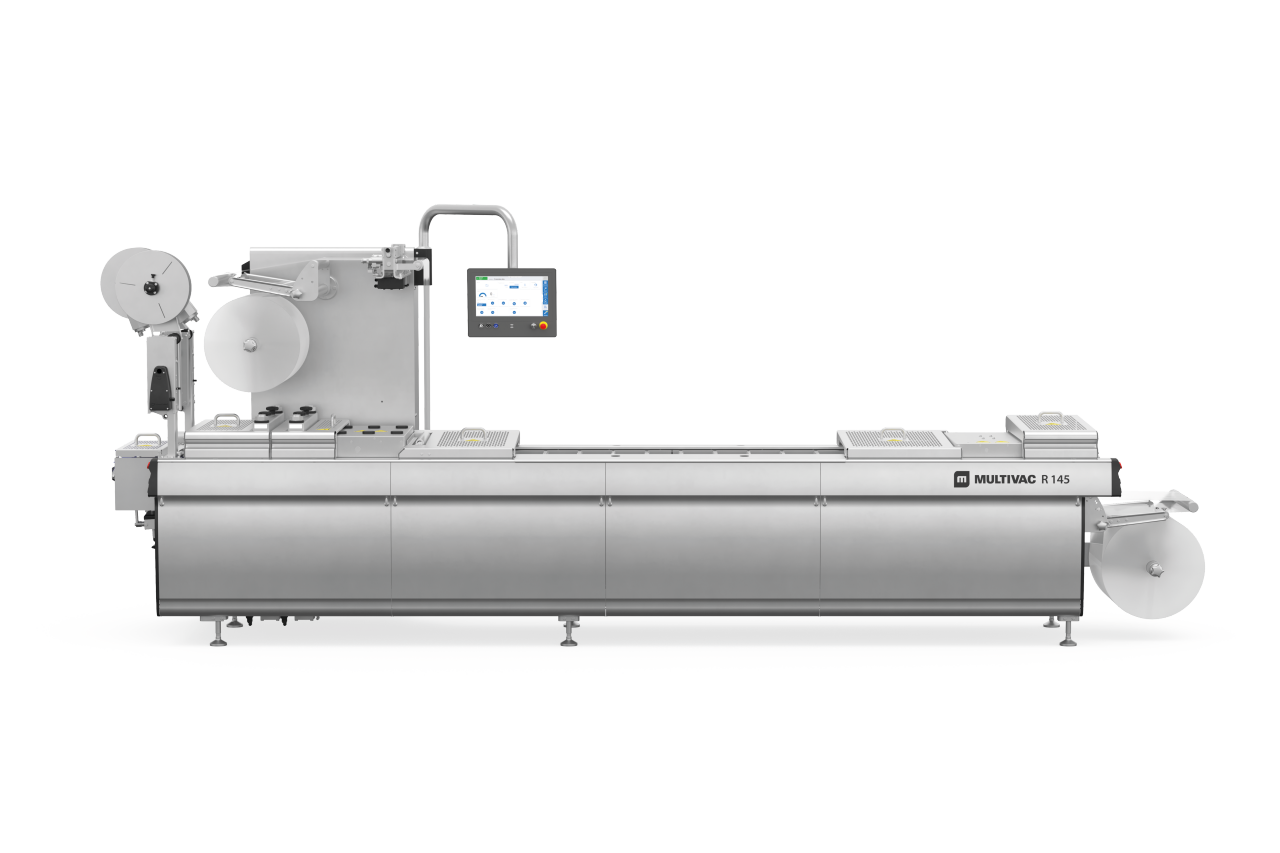

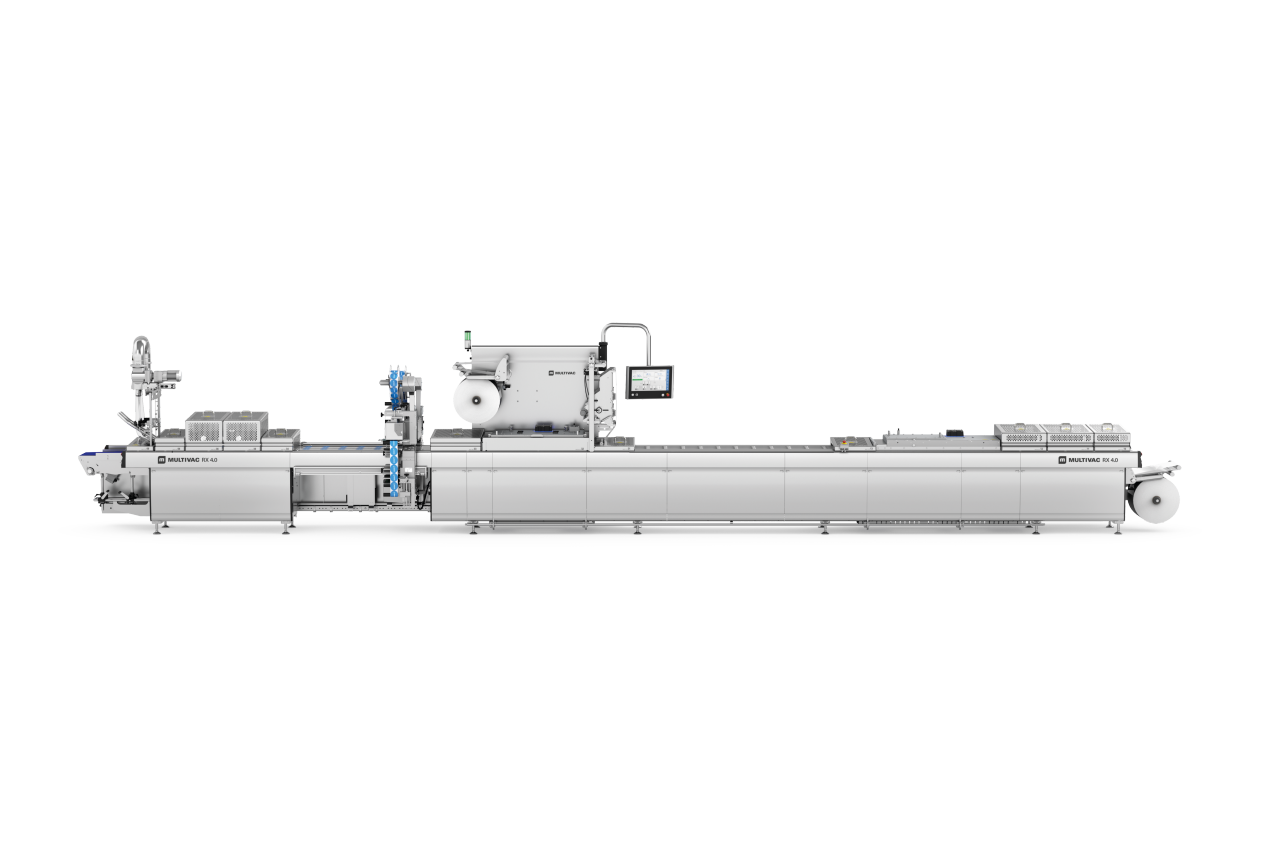

Do you have very special requirements for your thermoforming packaging machine? We will advise you and find your perfect solution from our wide product range. MULTIVAC sets the benchmark worldwide - with customized solutions for the food industry all the way through to the packaging of medical and pharmaceutical products. Modular design ensures a high level of process reliability as well as flexibility, reproducibility and ease of operation - while meeting the critical hygiene requirements of your specific sector. The result: outstanding packaging results that meet and even exceed your high quality requirements.

Other topics of interest

Success stories

Secure packaging of wound contact products

With its patented Debrisoft® wound contact products, Lohmann & Rauscher offers an holistic concept for all aspects of therapeutic wound cleaning, and one which is painless for patients in its application. For these products, the packs have to be capable of being sterilised with ethylene oxide. In order to ensure a high level of pack security is achieved, particular emphasis was placed during the development of the packaging solution on the quality of the seal seam, where an even distribution of sealing pressure and temperature during the sealing process is absolutely critical.

With its patented Debrisoft® wound contact products, Lohmann & Rauscher offers an holistic concept for all aspects of therapeutic wound cleaning, and one which is painless for patients in its application. For these products, the packs have to be capable of being sterilised with ethylene oxide. In order to ensure a high level of pack security is achieved, particular emphasis was placed during the development of the packaging solution on the quality of the seal seam, where an even distribution of sealing pressure and temperature during the sealing process is absolutely critical.

Learn more

Halal meat and sausage products in many varieties

Burger patties, pizza toppings, sausage and sausage products as well as tasty snacks and convenience foods are the core business of Fettayleh Foods. Since it was first founded, the Australian family business has developed into a leading supplier of halal food and it now exports its high-quality products all over the world. A traysealer had previously been handling the packaging procedure, but the company’s attention was drawn to MULTIVAC’s R 105 MF thermoforming packaging machine at Anuga FoodTec 2015 and they have seen benefits from its use ever since.

Burger patties, pizza toppings, sausage and sausage products as well as tasty snacks and convenience foods are the core business of Fettayleh Foods. Since it was first founded, the Australian family business has developed into a leading supplier of halal food and it now exports its high-quality products all over the world. A traysealer had previously been handling the packaging procedure, but the company’s attention was drawn to MULTIVAC’s R 105 MF thermoforming packaging machine at Anuga FoodTec 2015 and they have seen benefits from its use ever since.

Learn more

MultiFresh™ packs with full-wrap labelling increase the attractiveness at the point of sale

With its deep, clear and cold fjords, Norway is a paradise for salmon and salmon farms alike. Best conditions therefore for Seafood Farmers of Norway AS, which was founded in 1986, and its parent company the HOFSETH Group, which processes the freshly caught fish and exports most of it abroad. In order to increase the attractiveness of the fish products at the point of sale, the company in Valderøy recently invested in a thermoforming packaging machine for producing high-quality vacuum skin packs and in a labelling solution for the D labelling of the packs.

With its deep, clear and cold fjords, Norway is a paradise for salmon and salmon farms alike. Best conditions therefore for Seafood Farmers of Norway AS, which was founded in 1986, and its parent company the HOFSETH Group, which processes the freshly caught fish and exports most of it abroad. In order to increase the attractiveness of the fish products at the point of sale, the company in Valderøy recently invested in a thermoforming packaging machine for producing high-quality vacuum skin packs and in a labelling solution for the D labelling of the packs.

Learn more

Valve sets packed efficiently and reliably

Science and technological progress, combined with inspiration and

determination - this is the basis of Boston Scientific's success.

Science and technological progress, combined with inspiration and

determination - this is the basis of Boston Scientific's success.

Learn more

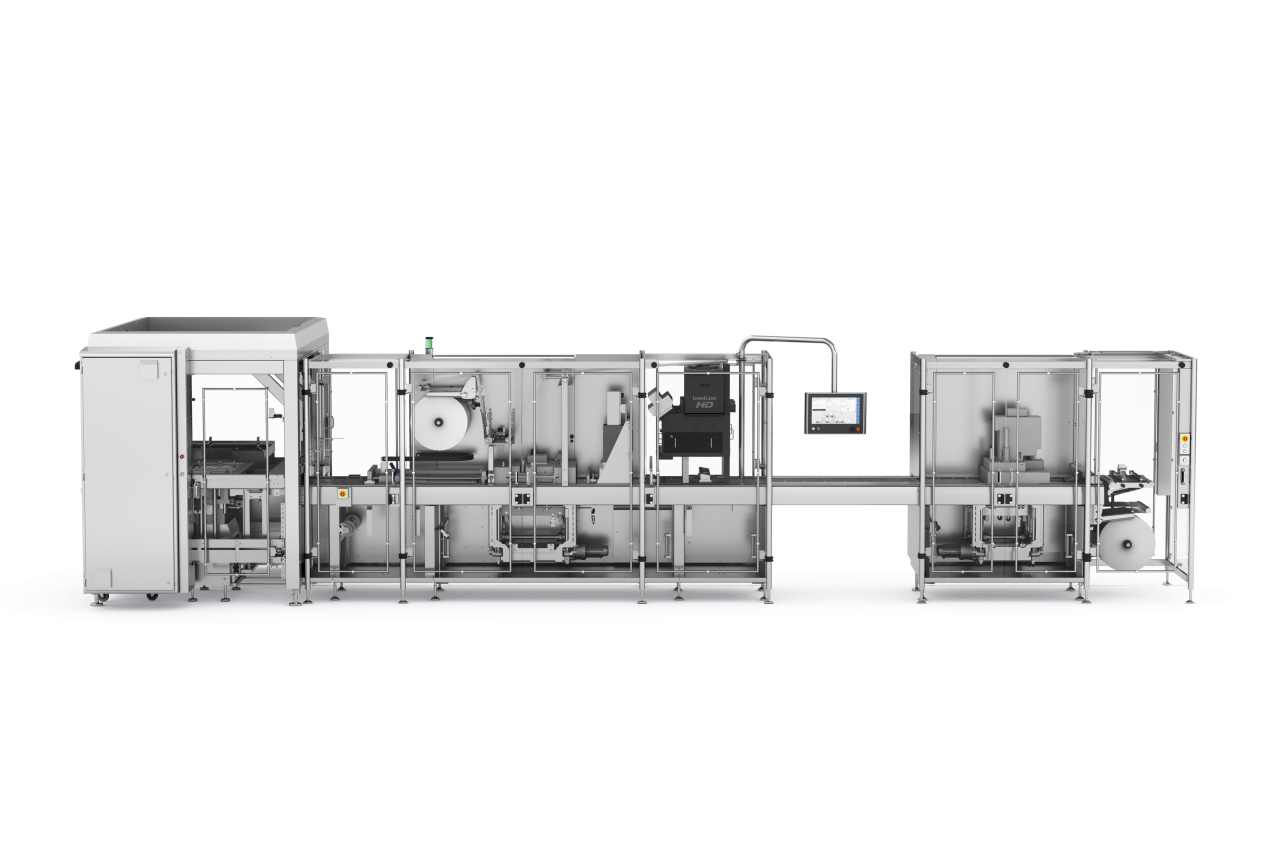

Automated production of combi packs

Packaging procedures with a high degree of complexity are often used to produce combi packs for pharmaceutical products. Infeed systems, which have to be tailored precisely to the particular components, and also integrated into the packaging line, are required for the automated infeed and loading of the various product components. This means the top priority is the precise and secure positioning of the product components, which are usually very small.

Packaging procedures with a high degree of complexity are often used to produce combi packs for pharmaceutical products. Infeed systems, which have to be tailored precisely to the particular components, and also integrated into the packaging line, are required for the automated infeed and loading of the various product components. This means the top priority is the precise and secure positioning of the product components, which are usually very small.

Learn more

Wine serving 4.0 – how a Belgian start-up company revolutionizes the hospitality industry

The trend in wine consumption in the hotel and restaurant sector is clearly moving towards serving wine by the glass. This gave a Belgian businessman and his two associates the opportunity to invent a completely new way of serving wine. The development of a suitable solution and new wine packaging proved to be highly ambitious. The inventors therefore turned to MULTIVAC for implementing a marketable and innovative solution.

The trend in wine consumption in the hotel and restaurant sector is clearly moving towards serving wine by the glass. This gave a Belgian businessman and his two associates the opportunity to invent a completely new way of serving wine. The development of a suitable solution and new wine packaging proved to be highly ambitious. The inventors therefore turned to MULTIVAC for implementing a marketable and innovative solution.

Learn more

Beef jerky in attractive aluminium packs

Dried meat is one of the most popular snacks in China. But jerky has now also become one of the top sellers in the USA, and even recently in Germany. The market for the spicy, long-life strips and pieces of beef, duck, and ostrich meat is booming worldwide. The sales figures in the snacks segment are strongly driven by marketing. The Chinese company, Zhangfei Beef, recognized this trend at an early stage and now presents its high-quality beef snacks at the point of sale in attractive aluminium packs.

Dried meat is one of the most popular snacks in China. But jerky has now also become one of the top sellers in the USA, and even recently in Germany. The market for the spicy, long-life strips and pieces of beef, duck, and ostrich meat is booming worldwide. The sales figures in the snacks segment are strongly driven by marketing. The Chinese company, Zhangfei Beef, recognized this trend at an early stage and now presents its high-quality beef snacks at the point of sale in attractive aluminium packs.

Learn more

Reliable quality control

Thanks to visual inspection systems, quality control can be automated within the packaging procedure. These systems offer added value, particularly for food-processing businesses, since all the packs in a batch can be checked seamlessly instead of random sampling. Bell Schweiz AG with its headquarters in Basel is currently evaluating a pilot inspection system with a view to major investment. Pack aktuell* spoke to the person responsible for the project.

Thanks to visual inspection systems, quality control can be automated within the packaging procedure. These systems offer added value, particularly for food-processing businesses, since all the packs in a batch can be checked seamlessly instead of random sampling. Bell Schweiz AG with its headquarters in Basel is currently evaluating a pilot inspection system with a view to major investment. Pack aktuell* spoke to the person responsible for the project.

Learn more

--Stefan-Wenisch-(Metzgerei-Wenisch),-Martin-Dattler-(MULTIVAC)).png)