Minimum conversion times for maximum efficiency

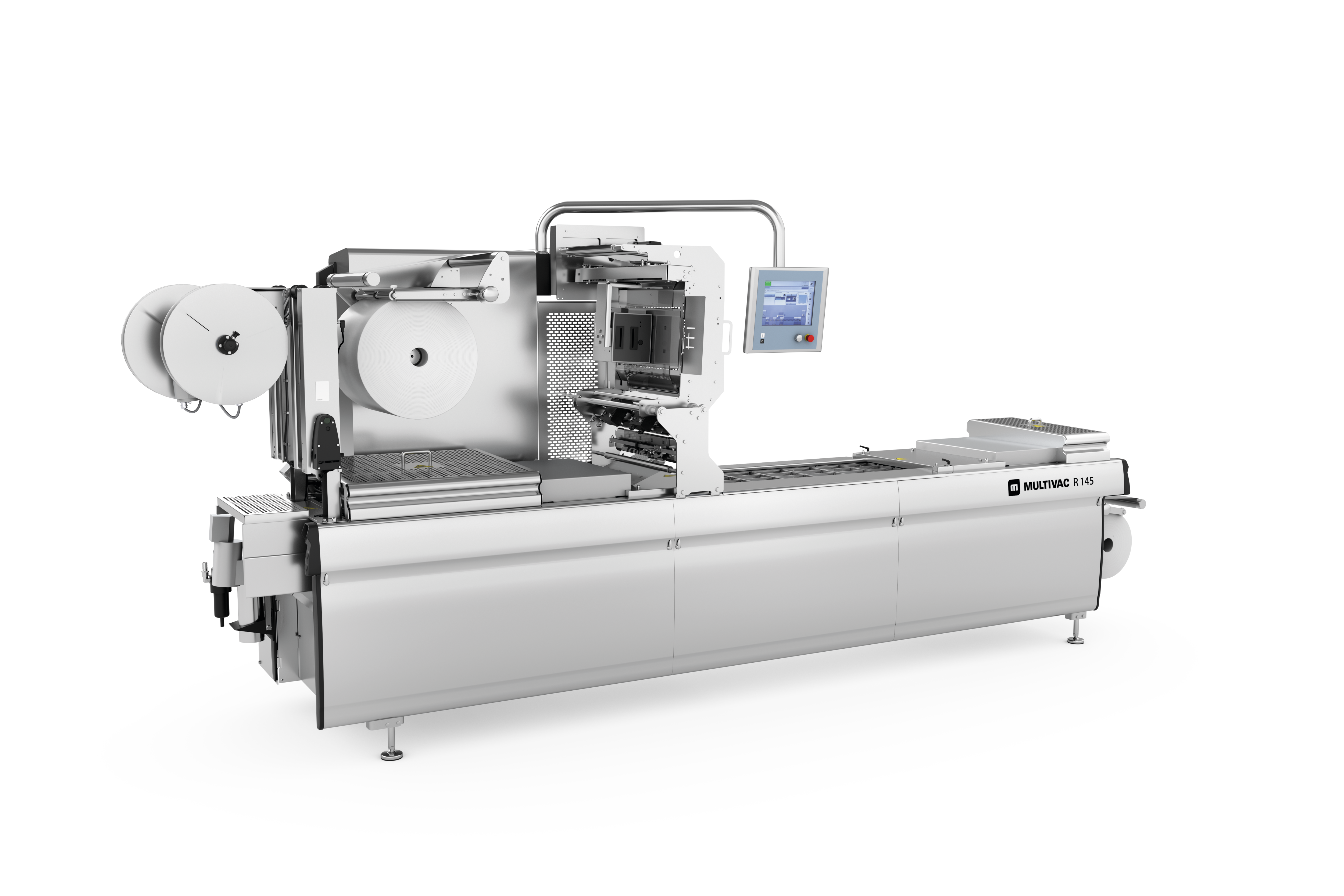

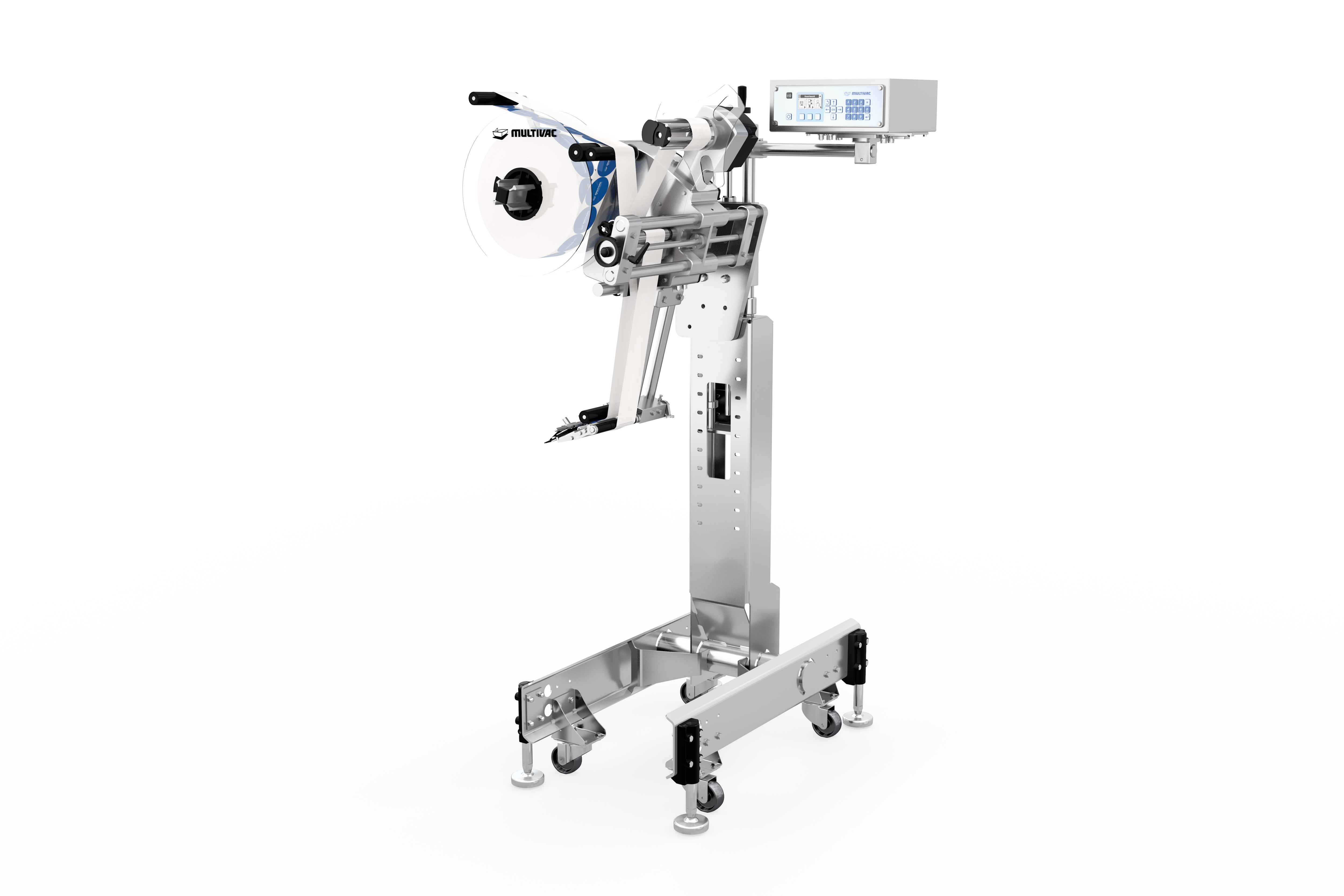

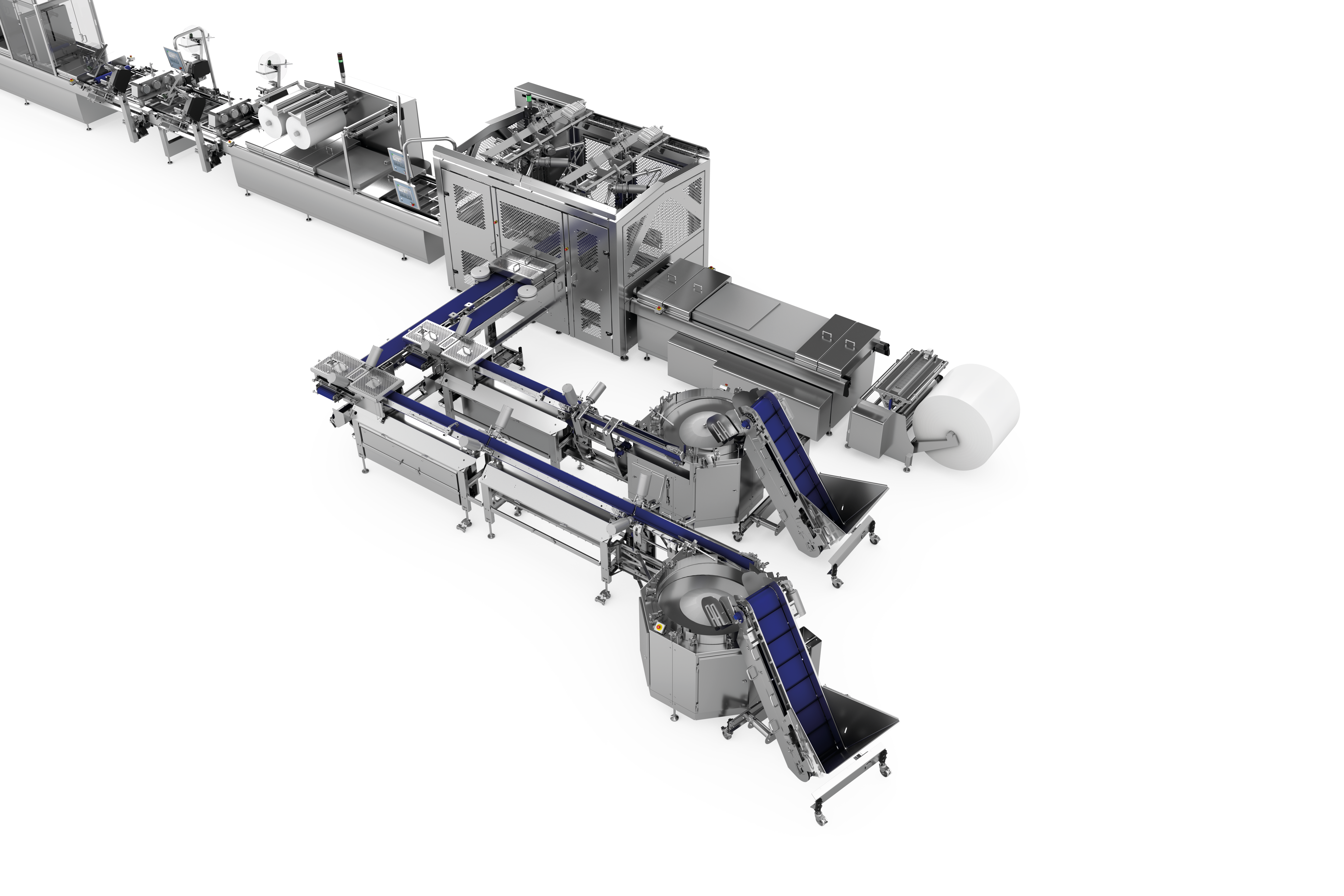

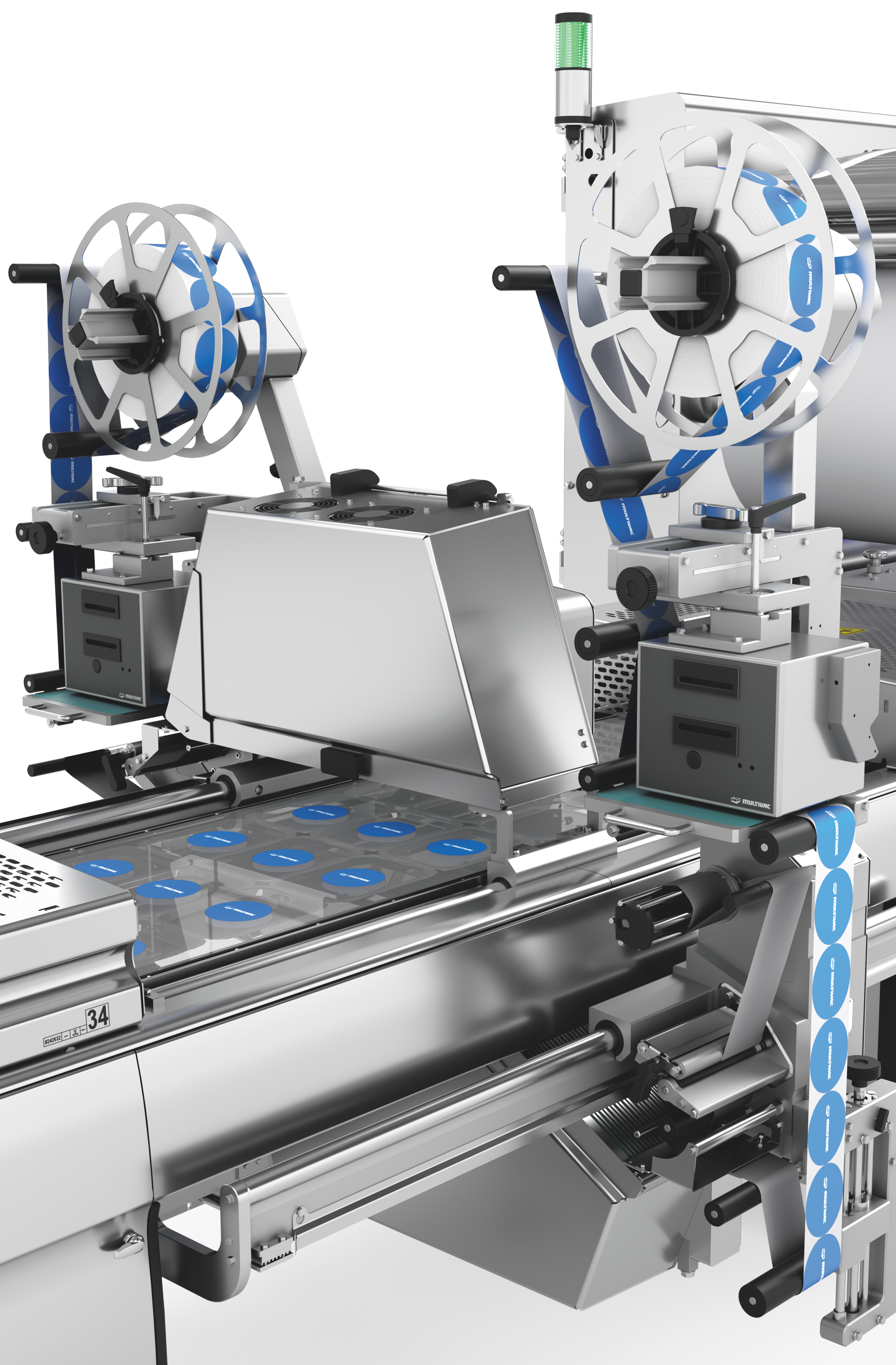

The MULTIVAC range of solutions covers a wide range of labelling procedures and adapts itself specifically to your requirements.

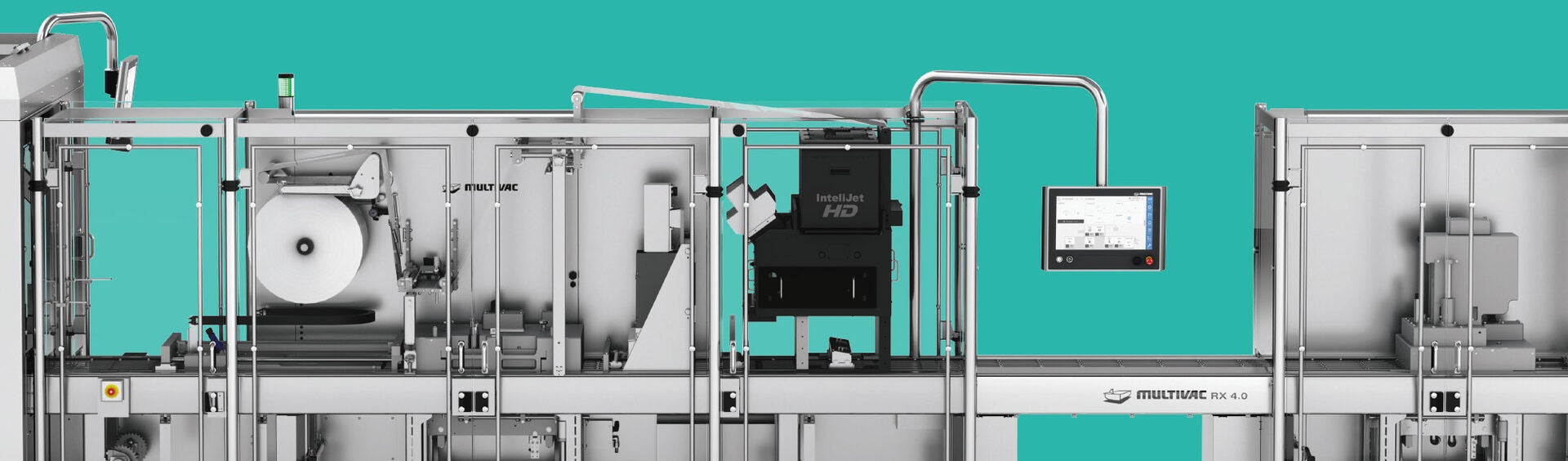

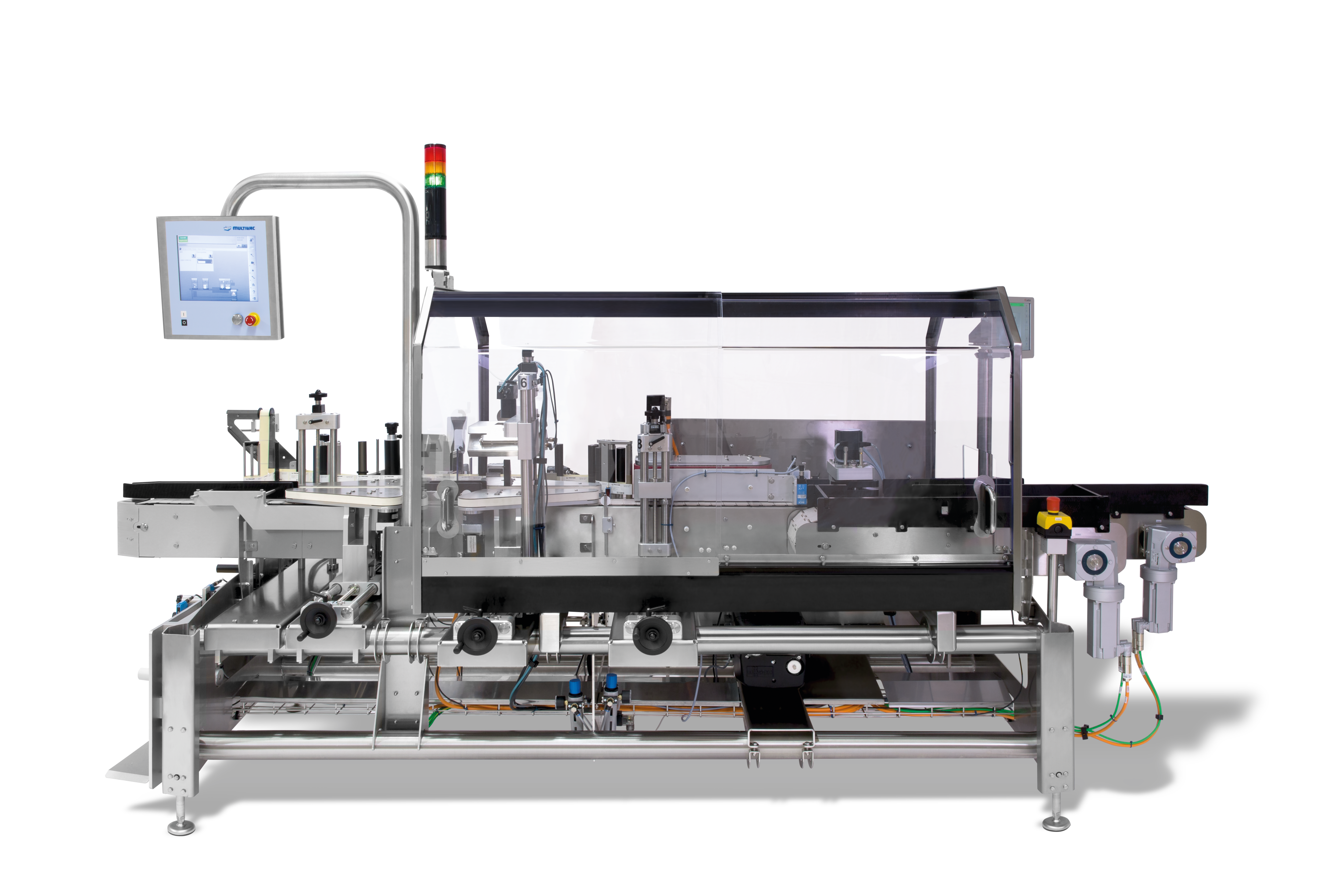

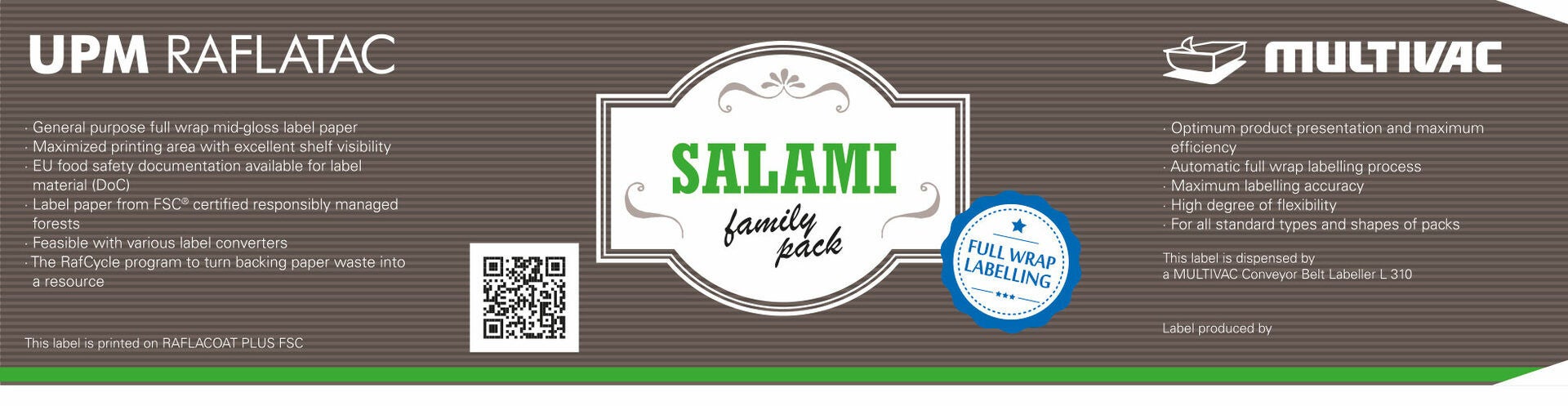

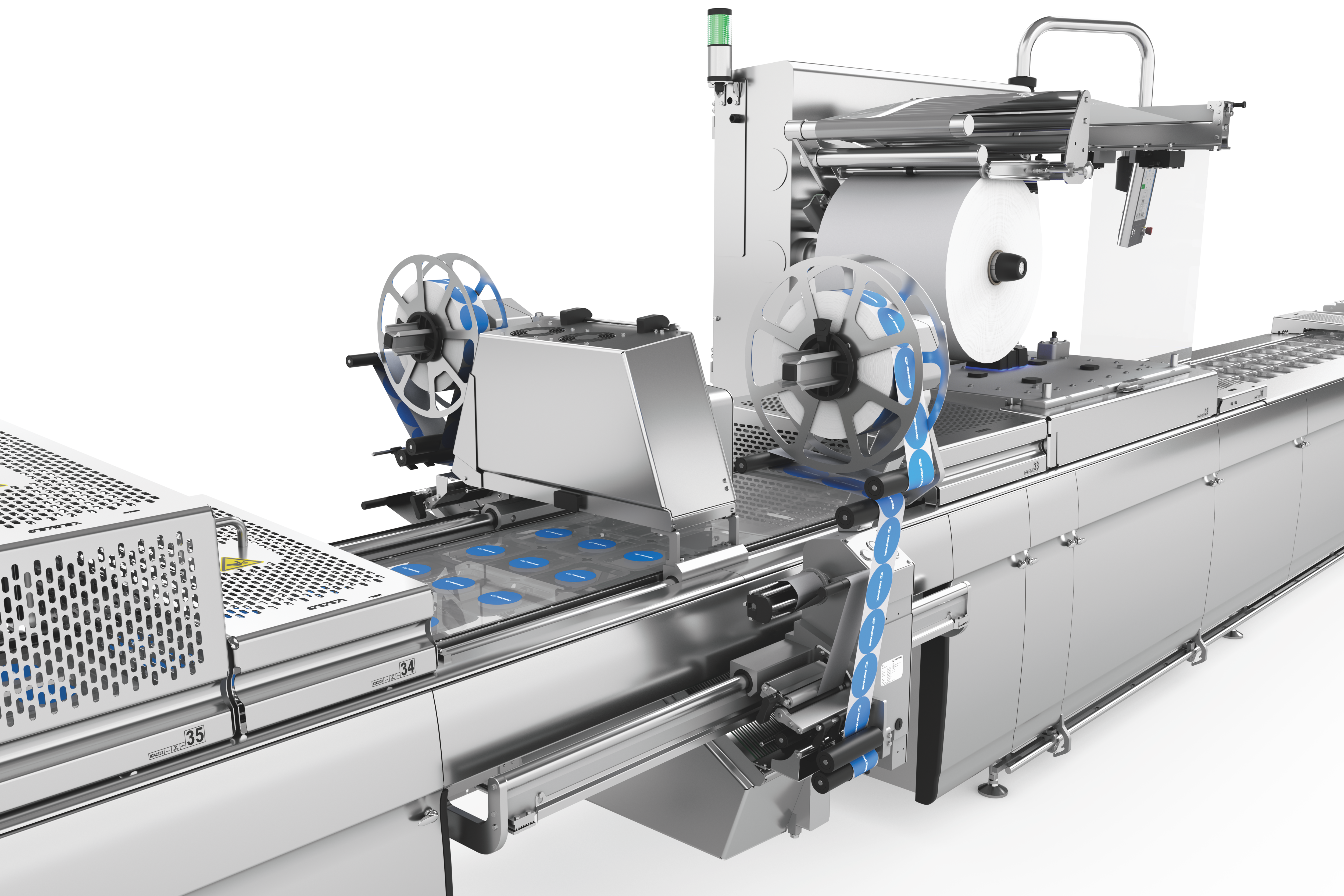

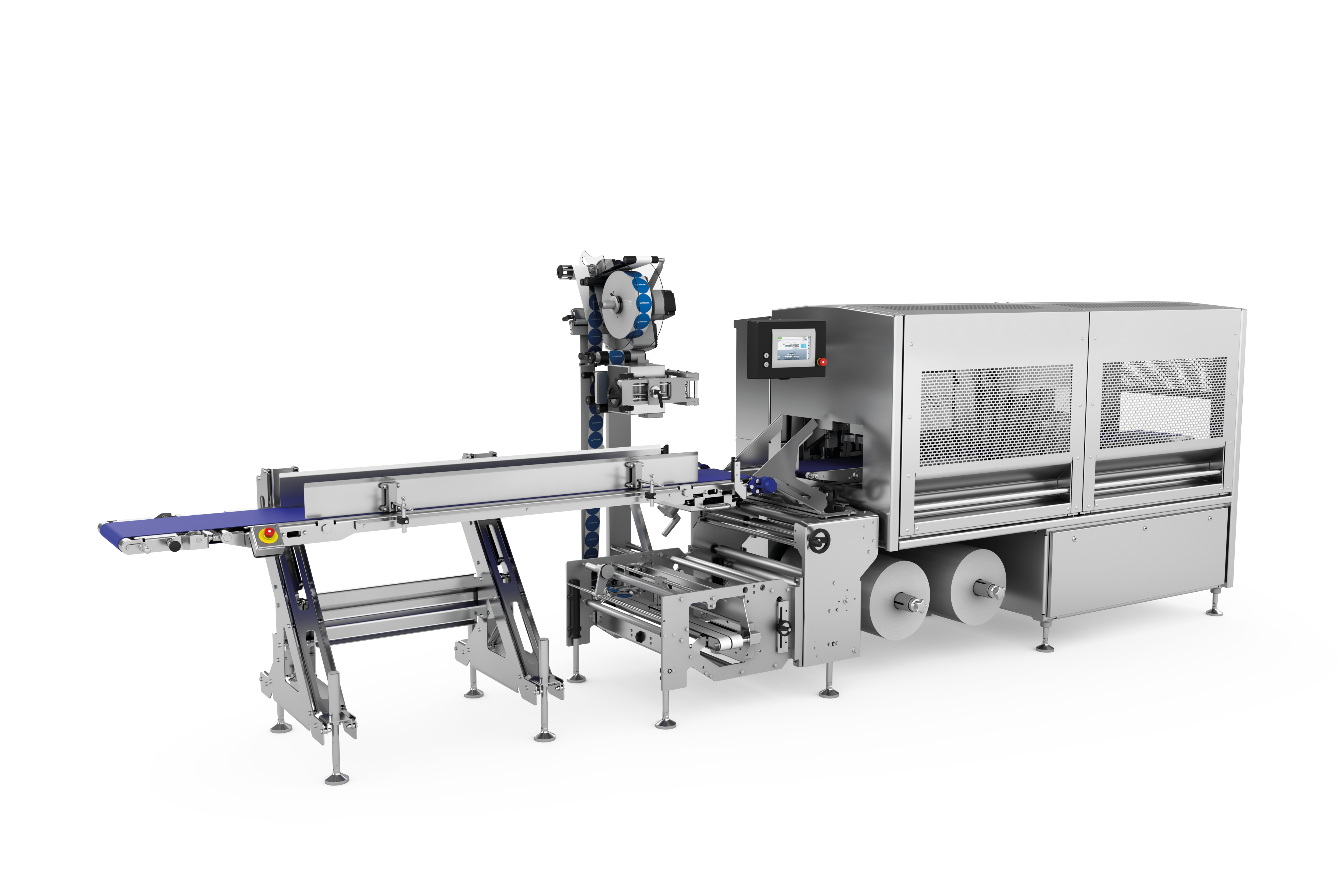

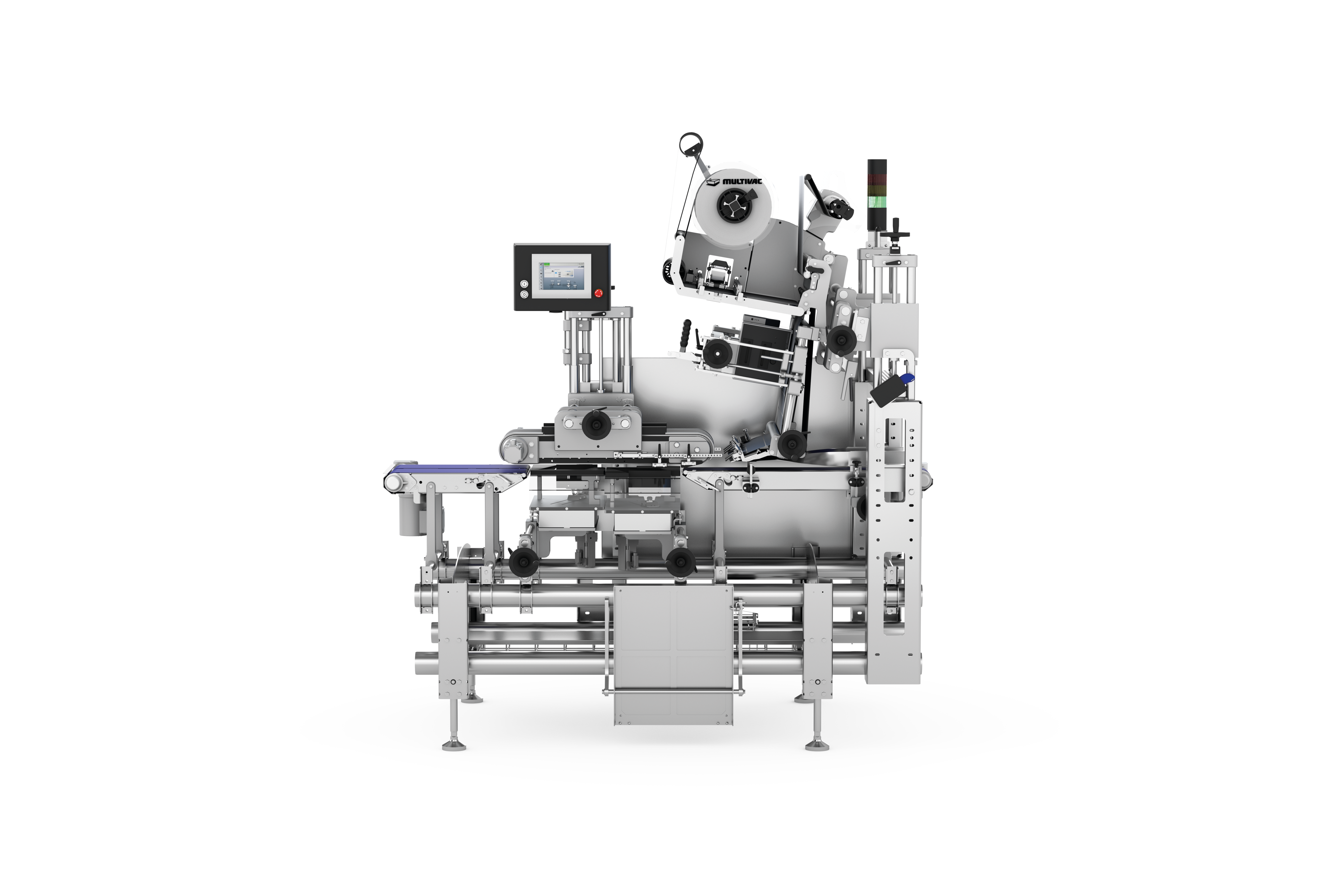

Our labelling systems and printers generate excellent results, so that your products stand out from those of your competitors at POS. Short conversion times and a hygiene-friendly and low-maintenance design increase the efficiency of your system. Our labelling and marking solutions can be seamlessly integrated into your existing production and packaging line. They can be controlled via HMI (Human Machine Interface) or directly via our packaging machines. When it comes to labelling, you are virtually independent of format and material.

Cost-effectiveness and reliability

Thanks to our many years of experience and expertise in individual process stages - and especially for entire processes - we can implement solutions tailored to your specific requirements, even if they are extremely complex. Our solutions ensure an optimised line footprint, low operating costs and maximum flexibility in terms of technology and consumables. Our systems are designed for durability and are available in a variety of hygiene standards. Your investment is safeguarded with MULTIVAC quality.

Other topics of interest

Success stories