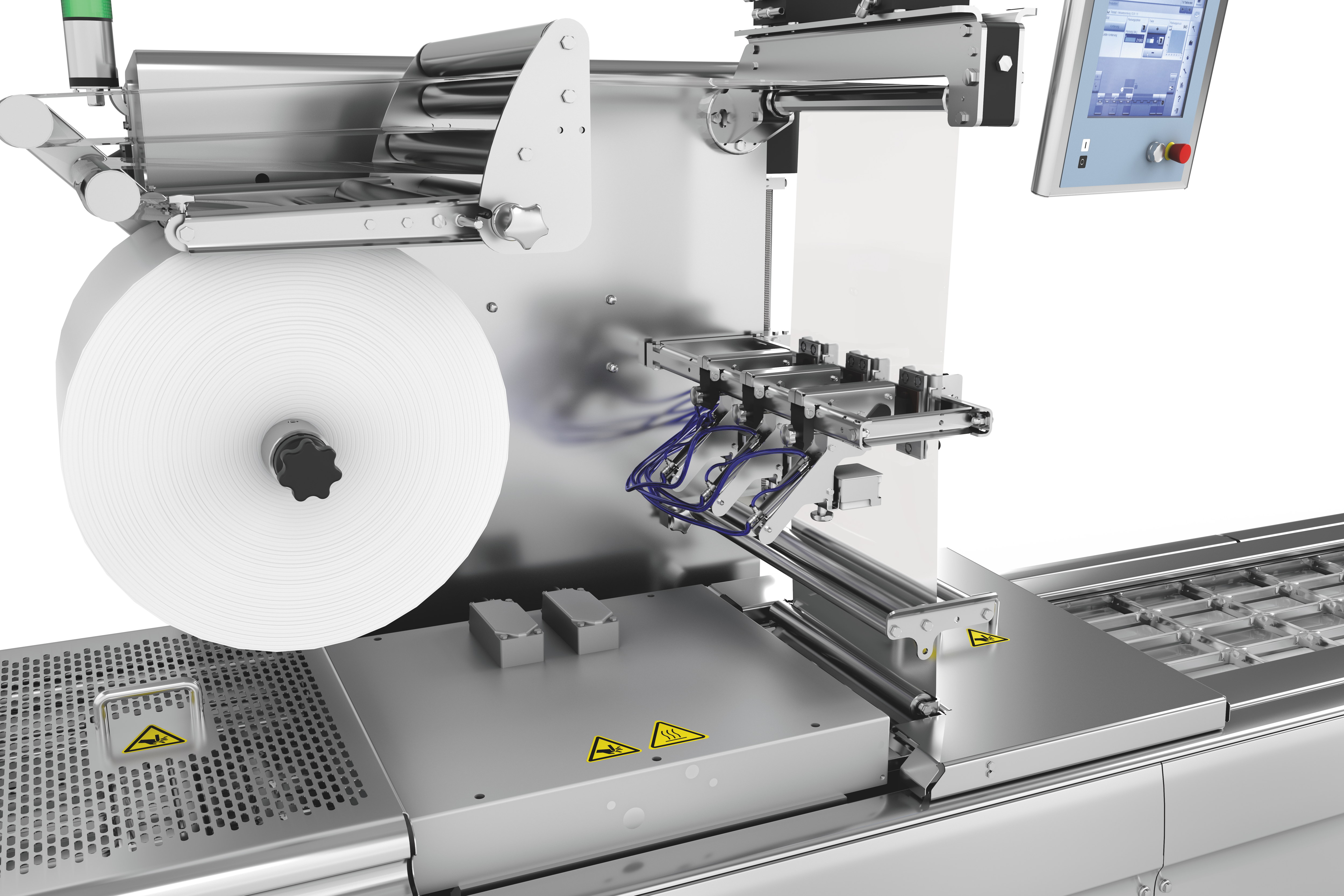

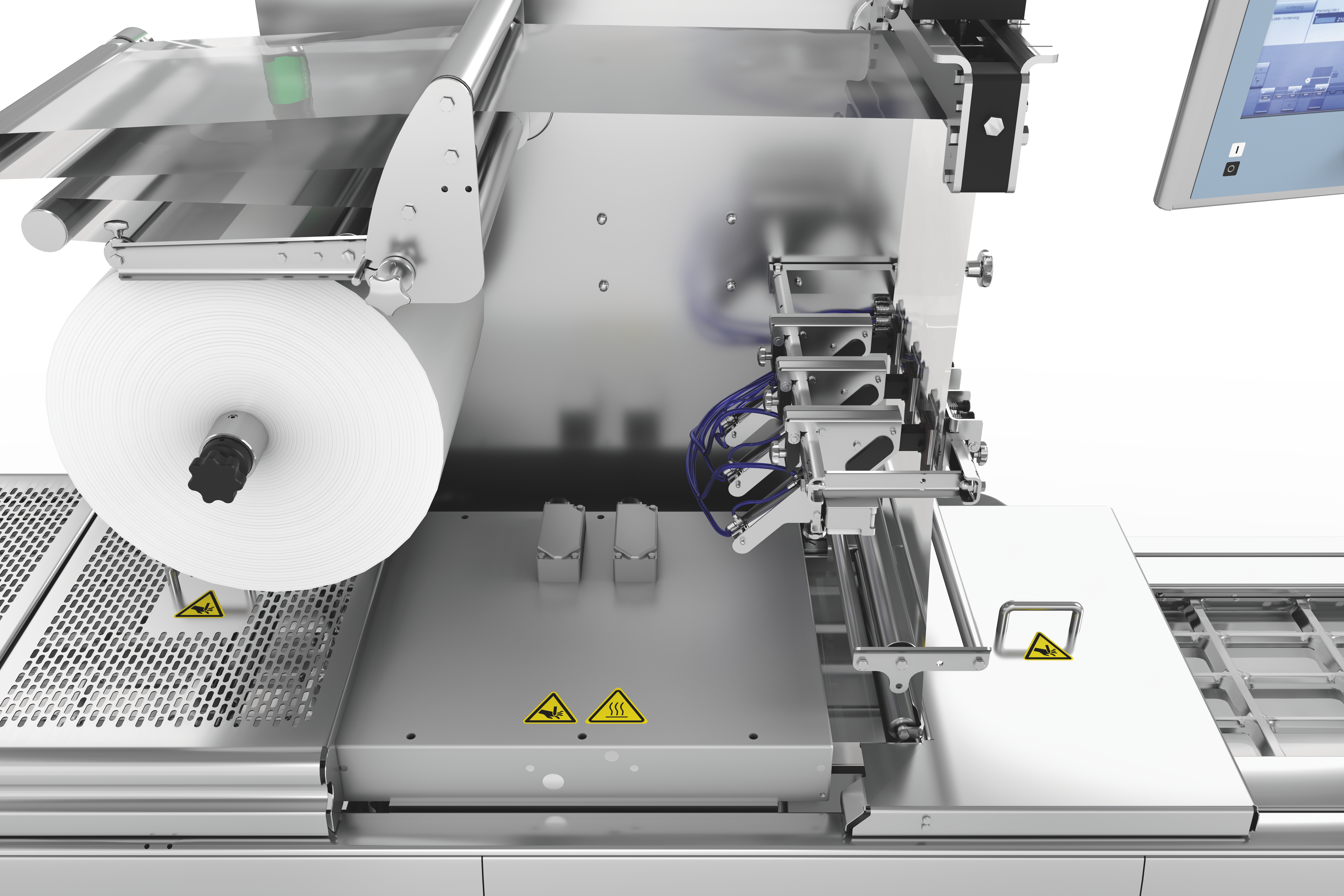

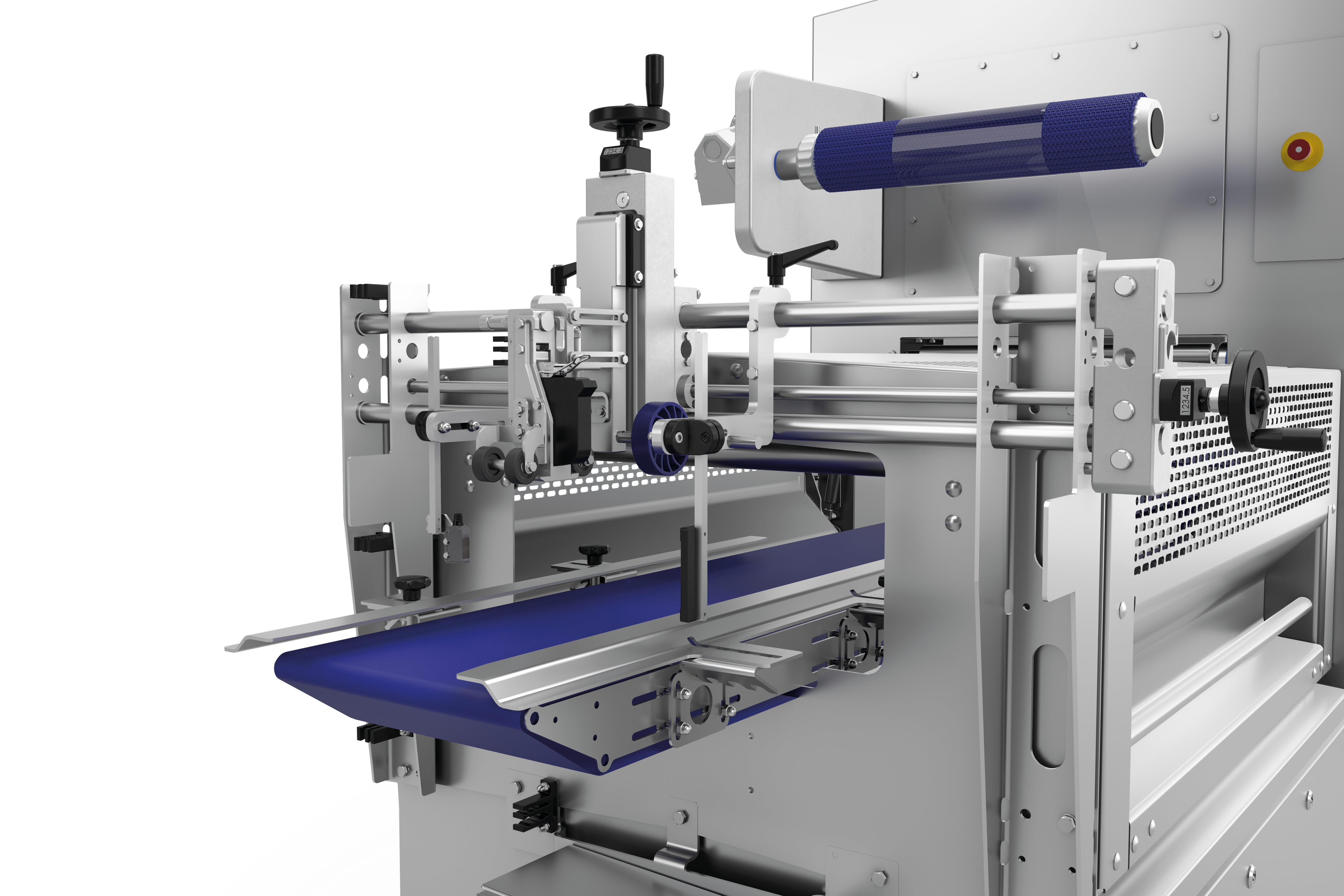

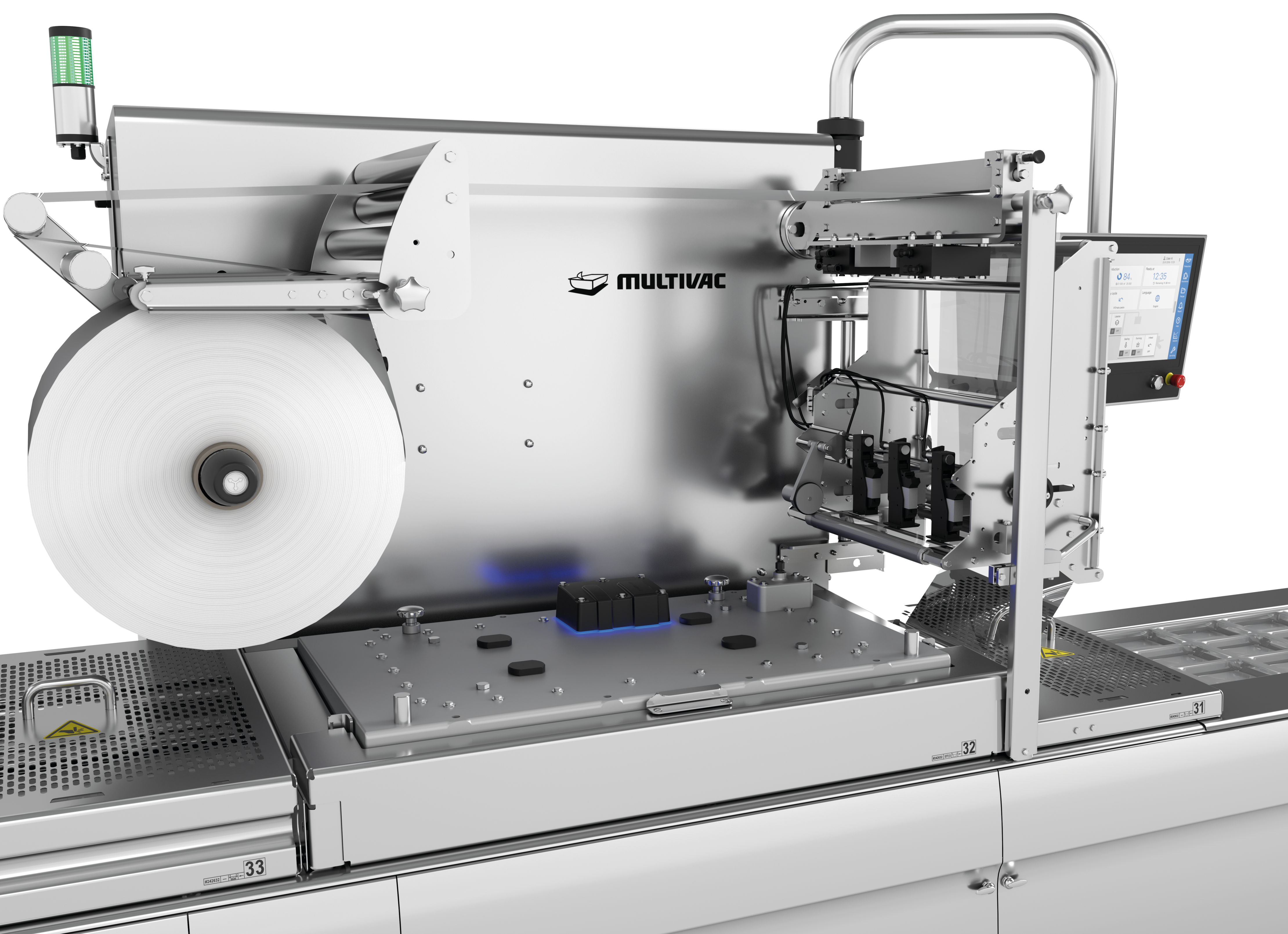

Minimum changeover times for quick product change

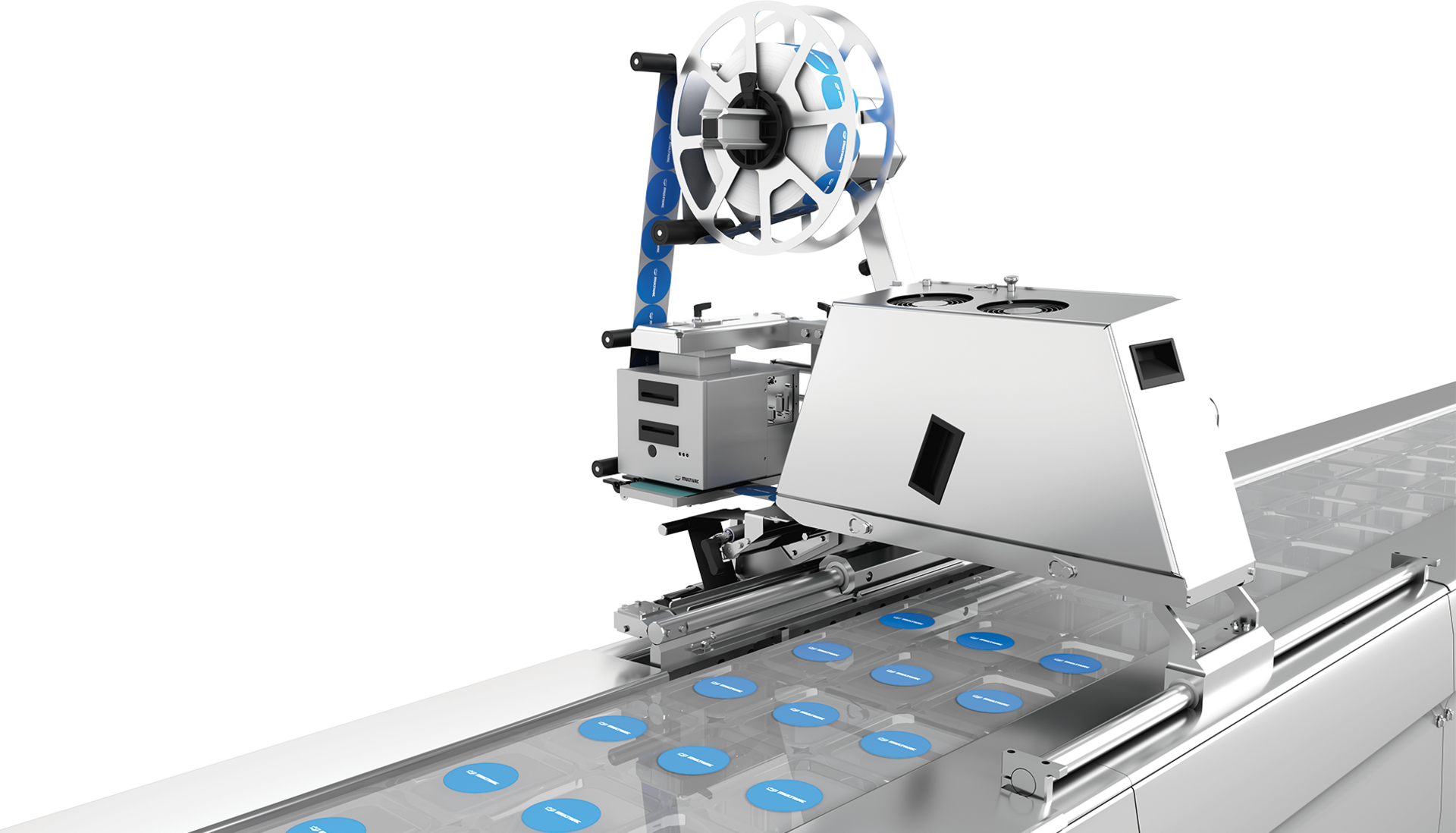

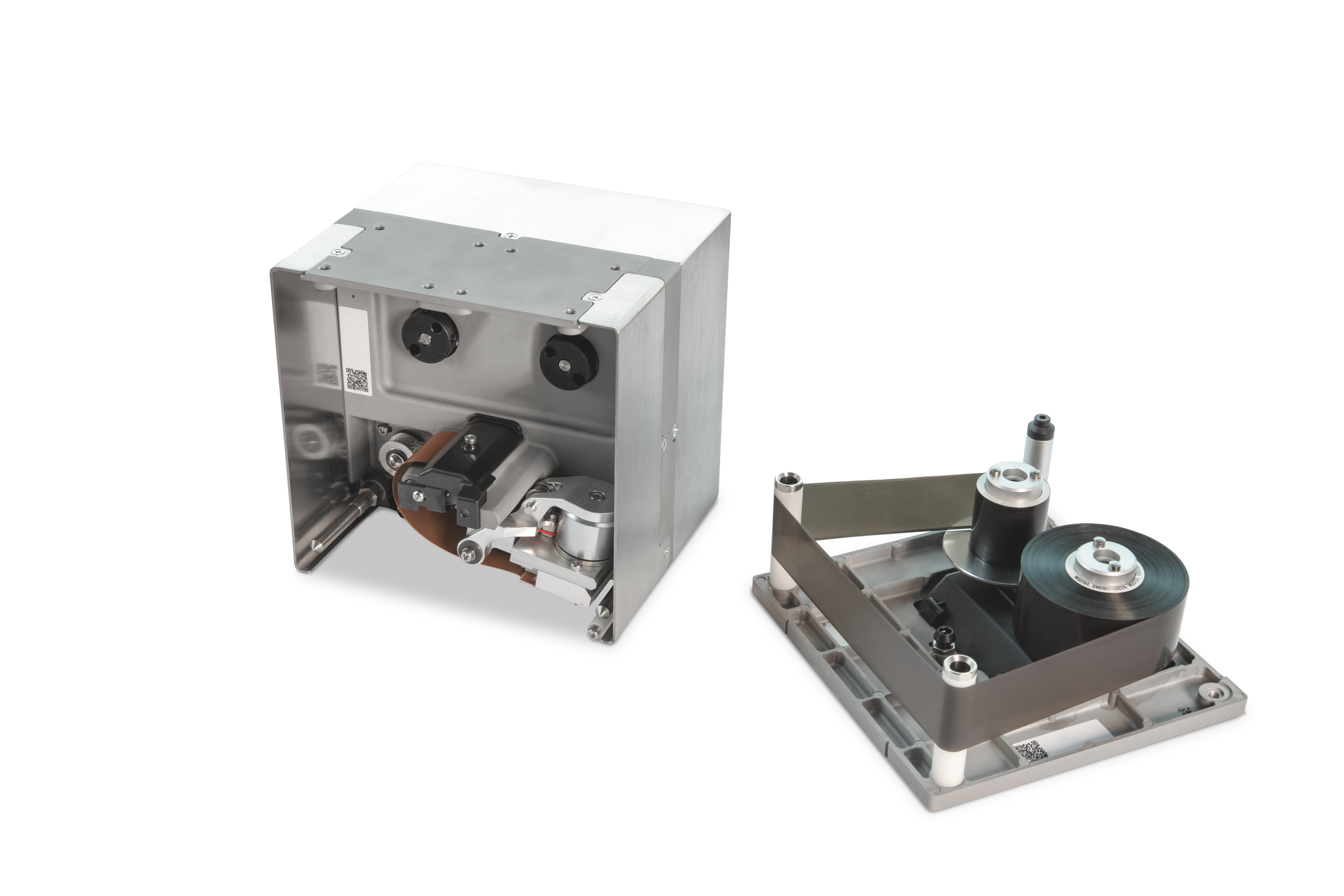

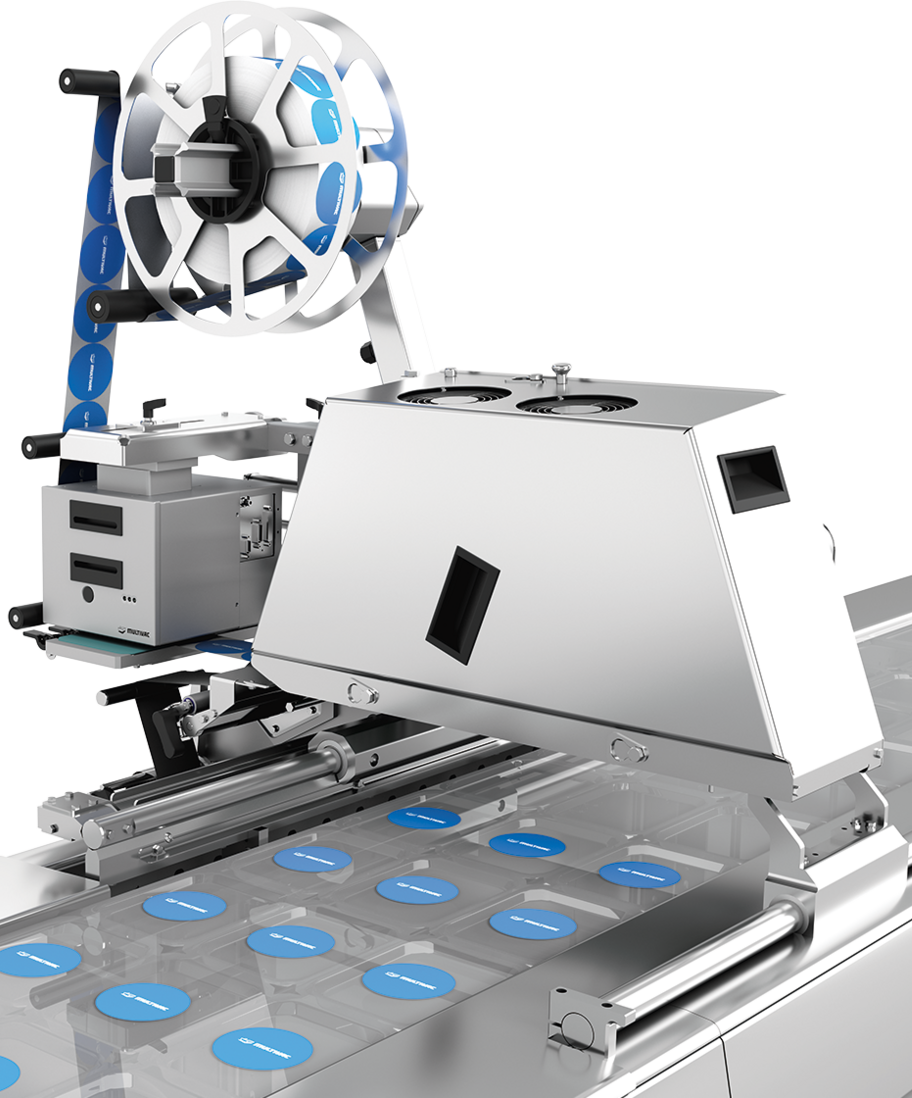

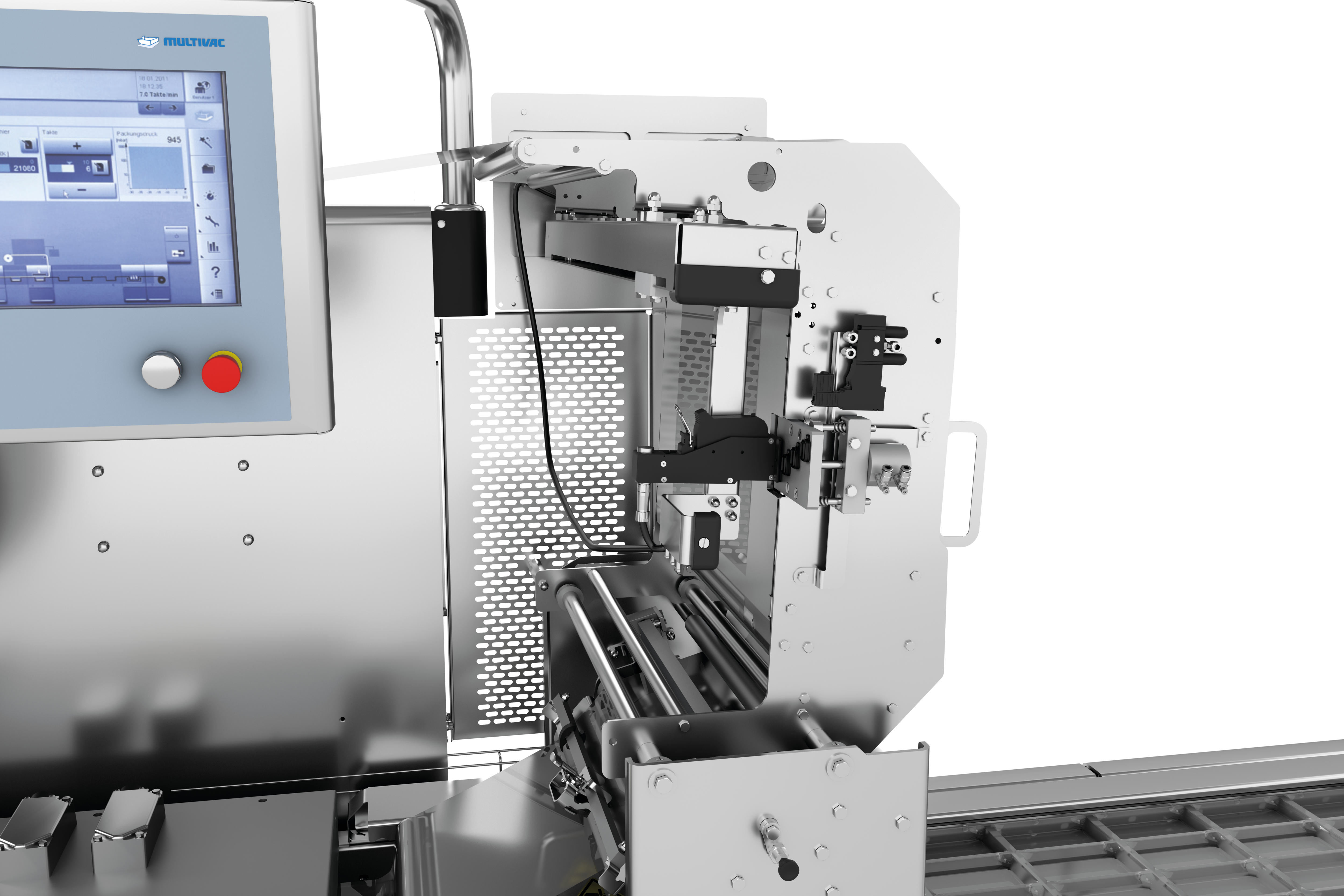

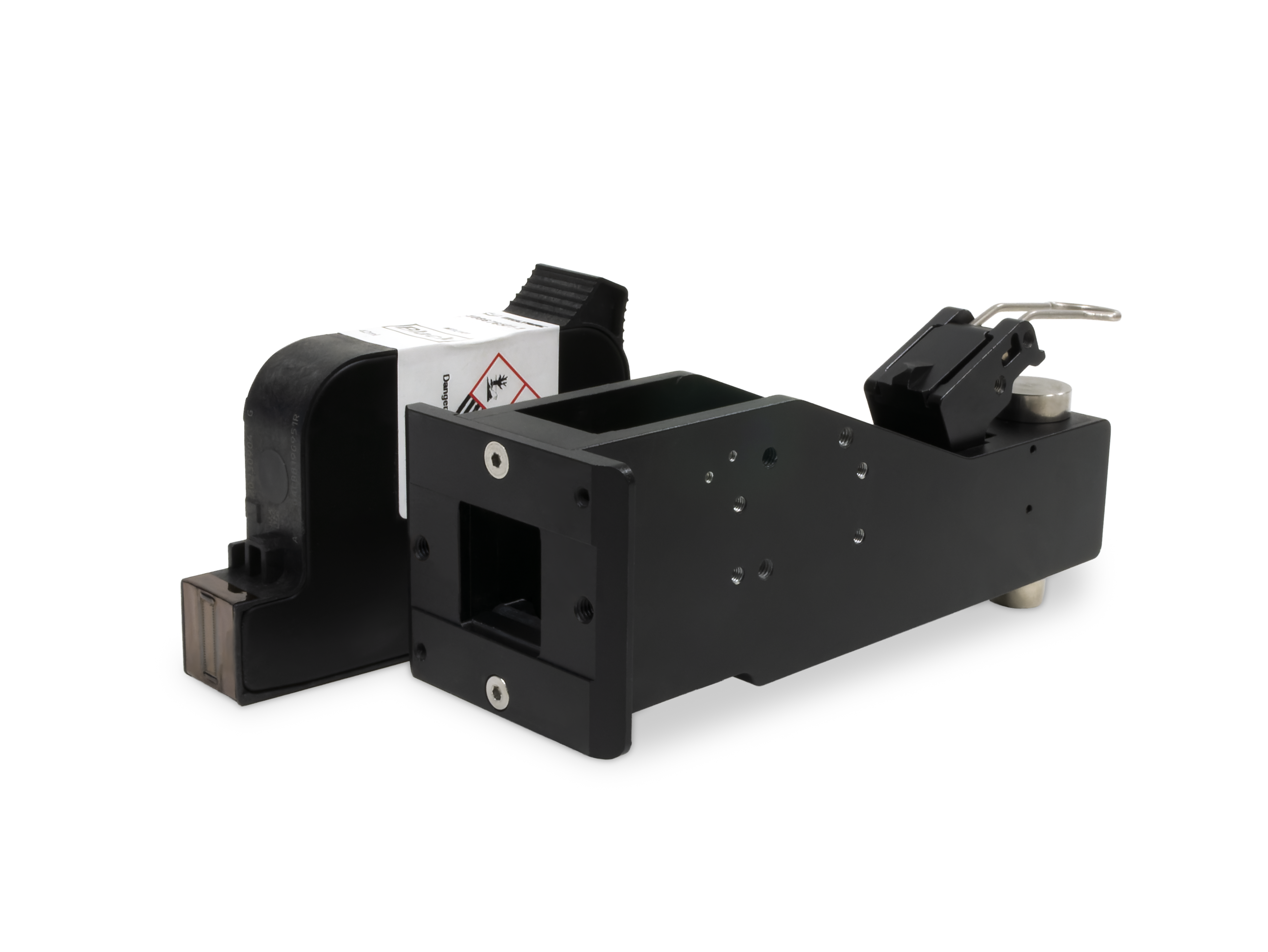

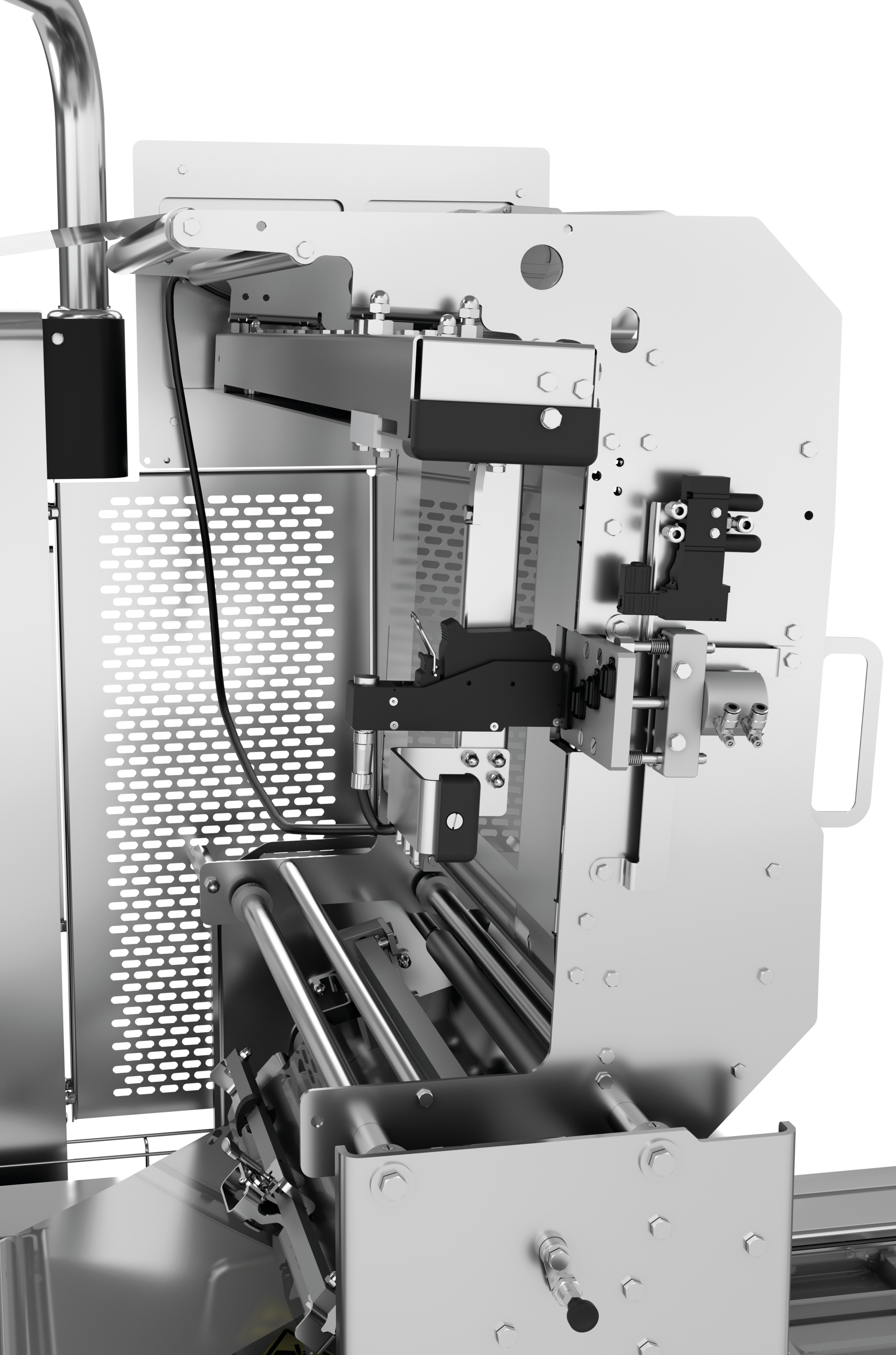

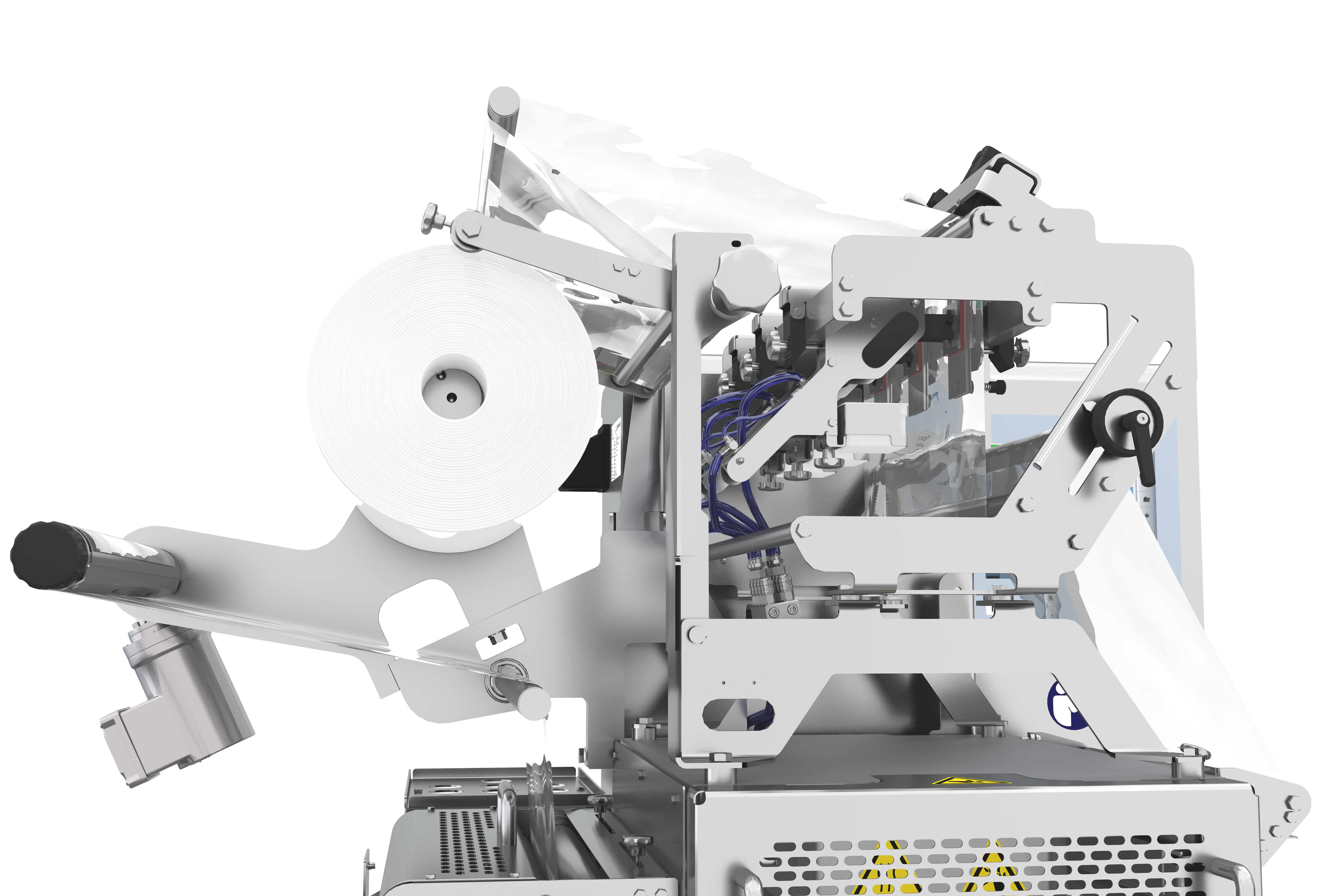

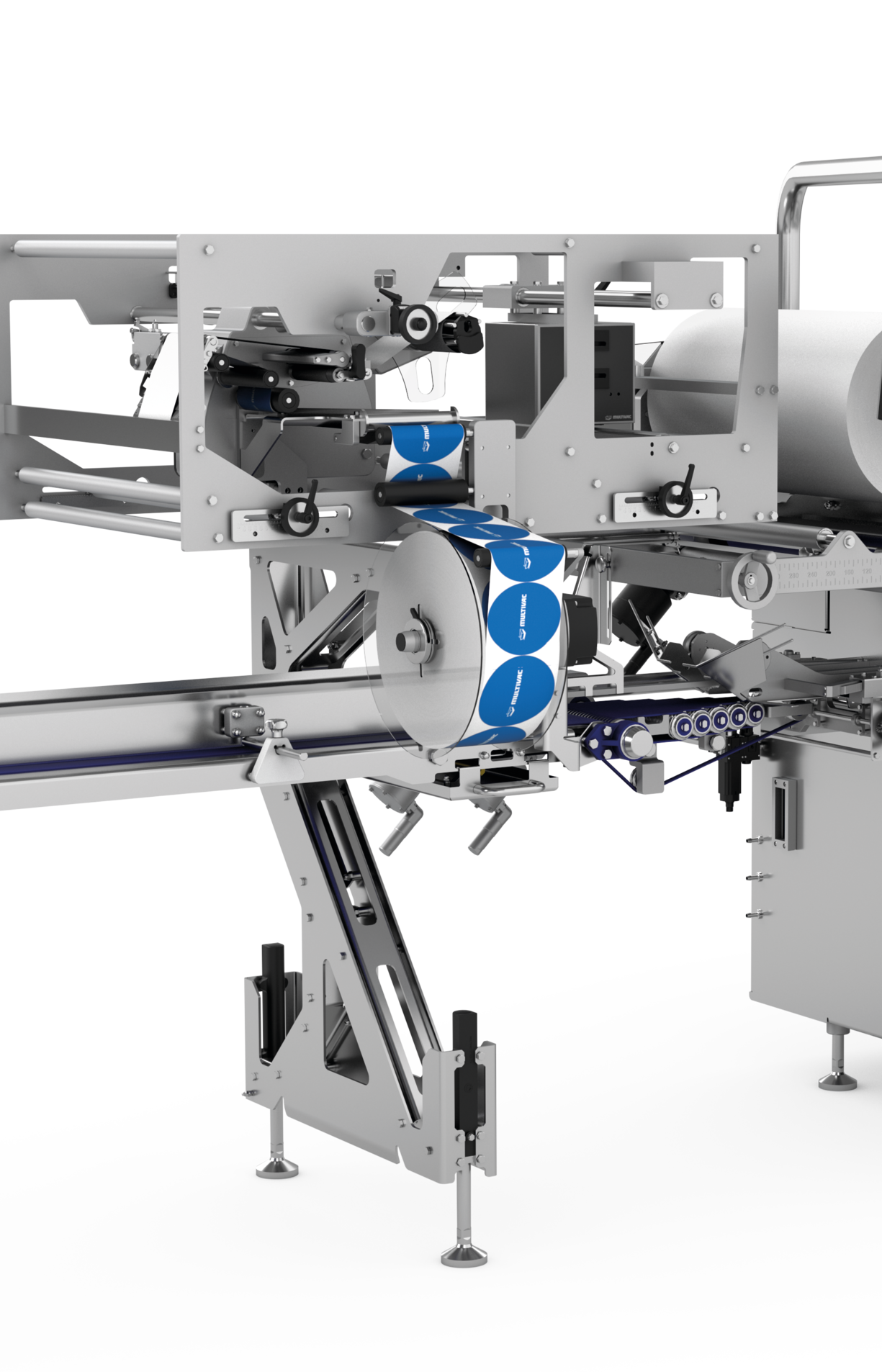

When it comes to increasing efficiency and cost-effectiveness, flexibility and speed are indispensable. What also makes your machine cost-effective? This complete integration into existing MULTIVAC labelling systems and direct web printers, as well as being centrally controlled from one HMI. The automatic loading of the print layouts via the recipe ensures the correct print data is used, and this in turn ensures that the print result is printed. We accompany you throughout the entire lifespan of your line, and we will be at your side with advice and help, and ensure that your products shine with a brilliant print image at the point of sale.

Other interesting topics

Success stories

Automated label and print inspection in the food industry

Although present legislation does not yet stipulate the use of visual inspection systems for checking labels, investment in automatic inspection systems can be very beneficial for many reasons.

Although present legislation does not yet stipulate the use of visual inspection systems for checking labels, investment in automatic inspection systems can be very beneficial for many reasons.

Learn more