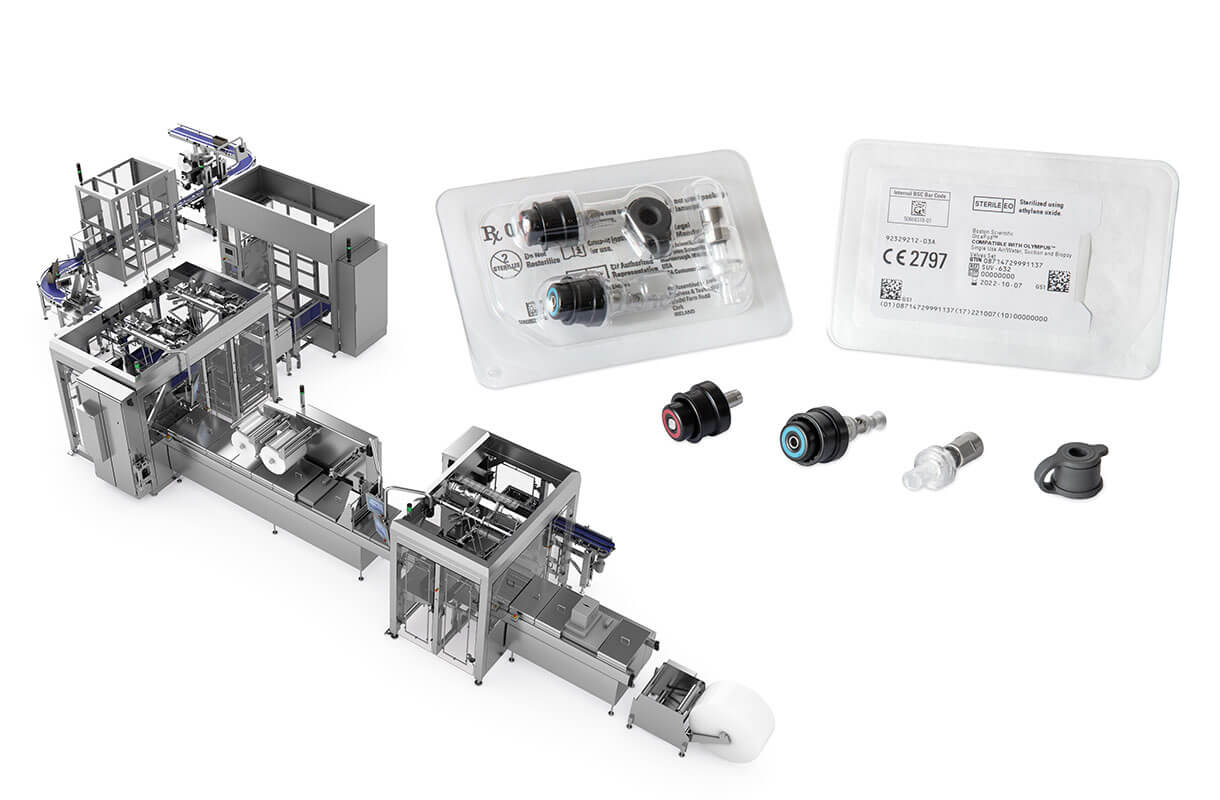

Medical technology manufacturers need packaging solutions that can not only guarantee high process, product and ultimately patient safety, but can also operate in the most environmentally friendly and energy-saving way possible. To meet these requirements, we work closely with our customers worldwide to develop packaging lines that combine several well-coordinated, state-of-the-art technologies from a single source. In addition to our packaging machines, these include inspection systems, printing systems, labellers, loading and unloading systems, as well as downstream cartoners and palletizers. Customers use these solutions to package conventional disposable products such as needles, syringes and gloves – mostly in large quantities in high-speed applications – as well as increasingly small batches of high-tech, extremely sensitive medical products.

MULTIVAC is evolving from a machine supplier to a solution provider. Our project managers, who have many years of experience, are available to medical technology companies as expert partners. They place great value on close collaboration to bring to life customized solutions based on very specific requirements. This begins with the development of an initial idea for a packaging solution, through concept design and the selection of packaging material, to installation and staff training, maintenance and repair. In each individual case, the solutions have to deliver maximum safety, reliability, cost-effectiveness and sustainability. To achieve this goal, communication and trust play a key role in the collaboration. For instance, lines are being created to package sterile disposable gloves that guarantee optimal seal seam quality and a reliable sterile barrier even at high speeds, while nonetheless being exceptionally economical in terms of packaging material.

The last three years have been challenging for manufacturers of medical technology. There were and still are many uncertainties. With the Corona pandemic, disrupted supply chains, supply bottlenecks, price changes and energy issues, entirely new approaches have emerged. There are also increasing regulatory requirements, calls for environmental protection and sustainability, and a worsening shortage of skilled workers. At the same time, we are seeing rapid technological developments. The complexity and sensitivity of medical technology products are increasing. So is the trend toward smaller batch sizes and individualization.

As a provider of packaging solutions, we have to respond to all these developments. In addition to quality, product safety and productivity, simplicity, degree of automation and flexibility now also play a key role in investment security. Manufacturers need the flexibility to be able to quickly convert packaging lines to new products with increasingly smaller batch sizes. And only through automation and ease of operation can manufacturers be productive even with a limited workforce and while guaranteeing the required product safety. Today, we are discussing the use of alternative and environmentally friendly packaging materials with more and more customers. We are also constantly looking for ways to optimize the consumption of electricity, compressed air and water in our machines and to reduce the amount of material used – for example, by using thinner film thicknesses and reducing film waste during the packaging process itself. As well, many customers want extremely compact solutions to save expensive cleanroom space.

In terms of productivity, digitalization is opening up exciting new possibilities for manufacturers of medical technology. Our machines are equipped with numerous sensors whose data is made available via interfaces to higher-level systems (from SCADA to MES to ERP) for monitoring and assessing overall system effectiveness, identifying optimization potential and continuously optimizing the interaction of individual machines – from anywhere in the world, with a PC or mobile device via webpage. Also important is the documentation of all relevant process data that this enables and with it, proof that each batch was produced under the defined parameters. Another benefit of networking is the transfer of data in the reverse direction, from the higher-level system to the packaging line. In a closed system, variable data and print layout for a film printer can be loaded, for example, without an employee having to be on site. Always with the goal of improving process and product safety and boosting productivity through increased machine and line availability. Digitalization plays an important role not only in ongoing production, but as early as in the design phase of machines and lines. For example, the use of production simulations and virtual 3D models now greatly simplifies the decision-making process for many of our customers.

20.10.2022