Sustainable packs for the medical industry: maximum security with minimum impact on the environment

MULTIVAC at COMPAMED (11. – 14.11.2024)

26.09.2024

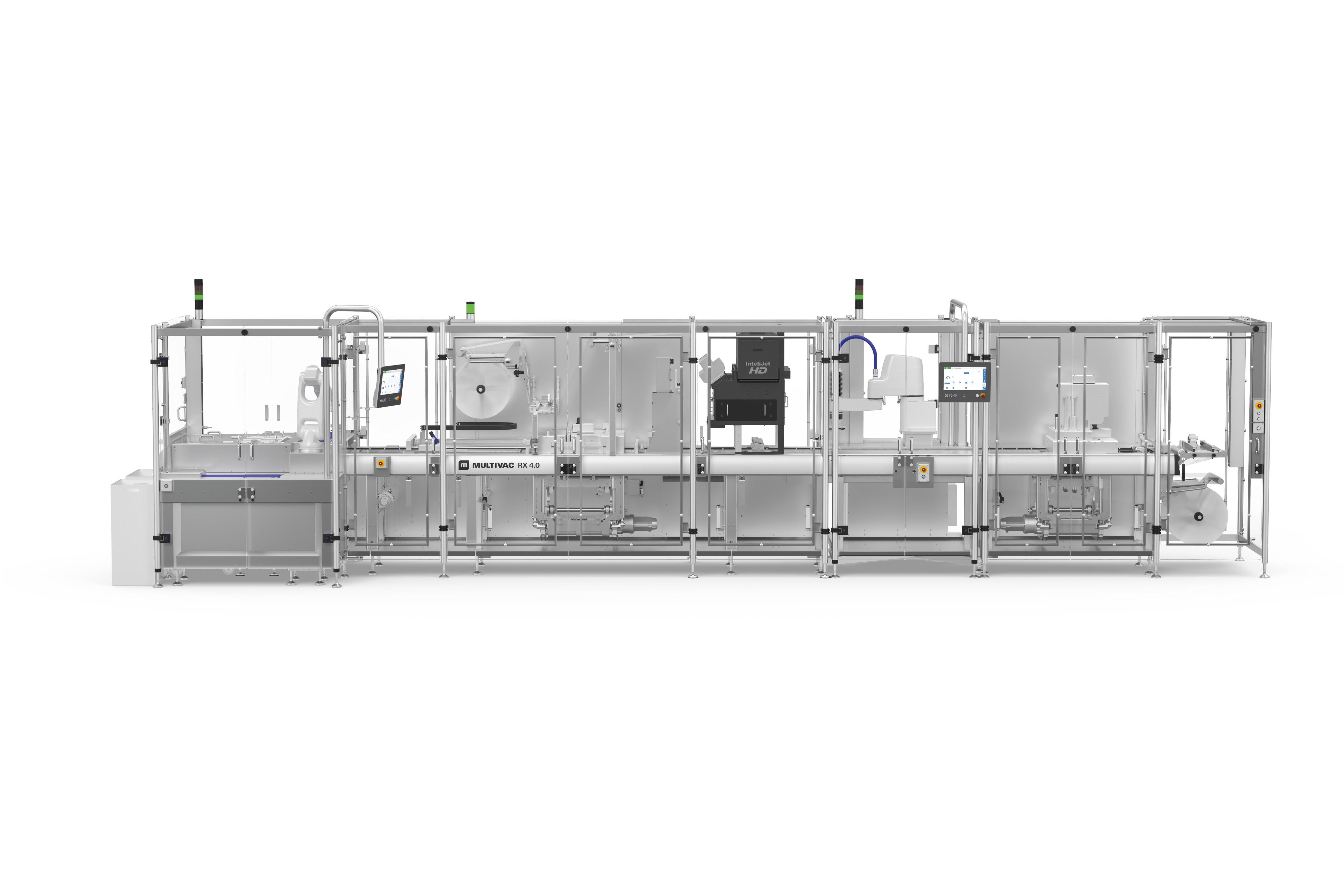

Wolfertschwenden, 26 September 2024 – Exhibiting at COMPAMED 2024 (Hall 8a, Stand H 01), MULTIVAC will be presenting innovative and sustainable packaging solutions to the medical products industry. The heart of the company's presence at the trade fair is a fully automated line for producing medical combi packs, which includes both loading and unloading robots. Various inspection solutions for inspecting the product and print will also be shown on the stand.

Sustainable medical combi packs

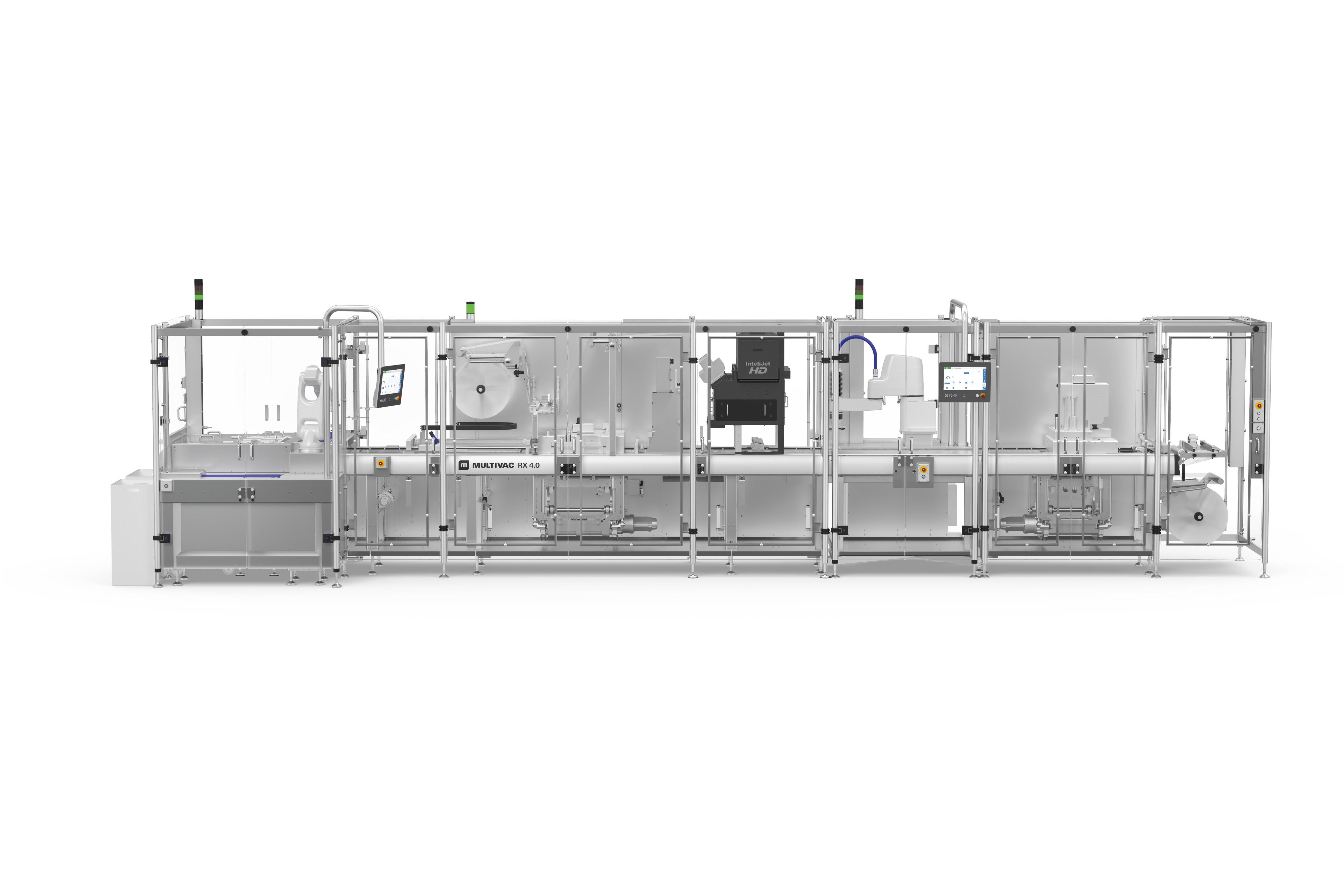

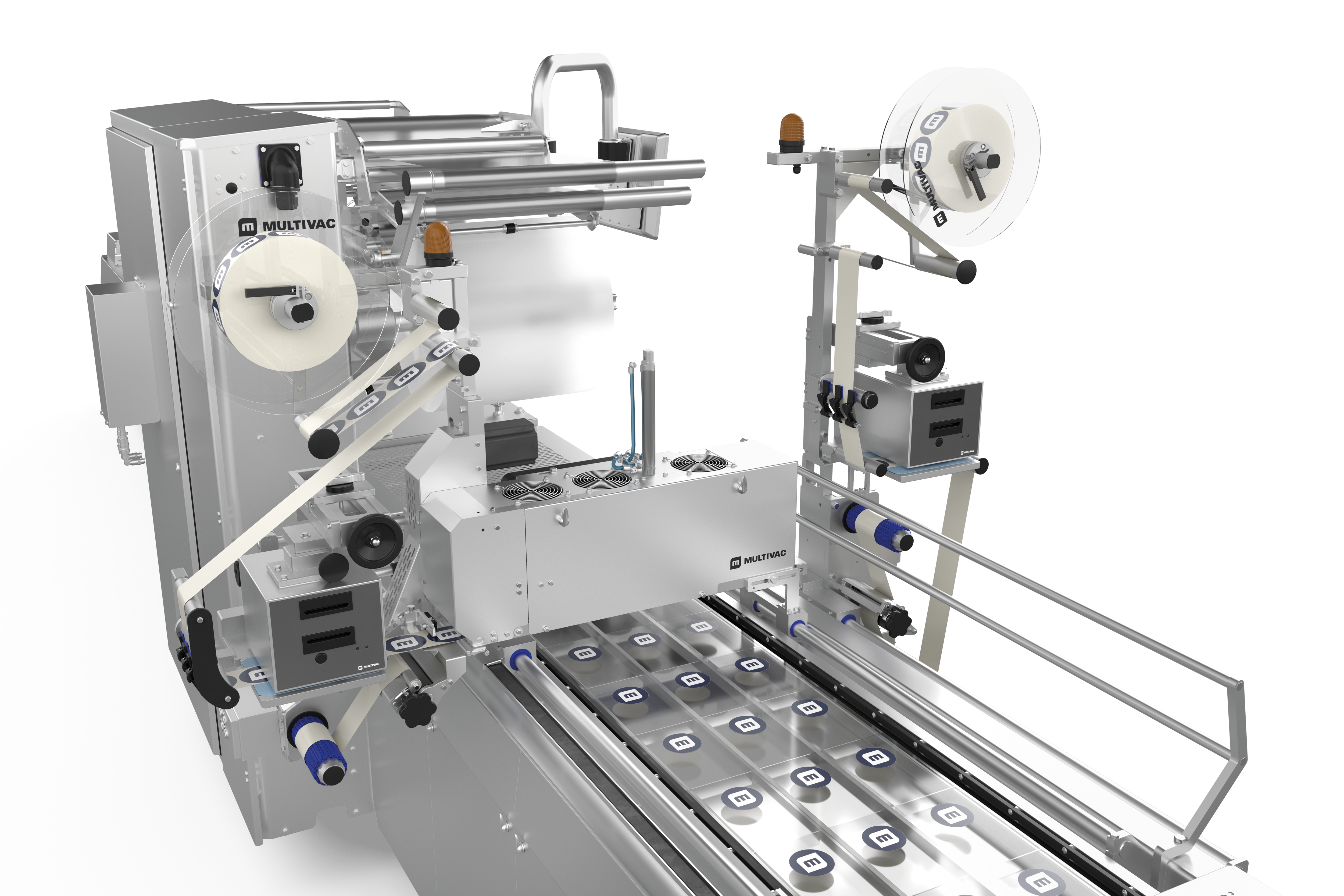

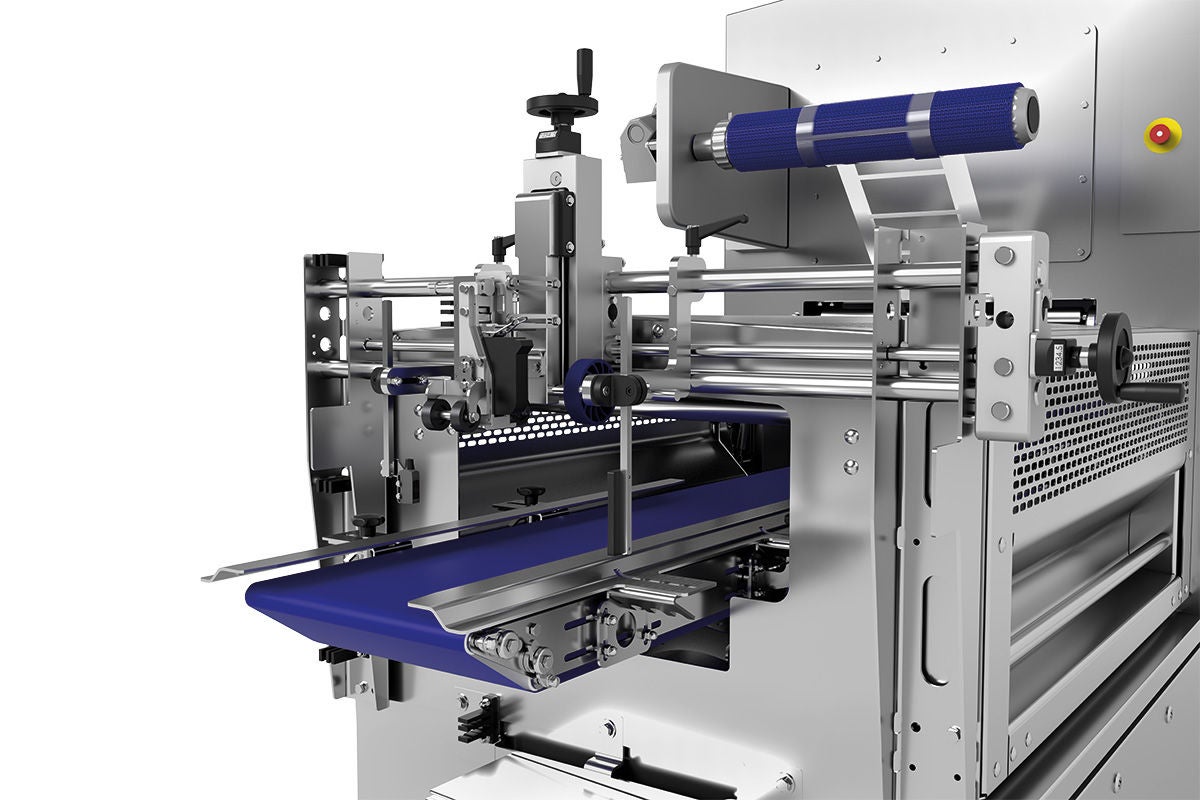

The exhibits include a line that produces medical combi packs from sustainable mono film. The core of this line is the RX 4.0 thermoforming packaging machine in GMP design, which is equipped with a glass safety enclosure for optimum overview of the process. An integrated SCARA robot is used for the precise and automated loading of the individual products into the preformed pack cavities. Before the upper web is sealed to the lower web, it is printed inline with UDI-compliant data in a multi-colour design by a digital printer. A visual inspection system subsequently inspects the print image on the packs.

Heat-sensitive products are protected during the packaging process by a cooled product shield plate: If the machine comes to a stop, the shield plate is automatically positioned between the hot sealing plate and the product. After the packaging process has been completed, a 6-axis robot separates the packs into good and reject packs, and it places them on various transport conveyors for downstream processing. As a leading supplier of integrated solutions, MULTIVAC now also provides SCARA and 6-axis robots, which can be integrated seamlessly into the line, as well as its other handling modules.

Thanks to its comprehensive sensor system and continuous process monitoring, the RX 4.0 thermoforming packaging machine offers a high degree of process precision and reproducibility. The RFID-coded dies with permanent status monitoring ensure that format changes are performed reliably, and that the changed dies are positioned correctly on the machine. The whole line can be operated conveniently and intuitively by the user-friendly HMI on the packaging machine.

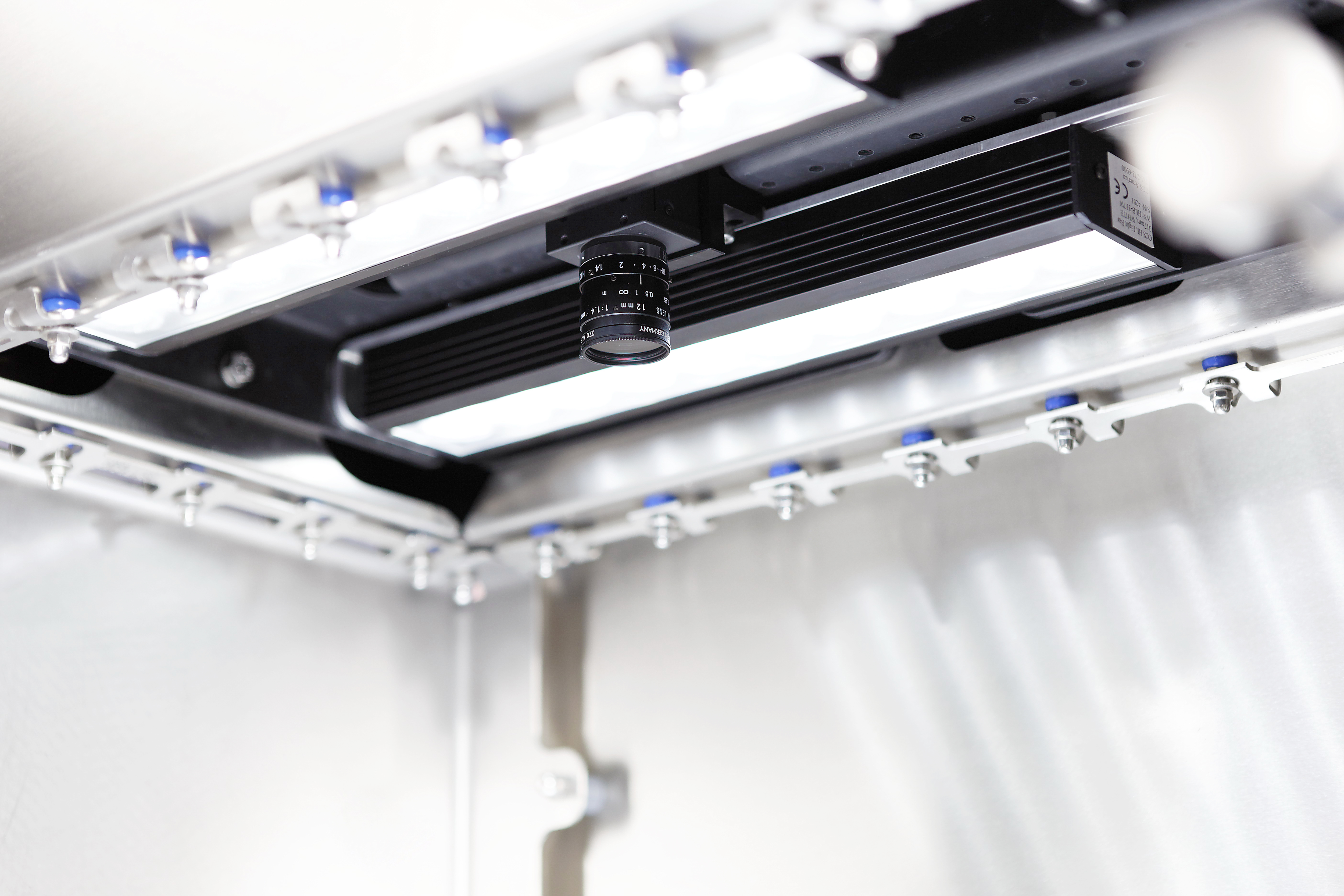

More flexibility in quality control: Comprehensive solutions for all requirements

“We offer medical companies a wide range of innovative inspection solutions for inspecting the product and print. Depending on the particular task, various components can be used, such as cameras, code readers or sensors. These can either be integrated seamlessly into the packaging machine or labeller, or alternatively be used as stand-alone inspection systems. The result is a solution with perfectly matched components and a uniform operating concept. The resulting high level of integration guarantees efficient and secure processes,” explains Thomas Große, Sales Project Manager at MULTIVAC Marking & Inspection.

Different solutions for a range of inspection tasks will be fully demonstrated on the stand at COMPAMED. Visitors will be able to receive comprehensive advice about the possibilities and capabilities of the individual modules.

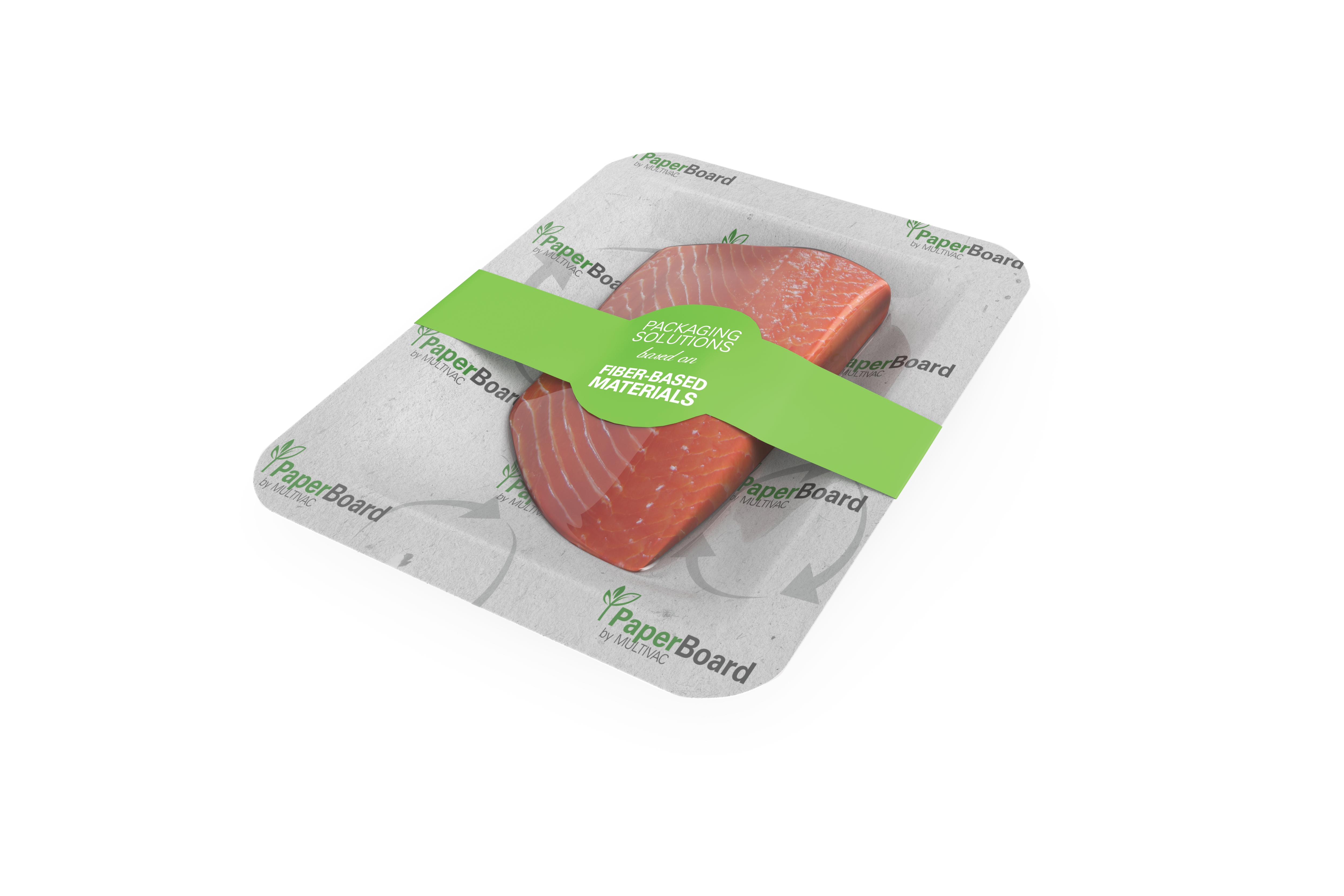

Sustainability meets innovation: The medical packaging of tomorrow

“The medical products industry will also come under pressure to establish sustainable packaging solutions. We are able to support this process by offering environmentally-friendly alternatives, and by providing our customers with packaging concepts, which reduce the consumption of materials and resources, or improve the recyclability of their packs,“ says Verena Vetter, Corporate Product Manager for Medical & Pharma at MULTIVAC. “Our machines are designed in such a way, that they can run different packaging materials without any problems, and this includes mono films, which are fully recyclable. Working together with our customers in our Corporate Training & Innovation Center, we can develop tailored packaging solutions and concepts, which offer both process reliability and sustainability.“

Press Release

Sustainable packs for the medical industry: maximum security with minimum impact on the environment

- حجم

- 90 KB

- تنسيق

Latest News

2327146963

2327146963

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

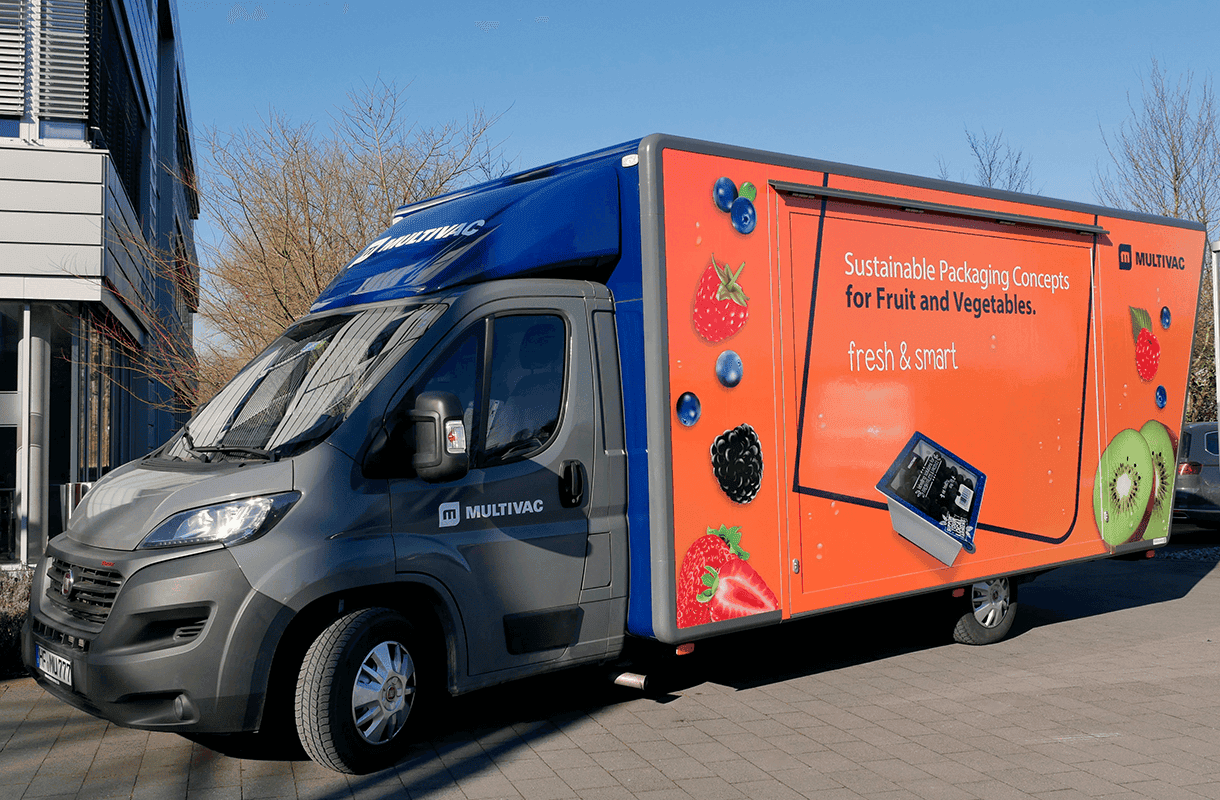

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC PDF

MULTIVAC PDF

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce