MULTIVAC and Watttron turn to "Smart Heating" for producing sustainable packs

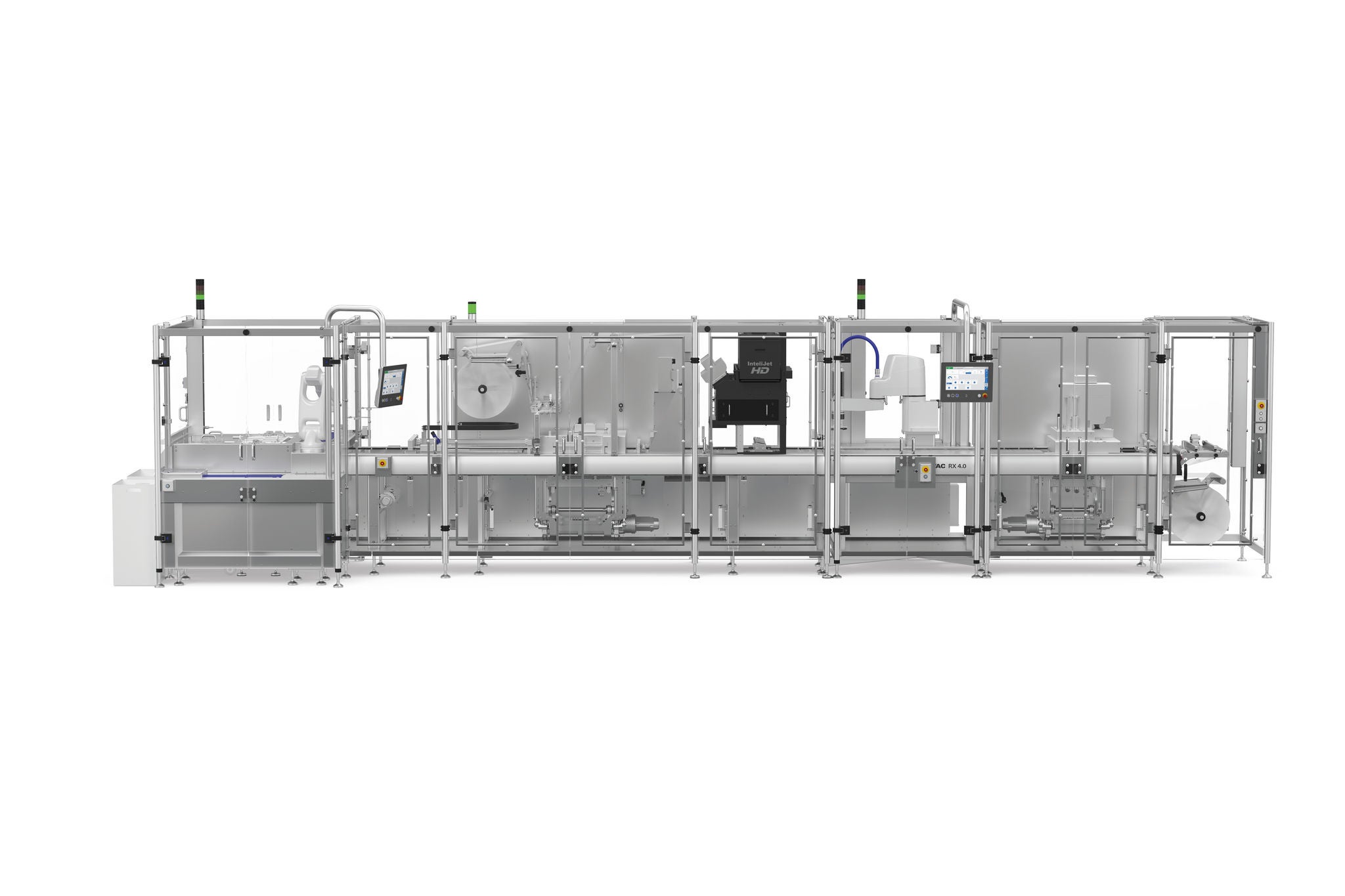

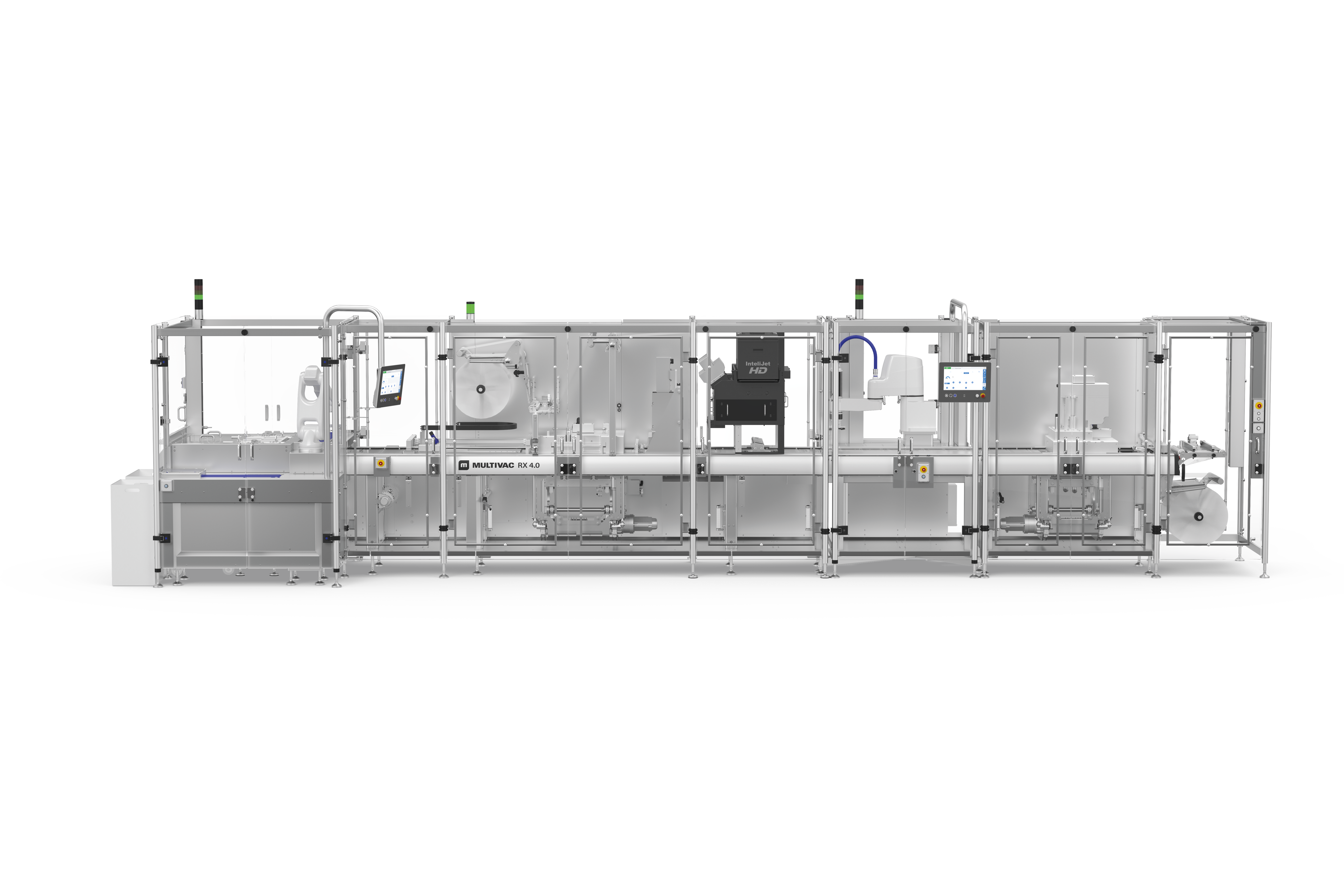

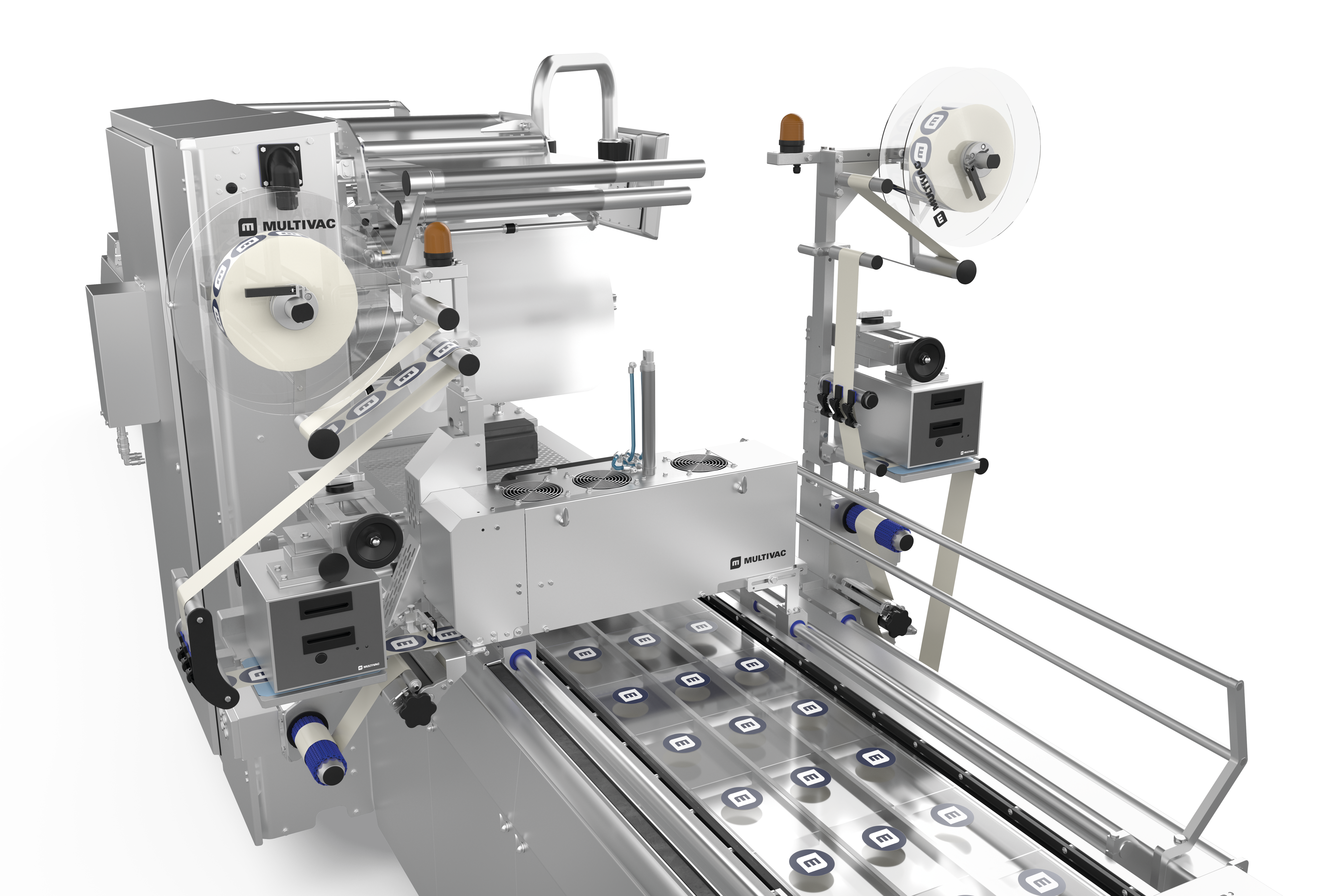

MULTIVAC at IFFA 2025 (Hall 12.1, Stand A 41): MULTIVAC pix-elHEAT forming system and MULTIVAC pixelSEAL sealing system

23.04.2025

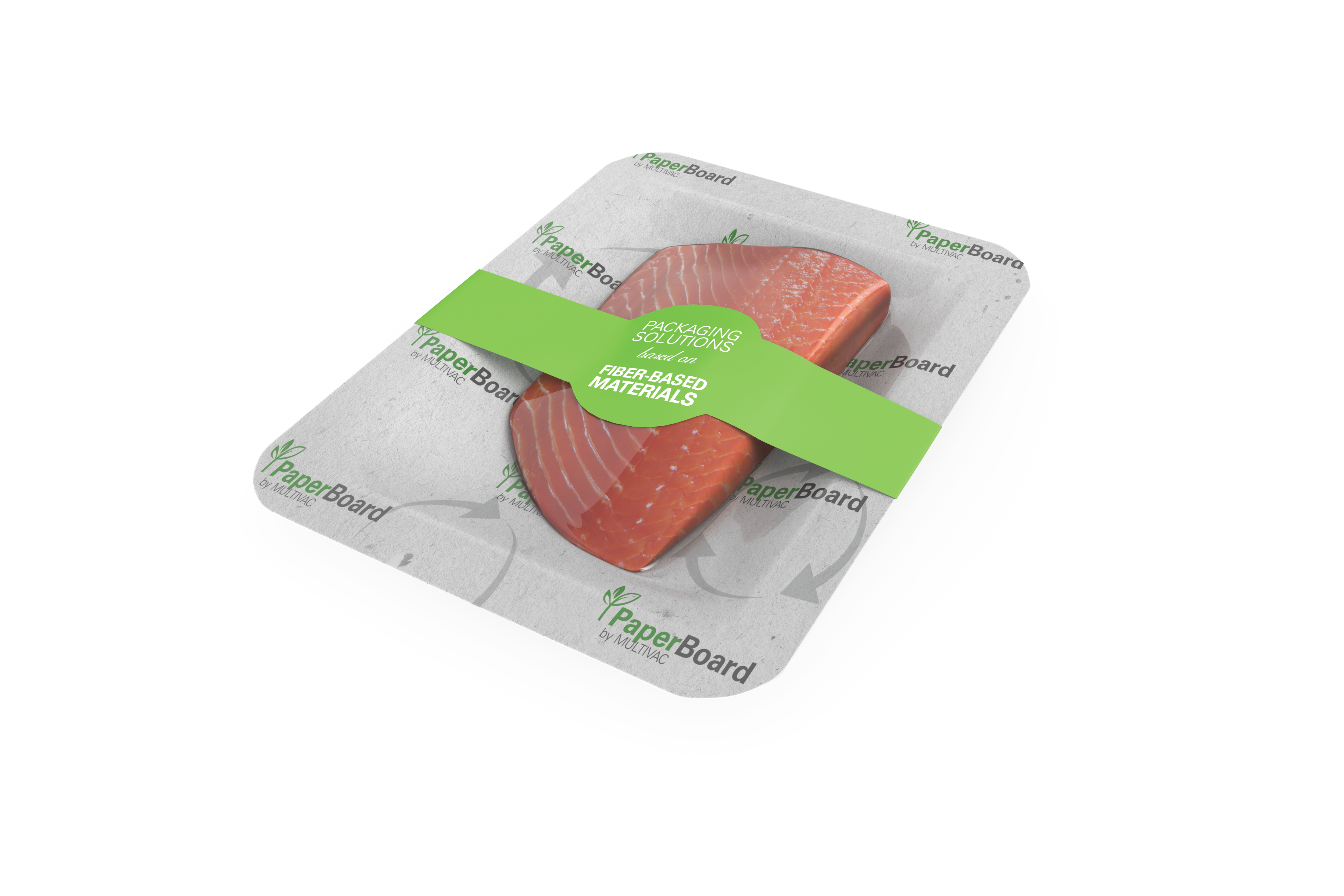

Wolfertschwenden, 23 April 2025 – Efficient, reliable and sustainable: With its new matrix heating systems, MULTIVAC is perfecting the forming and sealing processes on its thermoforming packaging machines, and in doing so it is meeting the growing demand for sustainable packaging solutions. At this year's IFFA the company will be presenting the new MULTIVAC pixelHEAT und MULTIVAC pixelSEAL heating systems, which are supplied in cooperation with Watttron GmbH. They can be integrated into thermoforming packaging machines of all output categories.

MULTIVAC pixelHEAT system: More precision, less film consumption

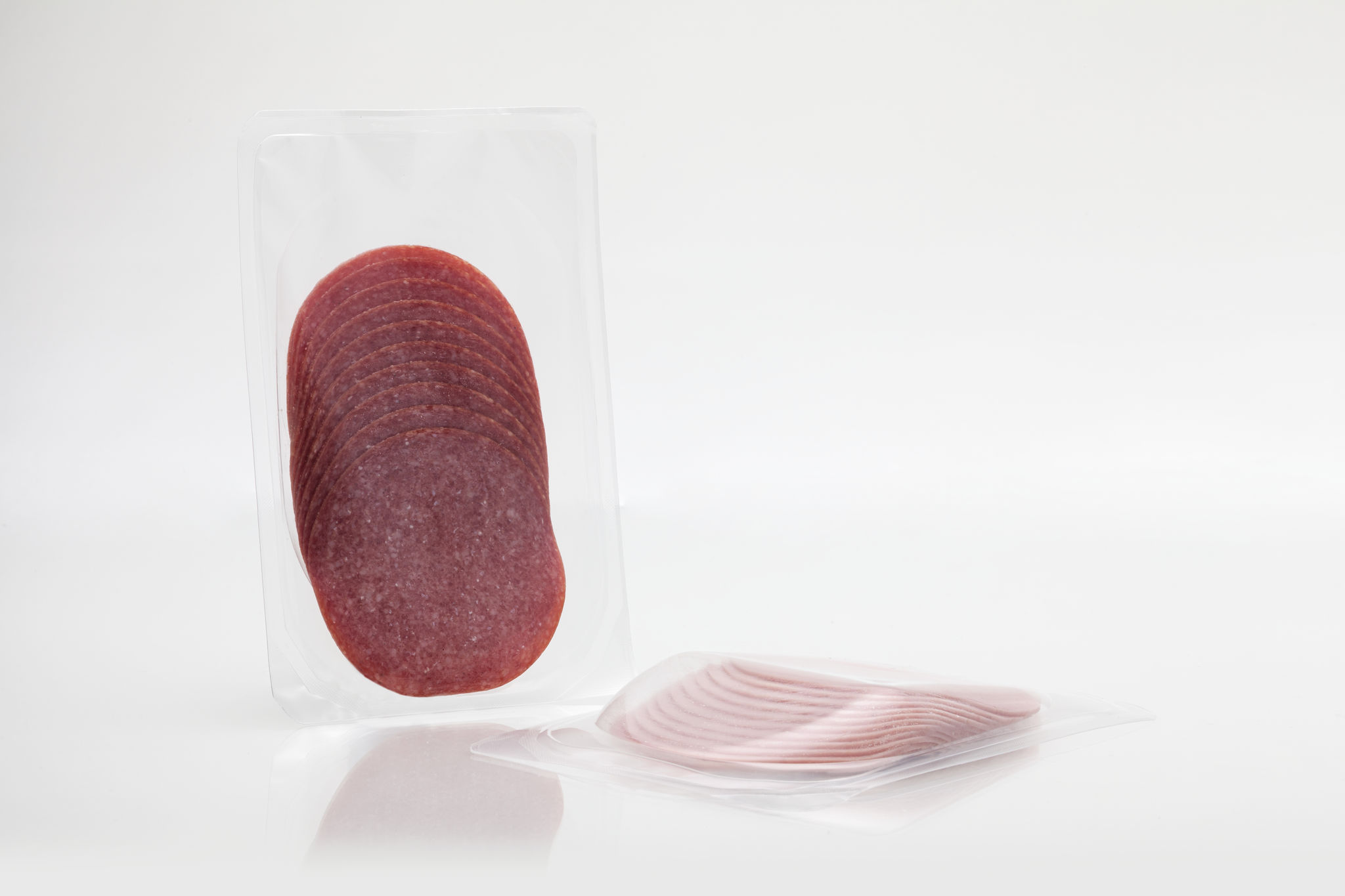

The pixelHEAT matrix heating system enables high-quality thermoformed packs to be produced with up to 50 percent less material. Precise temperature control ensures that stable packs are produced with thinner films, as well as saving resources and energy. Heating pixels, which can be controlled individually, make it possible to achieve targeted material distribution during the forming process in the thermoforming packaging machine. The thinner plastic films are still able to achieve the desired pack stability. Thanks to the rapid and precise pixel heating of the film, up to 30 percent of the energy can be saved. Heating-up times of less than one minute accelerate the start of production and the conversion time between different formats. The heating system is particularly suitable for running recyclable films, such as mono materials – and in this way it supports the use of sustainable packaging concepts.

MULTIVAC pixelSEAL system: For a consistently high level of seal seam quality

The main feature of the pixelSEAL contour sealing system, which can be controlled digitally, is very precise temperature control for optimum sealing of thermoformed packs. High-quality seal seams ensure that hermetically sealed packs are produced. Sealing pixels, which can be controlled individually, provide an even and precise temperature distribution. The energy consumption during sealing can be reduced by up to 50 percent with the new heating system, and the heating-up time is particularly short. The sealing system also ensures that recyclable films are sealed perfectly.

Visitors to IFFA can convince themselves of the new technology and its potential for reducing film consumption: The new MULTIVAC pixelHEAT system will be shown at the trade fair using demo equipment and pack samples. Customers and other interested parties can also make an appointment at the MULTIVAC Innovation Center in Wolfertschwenden, so that they can receive individual advice, as well as a demonstration and sample production.

Press Release

MULTIVAC and Watttron turn to "Smart Heating" for producing sustainable packs

- حجم

- 146 KB

- تنسيق

Image

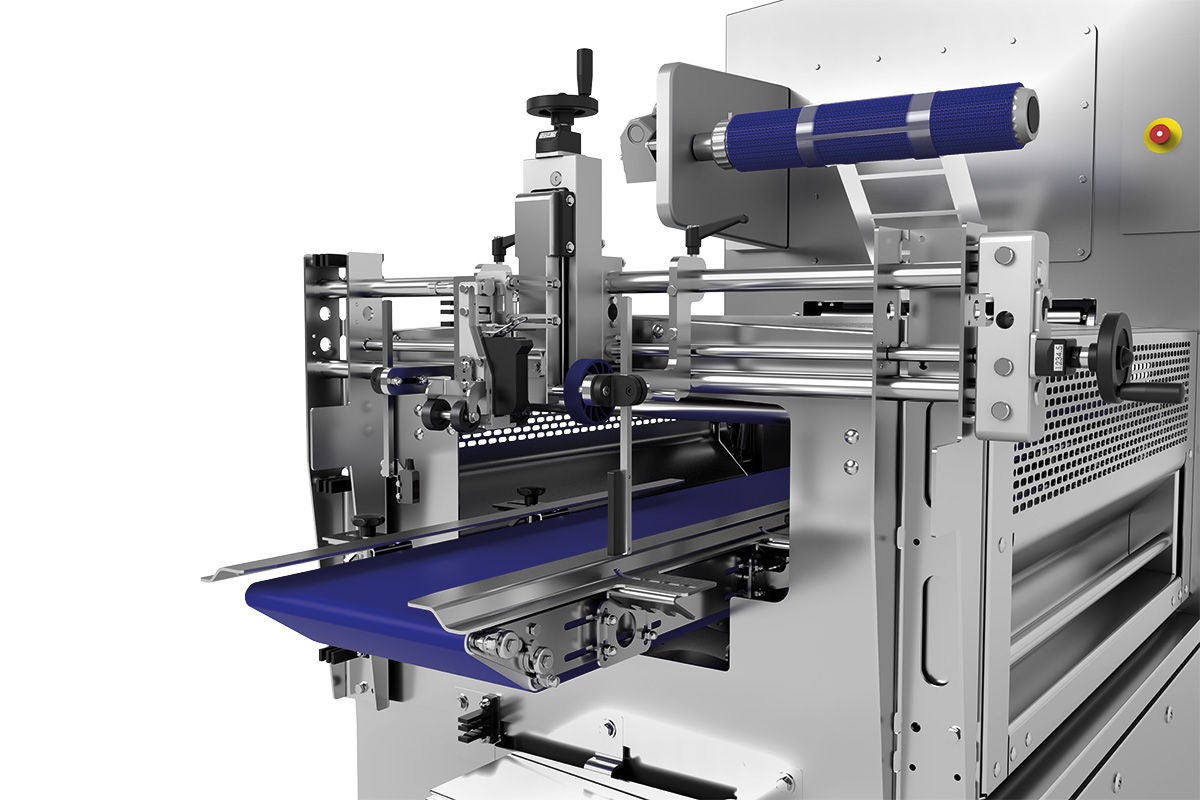

MULTIVAC pixelHEAT forming system and MULTIVAC pixelSEAL sealing system

- حجم

- 1 MB

- تنسيق

- jpeg

Latest News

2327146963

2327146963

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC PDF

MULTIVAC PDF

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

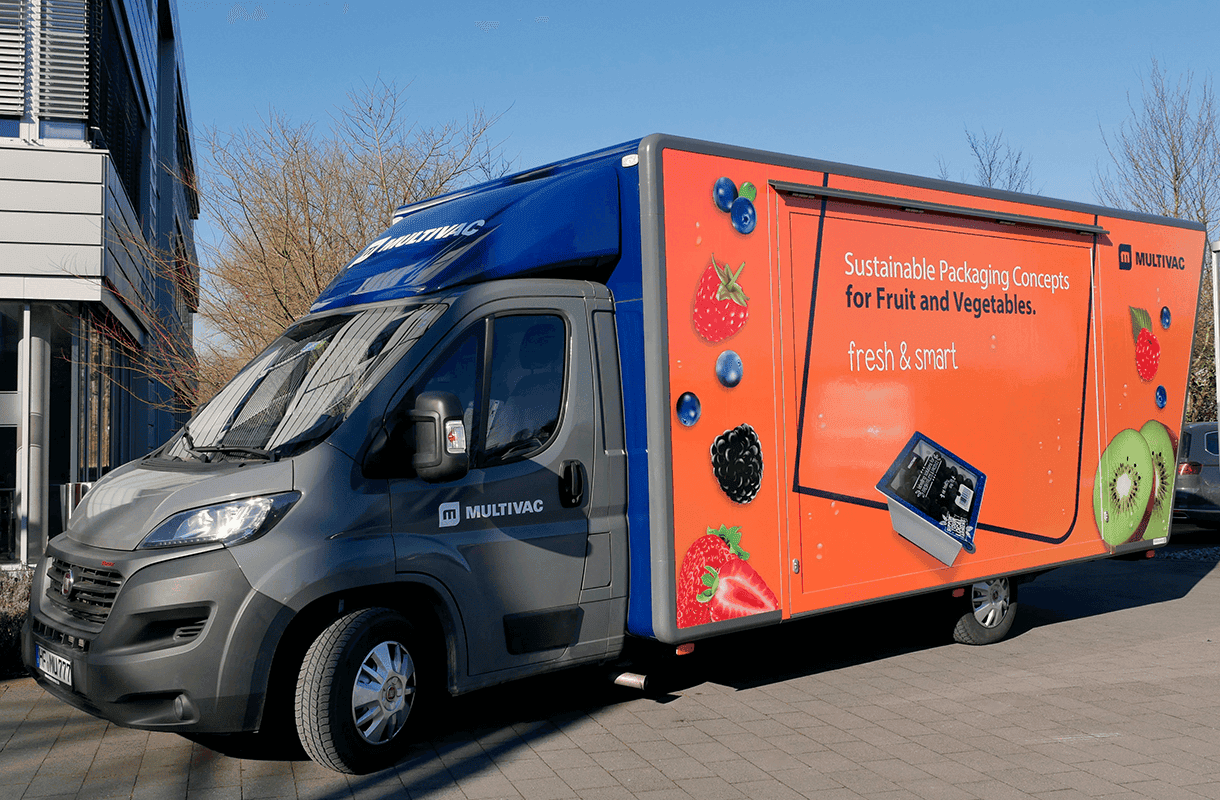

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

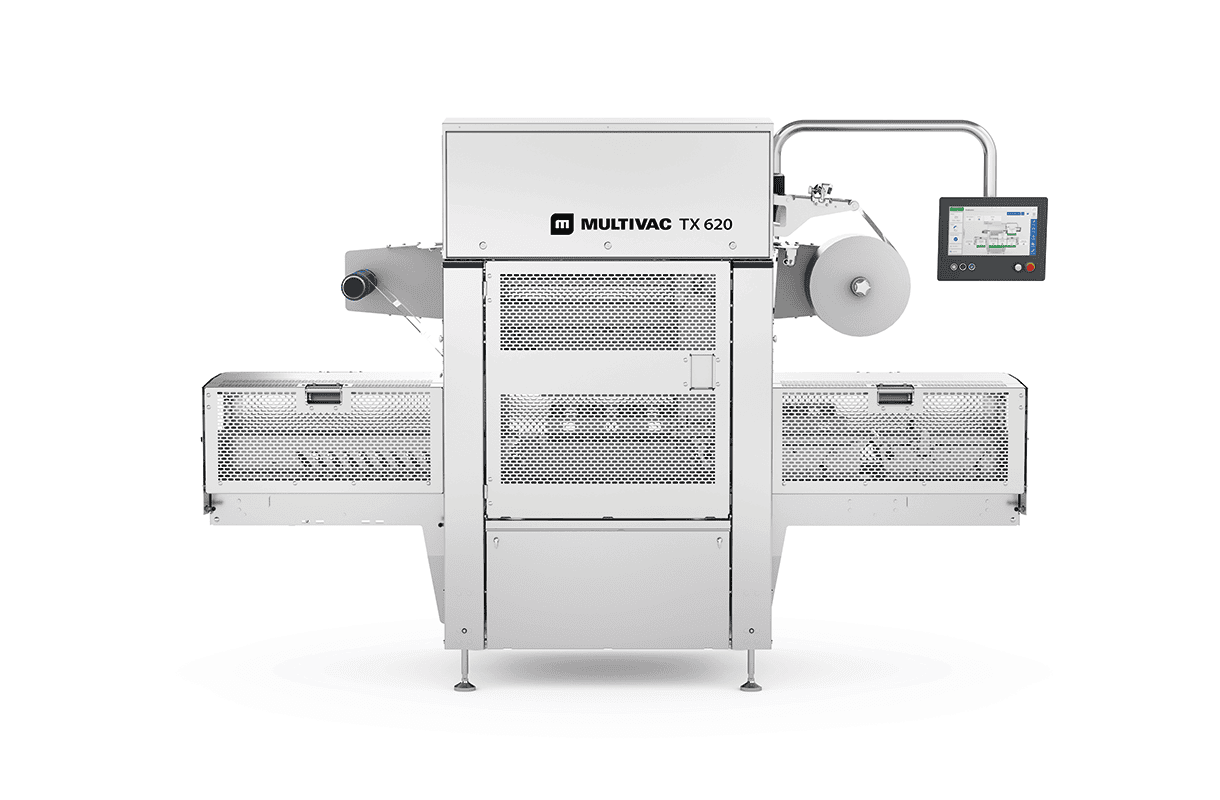

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce