The triggers for spoilage in dairy products are essentially biological or microbial processes as well as chemical, biochemical, or physical reactions to these. Sliced cheese for example consists of four main constituents, namely water, protein, fat, and minerals or vitamins. It is for this reason, that these products are quite susceptible to microbial spoilage and undesirable oxidation reactions. The individual factors are explained below, and there is also a description of the requirements, which a pack must fulfil in order to counteract food spoilage. Suitable packaging concepts for sliced cheese are also presented.

Microbiological spoilage is generally caused by bacteria, yeast, and mould. A large number of factors play a role here, such as hygiene in the production process, the heat treatment used, the nutrient availability, the aw value, the oxygen availability, the pH value, and last but not least the chill chain. Microbiological spoilage of sliced cheese manifests itself most frequently as undesirable mould growth. Since mould growth requires oxygen, it is very important that there is as little residual oxygen as possible in the pack. If a shelf life of more than 21 days is required, it is recommended that barrier films are used, for example films with a barrier layer of EVOH (ethylene vinyl alcohol co-polymer). If on the other hand a defined mould growth on the cheese is required, the packaging films used should have a defined oxygen permeability.

Chemical or biochemical spoilage is understood to be oxidation, autolytic processes, or enzymatic reactions, which manifest themselves for example in undesirable browning of the products. Dairy products are very susceptible to oxidation reactions. Their chemical spoilage can generally be detected by a bad taste, discolouration, loss of aroma, and a reduction of important nutrients. The fats, proteins, and riboflavin, which are contained in dairy products, are particularly affected by oxidation reactions. Oxidation is caused by light in the UV and visible spectrum as well as by oxygen, and it can even be accelerated by these under certain circumstances. In order to counteract this, it is beneficial to have packs that are impermeable to light. This is however in conflict with the requirement of consumers for transparent packs, which allow the product to be viewed at the point of sale. It is for this reason that transparent materials, which are permeable to light, are generally used for most retail packs.

The light transmission of transparent packs in the visible spectrum is up to 90 percent. Therefore, in order to prevent oxidation reactions, every effort must be made when packing sliced cheese to reduce the residual oxygen content in the pack to a minimum. If a shelf life of more than 21 days is required, films with an oxygen barrier must be used for the pack. The less residual oxygen there is in the pack, the fewer undesirable oxidation reactions will occur in the product.

Physical spoilage includes for example drying out, syneresis (phase separation), becoming moist, as well as loss of aroma. Sliced cheese is generally susceptible to drying out. This depends crucially on the aw value. This is a measurement of water activity, i.e. the amount of water contained in the food, but which is not bound in the mass. The amount of water can theoretically be between 0 (water-free food) and 1 (pure water).

In the case of sliced cheese, the aw value is 0.90 to 0.98. The cheese is generally stored in the consumer's refrigerator, where the air humidity is between 90 and 95 percent. This equates to a water activity of more than 0.9. This means that there is no concentration differential between the product and the storage environment, so it is not necessary to have a special moisture vapour barrier for the pack. Should a concentration differential exist between the product and the pack environment, an equalisation process would take place over time between the two concentrations. In order to prevent this, packaging materials with a barrier layer would have to be used. The ideal storage conditions for sliced cheese are therefore a dark, cooled, and oxygen-free environment.

Since the EVOH barrier material is hygroscopic, its barrier effect towards oxygen can be negatively influenced by the amount of moisture absorbed from the environment. It is for this reason, that the EVOH barrier in multi-layer films must be protected against moisture by the use of a moisture vapour barrier layer, for example an appropriate polyethylene layer. The polyethylene polymer has a high moisture vapour barrier, enabling the required oxygen barrier of the EVOH layer to be preserved.

When designing a sustainable packaging concept for sliced cheese, the challenge is to retain the protective function of the pack, while minimising material consumption and at the same time achieving an attractive pack appearance.

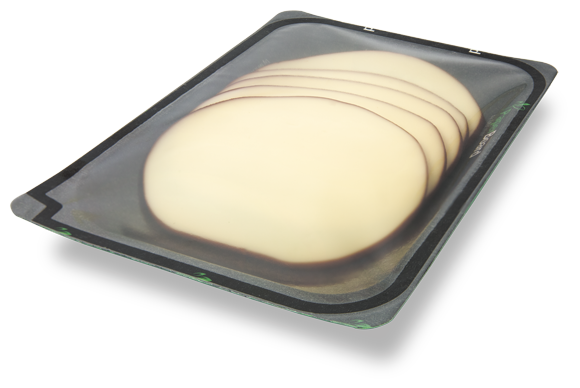

A typical pack for sliced cheese is for example a thermoformed pack, where for the lower web a multi-layer rigid film is used, which consists of APET (amorphous polyethylene terephthalate) and PE (polyethylene). For the upper web a flexible multi-layer film can be used, which consists of an OPET (oriented polyethylene terephthalate) carrier material and a barrier layer of PE/EVOH/PE. The sliced cheese is packed in a modified atmosphere (MAP), so the microbial and chemical spoilage is slowed down.

Another packaging concept is the so-called envelope pack made of flexible film. This can provide an attractive alternative to the traditional thermoformed pack made of rigid film, if one is packing slices of cheese or even ham and sausage, and one of the main features of the pack is its significantly smaller packaging volume. This means the consumption of material is reduced when producing packs, and this meets the increasing demand of consumers and retailers for sustainable packaging concepts. When producing envelope packs, flexible multi-layer OPET/PE/EVOH/PE films can be used for both the upper and lower webs. The MAP process is also used with this type of pack to slow down the microbial and chemical spoilage of the product.

When compared directly, both packs have several things in common. As regards the shelf life extension of the products, both packaging concepts are equally effective, since both pack types ensure the product is protected against microbial and biochemical spoilage thanks to the use of modified atmosphere and barrier films. Due to its more rigid structure, the thermoformed pack does however offer better protection against mechanical effects than the envelope pack. The rigid pack also features a convenience function, since the pack can for example be used as a container for serving the product.

Both packs can be provided with an opening aid as well as a reclosure function. In the case of the thermoformed pack made of rigid film, this can for example be a peel corner, which is used to open or reclose the pack. In the case of the flexible envelope pack, an adhesive flap can be used for reclosing the pack.

It is also possible with both pack concepts to print the upper web or apply labels, so that the legal requirement for information on the pack can be met, as well as creating a buying incentive for consumers.

The major difference between the two packs lies in their weight. The flexible lower web, which is used to produce the envelope pack, is up to 85 percent lighter than the lower web of the rigid thermoformed pack.

Since multi-layer films with different polymers are used for both packaging concepts, recycling is not possible with the current recycling technology for either the thermoformed pack or the envelope pack, because the multi-layer films can not be fed into a material recycling stream. In order that the material in multi-layer films can be recycled, the packaging film industry is currently working on the development of material structures, which consist primarily of polyolefins - and this means they can be fed into the recycling stream for polyolefins. These types of materials are currently being tested by MULTIVAC for their running suitability, and they could in future replace conventional multi-layer films for packing sliced cheese, as well as other products.

Another alternative for packing sliced cheese is the use of paper fibre-based materials, e.g. MULTIVAC PaperBoard. The product portfolio includes different materials and pack concepts for both thermoforming packaging machines and traysealers. The materials consist of a paper or cardboard backing and a functional layer made of plastic. The different layers can be separated by the end user into their individual materials and then fed to the appropriate recycling stream. Since closed-loop recycling streams already exist everywhere for paper fibre-based materials, this makes a major contribution to implementing a closed-loop system for the packaging industry. The sliced cheese is packed in a modified atmosphere (MAP), so that the microbial and chemical spoilage is stemmed. And last but not least, this pack can also be printed (product marketing, contents of product etc.) and provided with a reclosure function.

Envelope packs made of flexible multi-layer films can be a sustainable alternative to traditional rigid thermoformed packs for packing sliced cheese. This packaging concept offers virtually the same shelf life protection to the product, although the protective effect against mechanical impact is less. Thanks to its significantly smaller packaging volume, the envelope pack does however meet the current requirements for a resource-saving pack solution. If polyolefin-based materials are used in future, envelope packs could also be produced, which allow multi-layer materials to be recycled. Packs made of paper fibre-based materials also offer a sustainable solution for packing sliced cheese. These score highly as regards recyclability and also provide the same convenience function as a traditional pack made of rigid film.

03.12.2019