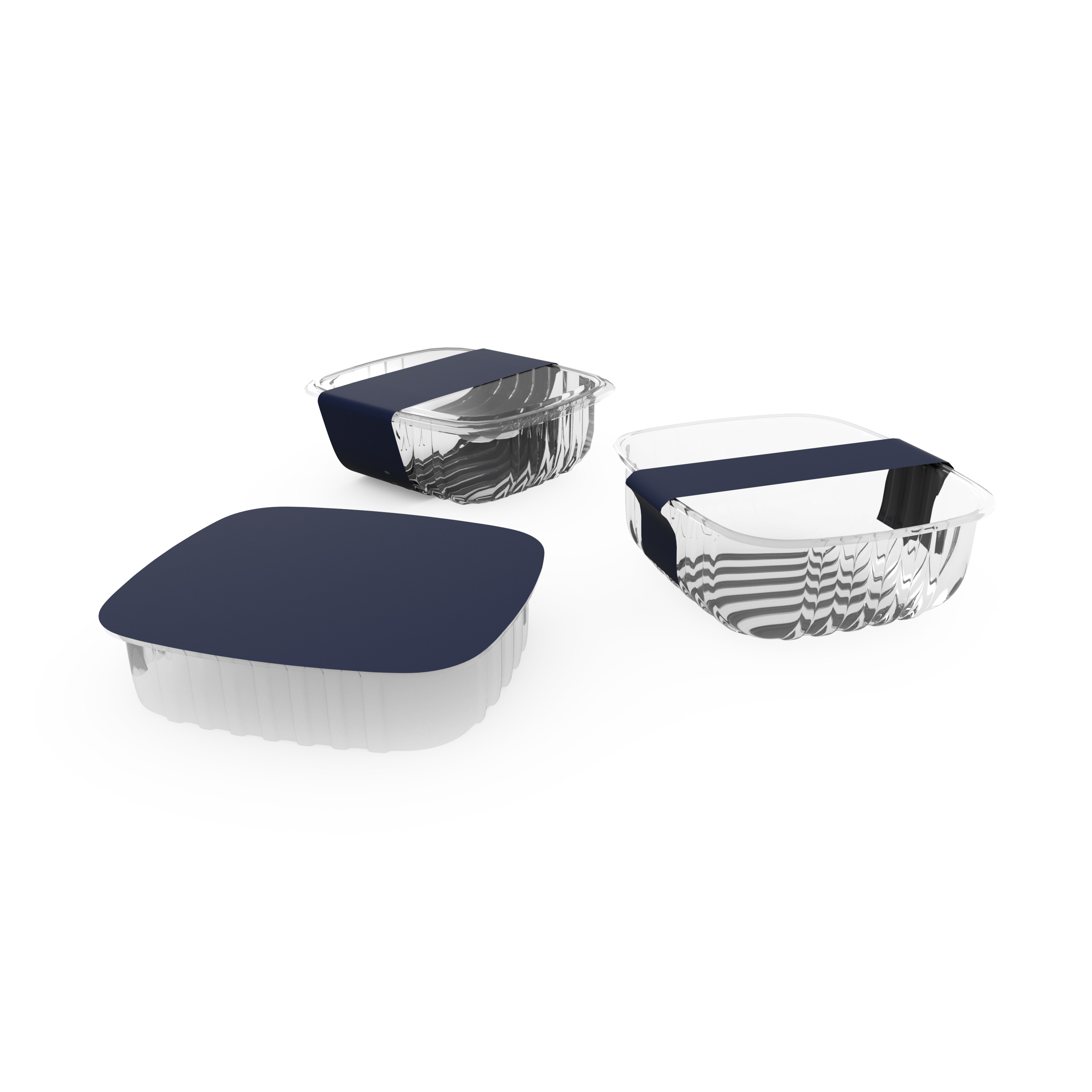

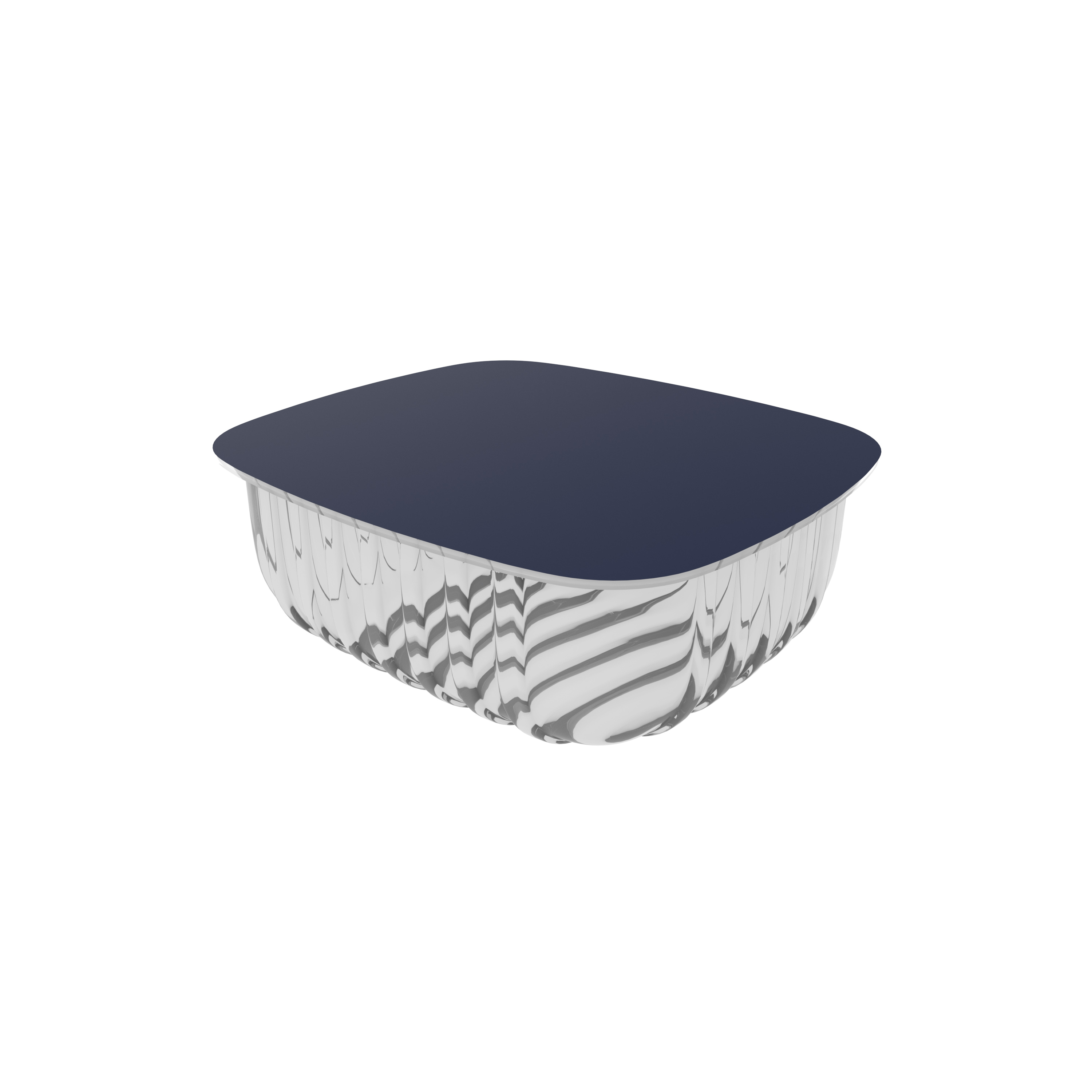

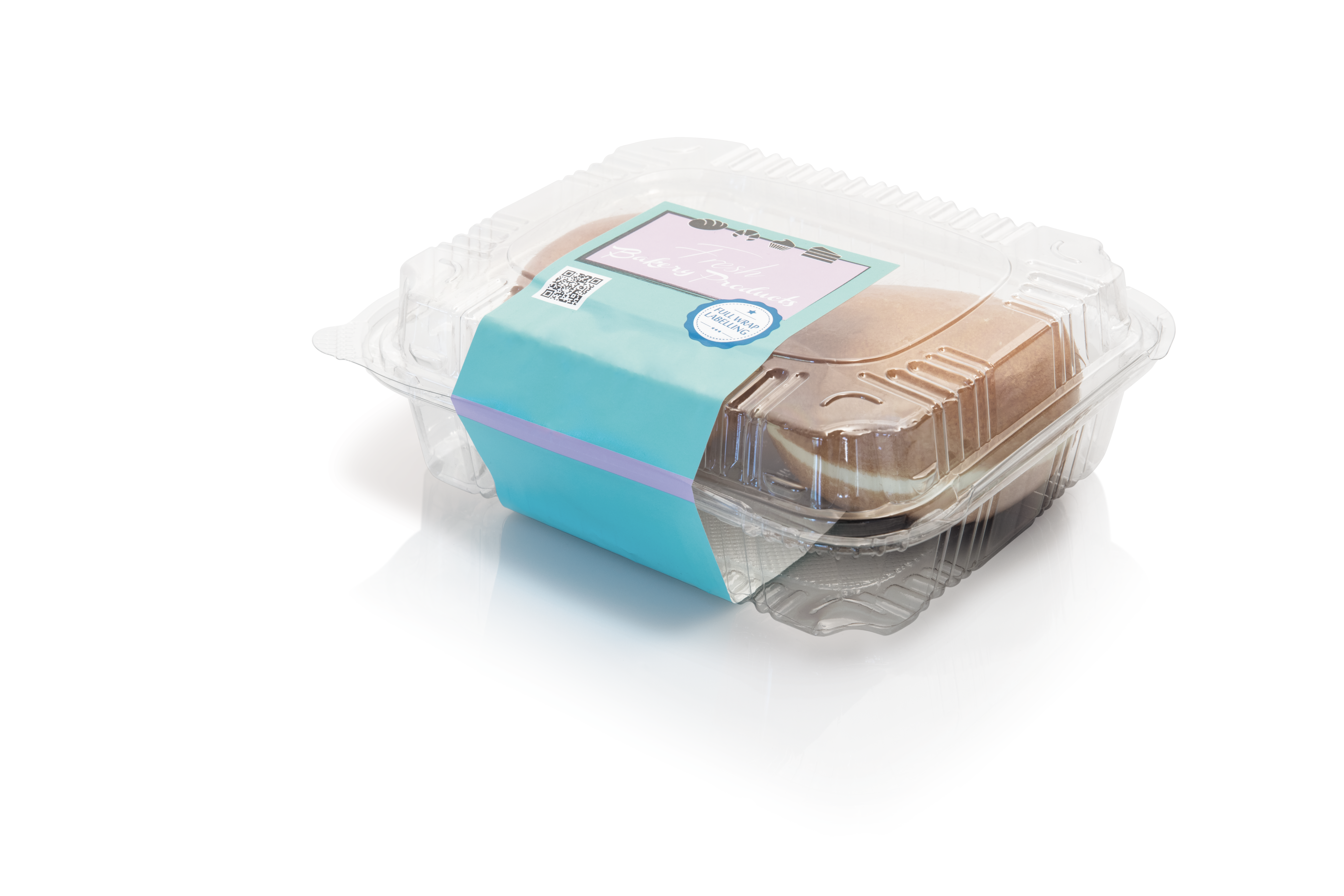

TopWRAP™ & TopCLOSE™ – Sustainable packaging of fruit and vegetables.

If fruit and vegetables don‘t have to be packed in a modified atmosphere or a vacuum, there is a simple solution: the trays can be closed with labels and marked directly. MULTIVAC offers two solutions for sustainable and recyclable packaging which help you to fulfil the requirements of the EU Packaging and Packaging Waste Regulation (PPWR).

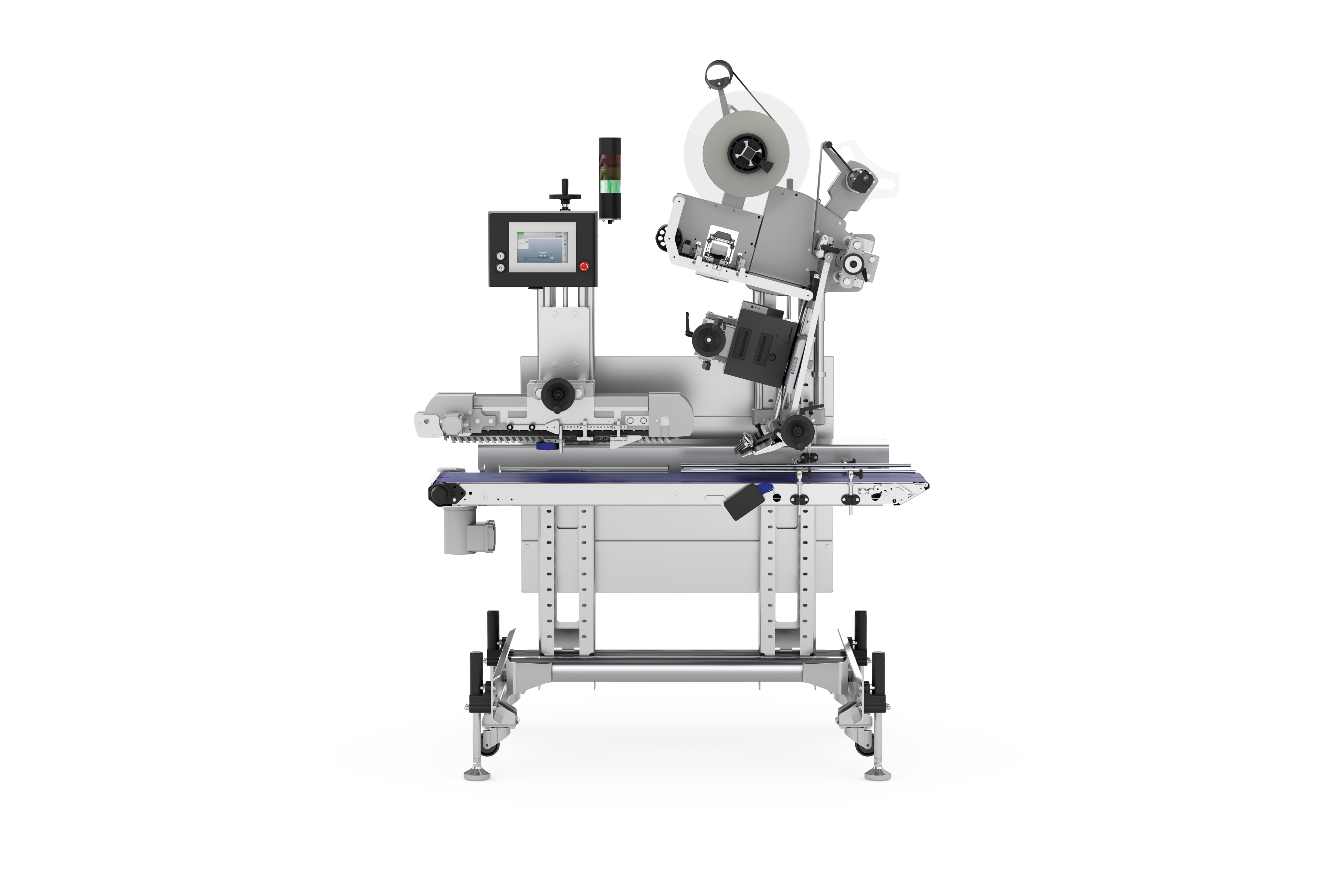

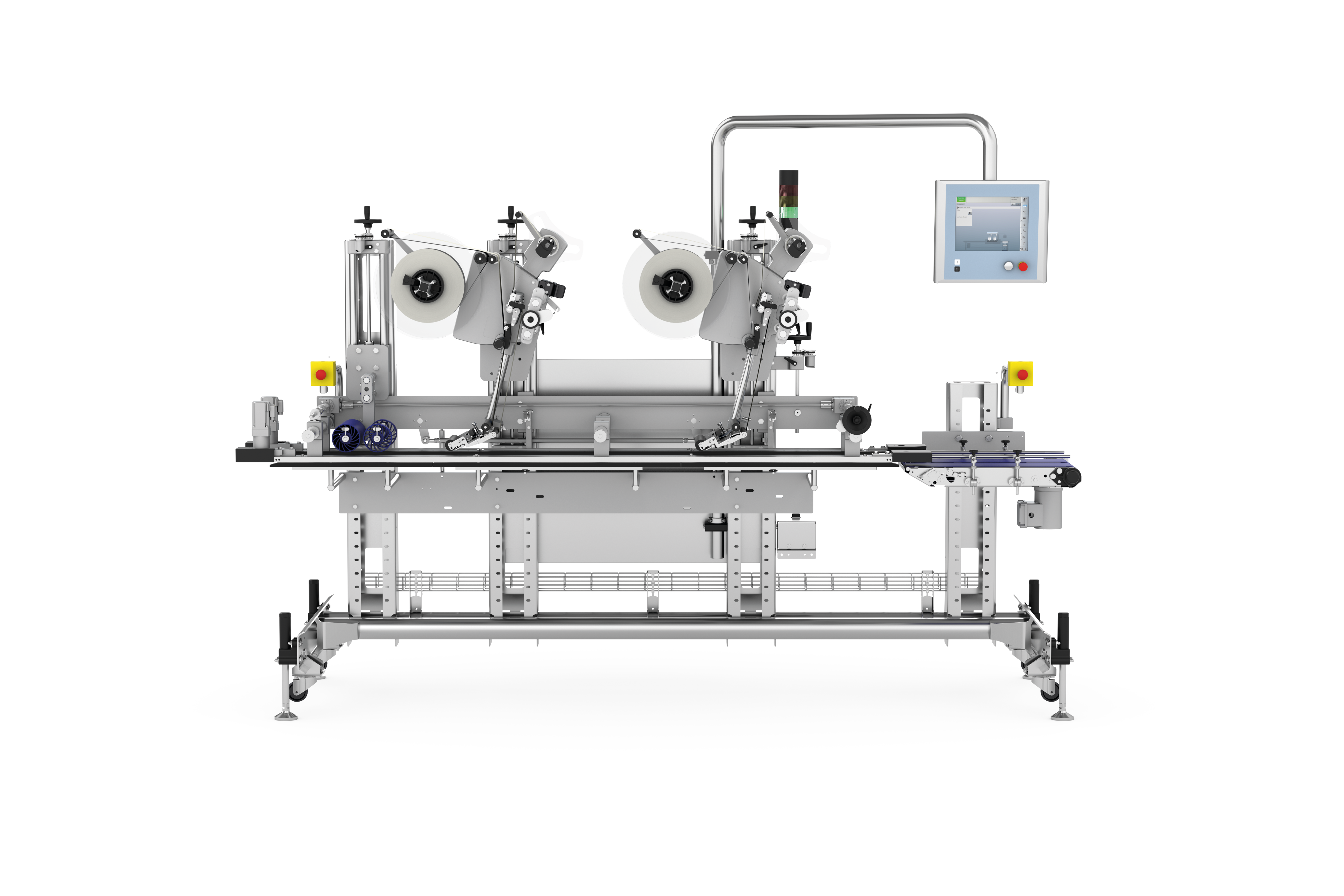

- Automatic closing of the trays at high speeds

- Labelling, printing and inspection on one machine

- Materials from renewable resources possible

- No compressed air and water consumption

- Toolless change-over to alternative tray sizes or designs

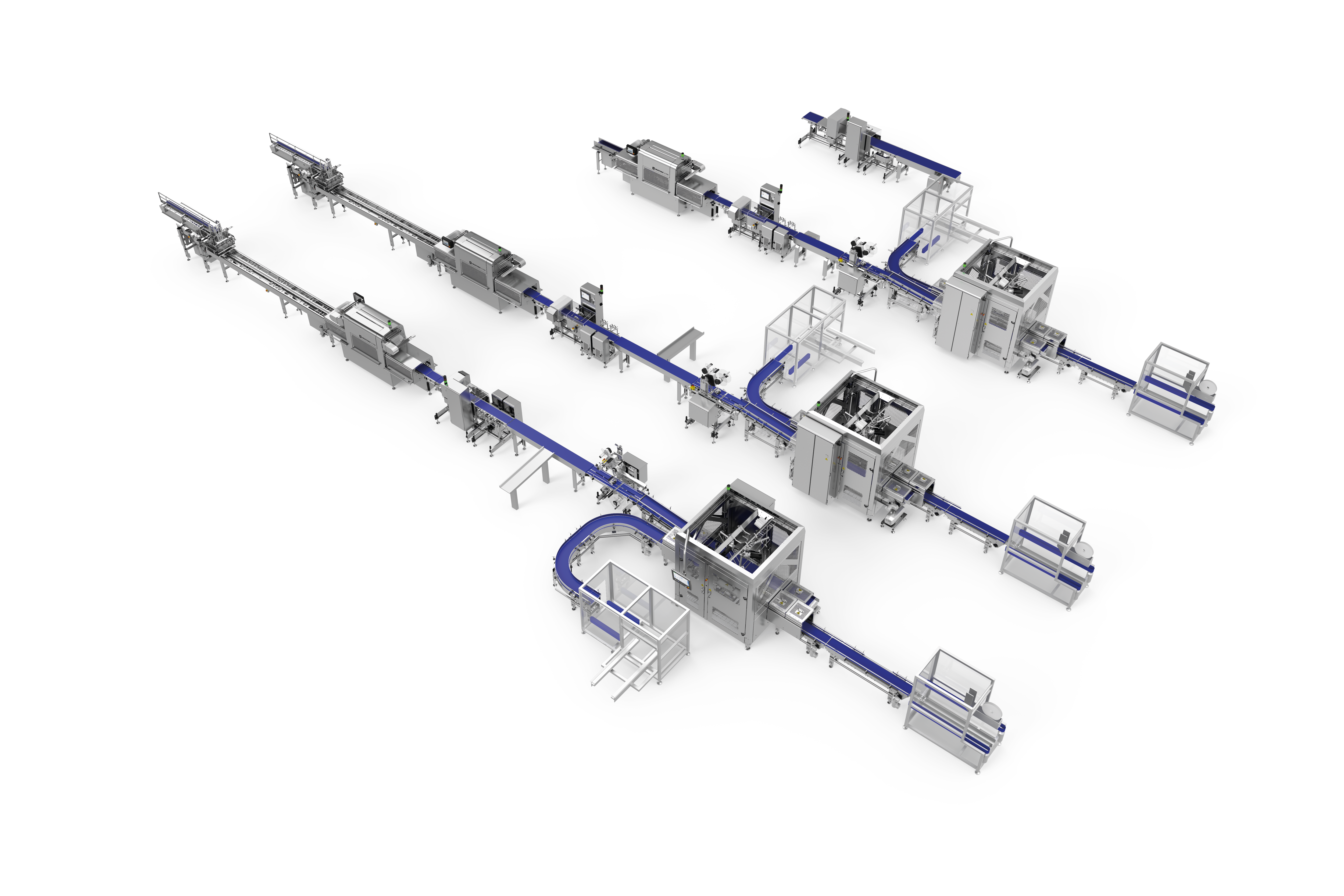

- Various automation options