Sustainable packaging solutions for fruit and vegetables.

09.01.2023

MULTIVAC at Fruit Logistica in Berlin (Hall 2.1, Stand A-10)

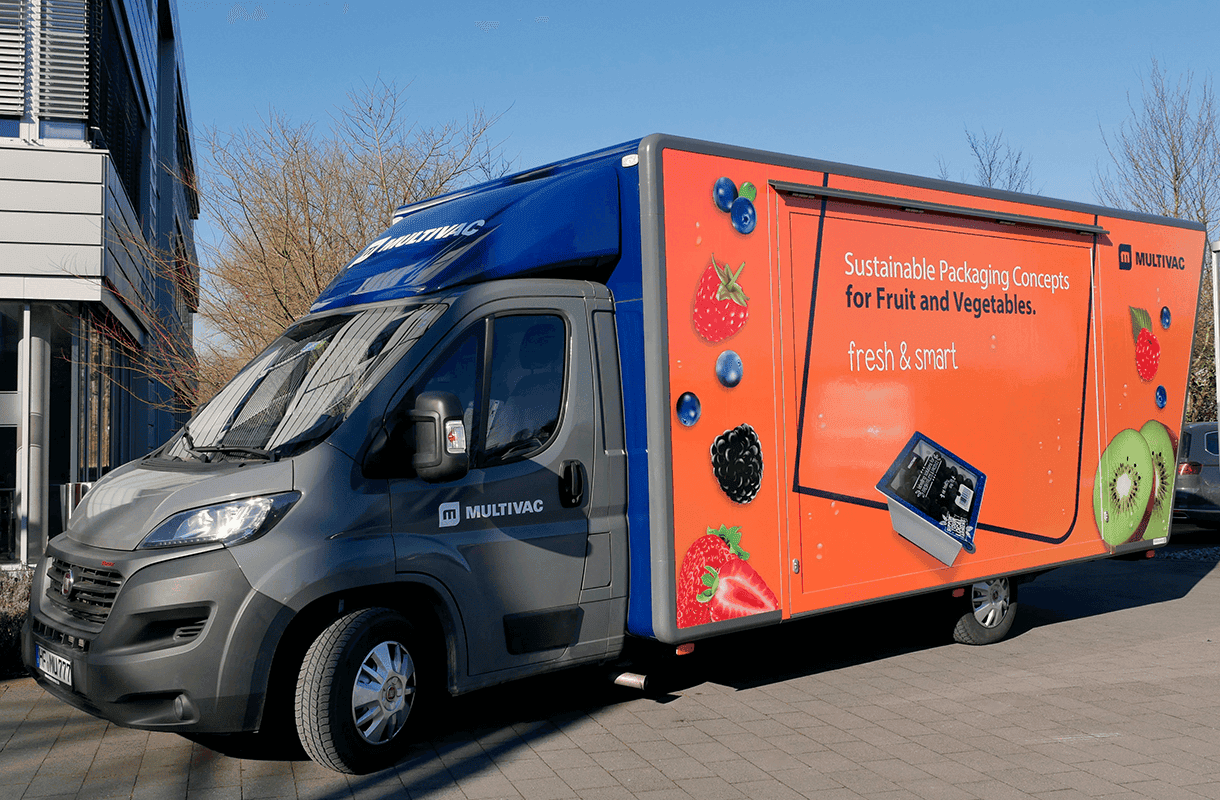

Wolfertschwenden, 9 January 2023 – France is leading the way: It will in future no longer be possible to retail fruit and vegetables in plastic packs. In the case of more perishable products such as tomatoes, grapes and beans, the law will apply from the middle of 2023, while for products such as sprouts and berries, the law will come in from the middle of 2026. MULTIVAC is therefore placing particular emphasis on its sustainable packaging concepts at Fruit Logistica, which runs from 8 to 10 February 2023.

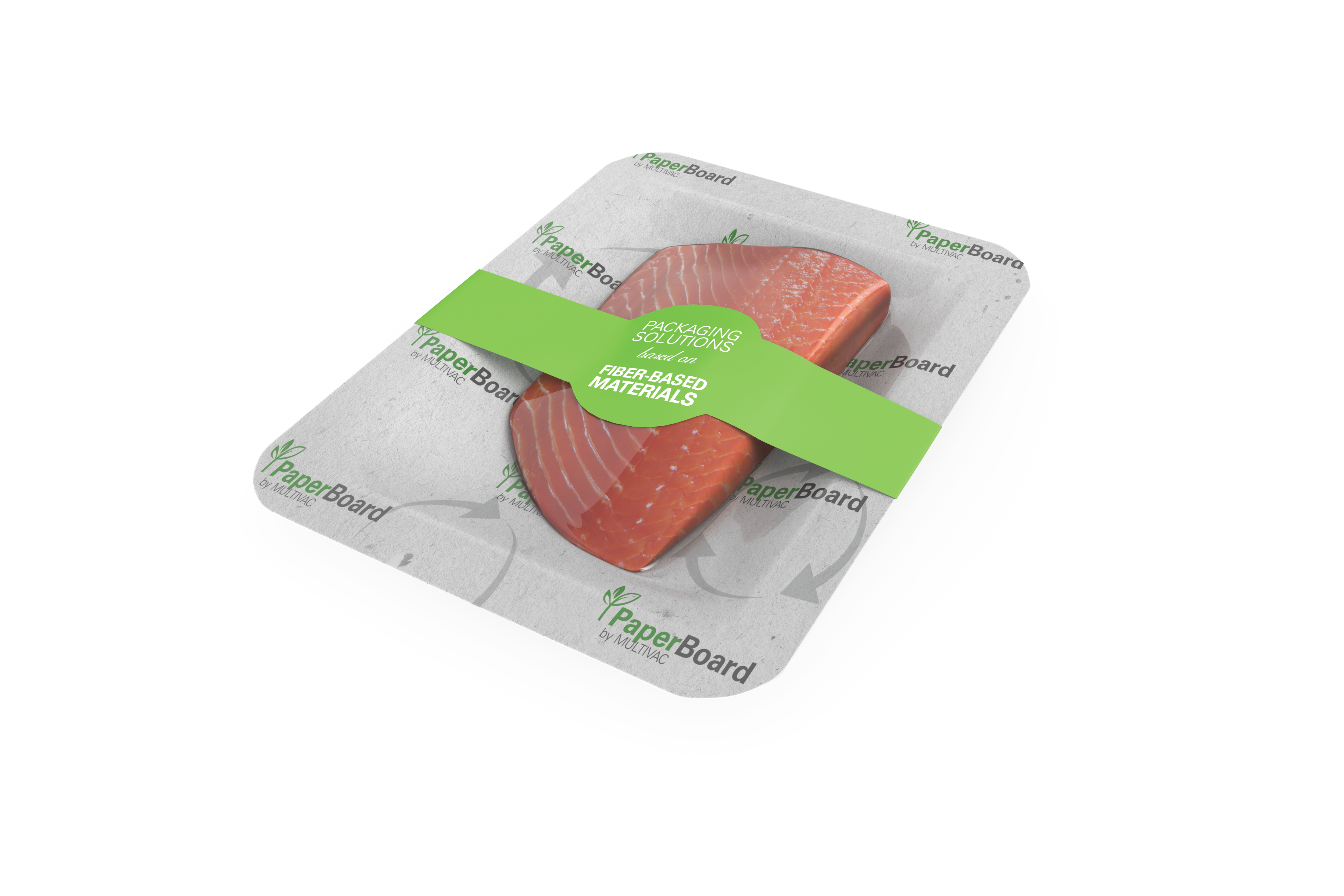

MULTIVAC will be presenting sustainable packaging solutions for a wide range of fresh products over more than 250 square metres of exhibition space. The company is expecting a high level of interest from visitors, particularly in regard to the MULTIVAC PaperBoard range, as well as for the company's other packaging concepts, which have a high level of material efficiency and recyclability, while still providing extended shelf life for the food products.

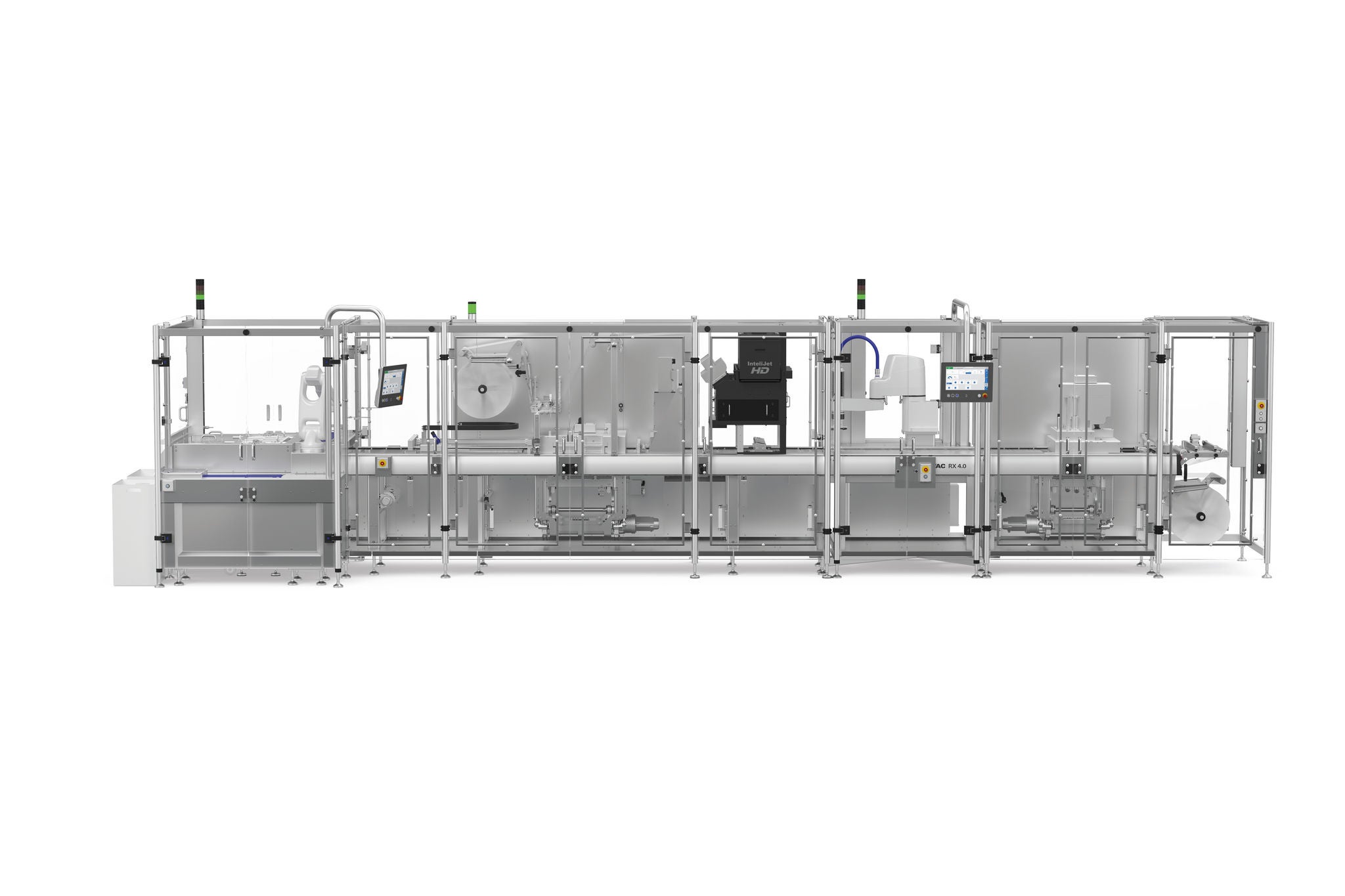

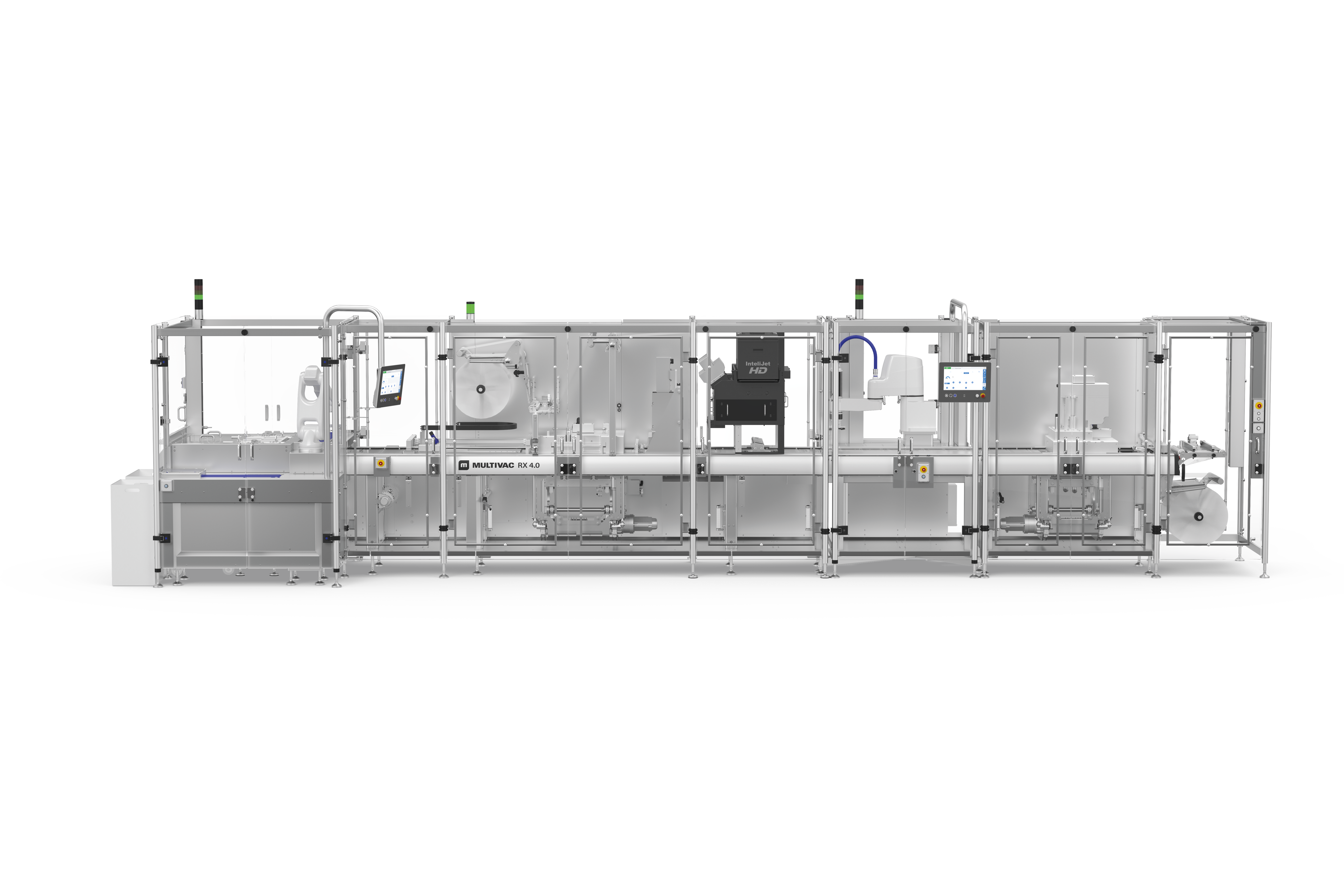

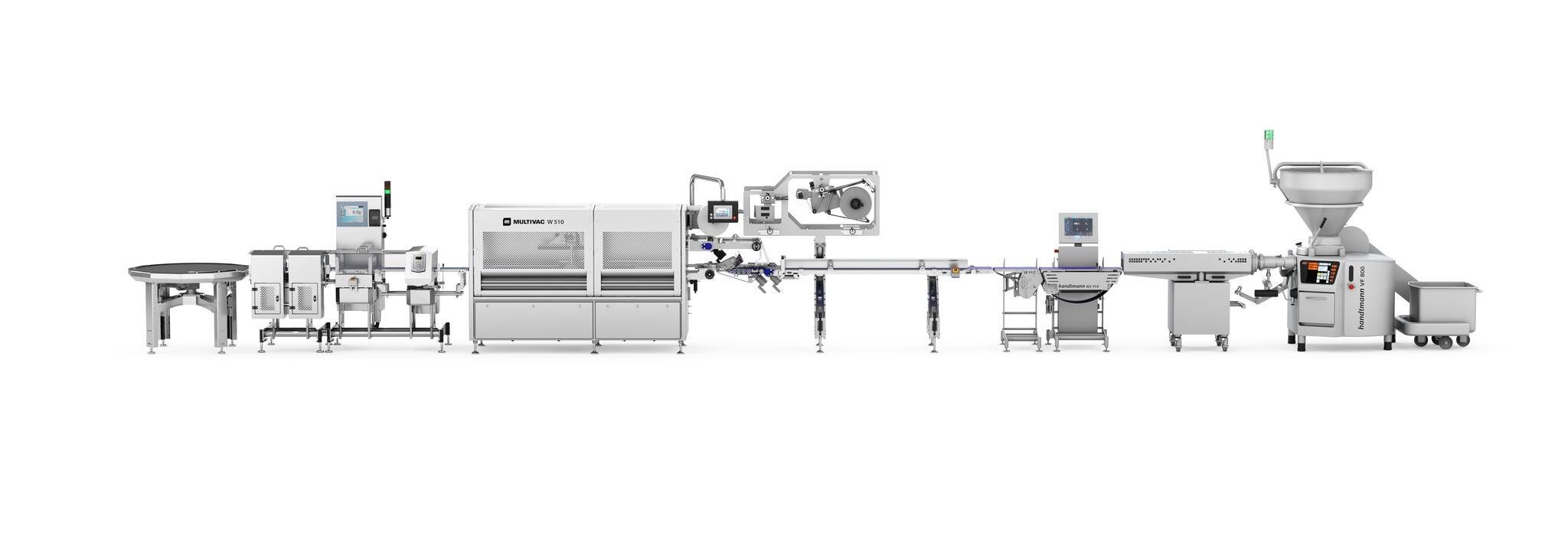

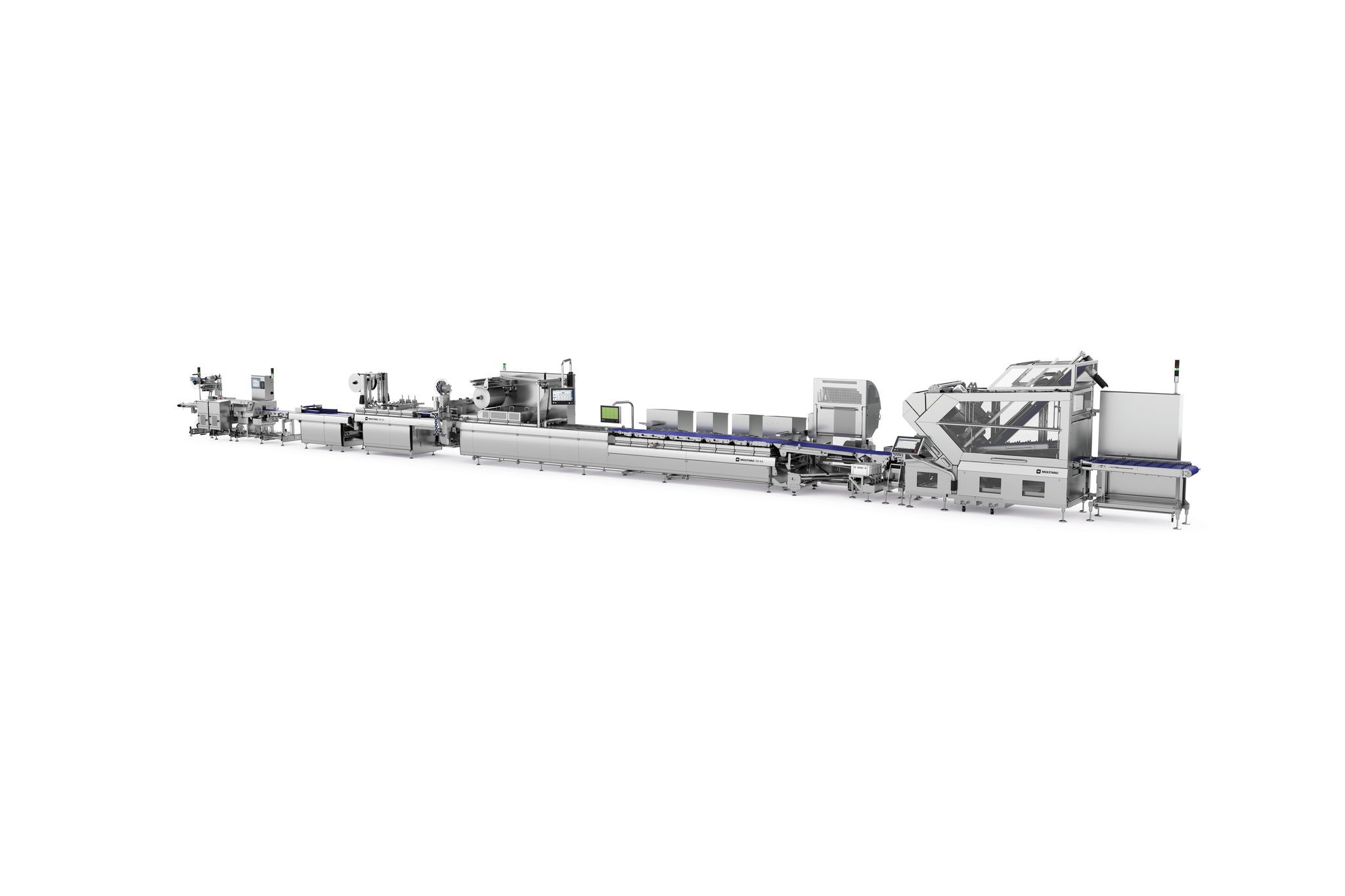

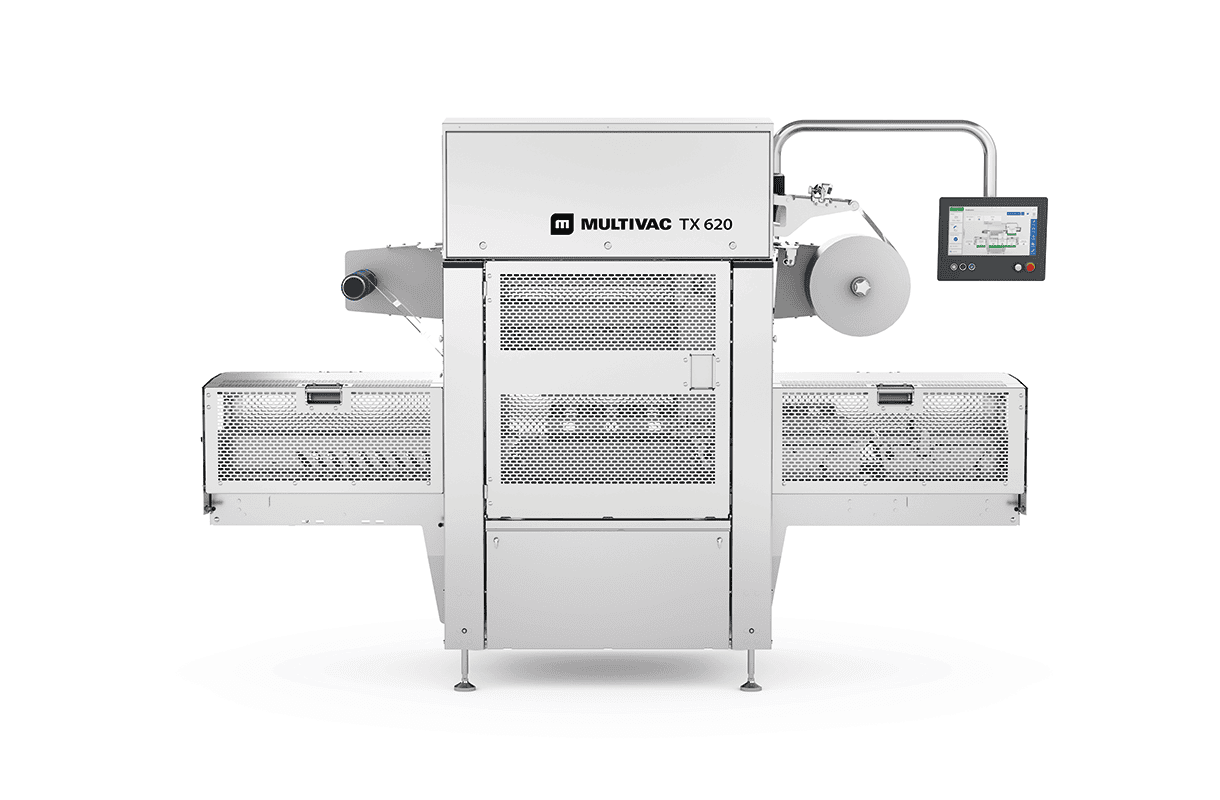

The exhibits on the trade fair stand will include the T 305 traysealer as well as a complete line, in which the core feature is the high-output TX 710 traysealer. The compact T 305 is the ideal choice as an entry-level model into fully automatic tray packing, as well as for those companies that need to pack smaller batches. The TX 710 on the other hand is designed for large batches, and it is very impressive in its innovative machine technology, comprehensive sensor system, intelligent controls and high degree of process reliability. This traysealer sets the benchmark when it comes to pack quality and consistently high cycle output. The tray made of cellulose is biologically degradable, and this also contributes to the sustainability of the packaging solution. A BASELINE labeller of the L 301 series is also integrated into the line. This cost-effective labelling solution applies labels with variable data, such as for example a best-before date, to the top of the trays. The integration of the labeller controls enables many tasks to be automated, such as for example the loading of a print layout, or the parameter settings of the labeller. This data can be saved directly in the product recipes of the TX traysealer. The L 301 is therefore controlled efficiently and reliably via the control terminal of the traysealer.

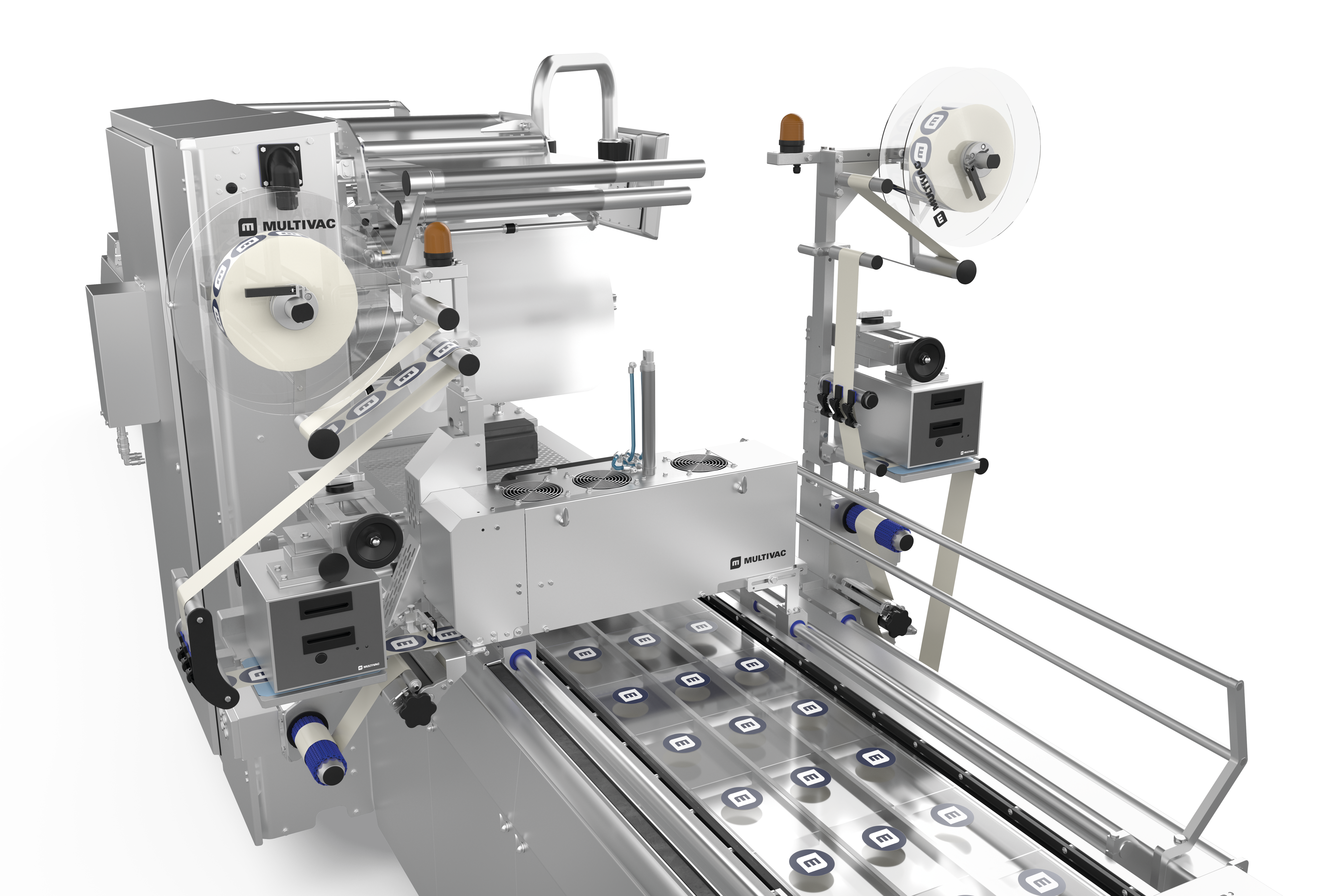

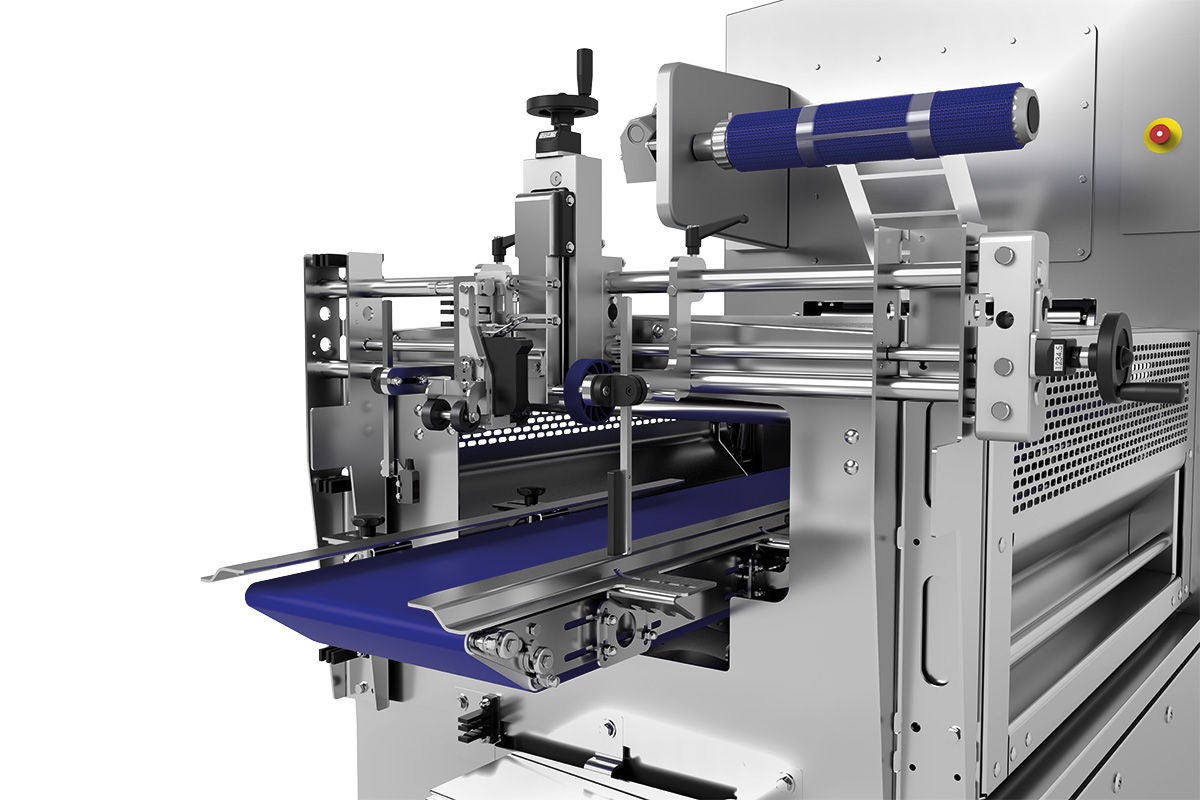

The flexible L 310 Top Wrap conveyor belt labeller , which can be seen at Fruit Logistica as a stand-alone model for selected products such as tomatoes and berries, shows how MULTIVAC is meeting the new trend for packs made of paper and cardboard that can be recycled separately. These packs are gradually replacing not only the previous plastic trays, but also the cardboard sleeves, which may be recyclable but are very material-intensive. If fruit or vegetables are not packed in modified atmosphere or airtight in a vacuum pack, the trays can be sealed closed easily and branded attractively using a label. The version of the labeller to be shown in Berlin enables two types of packs to be produced: Top Wrap, where the label is applied to the top and both sides, and Top Close, where the label is applied to just the top of the pack. The high level of flexibility in terms of the material thickness and shape of the self-adhesive labels offers a wide range of possibilities for product presentation. It is possible for example to have cut-outs in the label, as well as adhesive-free zones, so that contact with the product is prevented. Some of the most important benefits of this conveyor belt labeller include its automatic and highly efficient labelling, its rapid batch change, and last but not least its attractive packaging and branding concept, which is always well received by consumers.

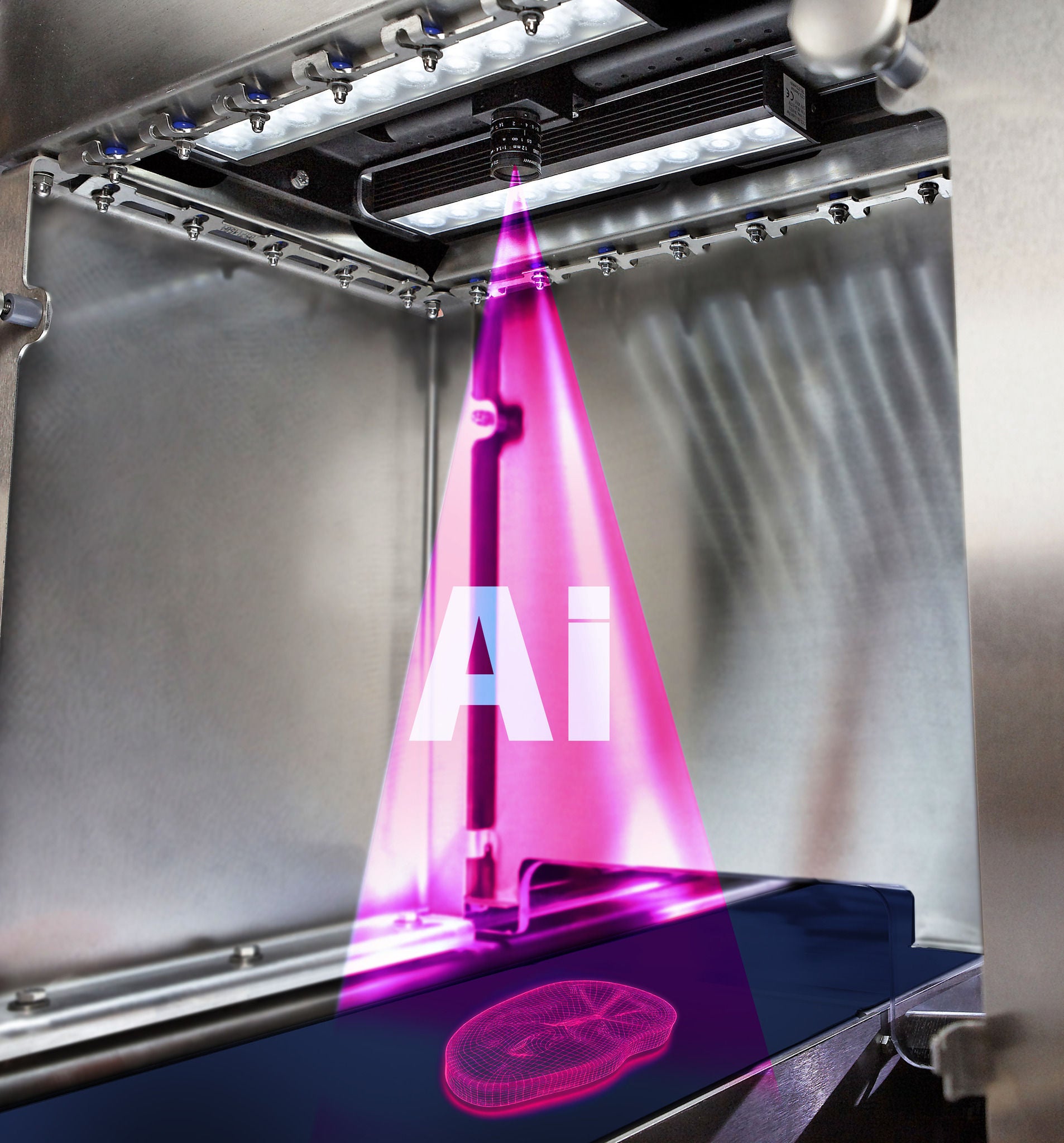

For those visitors to the trade fair, who prefer to play it safe when it comes to highly automated processes, MULTIVAC is also showing its I 410 visual inspection system , which is a high-output, integrated solution for quality control with its own transport conveyor. The packs are either transferred from an upstream transport unit or fed in manually. As an alternative, the packs can be ejected by means of an electric motor, so that no compressed air is required. The system is an intelligent option, when packing leaf salads for example, and checking the seal seam for contamination. The I 410 can be installed for label and print inspection at the end of a traysealer and labelling system.

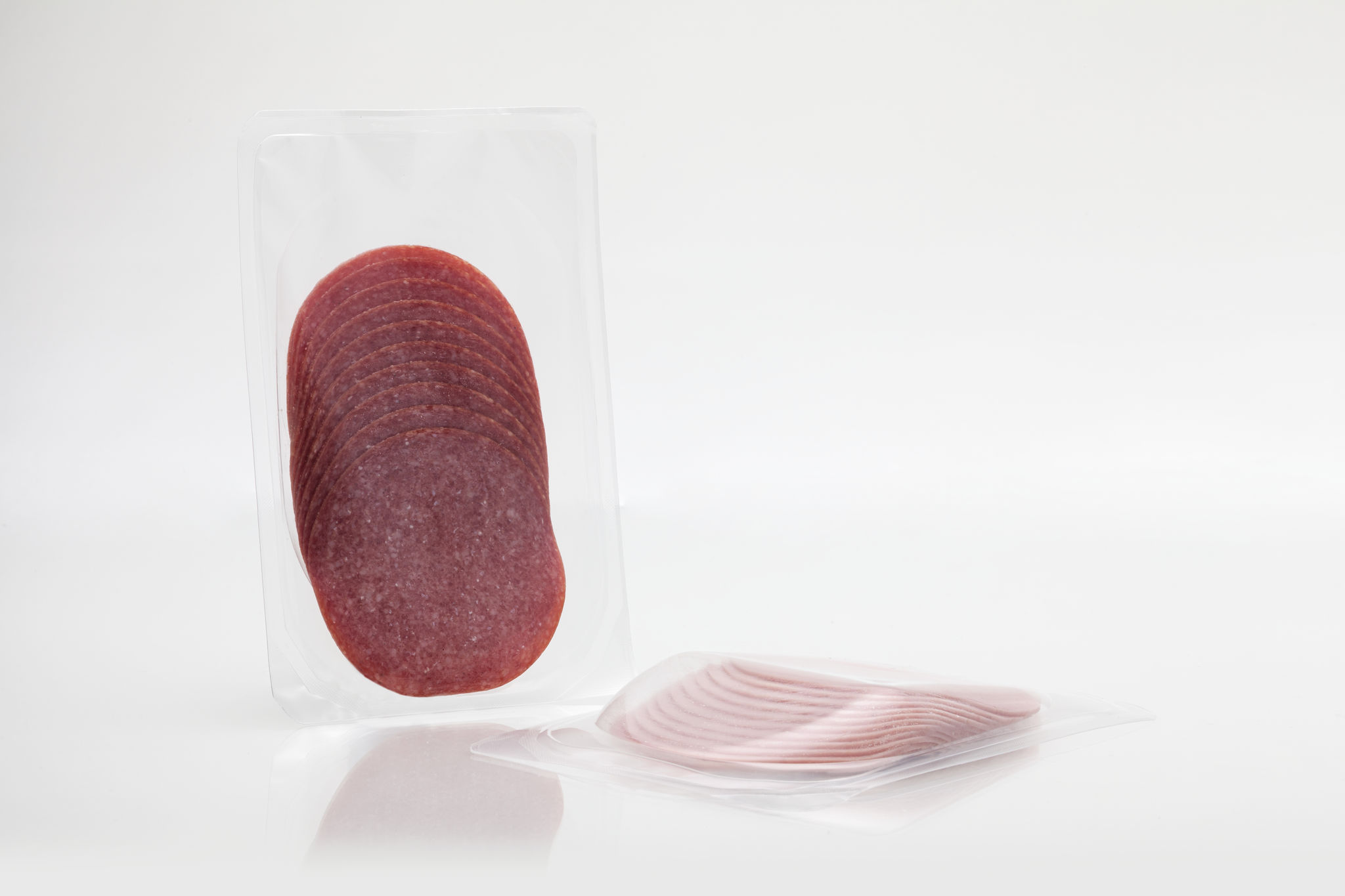

MULTIVAC will be showing the R 245 in action as an example of packing fresh produce in thermoformed packs. The R 245 is a freely configurable thermoforming packaging machine, which offers a comprehensive range of equipment options, and also allows complex pack shapes to be produced at high output.

MULTIVAC's presence at the trade fair is rounded off with a presentation by Christian Zimmermann (Project Manager, Market Intelligence & Applications) on the Tech Stage from 13.45 to 14.30 on 9 February. Topic: How can sustainable packs contribute to reducing food wastage? Ronald Helmel, Business Development Manager at MULTIVAC Marking & Inspection, will be alongside him.

Latest News

2327146963

2327146963

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC PDF

MULTIVAC PDF

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com