Fresh packaging solutions for fresh products

MULTIVAC at Fruit Logistica 2025 in Berlin, (5 – 7 February 2025)

12.12.2024

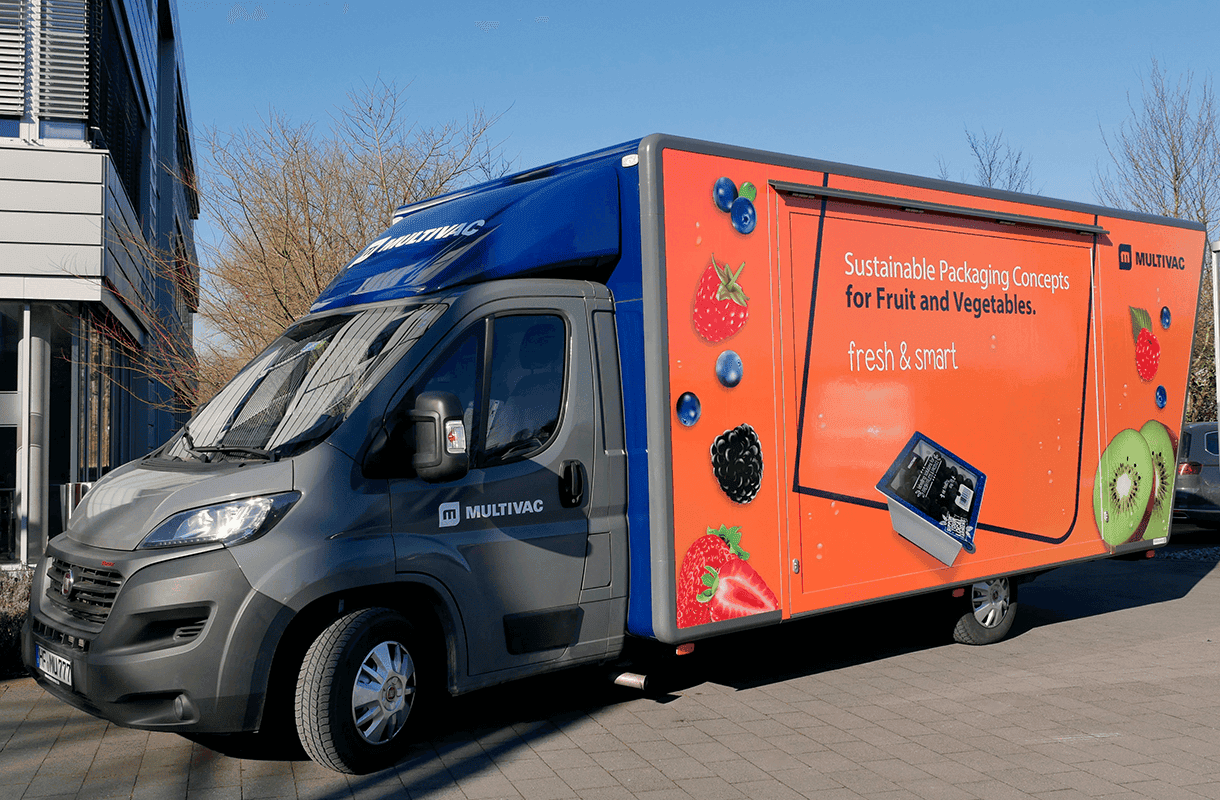

Wolfertschwenden, 12 December 2024 – With its motto of "Multiply your value“, MULTIVAC will be presenting packaging solutions for the fruit trade at Fruit Logistica 2025 (Hall 2.1, Stand A 10). The focus of the company's presence at the trade fair will be on innovative and sustainable solutions, which optimise the recyclability of packs and minimise the use of plastics – right up to the completely plastic-free pack.

TopSEAL: Attractively packed with less plastic

MULTIVAC offers the widest range of solutions for packing fruit and vegetable products of all types attractively, efficiently and sustainably – from single machines for smaller cultivation businesses right up to fully automatic lines.

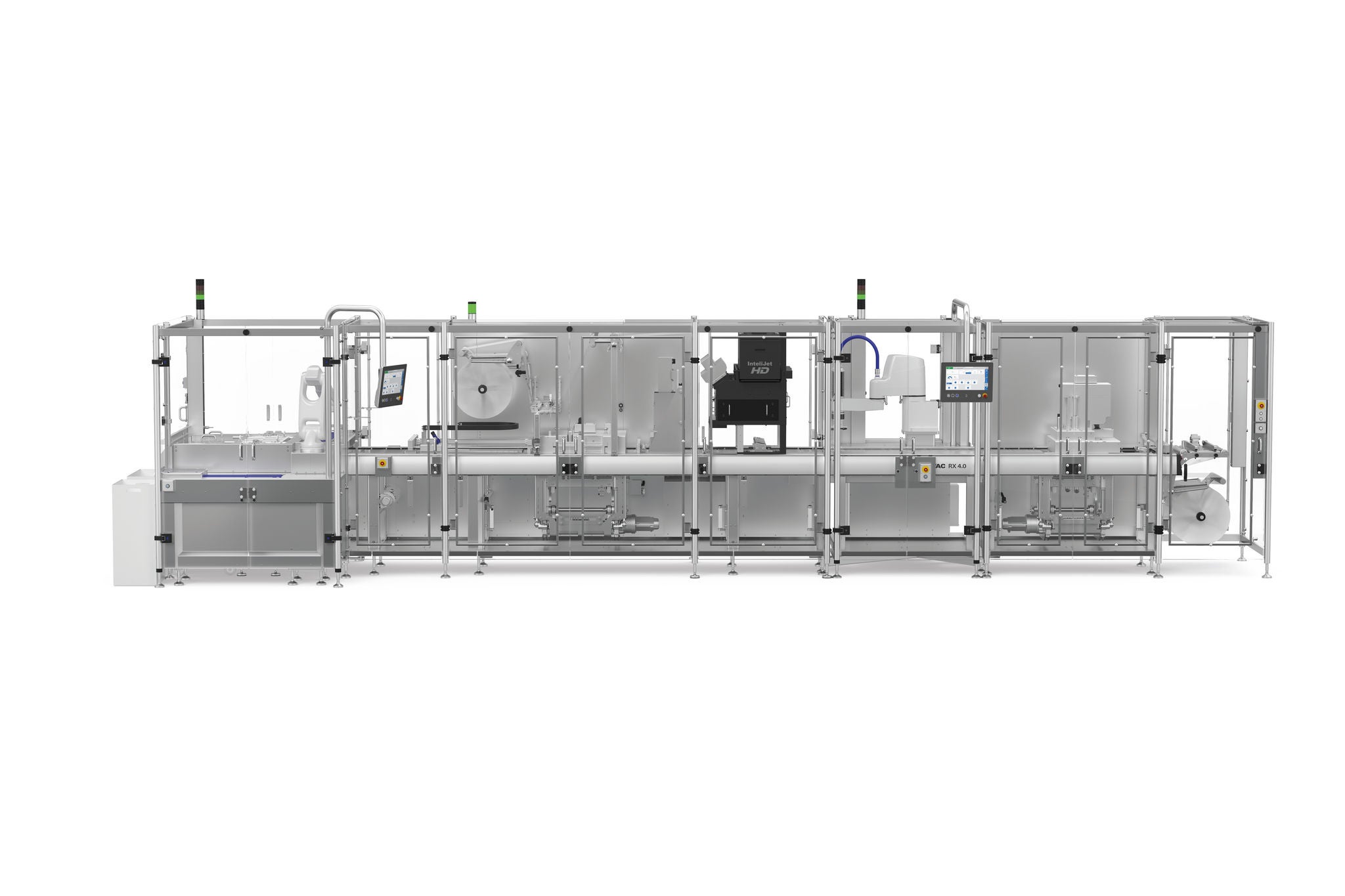

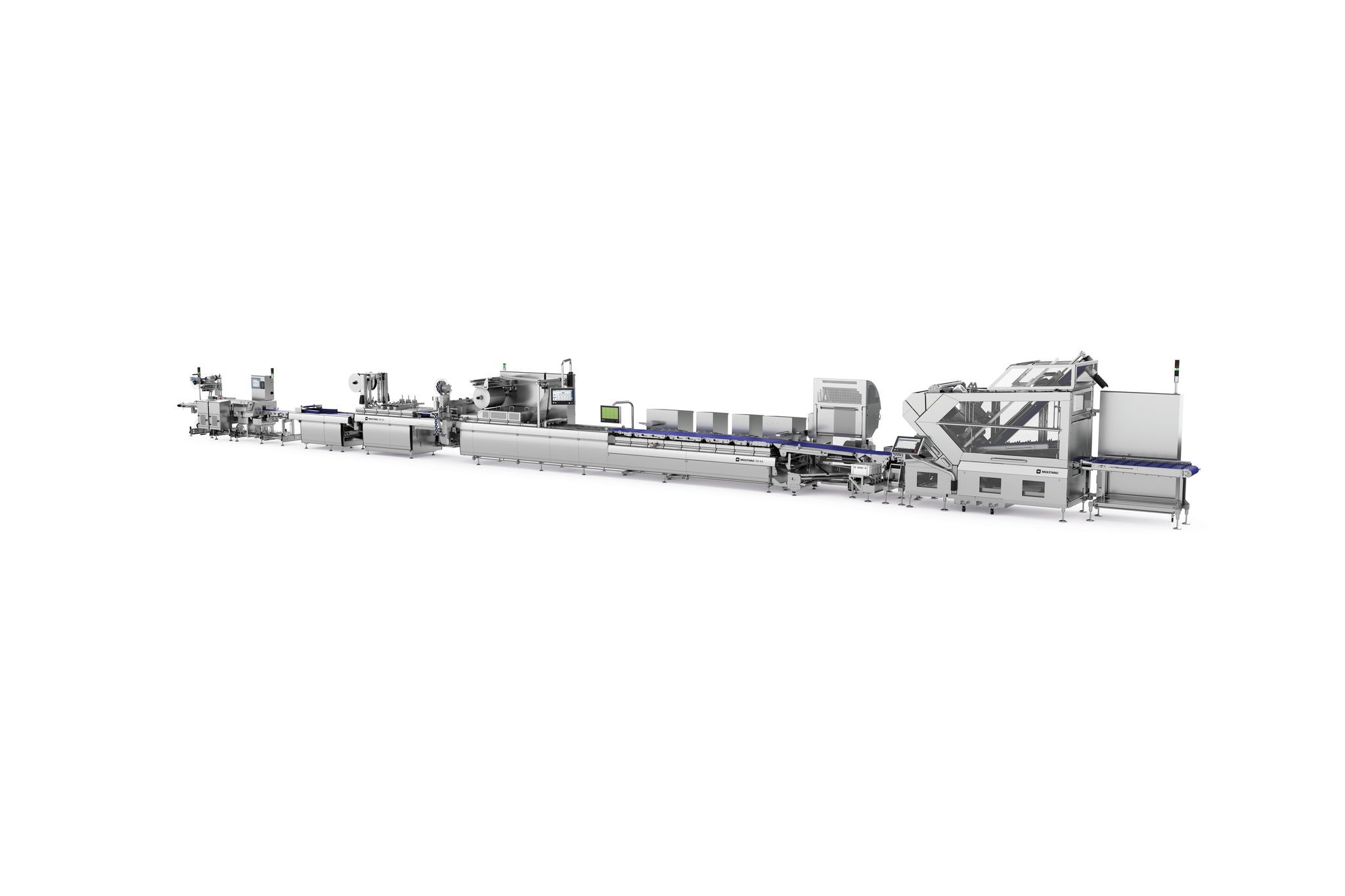

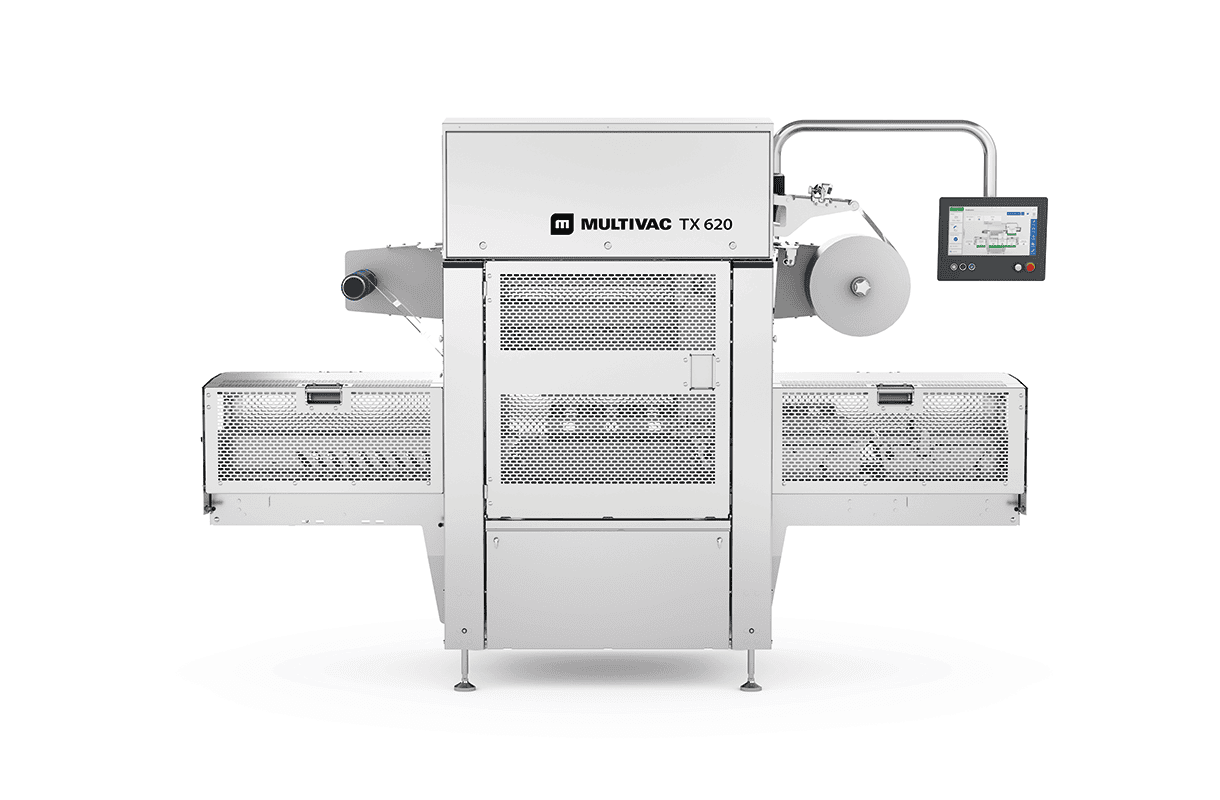

On the MULTIVAC stand will be shown a fully automatic line solution for packing large batches of product, and this line will include the TX 710 traysealer. The machine will be packing fresh berries in environmentally-friendly cellulose trays, which are then sealed with a thin, transparent and compostable film to protect the delicate fruits from being removed or falling out of the tray. “The traysealer is equipped with sensors and intelligent control technology, which provides constant synchronisation between the infeed of the trays, the sealing process and the transport of the trays within the traysealer,“ explains Franziska Schreiber, Product Manager at MULTIVAC. “This enables the machine to operate continually at the highest level, ensuring that the maximum output and pack quality are assured, while also reducing waste from the process. By using the optional connection to the dashboards with the MULTIVAC Smart Services, it is also possible to monitor and optimise the production efficiency in real time.” The compact H 130 handling module takes up the filled trays after the packaging process, and it then places these into containers with a high level of speed and accuracy.

Packing without a packaging machine

The MULTIVAC TopCLOSETM system for berries enables cardboard trays to be sealed closed in a very simple and environmentally-friendly way, using a labeller to apply self-adhesive labels, without a packaging machine being required. The transparent film label seals the top of the tray closed, while also labelling the pack at the same time. The adhesive is only partially applied to the outer edge of the label, so that it is safe for contact with food. The label is also equipped with consumer-friendly functions such as a tear flap and reclosure feature, and these can be designed for trays of any shape – whether round, square or rectangular. The proportion of plastic in the pack is under 10 percent, and completely plastic-free material combinations are also possible.

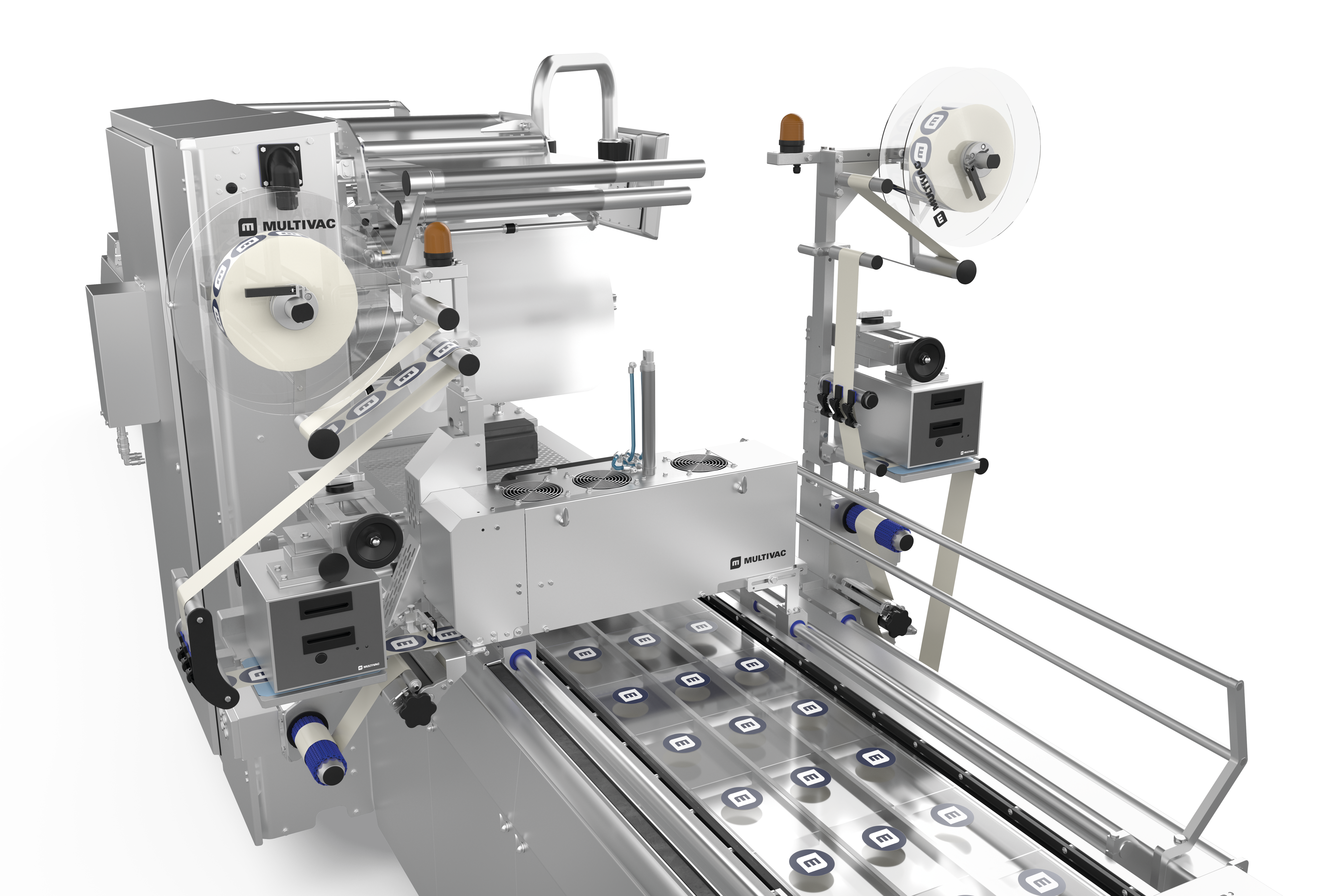

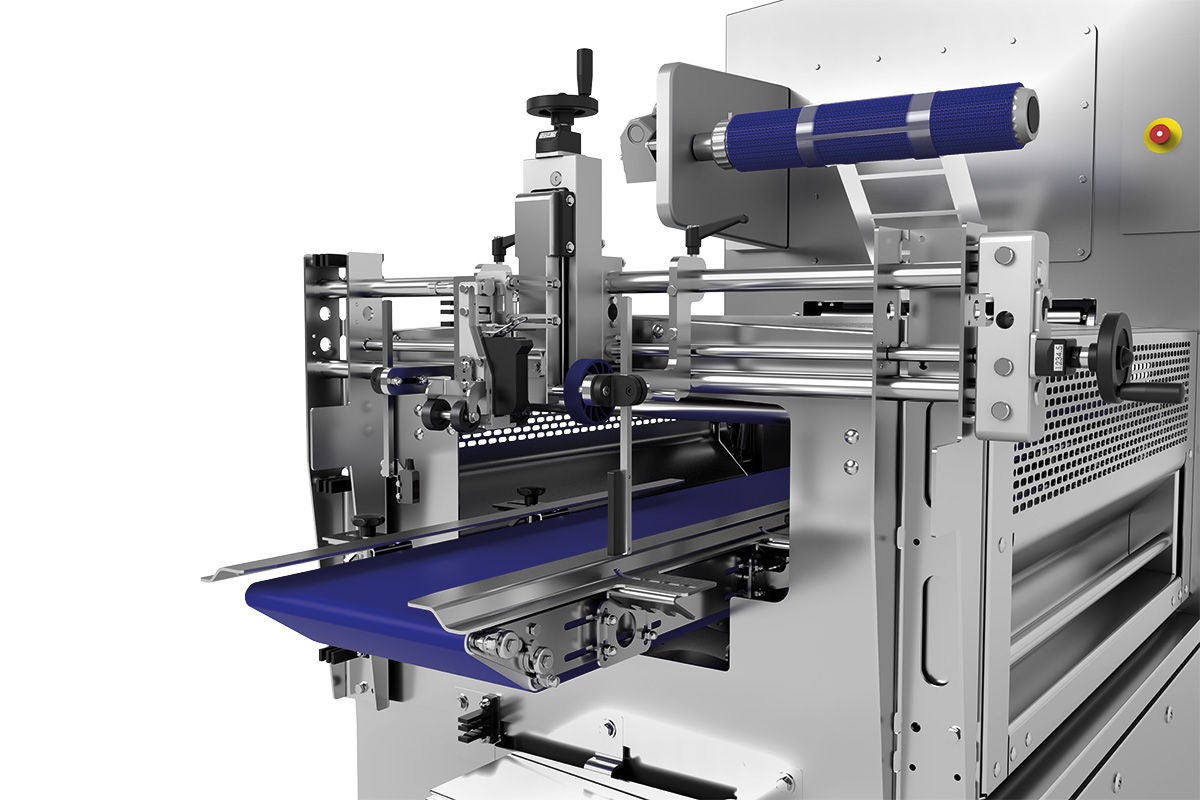

The MULTIVAC TopCLOSETM system uses the L 330 conveyor belt labeller, which enables the labels to be printed with variable data, as well as the print quality to be inspected. The trays are automatically sealed closed "on the run" – at an output of up to 250 packs per minute. This ensures that the delicate food products are processed very quickly, and personnel costs can also be reduced, since the same quantity of product is packed in a shorter time.

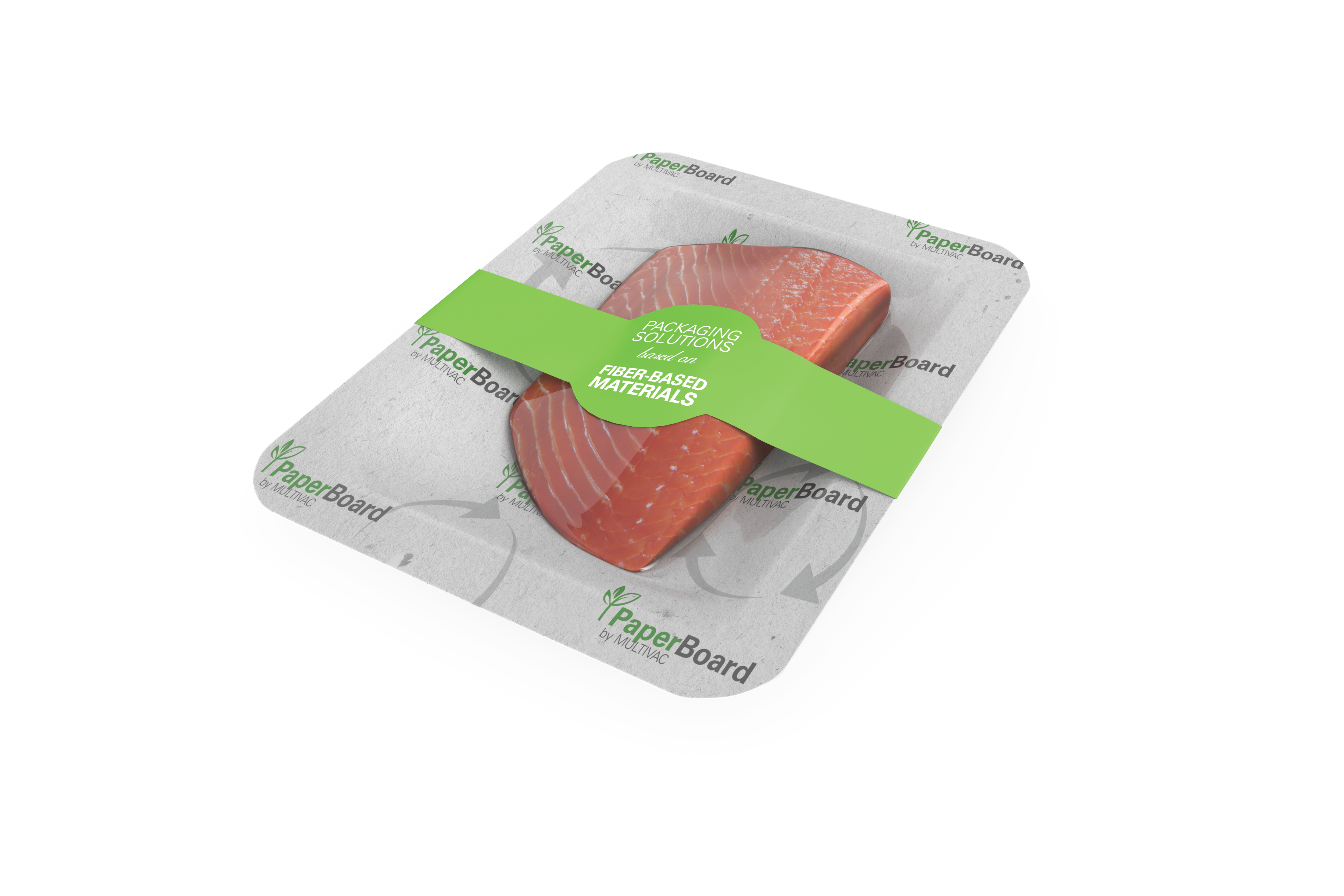

Packing with very little plastic

The MULTIVAC TopWRAP™ system is suitable for mushrooms and strawberries for example. Here the cardboard trays are filled and then sealed closed over three sides with a transparent film label. The proportion of plastic in the pack is under 10 percent. The label is also available in a cellulose version – so that completely plastic-free packs are possible. The adhesive is only partially applied, so that there is no contact with the product. The L 310 conveyor belt labeller is used for this packaging solution. It automatically seals the packs closed "on the run", and at an output of up to 150 packs per minute it ensures that the delicate products are processed quickly and efficiently.

Both labellers, the L 310 conveyor belt labeller as well as the L 330, can be converted to different tray shapes and sizes quickly and easily, without any change of tooling being required. In addition to this, a zero-downtime version is available for uninterrupted labelling, as well as various automation options such as denesters, or product infeed and discharge units.

“With our complete solution from one source, which comprises labellers, trays and labels, we want to offer the fruit and vegetable sector completely plastic-free packaging solutions, which are resource-saving and at the same time energy-efficient,” explains Ronald Helmel, Business Development Manager at MULTIVAC Marking & Inspection. “This means that today companies in the sector can already meet the requirements of the EU Packaging and Packaging Waste Regulations (PPWR).“

Current news

MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

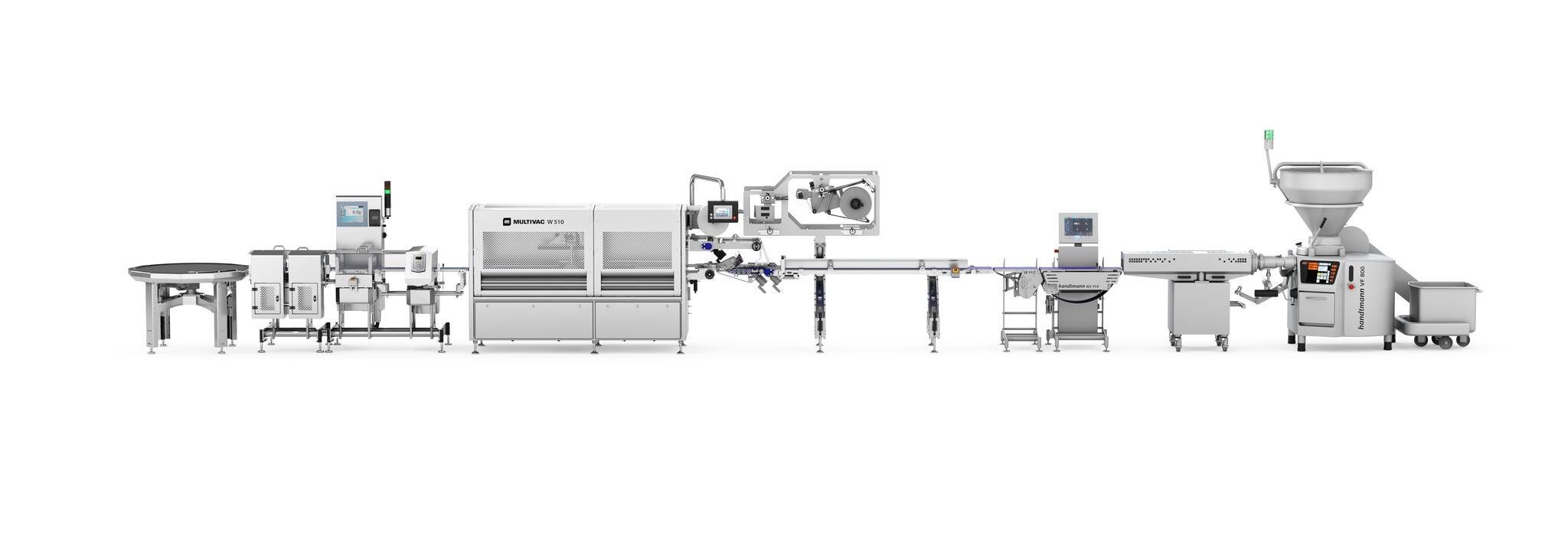

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com