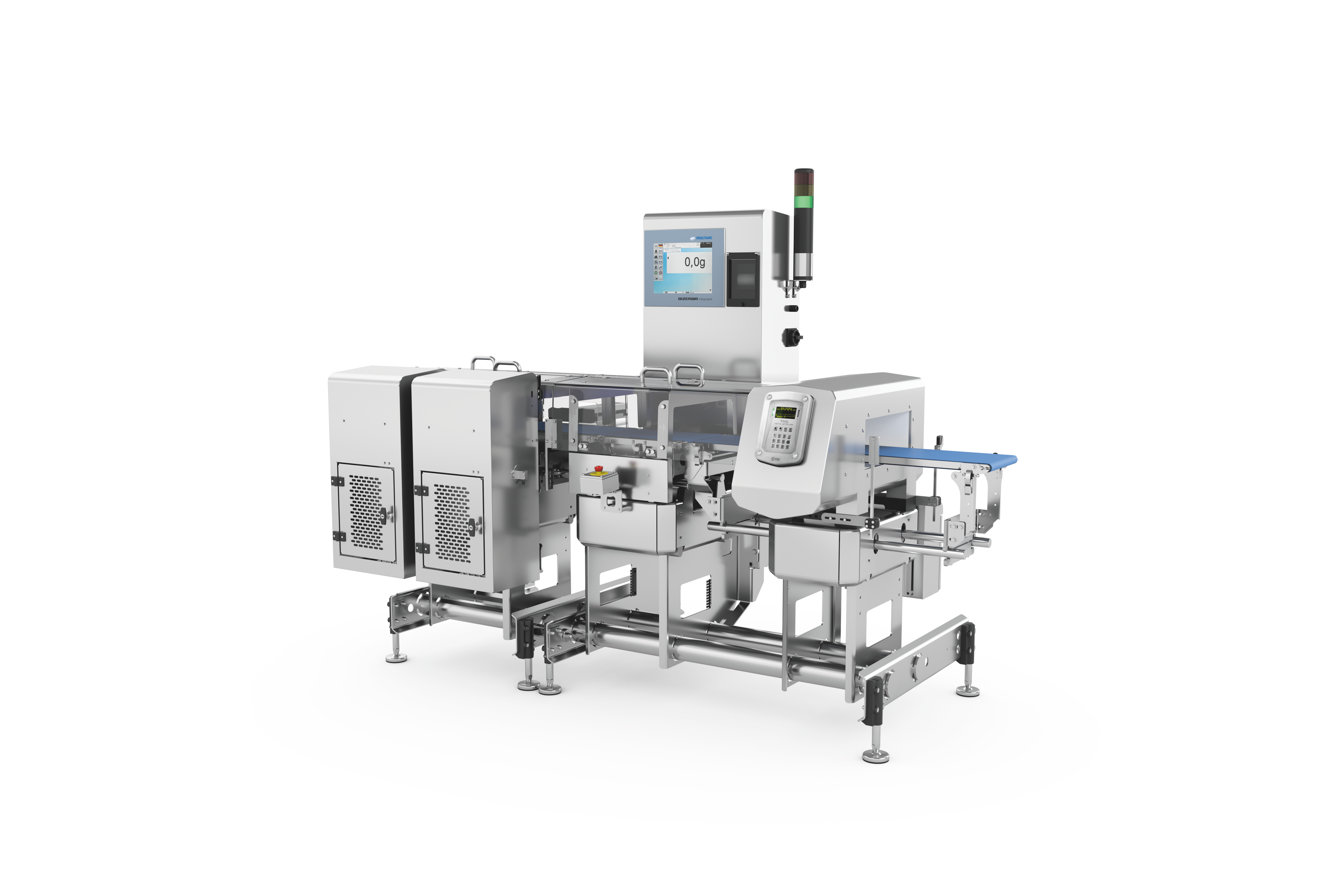

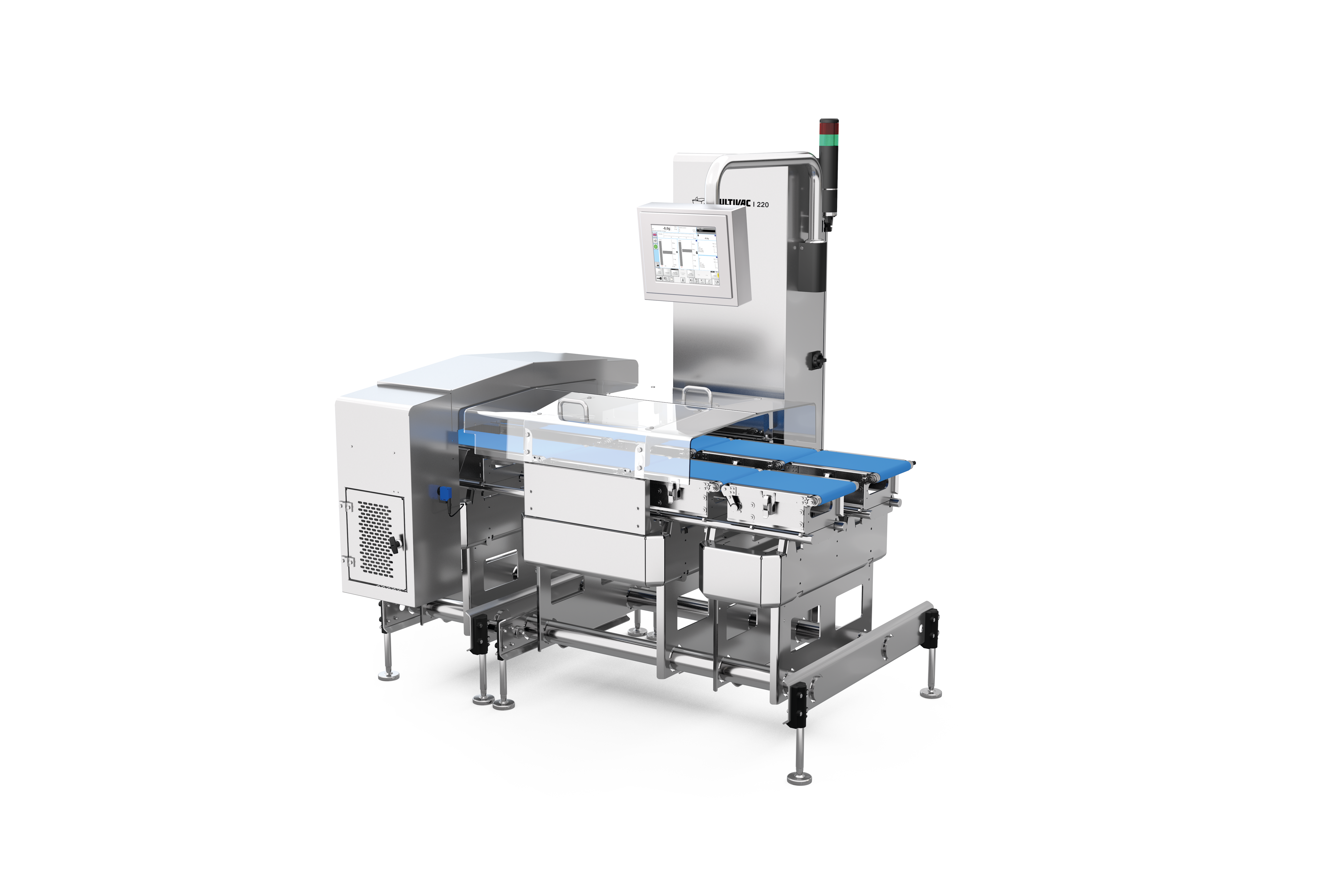

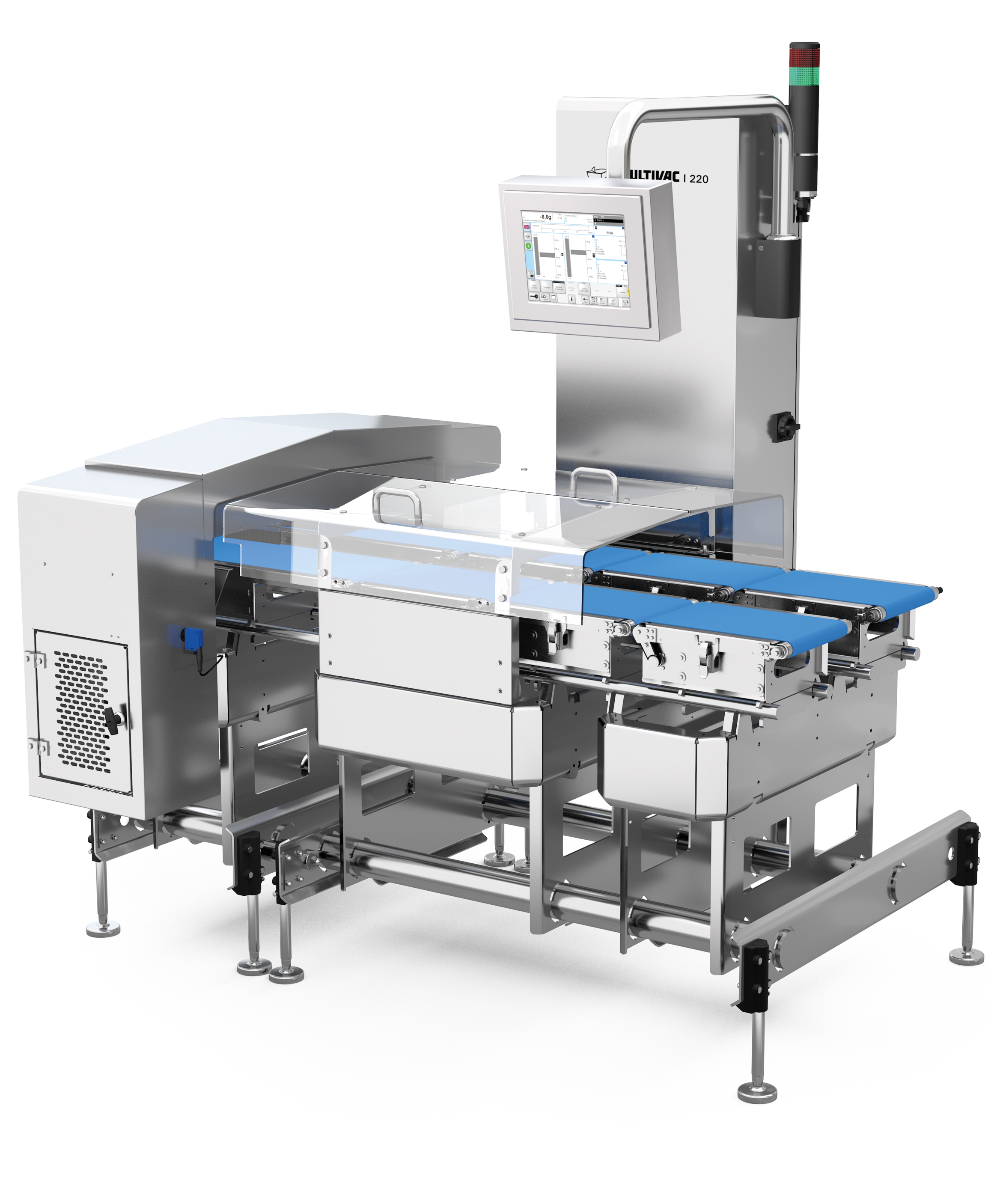

Precise and reliable - integrated automatic checkweighers

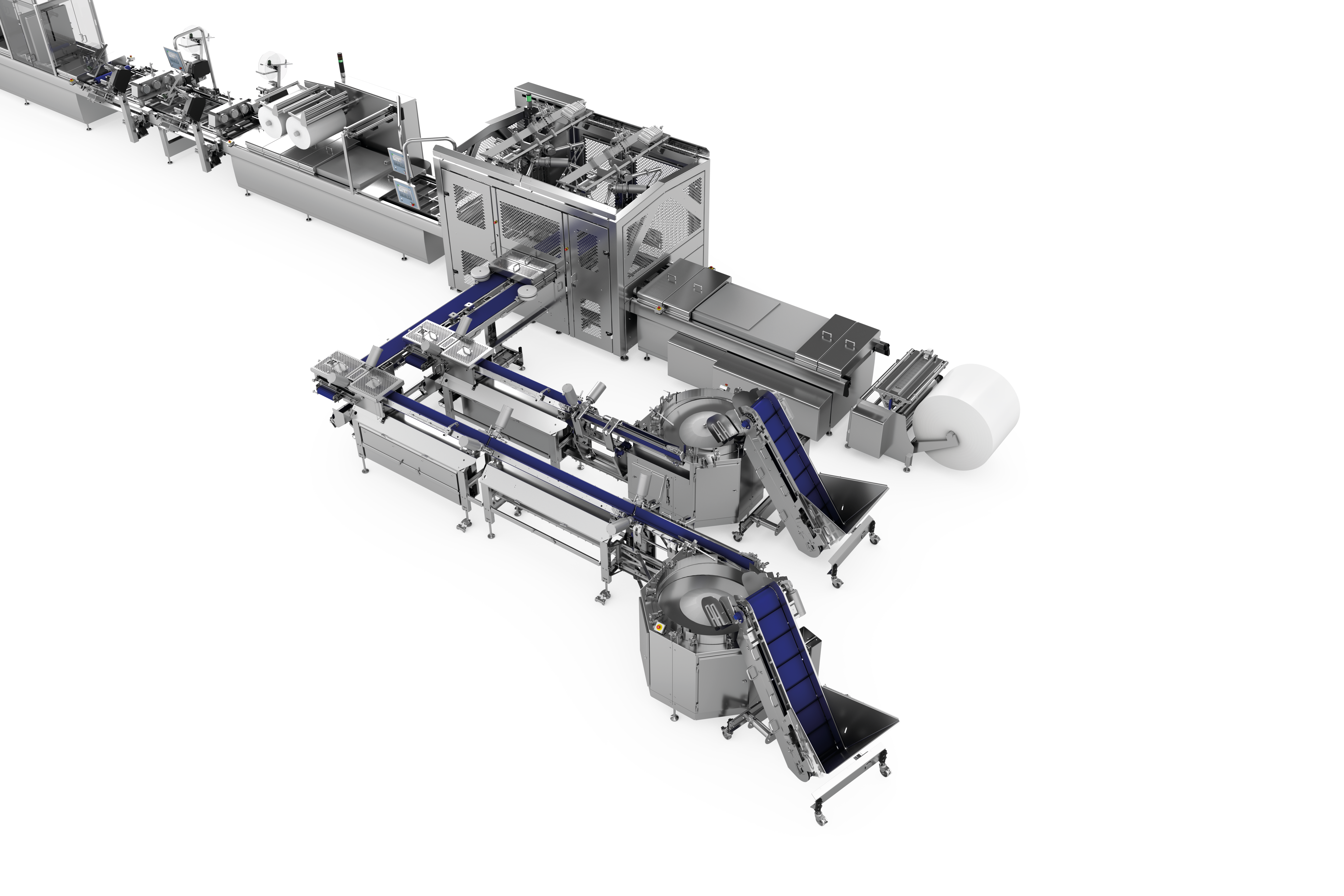

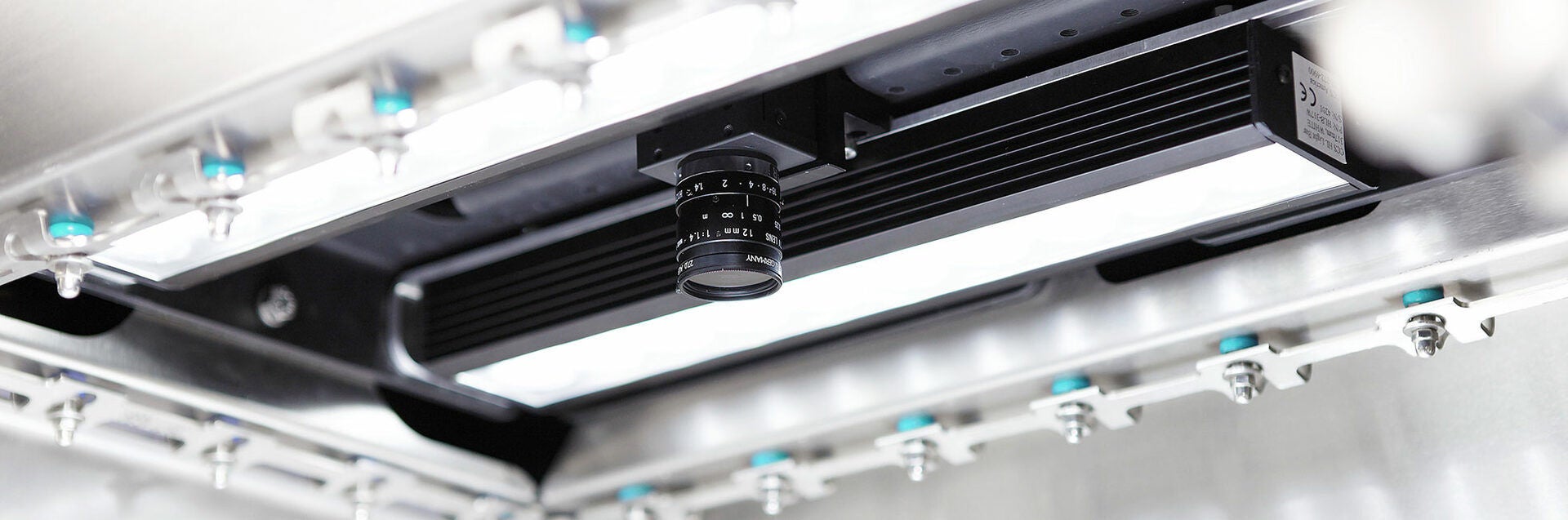

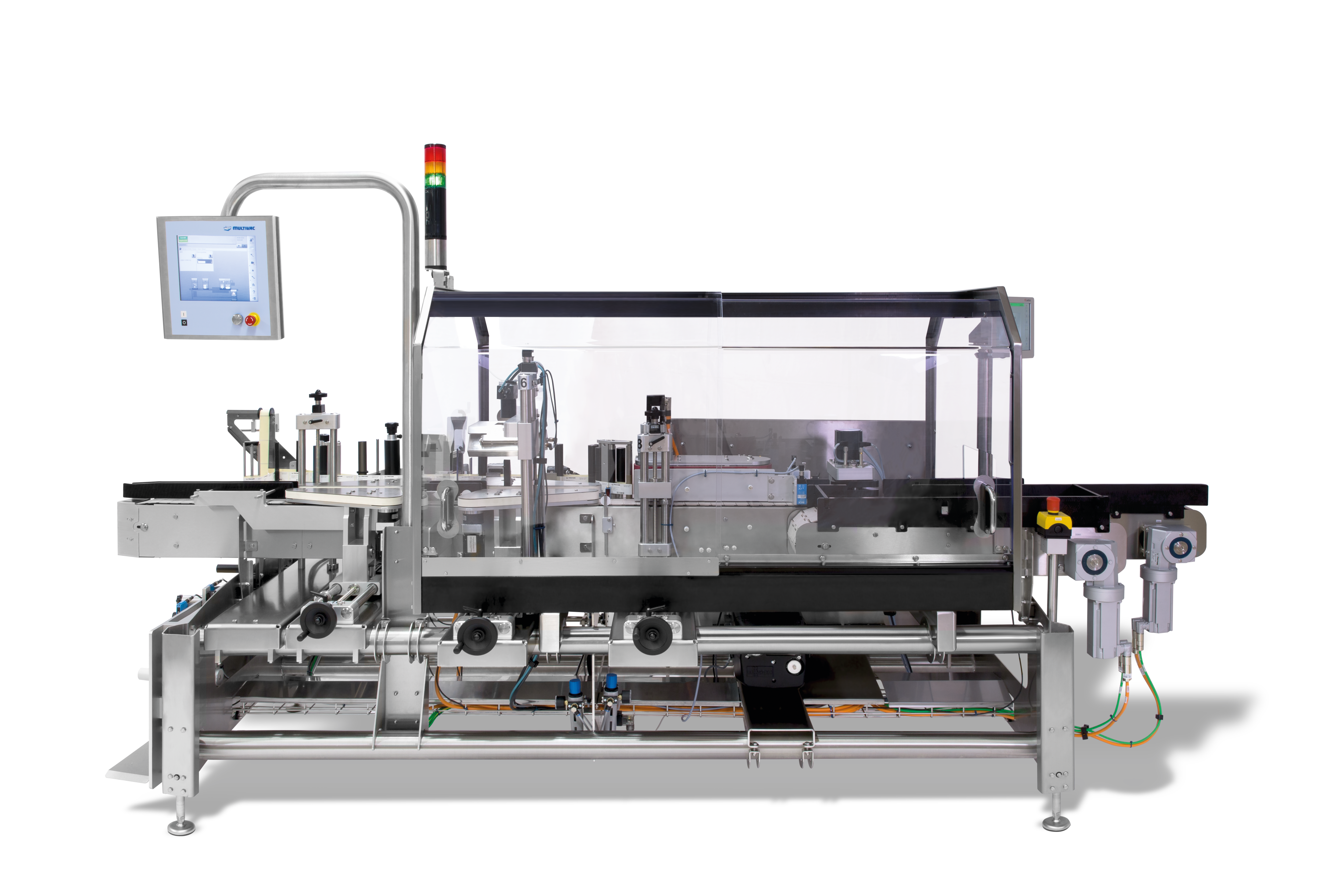

Reliable results are a precondition for reliable quality assurance. If weighing operations are not automatically integrated into the packaging process, the weighing operations are often imprecise. You can gain absolute precision and reliability with the fully integrated automatic checkweighers from MULTIVAC. They make a significant contribution to complying with internal and statutory quality requirements, optimize processes and ensure maximum efficiency. We match the checkweighers precisely to your needs. They can be easily integrated into existing production and packaging systems.

With many years of system expertise, we will be happy to support you in establishing intelligent connections and machine control over the entire line. In this way, you not only improve the efficiency and cost-effectiveness of your packaging process, but you also reduce the CO2 footprint of the whole line. In this way, you achieve a higher efficiency level and make a significant investment in sustainability.

Other interesting topics

Success stories

MULTIVAC Sausage Packaging Machine in Factory

MULTIVAC Sausage Packaging Machine in Factory