TVI sets a new benchmark in the meat industry with its latest portioning machine

18.03.2024

Product launch: GMS 1000

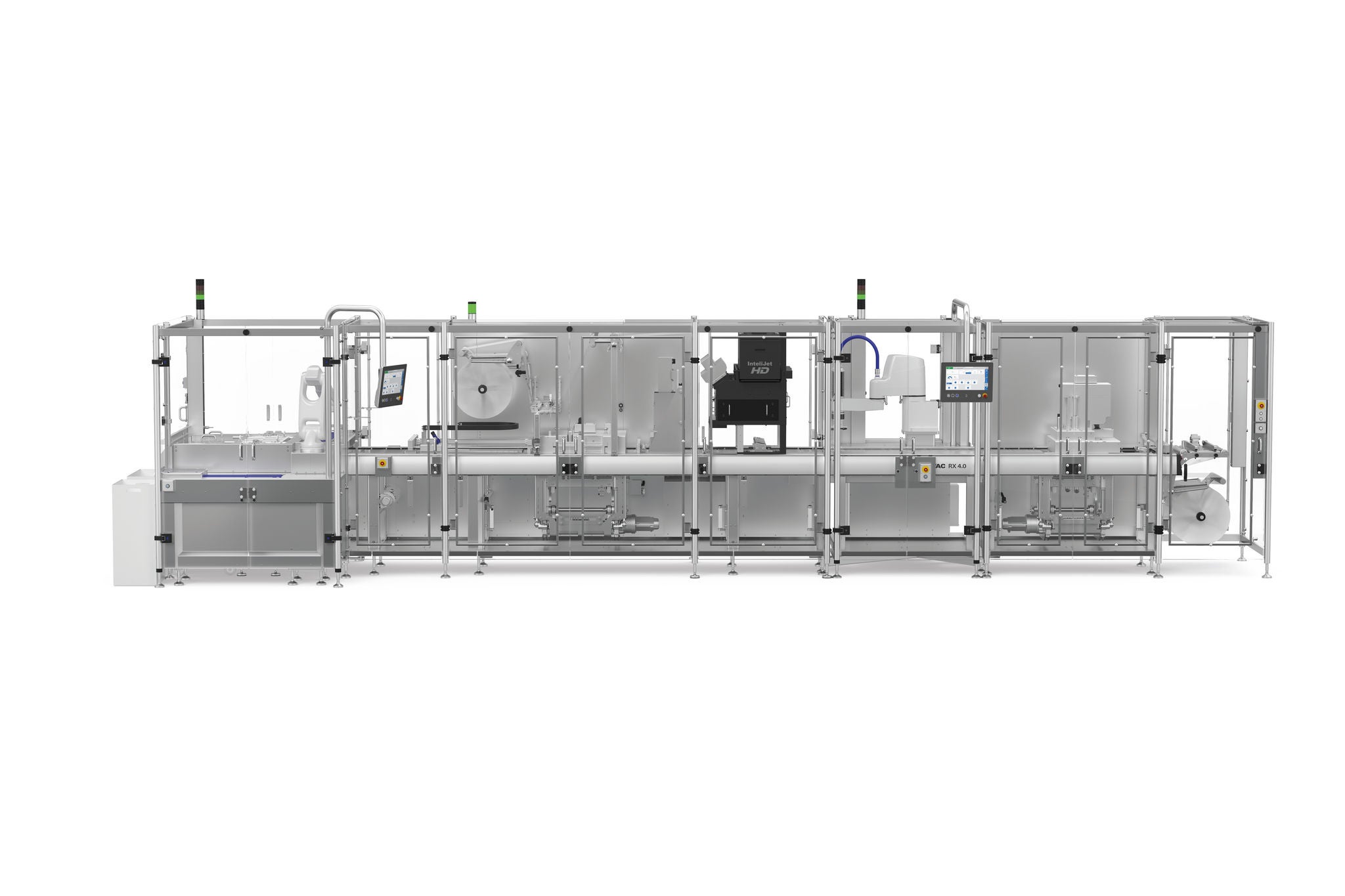

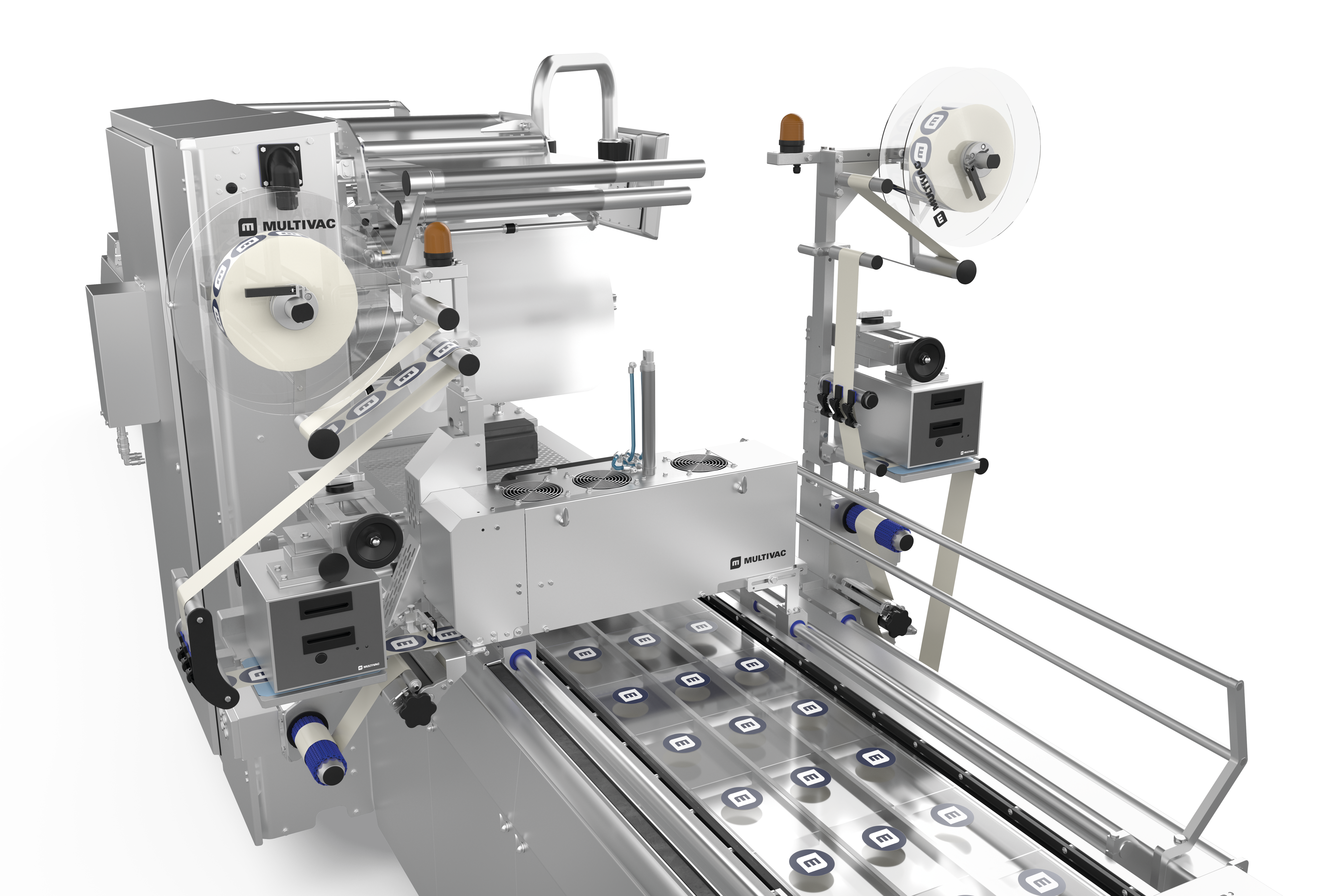

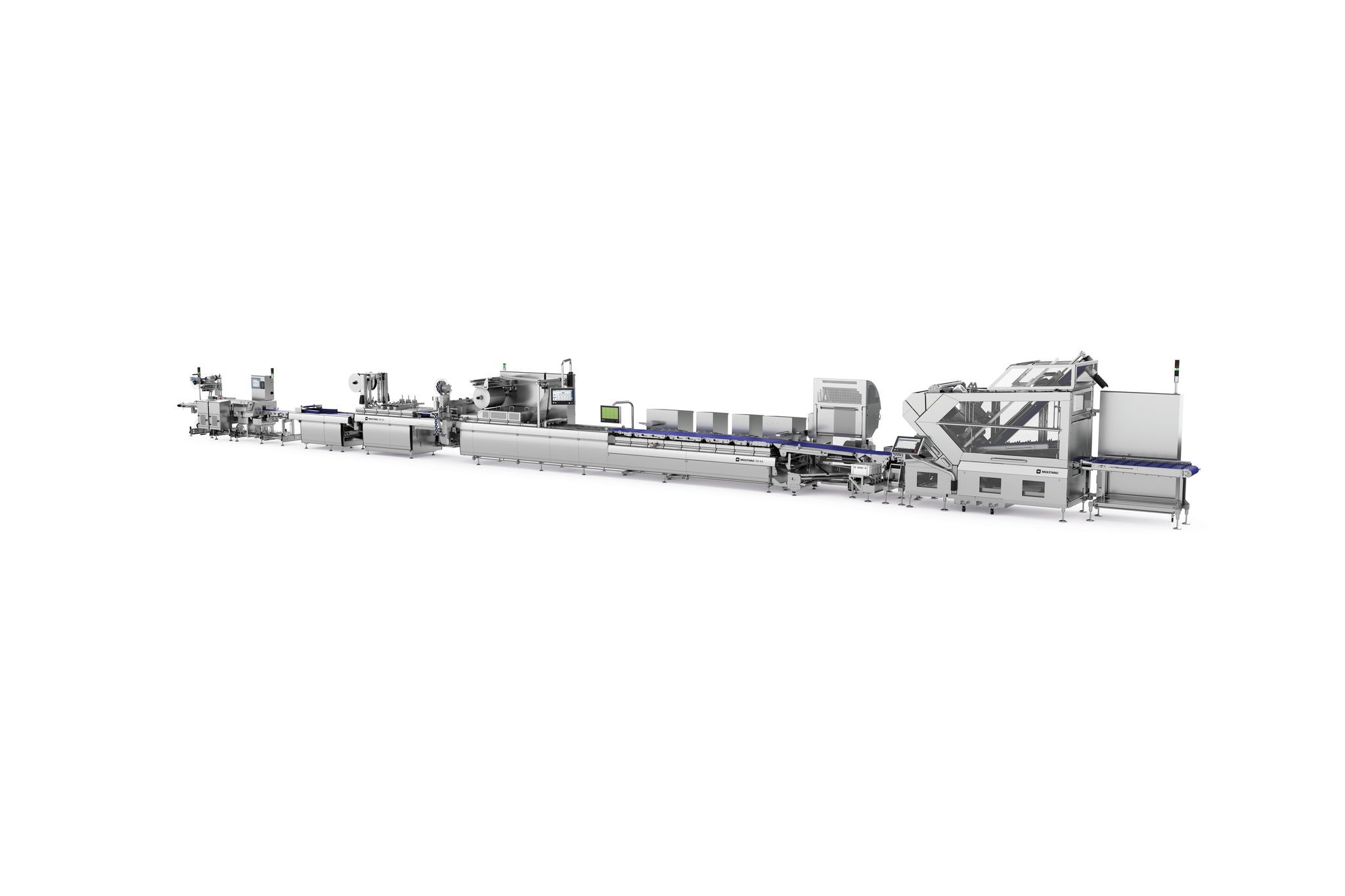

Bruckmühl, 18 March 2024 – Exhibiting the GMS 1000 at Anuga FoodTec in Cologne, TVI Entwicklung & Produktion GmbH will be presenting a highly automated single-track portioning machine. The new machine is certain to win the visitors over with its exceptional product yield and consistent forming of the product, as well as its versatility, user-friendliness, and ease of integration into existing lines. One of its main features is also a high degree of digitalisation. With this model the company is expanding its range of portioning machines in the medium-sized industrial sector, as well as setting a new benchmark in the meat industry.

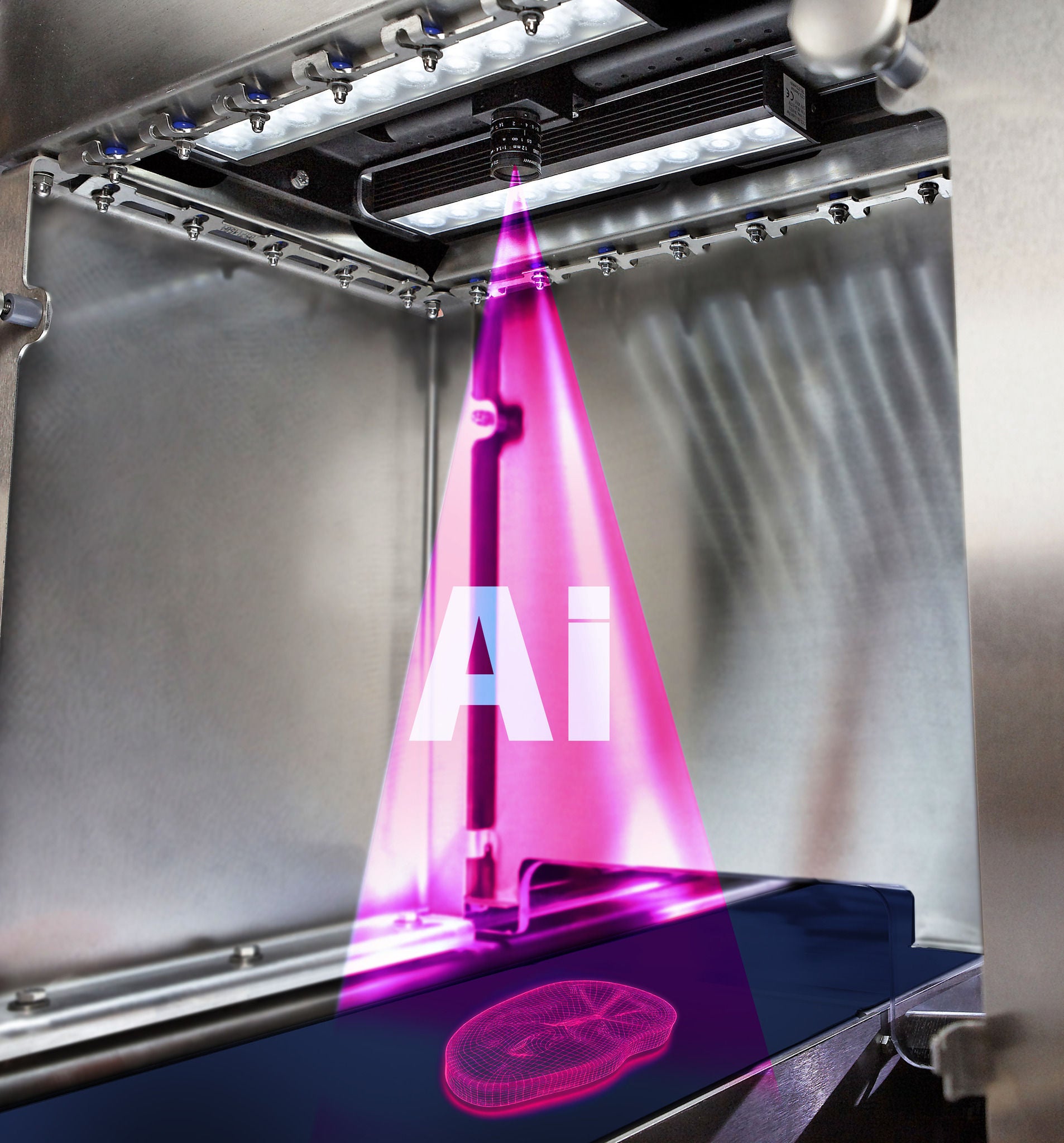

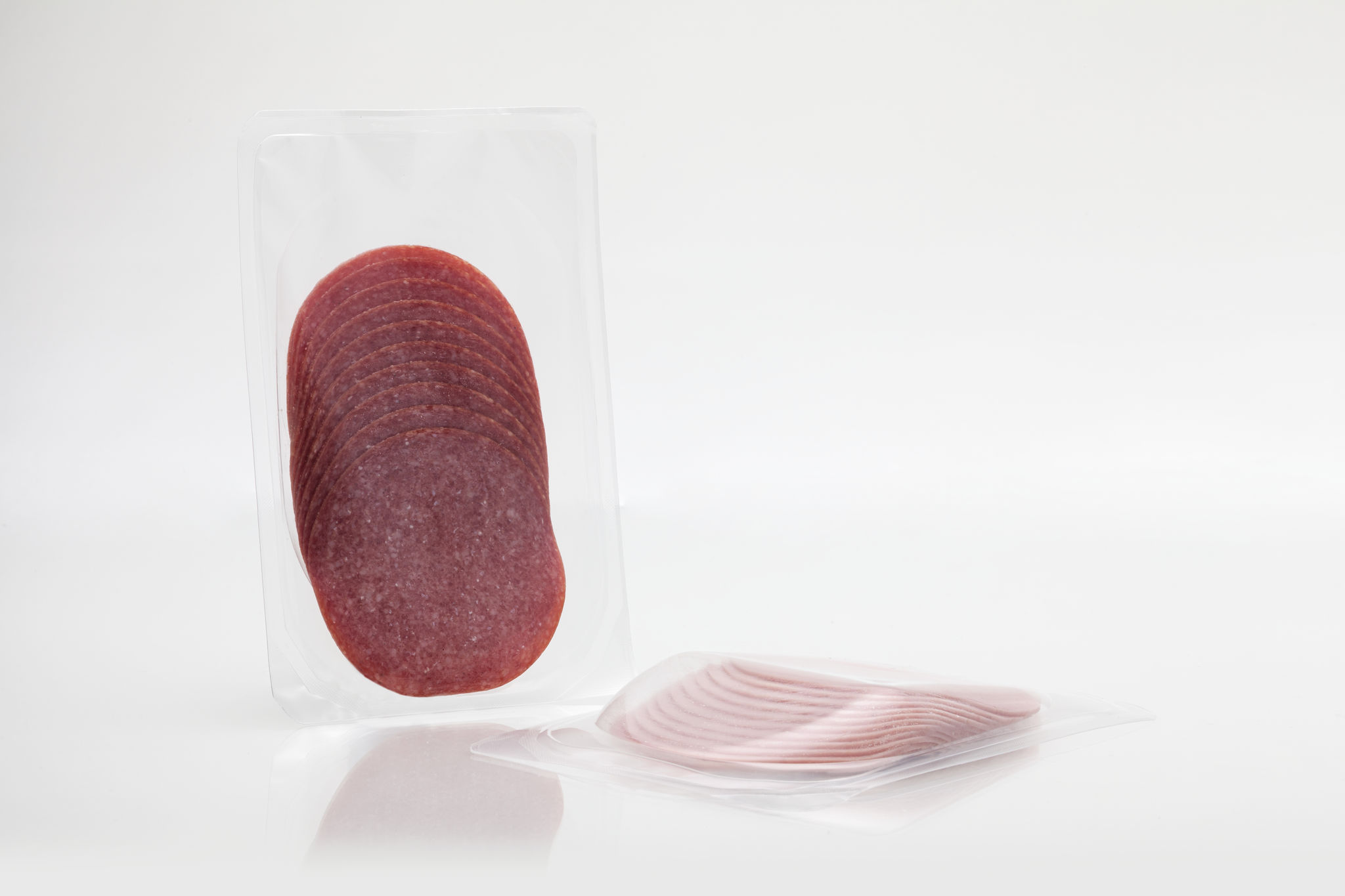

Thanks to its very precise 3D forming and high level of pressing force, the new GMS 1000 portioning machine achieves the optimum product yield and highest possible return. At the same time the machine also offers a high degree of flexibility in the size of the raw product. The portioning machine can deposit the end product in single slices, shingled portions or stacked portions. If required, the machine can also divide the products separately into different categories, fixed weight or maximum yield, depending on the wishes of the customer.

Simple operation and highly flexible integration

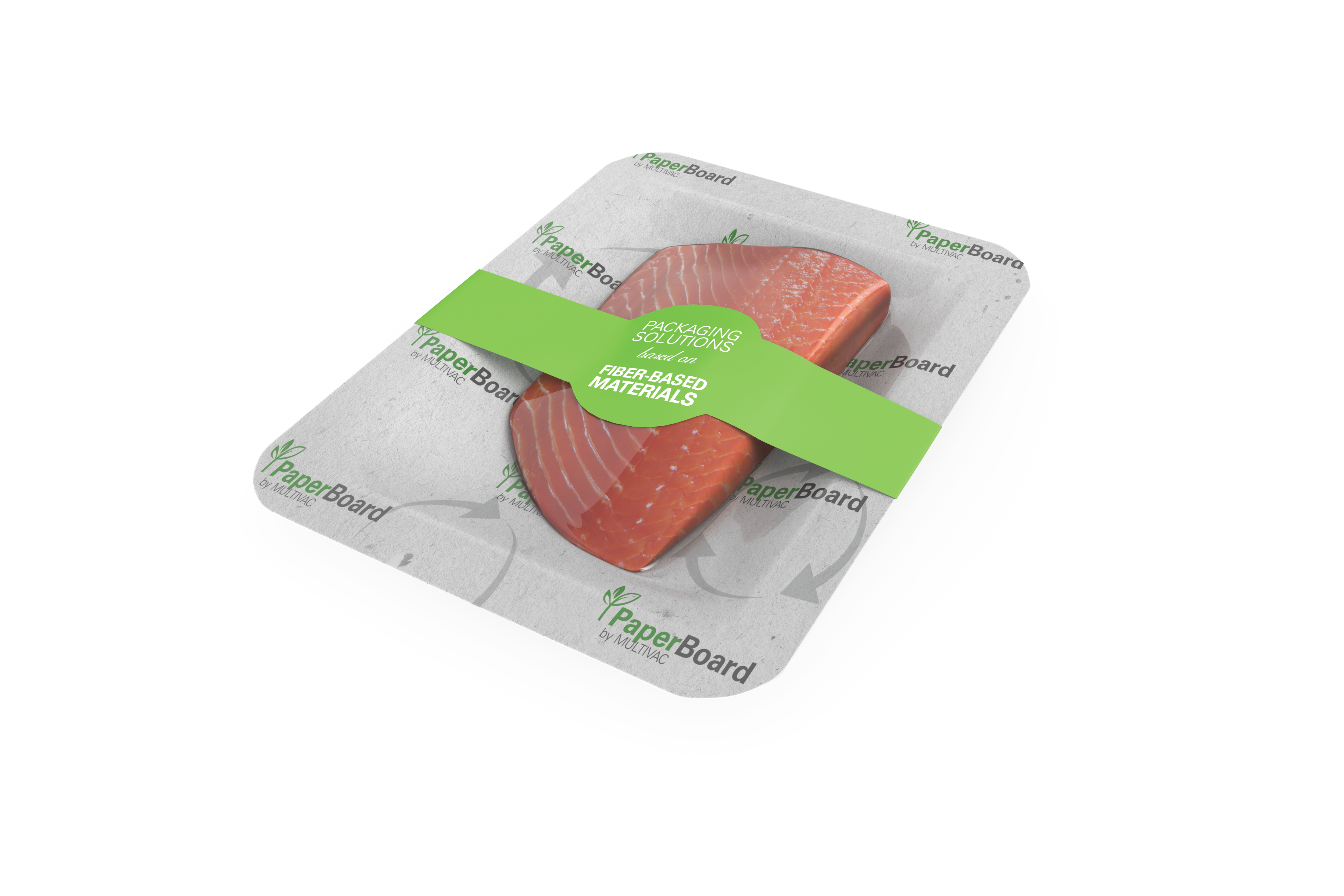

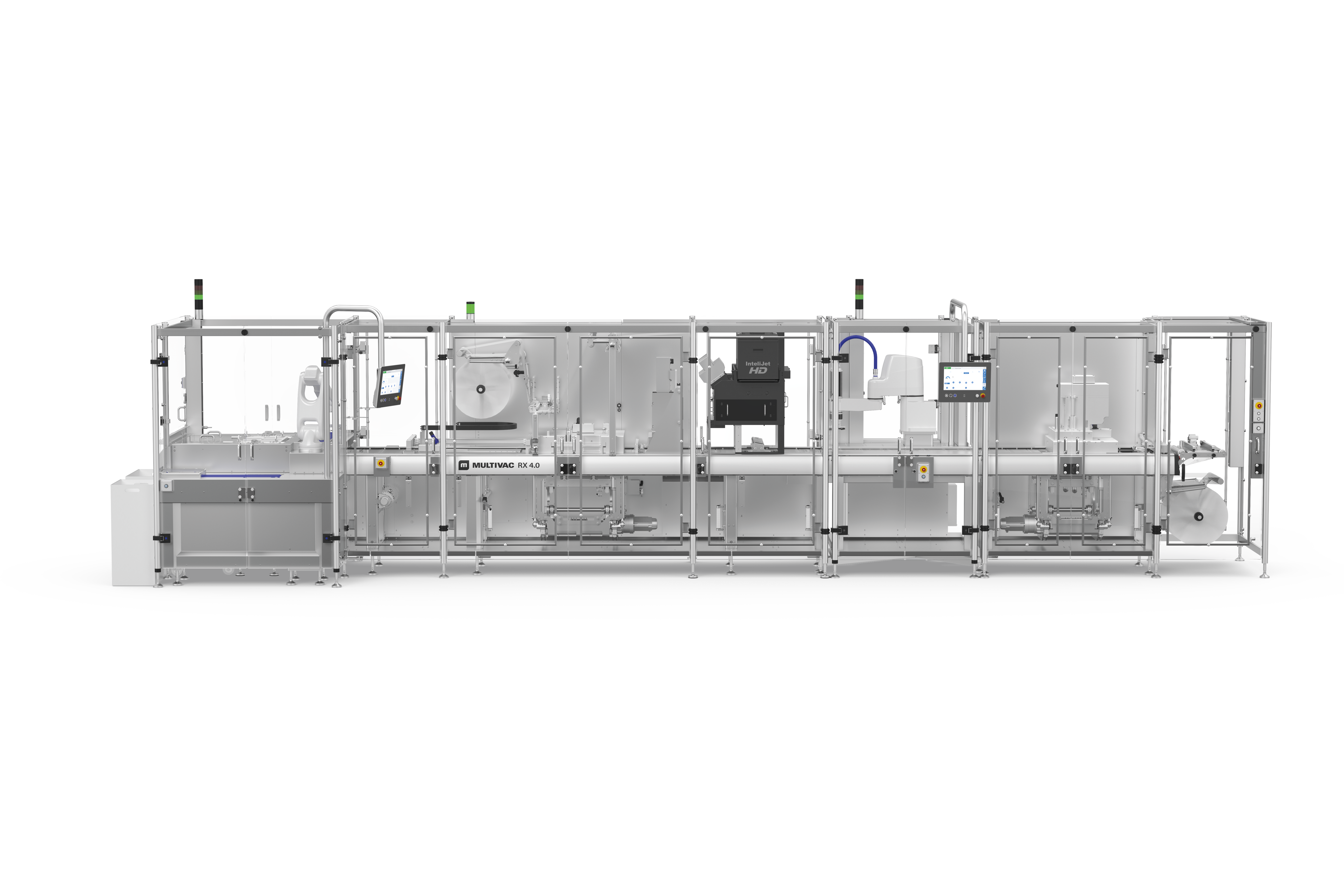

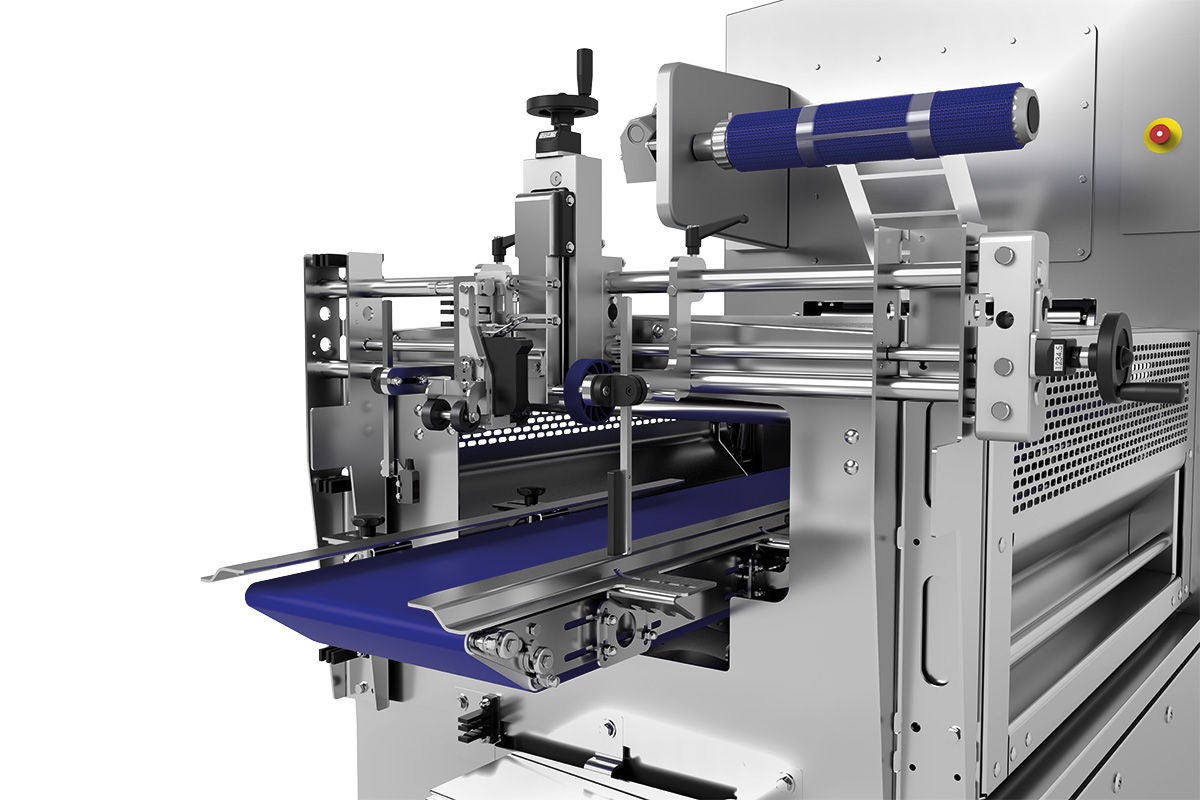

“Compared with the other portioning machines of the GMS series, the machine control software of the GMS 1000 is even more simple and intuitive, while the portioning machine itself is yet more versatile in cutting and shingling, and it can process an even larger range of product sizes,” says Florian Helfrich, Product Manager at TVI. “The new portioning machine also uses only state-of-the-art servo technology, therefore no hydraulics nor pneumatics, and it is equipped with the latest MULTIVAC control technology. This means that it is future-proof and energy-saving, as well as having the lowest possible risk of potential product contamination.”

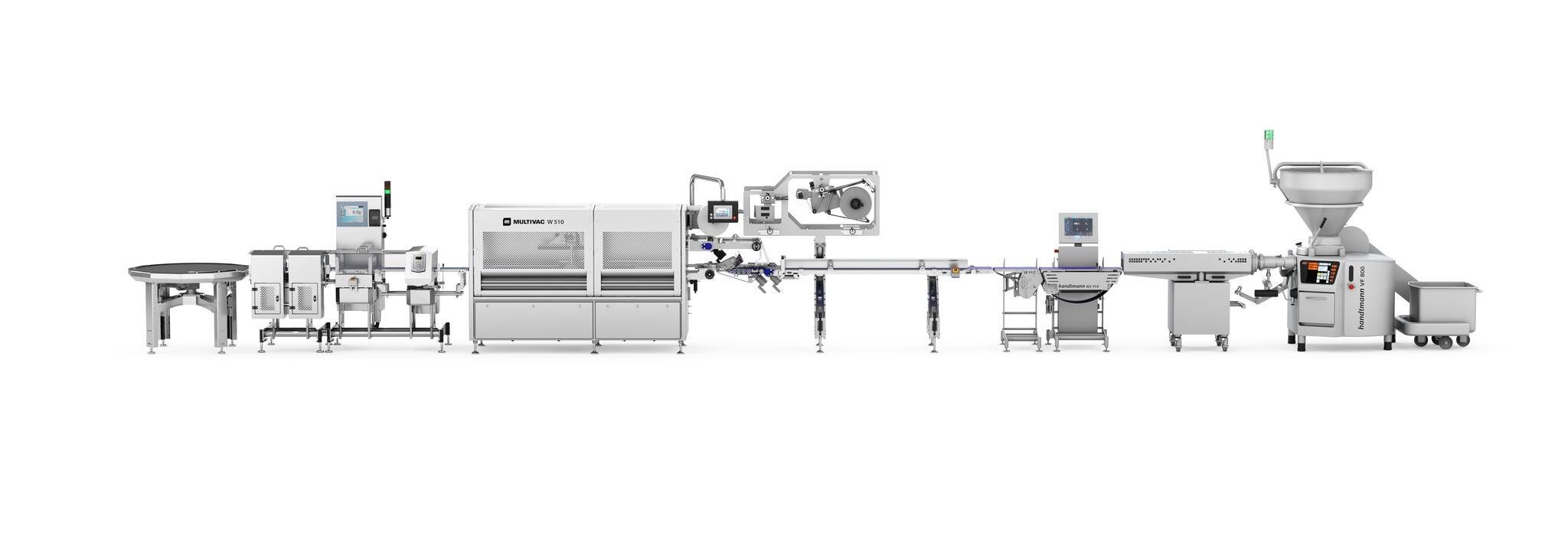

The highly flexible portioning machine facilitates upstream and downstream production processes, and it can easily be integrated into meat processing lines. Its operation is similar to that of other MULTIVAC and TVI machines, and it has easily comprehensible menu guidance. Thanks to the digitalisation options, such as MULTIVAC Smart Services, MULTIVAC Line Control and myMULTIVAC Customer Portal, the GMS 1000 offers many useful tools for supporting the planning, monitoring and control of production processes, so that the most is achieved from the customer's manufacturing operation.

Reducing costs while also achieving the best portion quality

“The meat industry is facing many challenges, such as rising raw material and wage costs, a growing shortage of personnel, as well as increasing demand for an ever wider range of products. At the same time there is the desire within the sector for long-term security and sustainability. With the GMS 1000 we are launching a highly automated single-track portioning machine onto the market, which precisely addresses these customer requirements,” says Florian Helfrich. “Thanks to this new portioning machine, companies will be able to save costs, while also increasing the quality of their portioning.“

Exhibited for the first time at Anuga FoodTec 2024

TVI is showing its new portioning machine for the first time at Anuga FoodTec in Cologne. Visitors can experience the new GMS 1000 in live operation in the Processing Marquee on the open-air site near to Hall 8.1, where they will also be able to view other innovations from the MULTIVAC Group. Appointments for the live demonstrations can be booked in advance on-site. The new GMS 1000 can also be seen as part of a line solution, which includes the new SCI 1000 sorting unit from TVI, on the main MULTIVAC stand in Hall 8.1, Stand C10.

- Size

- 83 KB

- Format

- Size

- 4 MB

- Format

- png

Latest News

MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

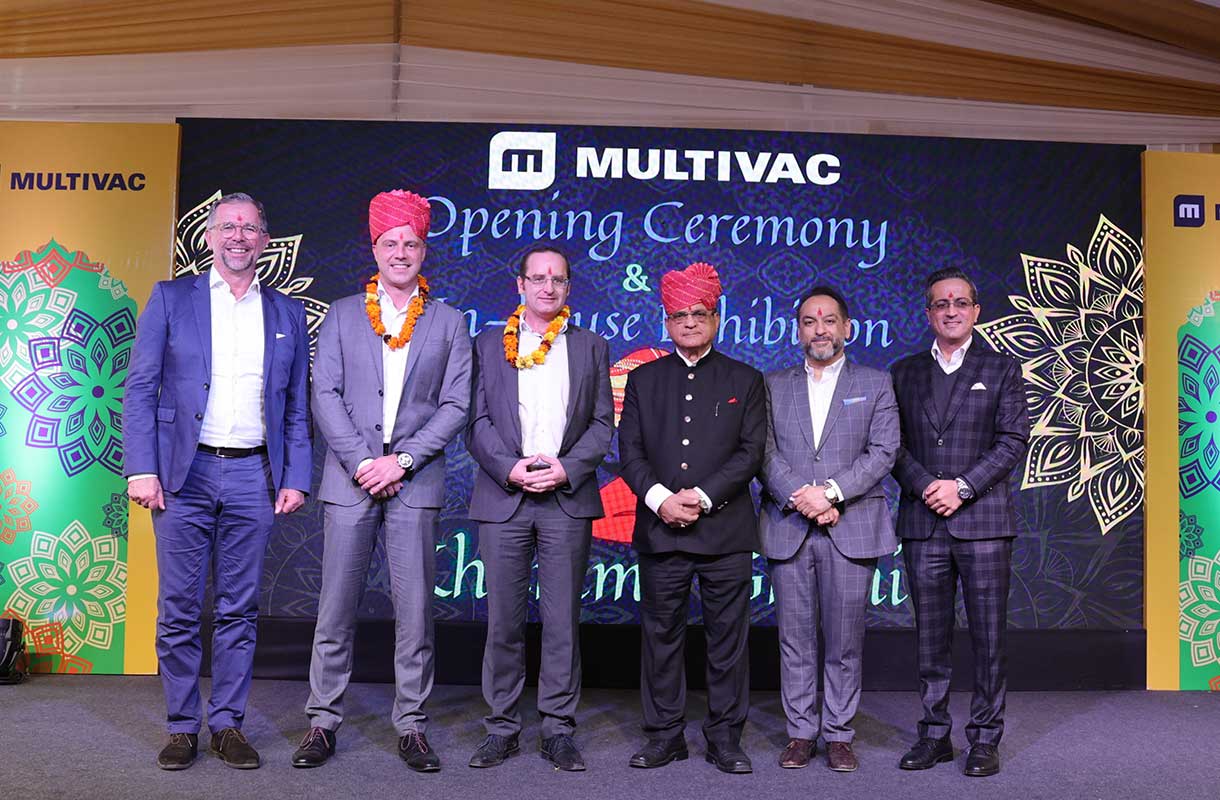

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

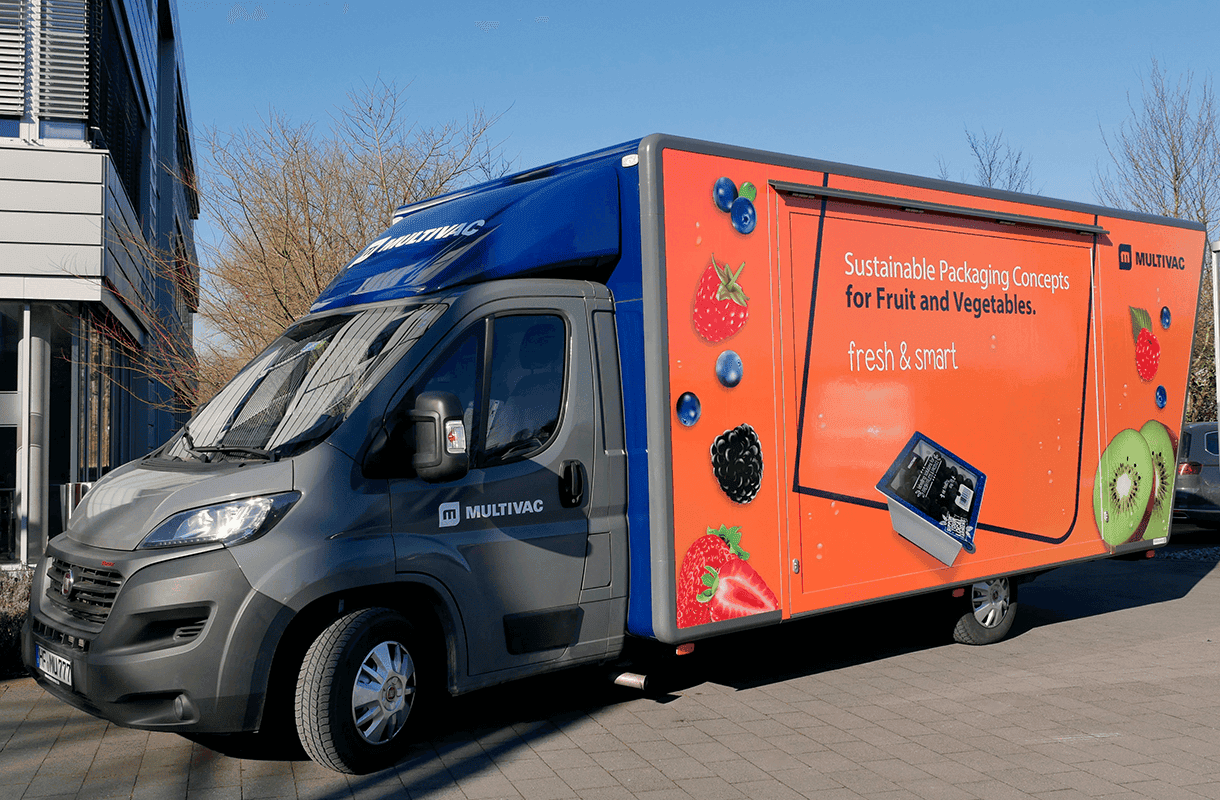

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

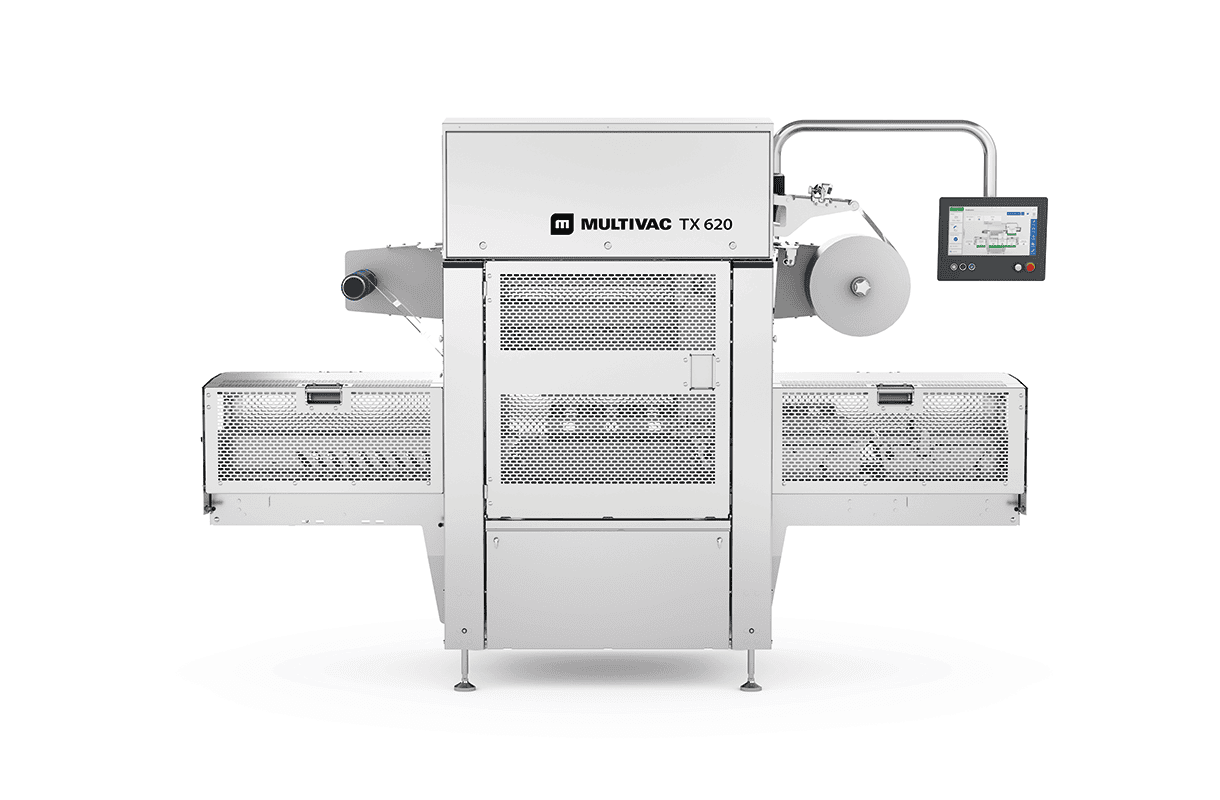

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com