The Migros cooperative in Eastern Switzerland offers the country's national sausage in over 100 supermarkets: the St Galler Bratwurst. It has been so successful, that production soon reached the limits of its capacity. The company therefore invested in an Industry 4.0-compatible line from MULTIVAC. Thanks to the line's very high level of automation, the company not only gained more throughput, but also greater flexibility and security in these times of skill shortages.

The Migros cooperative in Eastern Switzerland with its headquarters in Gossau produces for over 100 of its own supermarkets in several cantons - from St Gallen to Graubünden. So successfully in fact, that the production capacity reached its limits in 2021. New equipment was needed. “In order to increase our throughput, we began the search for a line with greater capacity to pack our St Galler sausages,” recalls Benjamin Germann, Team Leader at the Migros cooperative in Eastern Switzerland. And they struck it rich with MULTIVAC. The MULTIVAC Group offers complete solutions for packaging and processing food - from slicing through to packing, and right up to labelling and inspection. Integrated solutions, in contrast to more diverse alternatives, guarantee less friction between the various parts, since there is no requirement for synchronisation between different manufacturers. The benefits: The line is put into service more quickly, since the machines are precisely matched to each other in their design and technology, and all the necessary interfaces are already present. This means less downtime, because service work can be performed in a targeted way with rapid reaction. And a reliable supply of spare parts and consumable materials such as packaging films. “We have known MULTIVAC for 20 years. And in this time we have observed the hugely promising transition from a pure machine manufacturer to a supplier of integrated systems. It therefore seemed natural to continue in future relying on this cooperation to increase our productivity.”

The line, which is around twelve metres long, went into operation within eight months of being ordered. “We were really impressed with this tempo. Particularly since MULTIVAC had to tailor the new line to the limited space available in our factory like a made-to-measure suit,” says Benjamin Germann. The heart of this special line: the RX 4.0 thermoforming packaging machine. And also integrated into the machine is the space-saving DP 230 direct web printer, which is mounted over the sealing station. It prints the upper web of the pack, a flexible film made of polyamide (PA) and polyethylene (PE), directly after the film has been unwound from the roll, and it uses the thermal transfer process to print variable production data, such as batch number or best-before date. At the same time as the direct web printer is applying the print, the RX 4.0 makes the rigid lower web (APET) thermoformable through the effect of heat, so that pack cavities for the product can be produced by means of compressed air and vacuum during the subsequent thermoforming process.

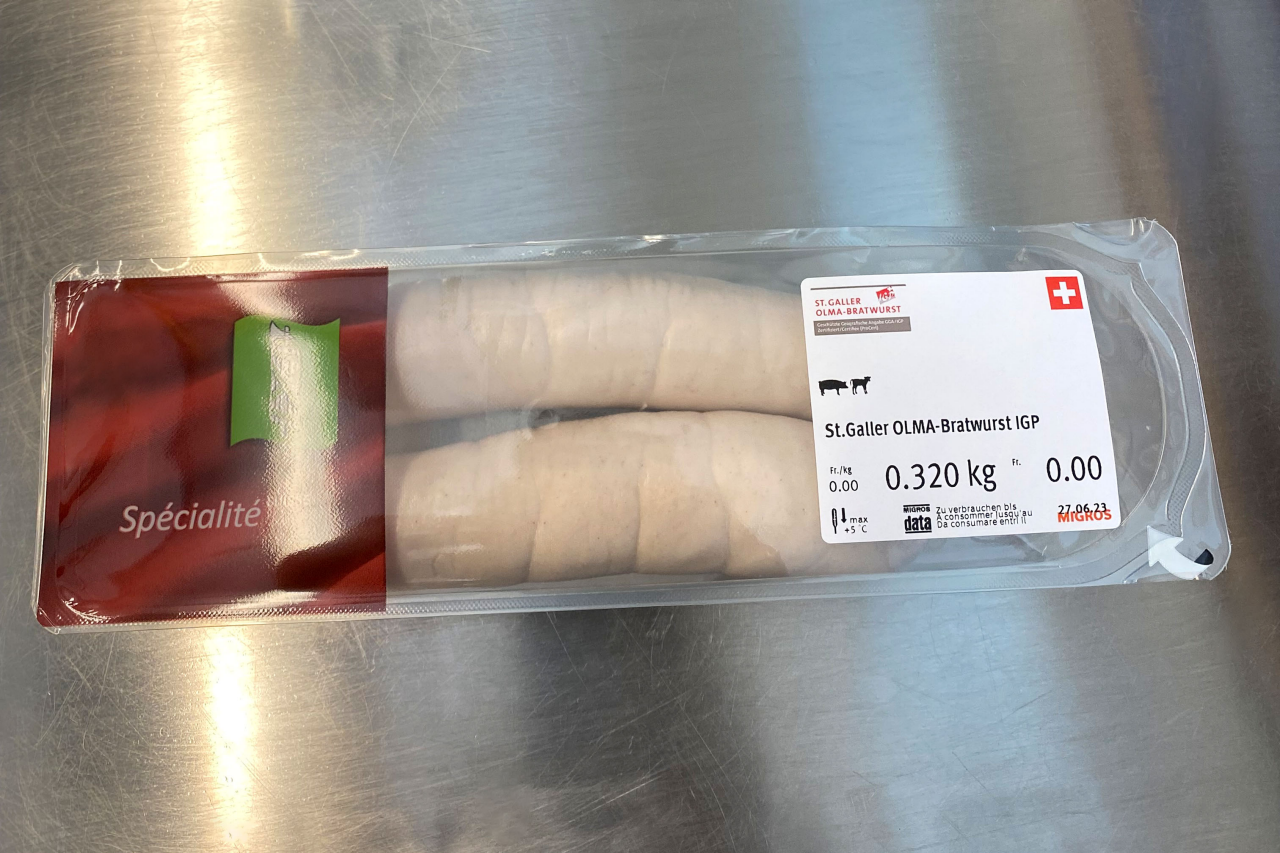

The next stage is manual loading of the product. Migros staff at the loading area of the machine place two sausages into each pack cavity. Then the machine takes over again. Using so-called Modified Atmosphere Packaging (MAP), the RX 4.0 introduces a modified atmosphere into the pack, and this is mostly a mixture of carbon dioxide, nitrogen and oxygen. This extends the shelf life of the product. Migros specifies a best-before date of twelve days for the St Galler sausages. Immediately after the packaging gas has been introduced, the thermoforming packaging machine seals the printed upper web to the pack cavities.

There then follows the labelling of the packs. Here two cross web labellers are used to apply a label, which gives the weight, price, best-before date and QR Code, to the top and bottom of the pack at the same time. Cross cutters and a longitudinal cutting unit subsequently separate the individual packs from the strip of packs. The I 420 visual inspection system with luminescence sensors then checks, whether the labels are in fact present on the packs. If a label is missing, the pack is ejected manually as a reject pack at the downstream discharge conveyor, and it is documented in the line-motion control of the thermoforming packaging machine. “Thanks to the new line's high degree of automation, we can now achieve a throughput of up to 80 packs per minute,” says Benjamin Germann with delight. And every single pack is labelled reliably. The pack can now also be opened more easily. Whereas consumers previously had to tear open the film at serrated teeth on the edge of the pack, they can now use peel corners, which enable the upper web to be easily gripped and pulled off. And last but not least, the line also scores in terms of flexibility. This means that Migros can convert the line very quickly to produce a vacuum pack of sausages in flexible film instead of the MAP pack.

Higher throughput was however not the only reason for investing in a line from MULTIVAC. Ease of operation also influenced the investment decision. Just as with almost all industrial companies across all sectors, the Migros cooperative in Eastern Switzerland is also confronted with the challenge of skill shortages. “A high degree of automation and ease of operation for the line are a great support to us in working productively with fewer personnel resources,” says Benjamin Germann. The whole line can be controlled via one touchscreen terminal. The HMI 3.0 user interface is designed in such a way, that it allows all the processes to be controlled intuitively. If the user sets a new print layout for example at the touchscreen, this automatically adjusts the direct web printer, thermoforming packaging machine, labellers and inspection system. It is also possible to link the line to MULTIVAC Smart Services.

Since the machines in the line are equipped with sensors and can be easily integrated into the MULTIVAC Cloud on the plug-and-play principle, it has recently also been possible for Migros to monitor, analyse and optimise production in real time. “As a manager, one wants to have a monitoring tool for production, without having to be physically present oneself,” says Benjamin Germann. Thanks to its Smart Services, MULTIVAC offers a wide range of applications, which increase machine availability, performance, pack quality and overall efficiency. If equipped with this connectivity, these machines and lines can for example provide live consumption figures for power, compressed air and coolant. Key performance indicators, which support customers in recognizing the potential for improvement. The MULTIVAC Smart Services are available via the myMULTIVAC Customer Portal at any time and at any place, using any device. “One day we noticed, that there was a drop in output on one shift. The reason why was however a mystery to us,” recalls Benjamin Germann. The Smart Log Analyzer supplied the answer. At regular intervals a fault message appeared, stating that the safety guard was opened. “We then saw on-site, that the particular shift was understaffed, and that some staff members were opening the guard to gain time through the resulting stoppage of the machine.” The problem was, that half an hour of production time per shift was quickly lost due to the constant restarting of the machine, after the guard was closed. “Thanks to this knowledge, we reduced the cycle rate of the machine and relieved the burden on the staff members. An improvement measure, which actually increased productivity in comparison with the constant stoppage of the machine. Without the MULTIVAC Smart Services, this deficit would probably not have occurred to us.”

06.09.2023