Low risk of faults thanks to visual inspection solutions

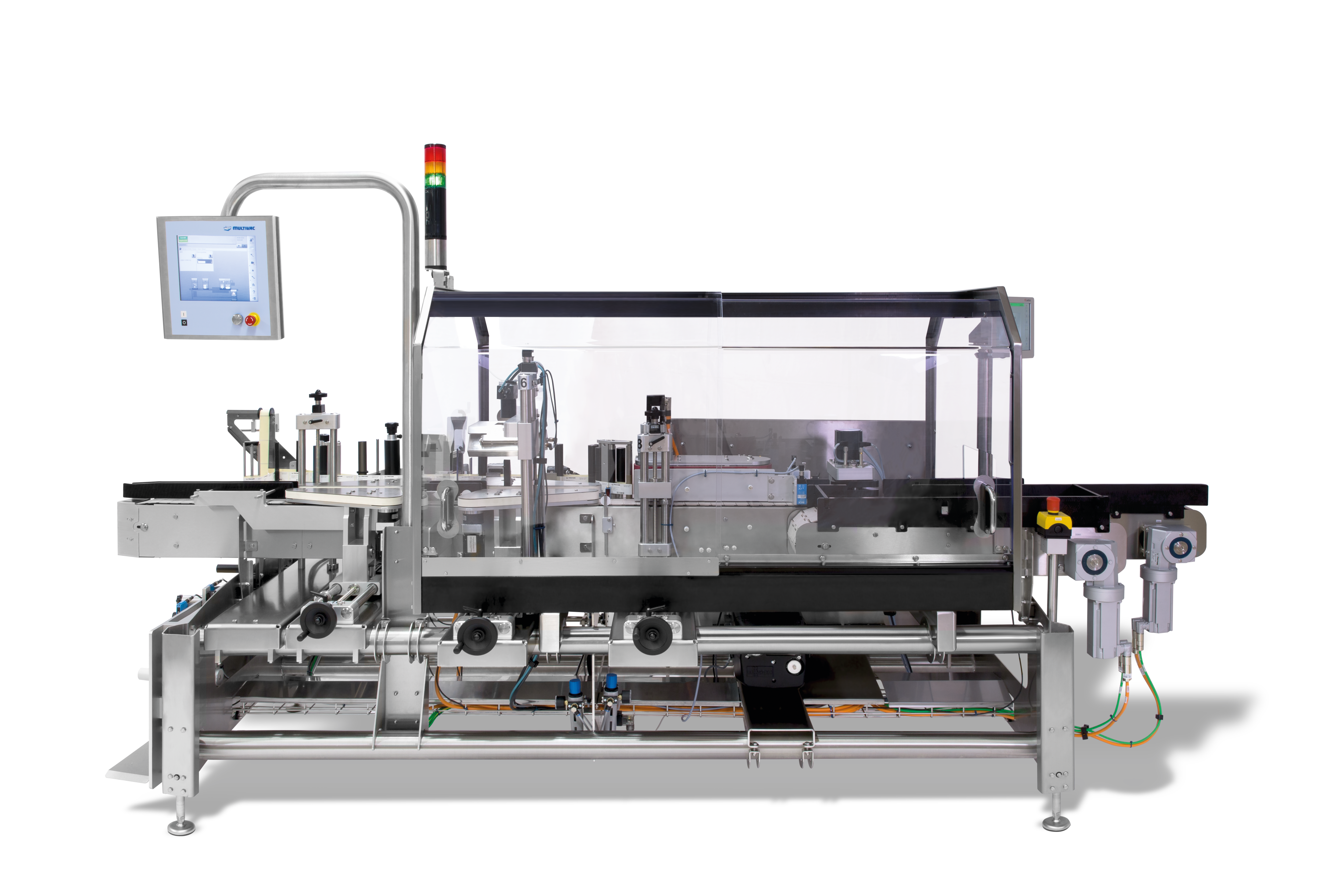

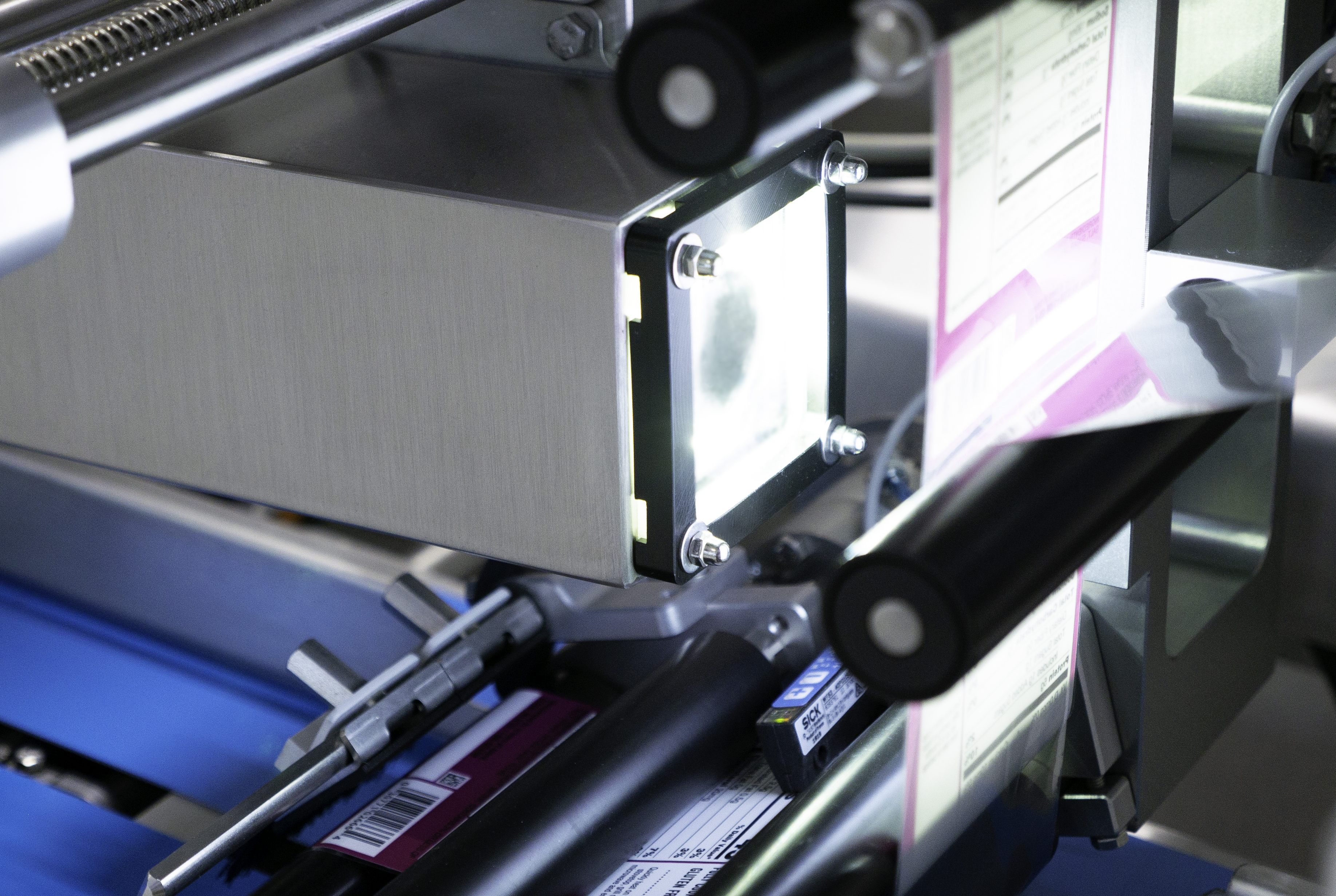

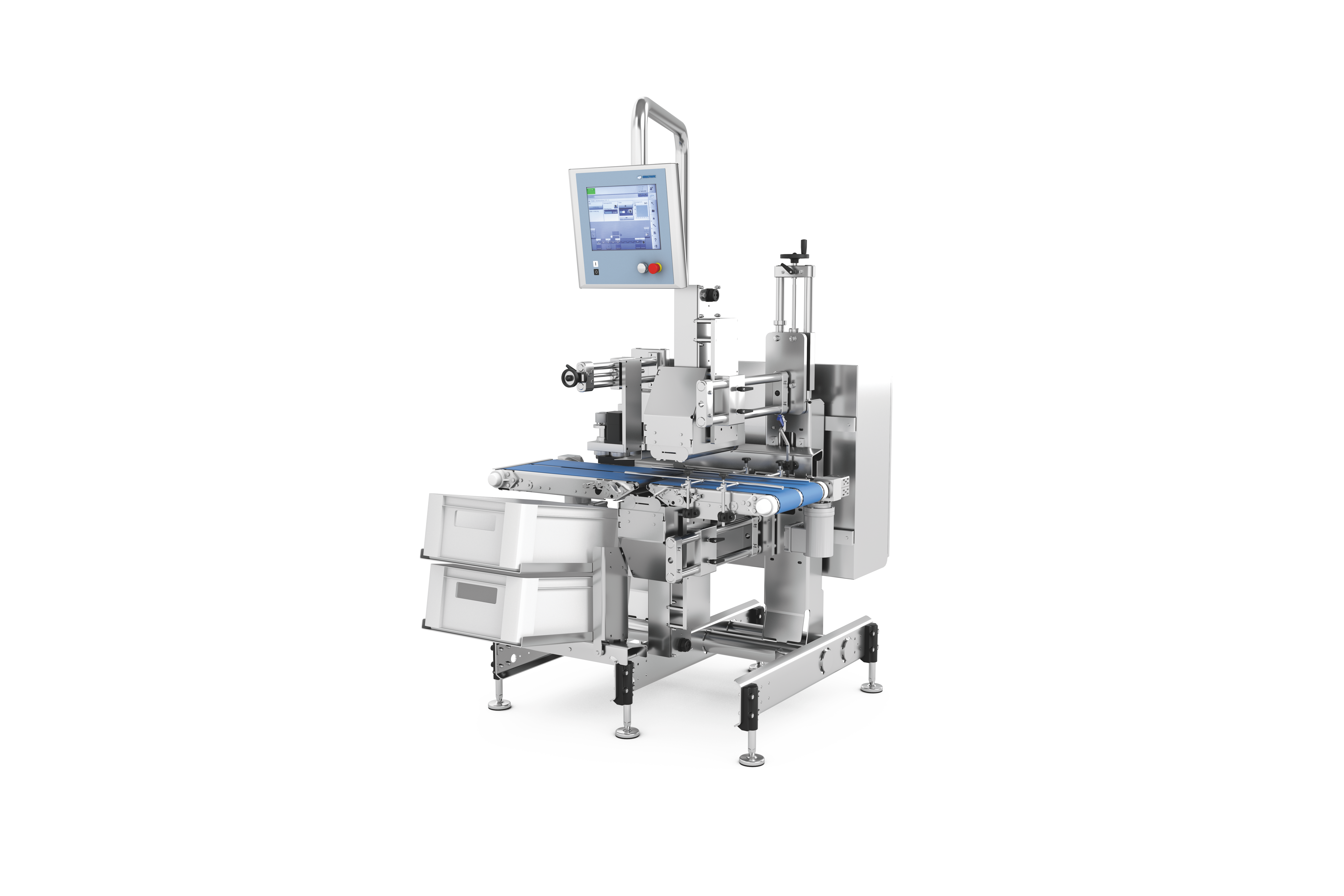

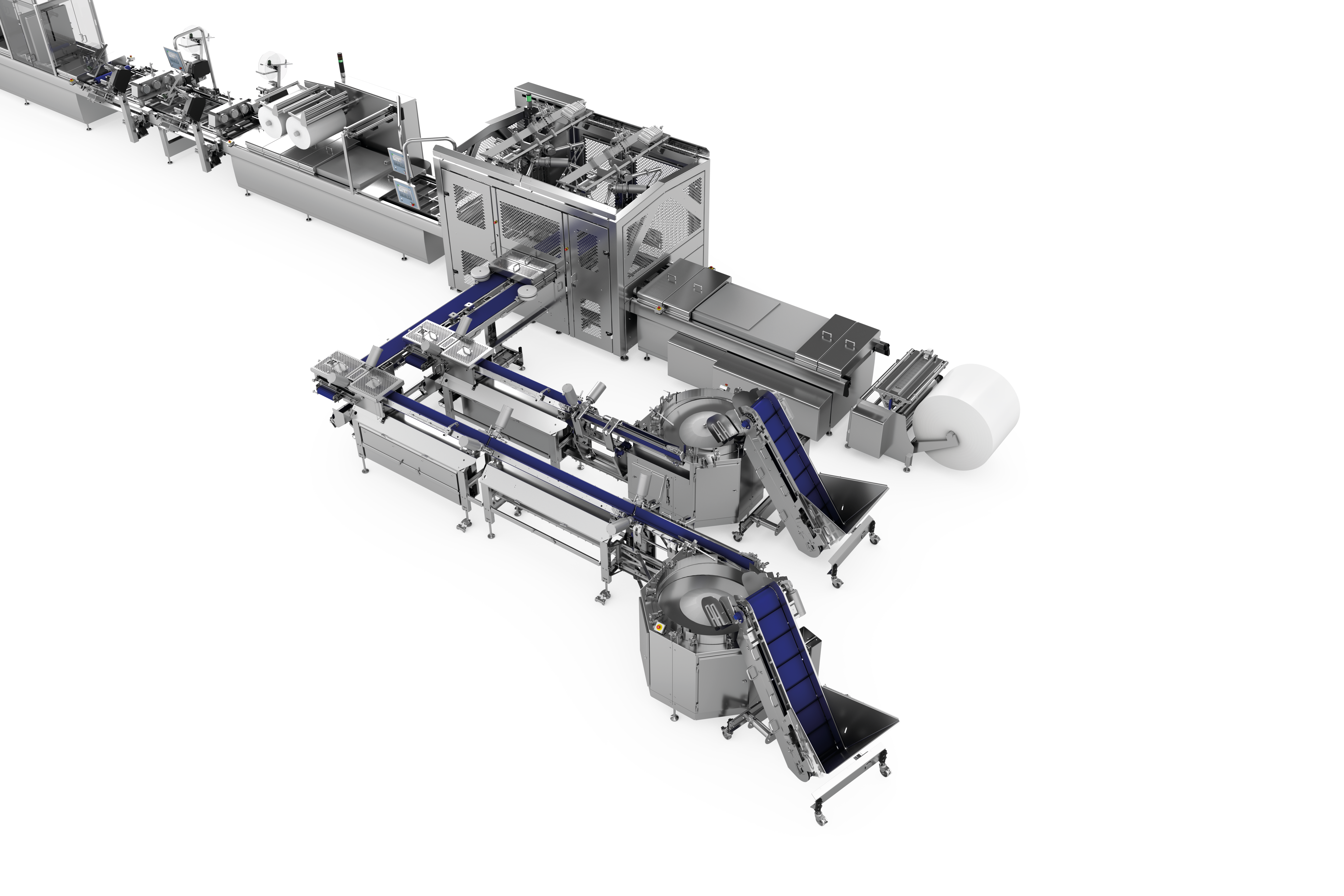

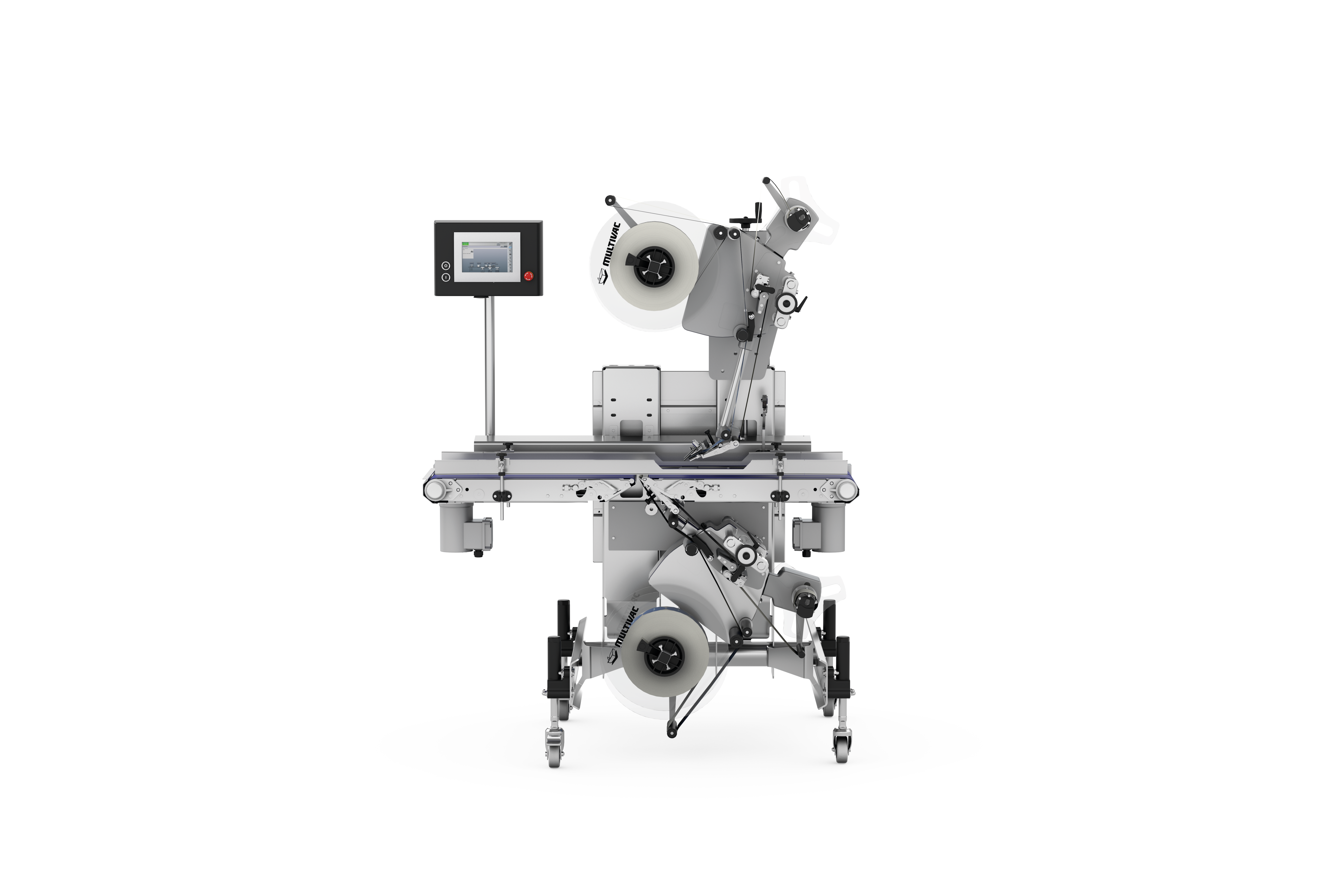

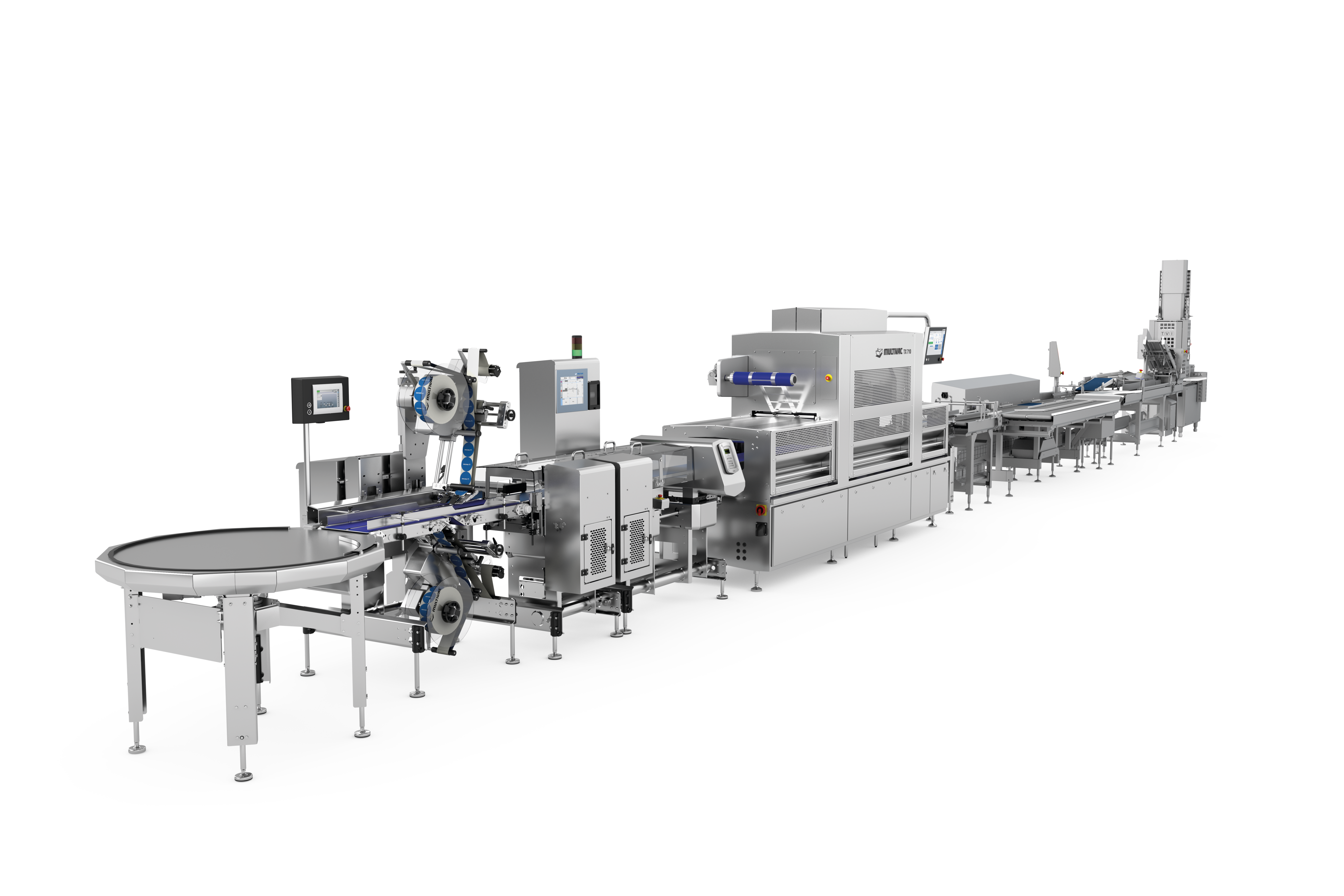

One must be able to rely on the quality of visual inspection solutions. They are, after all, the door to the consumer. We advise you to help you find the optimum solution for your quality control requirements in your packaging process. Sensors and code readers are often sufficient for simple checking tasks. If the requirements are more complex - as regards the quality of products, packs and their labeling or marking - we recommend MULTIVAC's camera inspection systems. Our visual inspection systems operate highly accurately, even under challenging conditions, such as varying measurement distances. This gives you a consistently high level of inspection quality. You benefit from reliable quality, extremely high throughput, and cost savings throughout the production line. Don't give mistakes a chance!

Success stories