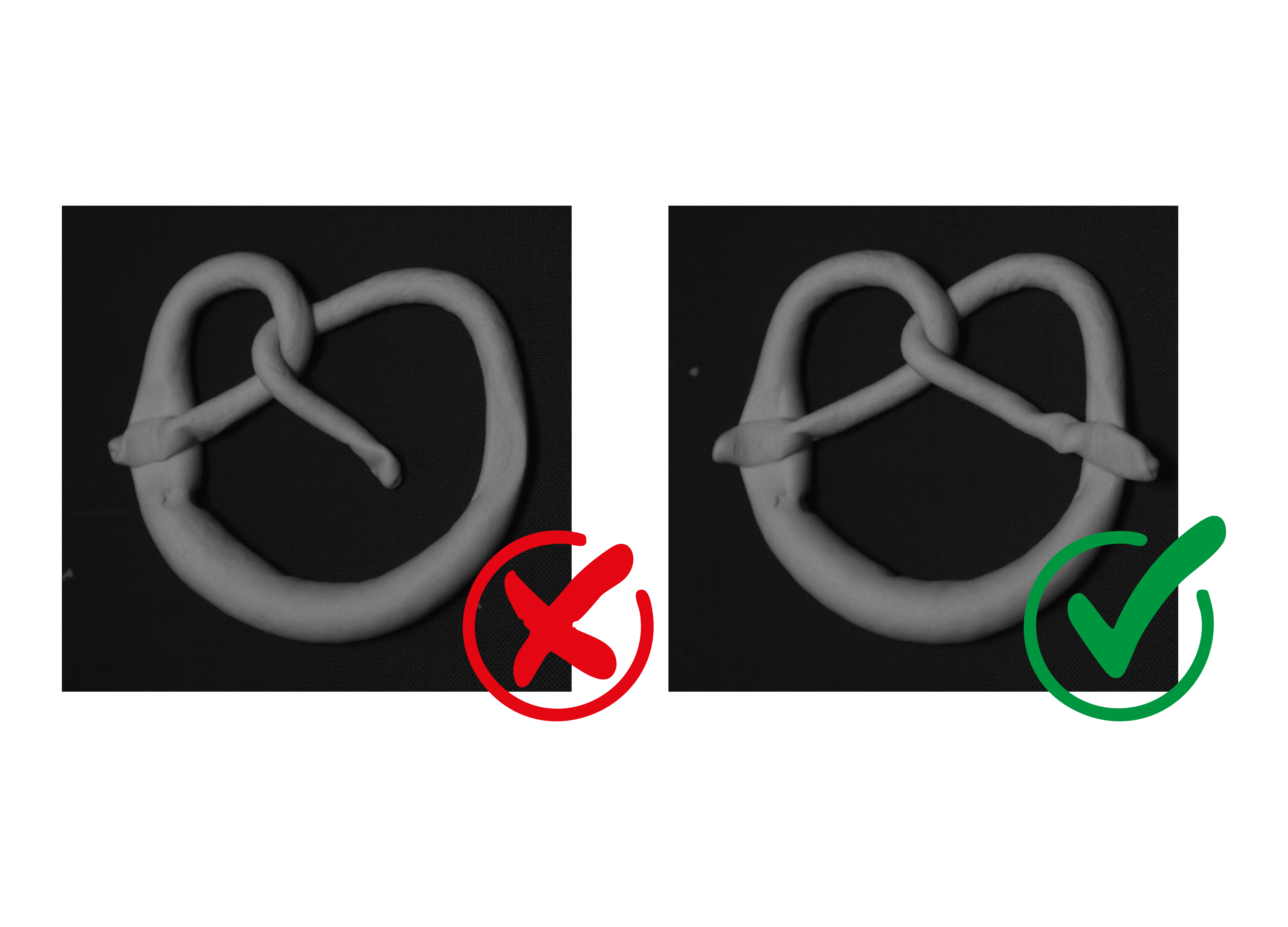

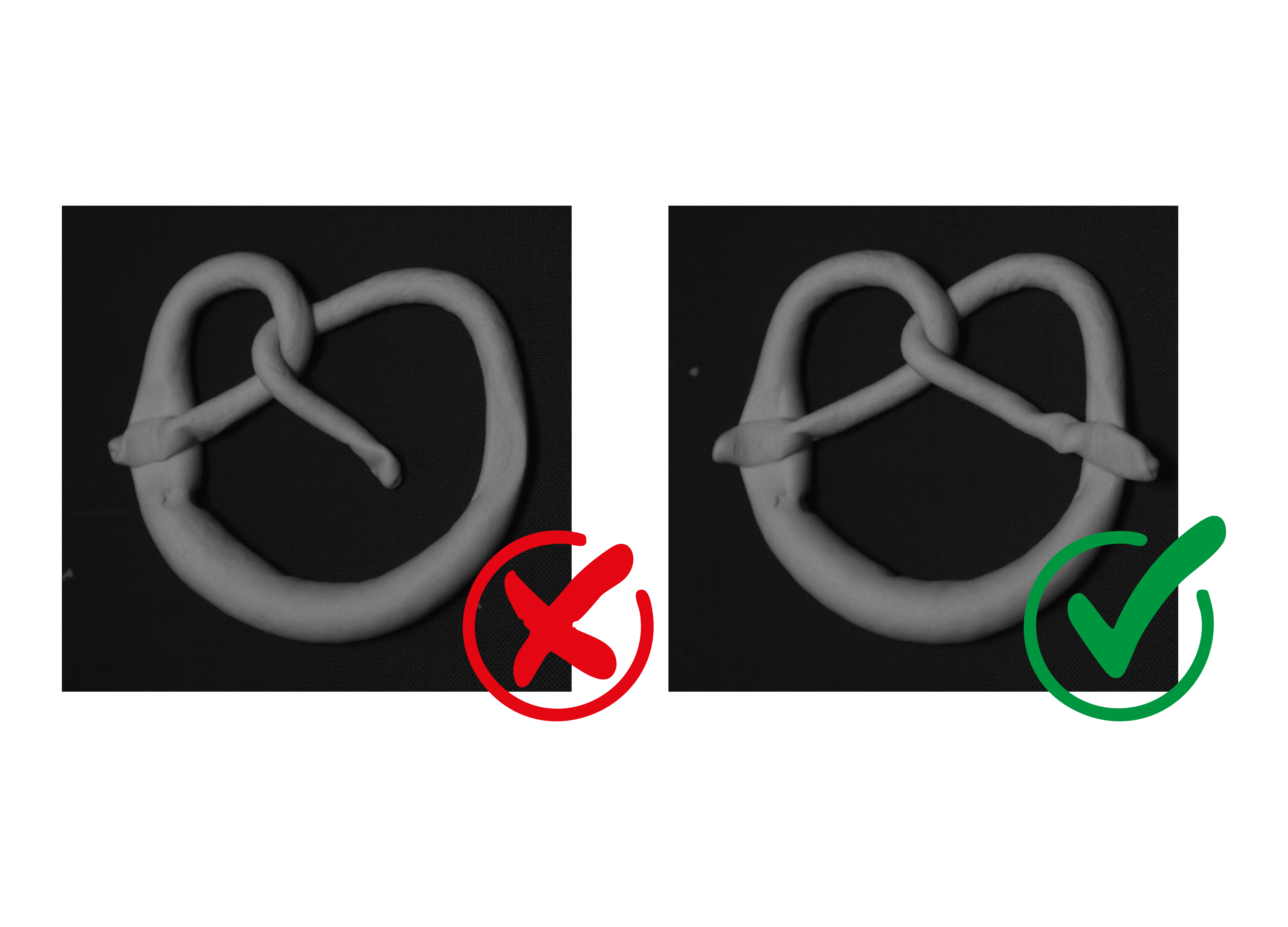

Rising quality demands and high processing speeds, as well as the need to meet ever more complex labelling requirements, provide challenges that can only be mastered by automated inspection systems. By using artificial intelligence (AI), the efficiency and precision of such systems can be maximised, and even very complex inspection or classification tasks can be completed quickly and consistently reliably.

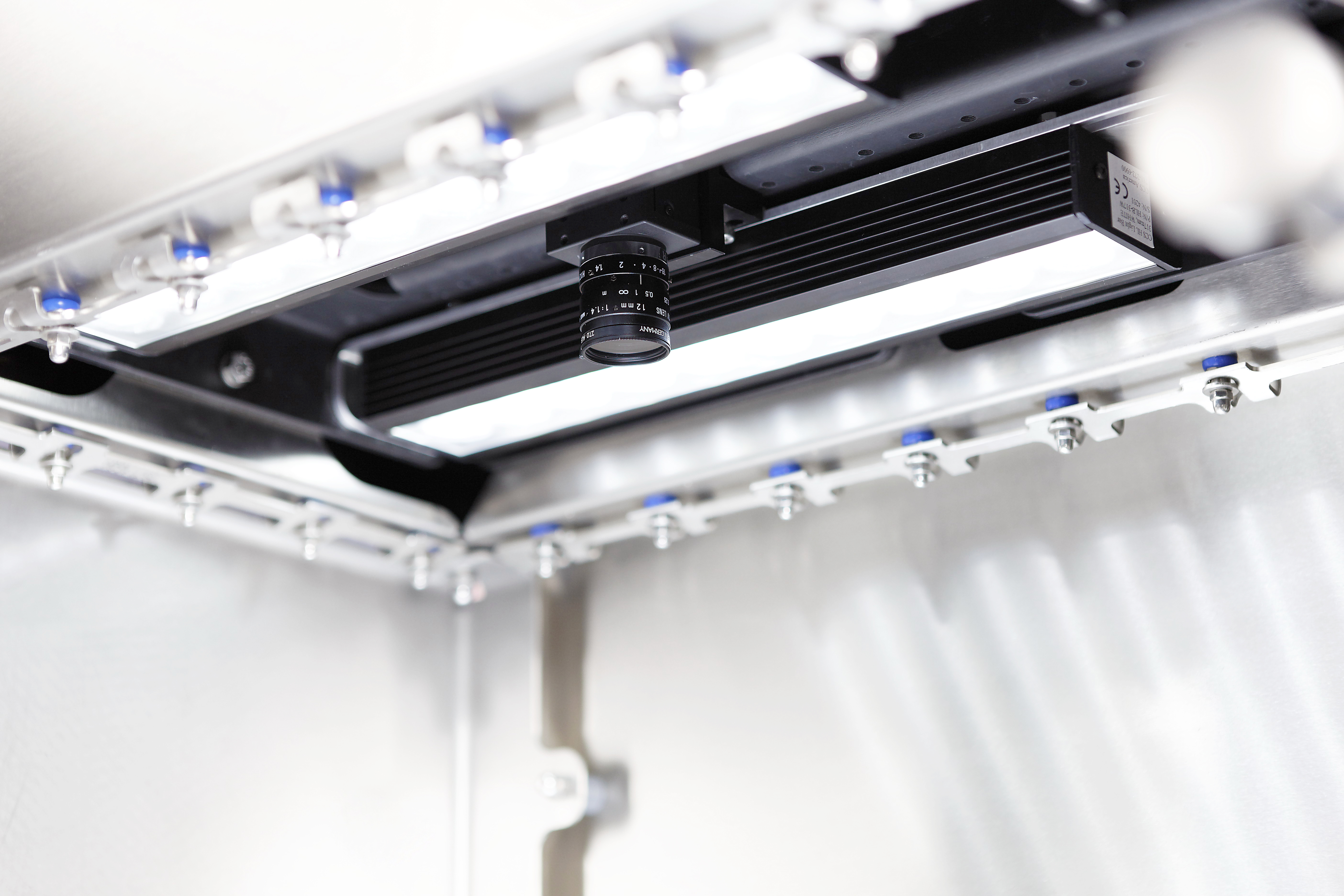

AI-supported vision systems meet the requirements for quality control and identification of food products. They can also classify products according to defined criteria, or check portion packs for quantity and completeness. This means that they make a crucial contribution to safeguarding your quality standards, as well as increasing line efficiency and therefore raising the production capacity.

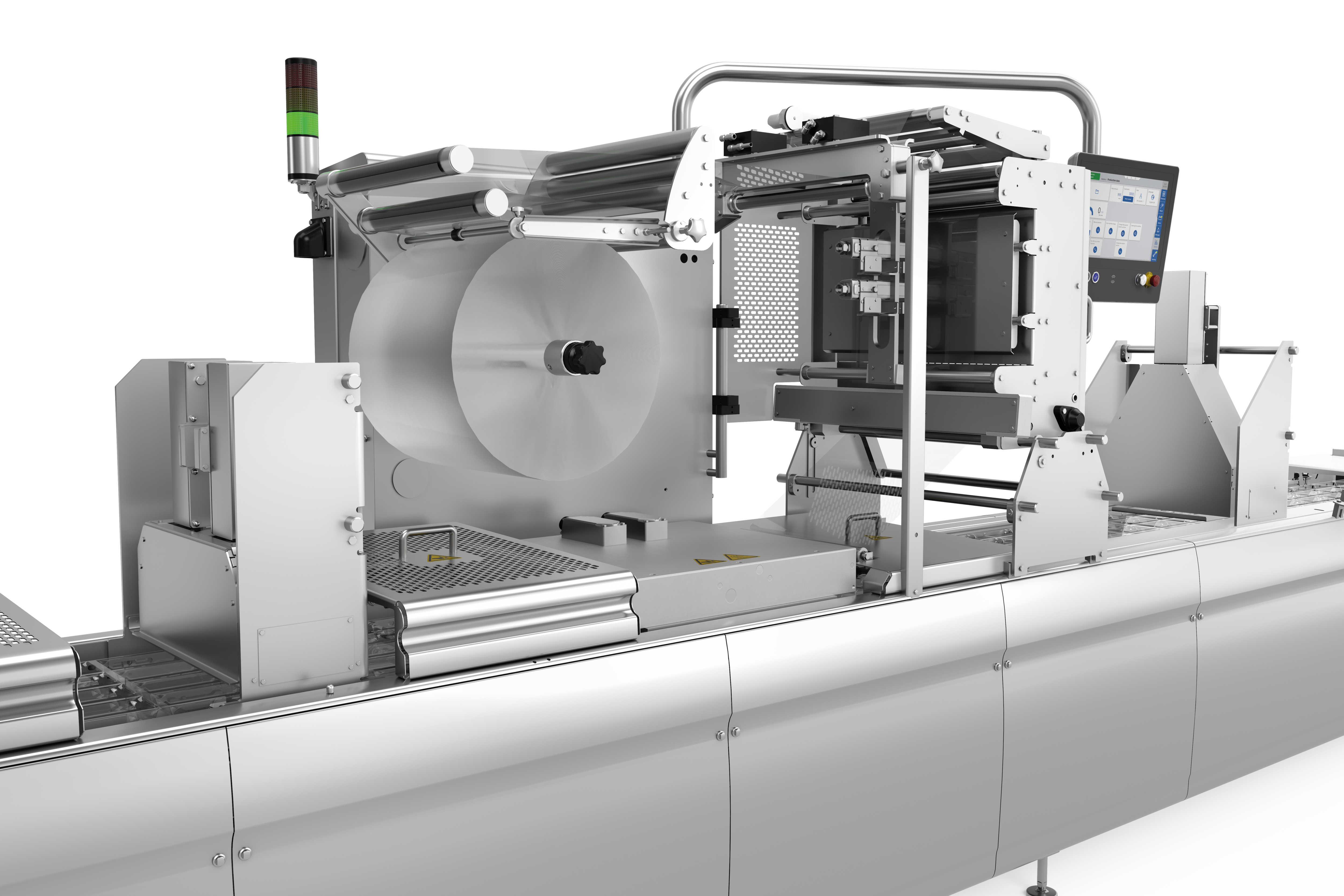

Other benefits of the AI-supported MULTIVAC vision systems are their customised configuration and seamless integration into your processing or packaging operation. For quality assurance without compromise.

Security for your product

AI-supported MULTIVAC vision systems automatically complete these tasks with consistent reliability

AI-assisted vision systems in action: Quality redefined

Discover how MULTIVAC vision systems with artificial intelligence are revolutionising quality control in food production. From product identification to pack inspection, this video shows how modern technology ensures maximum efficiency and product safety.

Your path to an AI-supported inspection solution

You would like to learn more about AI-supported vision systems or request your customized AI inspection solution?

Get expert advice: We evaluate your application, conduct a feasibility study, and work with you to develop the right AI vision solution for maximum quality and efficiency.