For several years now our nutrition has been influenced by the two megatrends of "Health" and the "Neo economy". Animal-based products in particular are greatly affected by this. A variety of different alternatives to milk, cheese and cream etc. have been available for a few years. The per capita consumption of milk and dairy products worldwide is rising very slightly, as reported by Food Outlook from the FAO (Food and Agriculture Organization of the United Nations); this was still 117.4 kilos in 2020, and the prognosis for 2024 is 120.6 kilos. According to Statista Consumer Market Insights, Germany is ranked 4th in the world for sales of dairy alternatives. Many manufacturers of dairy products, both established companies and start-ups, are not just watching these developments, but are also expanding their product range and becoming involved in this new sub-segment of the market.

These alternative products, which have arisen from this new trend, and which range from the replacement of milk itself right up to cheese, spreads and desserts, impose particular demands on processing and packaging. Subjects such as shelf life and sustainability play a special role here. Manufacturers are faced with several challenges: firstly, there may be a lack of know-how as regards product processing and packaging, as well as the machine technology required, and secondly, there are some issues to be aware of in the branding of the product. Producers, who also sell animal-based products alongside the alternative protein product, must ask themselves for example, whether highlighting the sustainability of plant-based cheese alternatives could be seen as a criticism of animal-based products. This risk can be avoided by marketing the alternatives through their own new brand. This does however mean, that the benefits of marketing the alternatives through an established and proven brand disappear, and manufacturers have to weigh this up.

Products, which are manufactured with plant-based ingredients, may differ from the animal-based equivalent in their processing: Animal-based cheese undergoes a ripening process. This can also be the case with plant-based cheese, if a ripening process is selected with cultures, which consist of a mixture of lactic acid bacteria. There is also a widespread manufacturing process, which does away with fermentation. Here the raw materials are mixed, and the texture and taste are created by means of food technology processes.

Vegan cheese alternatives have a particularly heterogeneous product consistency, ranging from soft to sticky and right up to very hard. This creates a challenge for slicing accurately to the required portion weight in a way that is gentle on the product. The necessary solutions have to be identified in discussions between machine manufacturers, such as MULTIVAC, and the producer of the product.

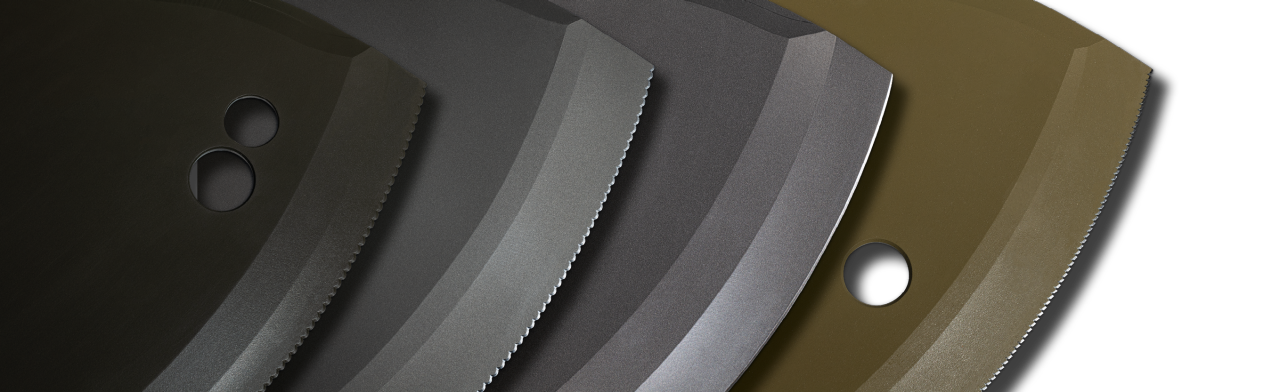

The choice of blade for the slicer often dictates the first starting point. The serration of the cutting edge can have a positive influence on the slicing quality. And a special coating of the cutting edge or the entire blade may also provide a solution, or alternatively a combination of the two measures. Another factor is the blade speed of the slicer. To achieve the ideal slicing result at the desired output, the application technicians subject the particular product to a thorough test, in order to find the right ratio between cutting edge serration, blade coating and slicing speed, so that an answer can be found to the challenge of consistency.

Experience shows, that plant-based protein products often have a high level of adhesion, and they can be described as "rather sticky". If the wrong parameters are set, this adhesion leads to abrasion, which can have a negative effect on the slicing result and the product placement. The second challenge is that the individual slices stick to each other, and the customer can not remove the product slices singly. The traditional solution is the so-called interleaver, which places interleaving sheets between the individual slices. These are generally however made of plastic, and this creates more packaging waste.

An alternative to interleaving film is the MULTIVAC Sustainable Liquid Interleaver, an innovative spray system used for packing thinly sliced or particularly sticky product slices. Precision nozzles on the spray system atomise a liquid food release medium, which is both odourless and tasteless and can be tailored to the particular characteristics of the product, for example the fat content. It is applied evenly to the underside of the slices. The adhesion between the individual slices is therefore reduced, but the product itself (taste, smell, colour) however is not altered. This means that there is no requirement for the conventional interleaving film between the slices – and the consumption of plastics during the packaging process can be reduced to the bare minimum. Vegan cheese alternatives can therefore be presented very attractively in the pack, and the individual slices can be removed cleanly by the consumer.

When processing and packaging food products of all types, the objective is to provide optimum protection for the product against external influences, as well as extending the shelf life within the pack. The resulting requirements for the processing and packaging solutions depend on the particular product. Whereas with animal-based food products the focus is mostly on preventing the product perishing, in the case of plant-based alternative products the critical factor is the tendency towards higher spore growth, which is triggered by the nature of the product. Machine manufacturers must therefore integrate suitable hygiene concepts into their machines.

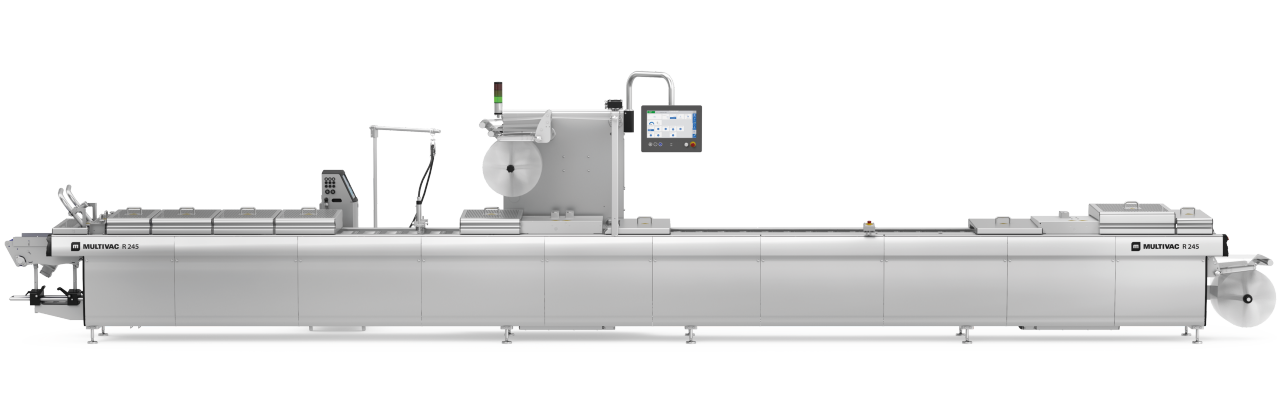

In order to guarantee food safety up to the point of sale and extend the shelf life, various measures are used during the packaging process. For example, the products are often packed under vacuum or modified atmosphere (MAP, Modified Atmosphere Packaging), either on traysealers or thermoforming packaging machines. The particular requirements of the food product determine, which packaging method is used, and whether the best choice is a vacuum or MAP pack, or even a pack without any gas exchange. The manufacturing process, the desired minimum shelf life, and the preference for the pack design all play a role here.

A particular feature when packing plant-based cheese alternatives is the precise composition of the gas mixture, when modified atmosphere packaging is being used. If fermentation forms part of the manufacturing process for a plant-based cheese alternative, the oxygen content within the pack must be taken into account. Packaging gases such as carbon dioxide and nitrogen are generally used here to reduce the oxygen content. This ensures that the microorganisms, which are contained in the product, do not allow the product to continue ripening. When combined with a high-barrier film, where there is a particularly high barrier against oxygen, this produces a packaging concept, which first removes the oxygen from the pack, and then also protects the product against the permeation of oxygen. Packaging specialists must understand the upstream and downstream processes, as well as the requirements of the customer, so that they can develop an individual packaging concept. Food manufacturers, who are new to the market, as well as start-ups benefit in particular from the advice of MULTIVAC, which brings decades of widespread experience.

DP 240 / R 245

DP 240 / R 245

FullWRAP - Cup

FullWRAP - Cup

In the case of plant-based dairy alternatives of all types, sustainability is an aspect that all companies in this target group are particularly interested in. Ideally this is also reflected in the packaging. In addition to the materials used, the design of the packaging itself also plays a large role. Plastic packs can be designed thinner by optimising the pack design, and this means that significantly less packaging material is used, while still ensuring that the packs remain sufficiently rigid and guarantee a long shelf life for the product. By changing from a rigid to a semi-rigid pack, or even to a flexible film pack, it is often possible to make a significant reduction in the pack weight.

Recyclable materials for packaging plant-based dairy products are also an excellent opportunity for companies in this target group to incorporate their values in the packaging. In recent years many companies have switched from multi-layer films to mono materials, and this has a significant effect on the sustainability of the total product.

The market for plant-based dairy alternatives and similar products is still in its infancy, but it has great promise. It is a dynamic environment with many new products, ranging from start-ups to established companies entering the market. The requirements for efficient and hygienic processing and packaging are as varied as the products themselves. For food manufacturers, who are often on their own, it is a mammoth task to define these variations and master the resulting challenges. In addition to supplying processing and packaging solutions, MULTIVAC provides its many years of expertise to its customers and partners. Through working together with its customers, MULTIVAC is able to find the right individual solution for the particular food product, by taking the specific product characteristics into account, and ensuring that the required output is achieved. This means that ideally the result is a pack, which reflects and enhances the values of the food product itself.

18.12.2024