A total of 14 MULTIVAC machines are currently in use at Bell & Evans and pack a wide range of poultry products in attractive packs. “MULTIVAC is the market leader and offers the best packaging systems worldwide. It is also a family-owned company, much like Bell & Evans, which has been established in the market since 1894. Both companies base their business dealings on similar values. We were, of course, very appreciative of this from the start,” explains Scott Sechler Sr., President and Chairman as well as owner of the American poultry producer.

The company was founded in 1894 by Howard H. Bell and Carlton Evans. This makes Bell & Evans one of the oldest brands of poultry products in the US – and the two founders acted as pioneers in the sector of natural and naturally produced food products. Milestones in the company’s history include the building of a large production site in Bellmawr (New Jersey) in 1910, as well as the purchase of the company in 1984 by Scott Sechler Sr. At the turn of the millennium, Bell & Evans already employed around 700 staff and worked in cooperation with more than 90 family agricultural businesses. Today, Bell & Evans employs over 1,700 team members and partners with 130 family farms.

The product range, which sits at the top end of the market, is systematically adapted to constantly changing consumer behavior. The range of products includes fresh whole chickens, poultry cuts and ground meat. In addition to these, there are also other further processed items such as chicken nuggets, chicken burgers and fully cooked grilled chicken breasts, which only have to be heated for several minutes before being ready to eat. The products processed are primarily chicken, however, Bell & Evans also offers turkey, duck and cornish hens. The poultry producer’s target groups include upmarket restaurants, premium butcher shops, specialty organic retailers and several hand-selected supermarkets. Their successful business model is essentially based on Scott Sechler’s simple but lucrative vision – his aim is to effectively live up to his quality claim by processing the best poultry in the best way.

All the animals therefore come from an animal-welfare-focused rearing and grow without antibiotics or hormone supplements. They eat only corn, soy beans, vitamins and minerals, and they drink only clear, fresh water. But Bell & Evans does not just place great emphasis on the well-being of the animals to, they also insist on processing and packaging procedures, which are in harmony with the company’s ecological convictions. To this end, the company uses a 100% Air Chilled process, which is based on air cooling and saves millions of liters of water every year. While traditional chilling methods require chlorinated water, that is absorbed by the chicken and dilutes its natural juices, the 100% Air Chilled method goes without the addition of water or chlorine.

“This technology also brings significant benefits for the product to the end consumer,” says the company President. “It enables us to ensure that the meat remains tender and tasty because it does not have to be cooled with chlorinated iced water, and it matures in its own natural juice.” There are no compromises for Bell & Evans either when it comes to packing its products. The decision was made in 2007 for the first machines from MULTIVAC “and we have not regretted that decision once,” confirms Scott Sechler. The first project was to implement a solution for packing whole chickens with FormShrink®, an effective alternative to packing in shrink bags. Thermoforming films with special shrink properties, which are activated in a shrink tunnel, are used for this packaging procedure. The result is attractive packs, which envelop the products like a second skin. The overhanging film trim that is familiar in conventional packaging in pouches is minimized. The process is particularly efficient, because it enables the open pack cavities to be filled easily and cleanly from above, which means that it can be largely automated. The process also offers benefits to retailers: the film’s high level of transparency enables unclouded product presentation and packs with impressive luster to be achieved.

Following the FormShrink® for whole chickens, solutions for the skin packaging of poultry cuts and large family packs came next. “Pack quality and attractive presentation at the point of sale are of course very important to us. They enable us to emphasize the quality of our products and our brand, and they distinguish our products clearly from the others in the marketplace. However, the poultry products from Bell & Evans are premium priced versus conventional or commodity products offered in stores,” adds the company President. Other aspects, which are very important to this US company, are the shelf life of their food products, the security of the packs and, on the processing side, a high level of efficiency including the cost-effectiveness of the entire processing and packaging procedure. As Scott Sechler says: “It is of great benefit to us that we can use the same packaging for our fresh as well as our frozen products. The solutions from MULTIVAC for shrink and skin packaging are exactly what we were looking for. They are perfectly tailored to our needs.”

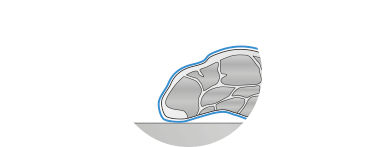

The FormShrink® process uses special, extremely shrinkable thermoforming films. The finished packs pass through a shrink unit. The shrink properties of the film are activated by the heat effect of the hot water, and the film then lies tightly around the product.

The range of machinery at Bell & Evans currently includes six packaging lines with R 575 MF high-output thermoform packaging machines. The first five models were put into service in the autumn of 2015 – installing these while the business was operating turned out to be a real challenge. But nevertheless, everyone at the company in Pennsylvania is very satisfied with the result. The machine enables MultiFresh™ vacuum skin packs to be produced in very large batches, and it offers great versatility in the range of MultiFresh™ applications. Five of the six models at Bell & Evans are equipped for LipFORM applications as a cost-effective alternative to packing with pre-made trays. In addition to this, five R 245 lines pack a range of products, such as 20 lb. bulk packs for higher volume foodservice companies, as well as smaller individual and family packs, which are sold through retailers. Bell & Evans also serves the international market with 10 lb. packs of poultry cuts, which are produced on the R 245 machines. This model is a freely configurable thermoform packaging machine in the mid-output range. Its extensive choice of equipment options can also produce complex pack shapes at a high cycle output. It offers a high level of efficiency thanks to its effective use of packaging materials and energy, which assists this poultry company with keeping its eye on sustainability and environmental awareness.

Another packaging solution is currently in its test phase to pack whole chickens in Mylar® COOK film. This film enables the product to be cooked with minimum effort and maximum aroma thanks to films, which have been specially developed for this process. Since the films can be used in a temperature range of -60 to +218 °C, the packaged food can be stored as chilled or frozen and then cooked in the oven or microwave. The moisture and aromas in the food are retained during cooking in the sealed pack. Upon reaching a defined pressure, the package opens automatically in the oven, and the browning process starts.

Whole chickens will also continue to be packed with the FormShrink® process on two R 555 machines. This thermoform packaging machine enables high-quality shrink packs to be produced in large batches, and it provides a significantly extended shelf life for the packed product when compared with shrink bags.

The latest arrival is an economical R 225 machine in the medium output range, which started service in June 2017 for producing large-size packs. It offers an attractive price/performance ratio with its practical selection of equipment options.

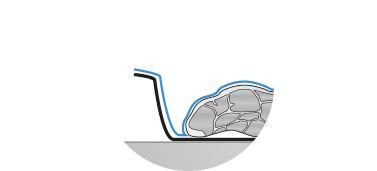

MultiFresh™ vacuum skin packaging uses a special skin film, which encloses the product without tension like a second skin and seals to the entire surface of the lower web. The upper web passes through a heating station to activate the film properties, and it is then pre-stretched in the sealing die.

Scott Sechler particularly appreciates the market leading system expertise. “We also use MULTIVAC’s labelling systems for base labelling as well as for applying labels to the top of the packs. They are perfectly designed for our machines, and they are fully integrated into the lines. We have found they are the best solution for our high-quality products. Overall, the installation of our machines went to plan. The introduction of new technology can sometimes seem a bit painful. The learning curve to perfect the machine settings and film characteristics proved to be quite steep, but we are thrilled with the end result,” says the company President.

The new packs from Bell & Evans have been very well received in the market. They are not only attractive but also convey to the consumer that the top-class products are fresh and of the highest quality. Thanks to these skin packs, the poultry products have a long shelf life and retain their natural juices, while there is virtually no loss of quality. “With Bell & Evans as the market leader, we have to positively set ourselves apart from our competitors in all aspects. This also makes it more difficult for others to copy our products and packs – and makes it easier for us to maintain our leading market position now and in the future,” says Scott Sechler in summary.

16.05.2018