Double distinction for solutions from the MULTIVAC Group

International Bakery Awards 2025

10.12.2025

Wolfertschwenden, 10 December 2025 – At this year's International Bakery Awards, organised by the UK media company, Hand Media International, awards were given in eight categories, and the MULTIVAC Group was able to secure two awards for itself: In the "Bakery Machine of the Year" category, the PROGRESSA pastry from FRITSCH came out top. The machine for producing pastries is characterised by its hygienic design, ease of use and flexibility. In addition to this, the Cooling@Packing solution from MULTIVAC was given the award as "Packaging Machine of the Year" – this is a technology, which cools products as they are being packed, thereby ensuring that freshness and longer shelf life are achieved very efficiently.

With its PROGRESSA pastry machine, FRITSCH presents its latest development in the semi-automatic manufacturing of premium pastries. Following the success of its new IMPRESSA bread machine (2023), the company is now systematically transferring its high hygiene standards to the premium pastry sector. At the centre of this is the company's focus on easy accessibility, fast cleaning cycles and user-friendly handling. The design is conceived with hygiene in mind down to the last detail: smooth and easy-to-clean surfaces, watertight threads for protection, and rounded corners that prevent product residue being deposited. Thanks to the linear quick-release mechanism for slackening the belt tension, for example on the infeed conveyor to the satellite head, there is effortless access even in very tight areas. In addition to this, the belts on the so-called "Omega drives“ can be completely removed in a few seconds, so that even difficult-to-reach points can be cleaned quickly and thoroughly.

The MULTIVAC Cooling@Packing system is a vacuum technology for cooling bakery products, which shifts the cooling process into the thermoforming packaging machine itself. This means that products can be packaged immediately after baking, so that the product shelf life and freshness are increased.

Thanks to the use of Cooling@Packing, bakery products such as baguettes, breads or biscuits can be loaded directly from the oven, using loading robots to hygienically place the products into the open packs at the loading station of the thermoforming packaging machine. The evacuation process in the vacuum chambers of the machine cools the products down within a few seconds from around 95 °C to approximately 30 °C. This saves space in the Production area, as well as reducing energy consumption during cooling, and also increasing production capacity due to shorter baking times. The new solution can be integrated into MULTIVAC thermoforming packaging machines in the high-output range.

Press release

Double distinction for solutions from the MULTIVAC Group

- Size

- 135 KB

- Format

Current News

MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

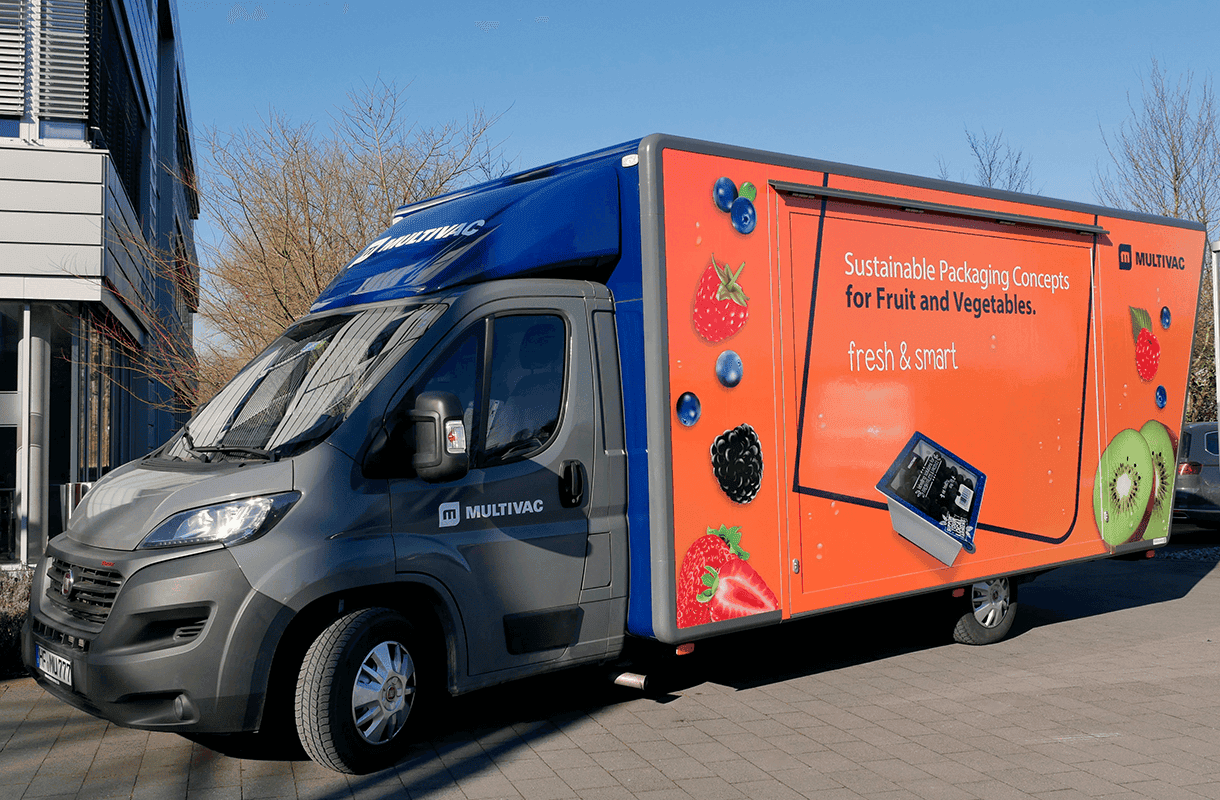

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com