The product and packaging are tempered

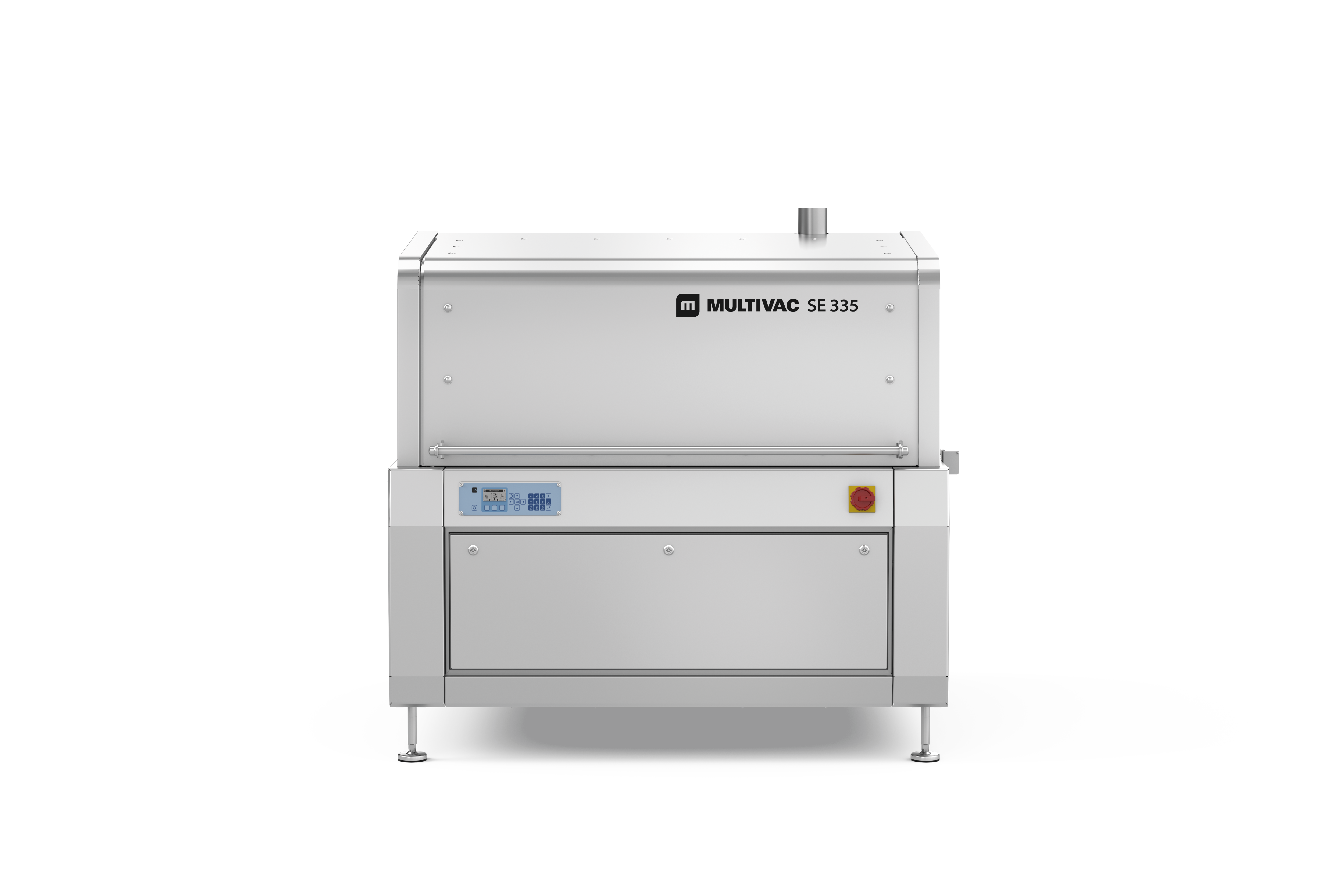

Shrinking and drying units from MULTIVAC guarantee perfect results with minimal temperature penetration and optimized energy consumption. They are easy to operate and very precise in their control. For optimum productivity, they fit seamlessly into new or existing production environments.

The different operating principles of MULTIVAC shrink units enable individual capacity and production flow requirements to be adapted perfectly. Shrink tanks or tunnels can easily be combined with packaging machines and downstream systems such as drying units to form automatic lines.

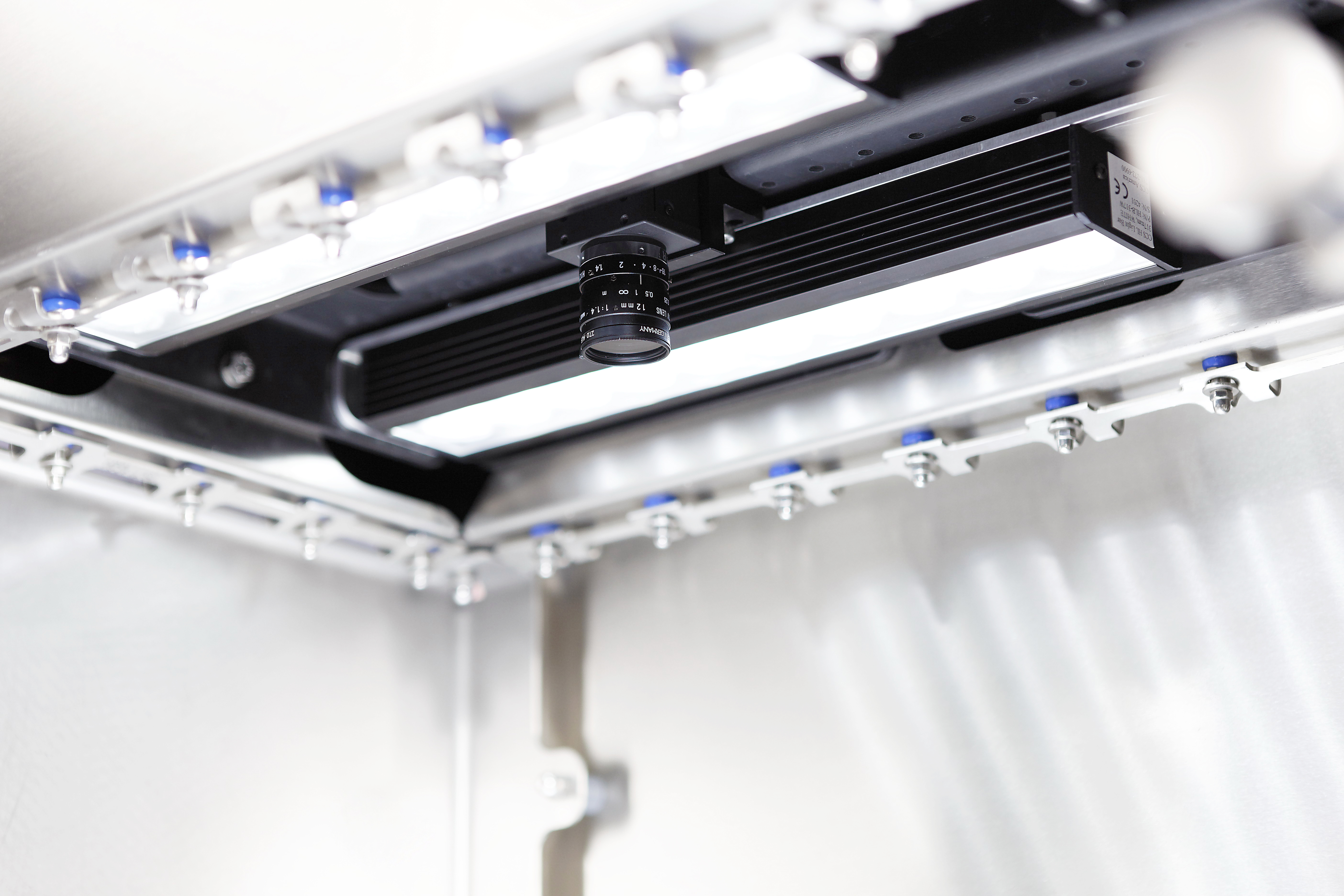

High-output drying process

MULTIVAC dryers, equipped with high-performance nozzles, significantly reduce the residual moisture after the shrinking process. In most cases, it is possible to label products directly after drying or pack them in boxes.