MULTIVAC Smart Services can do this for you

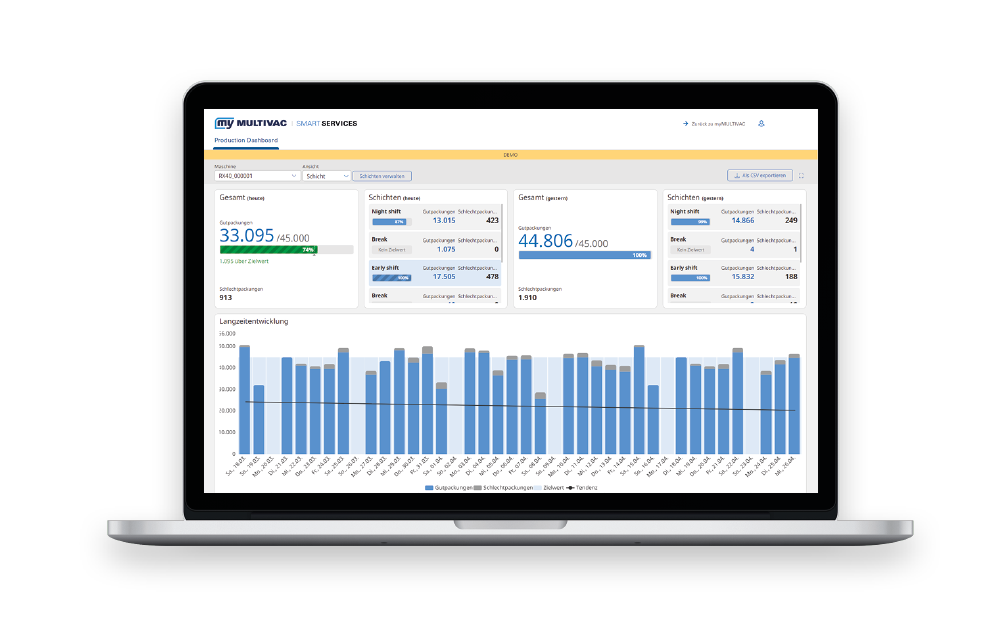

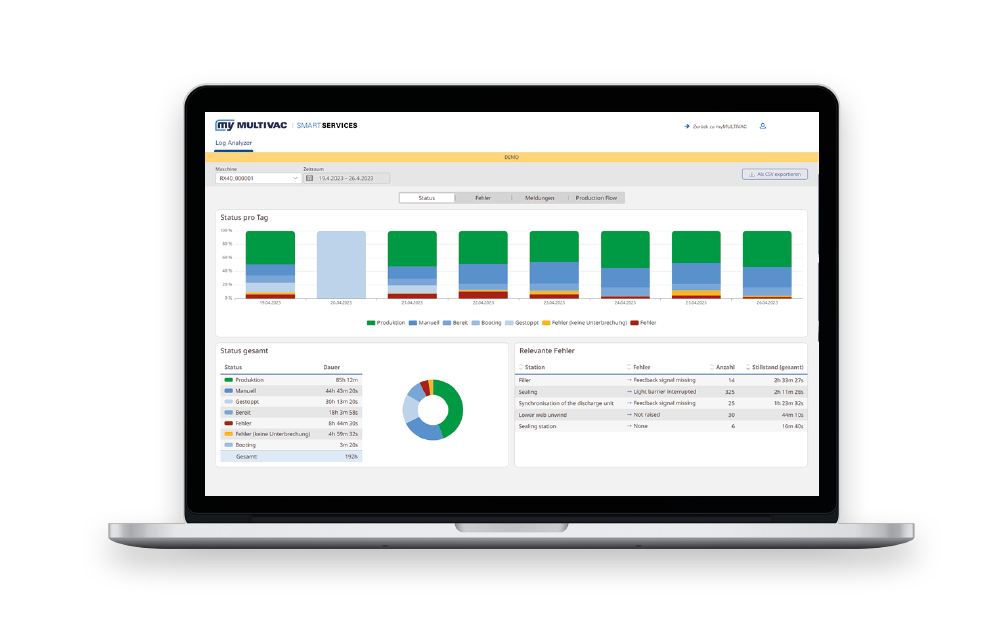

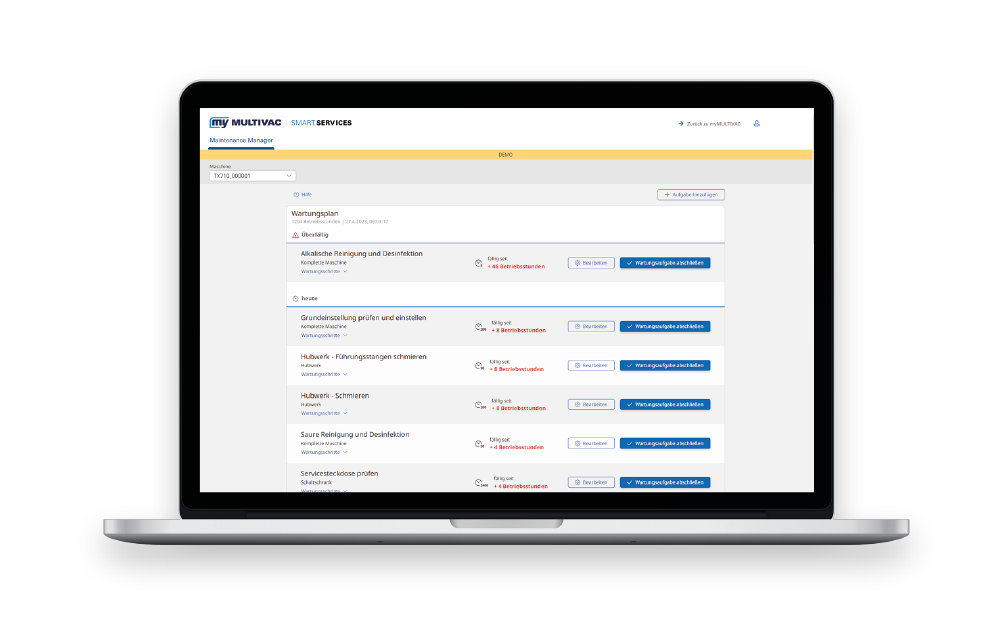

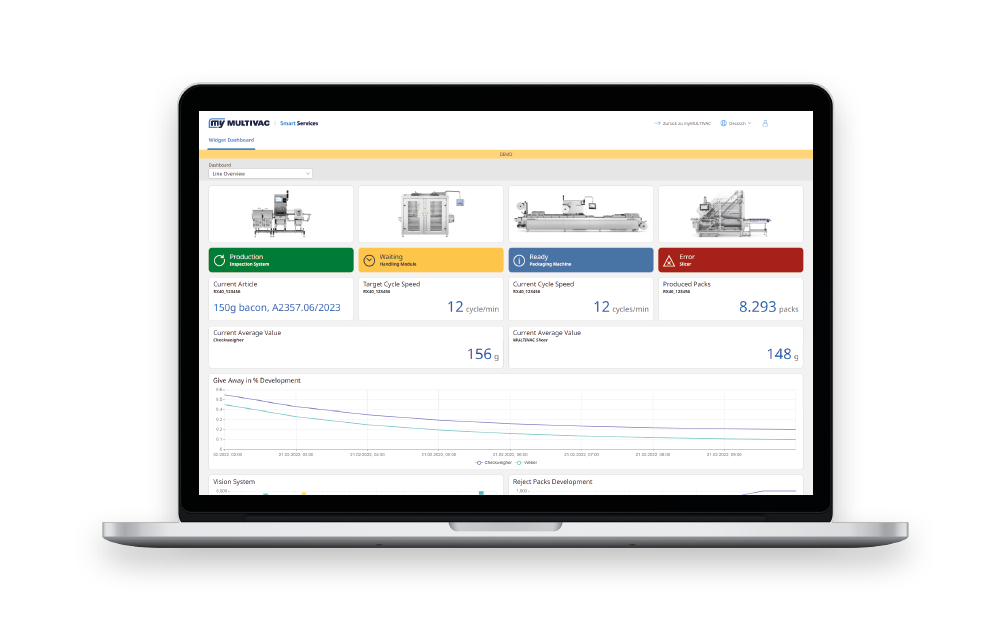

Availability and efficiency

Thanks to its groundbreaking digital solutions, MULTIVAC offers a wide range of tools for increasing machine availability, performance, quality, and efficiency. In addition, transparent processes and real-time data contribute to the effectiveness and cost-effectiveness of systems and lines.

Networked and convenient

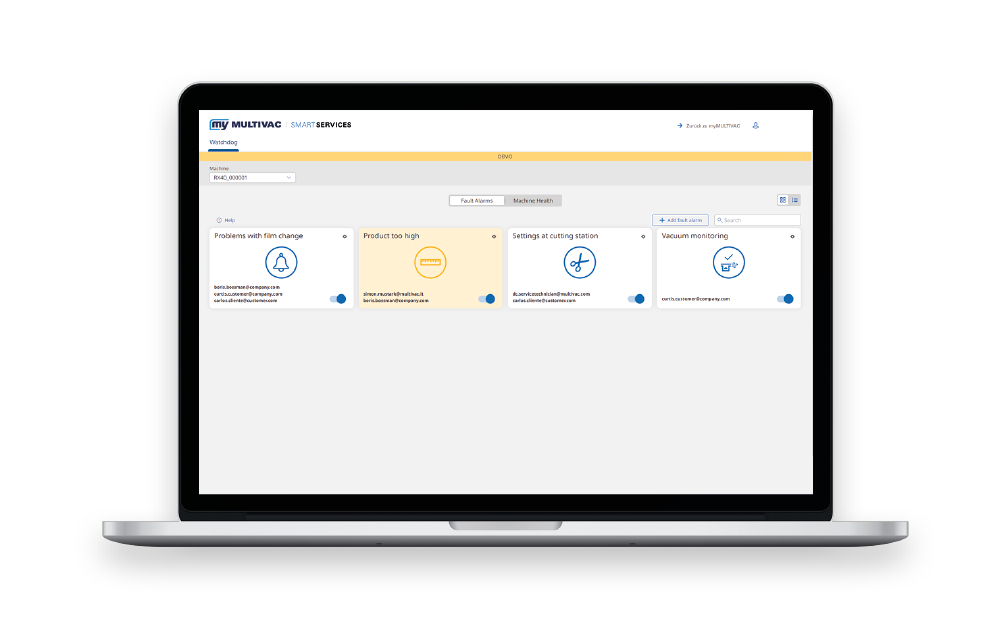

With MULTIVAC's digital products and services, we offer you innovative solutions for monitoring, controlling, and optimizing production. Available across all locations from anywhere in the world. Straightforward setup via the control cabinet, immediate use to go live for new equipment, and retrofitting to existing machines.

Added value for the machine operator right up to the managing director

The use of MULTIVAC Smart Services does not require a significant start-up investment. The well-established standard range of digital solutions is constantly improved and developed further - central to the customer's needs. Individuality? No problem; we can build a customized solution for you. The appropriate application waits for you beyond those of the machine operator or business manager.

MULTIVAC Smart Services

Future-proof solutions for monitoring, controlling and optimising your MULTIVAC machines

- Size

- 11 MB

- Format