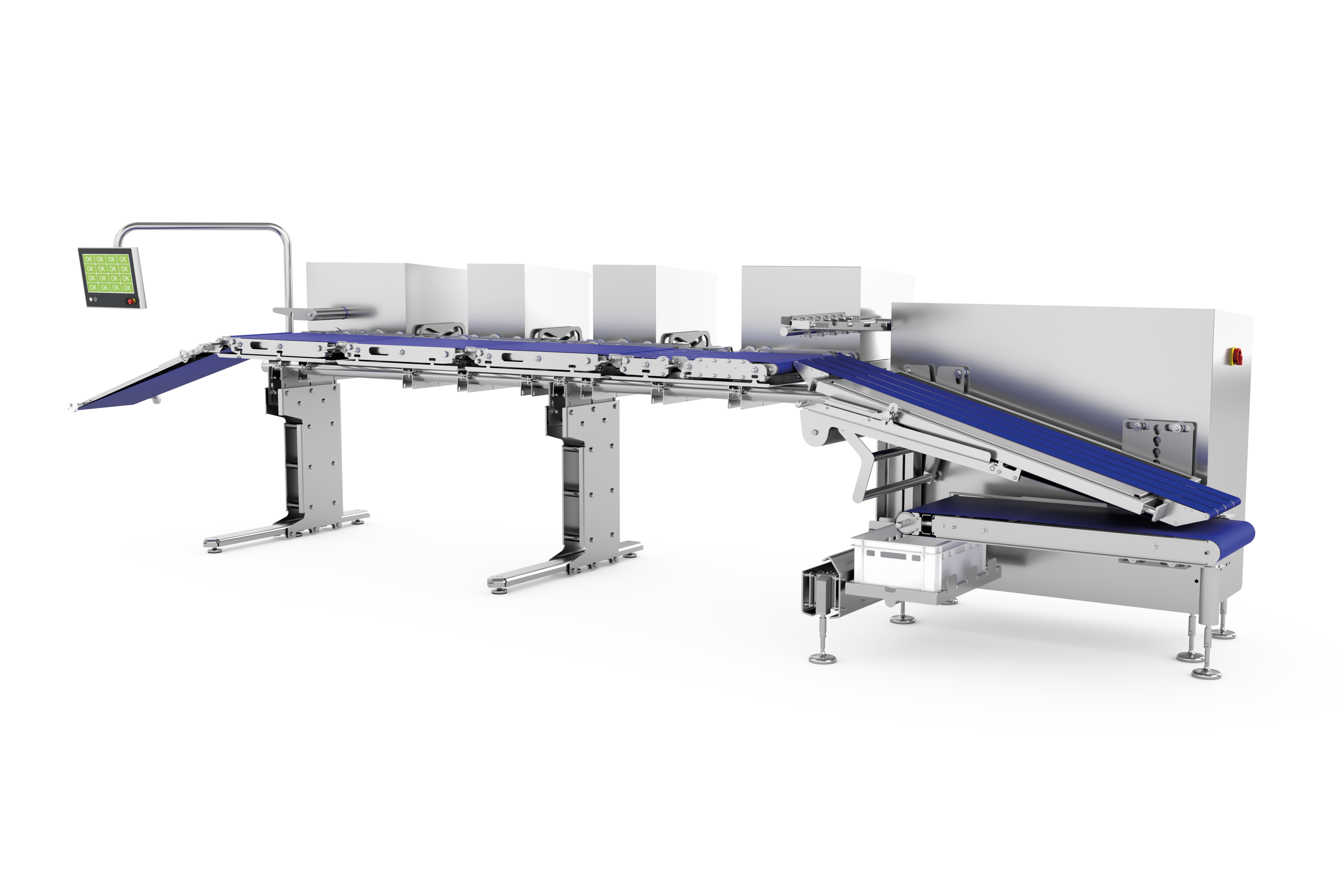

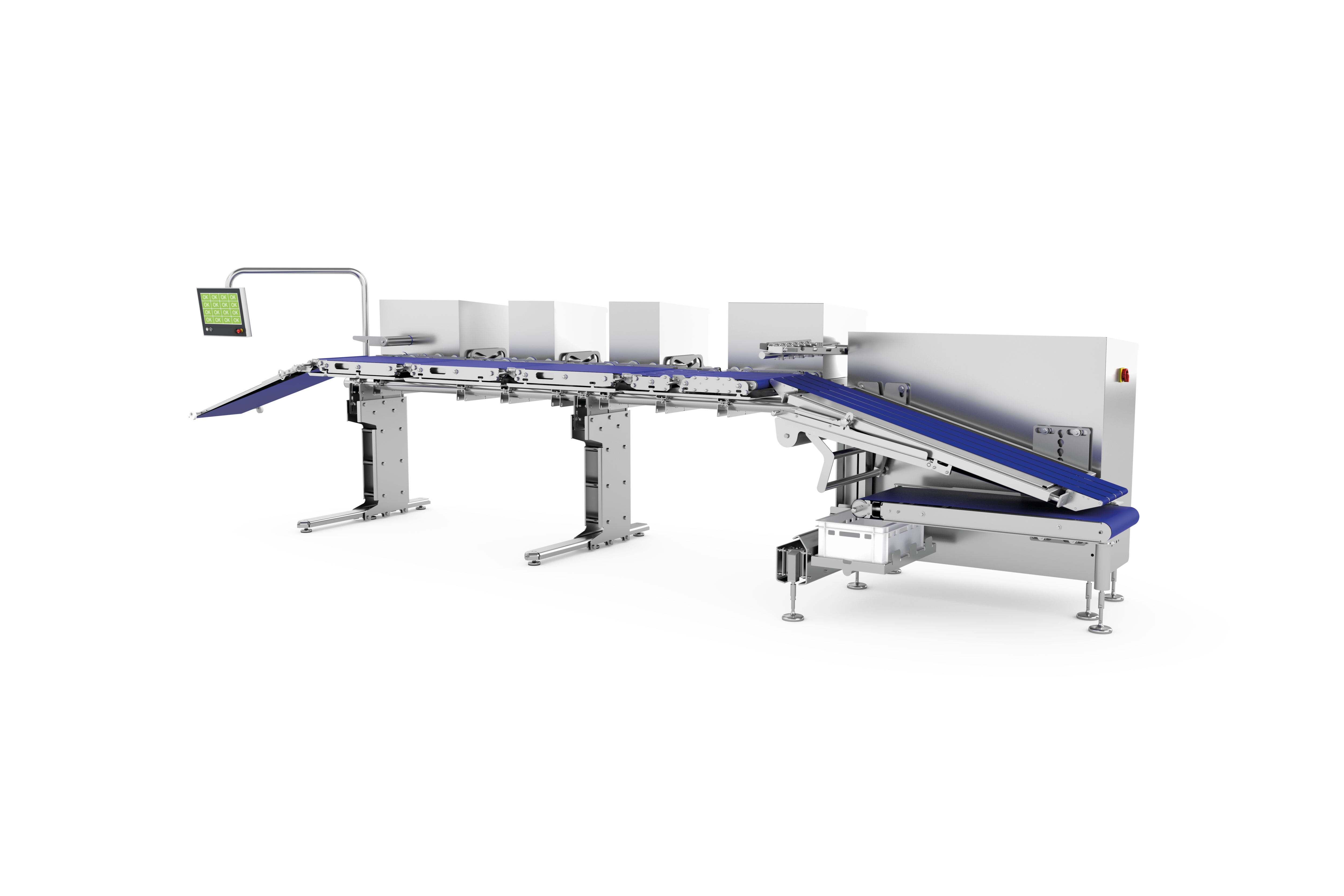

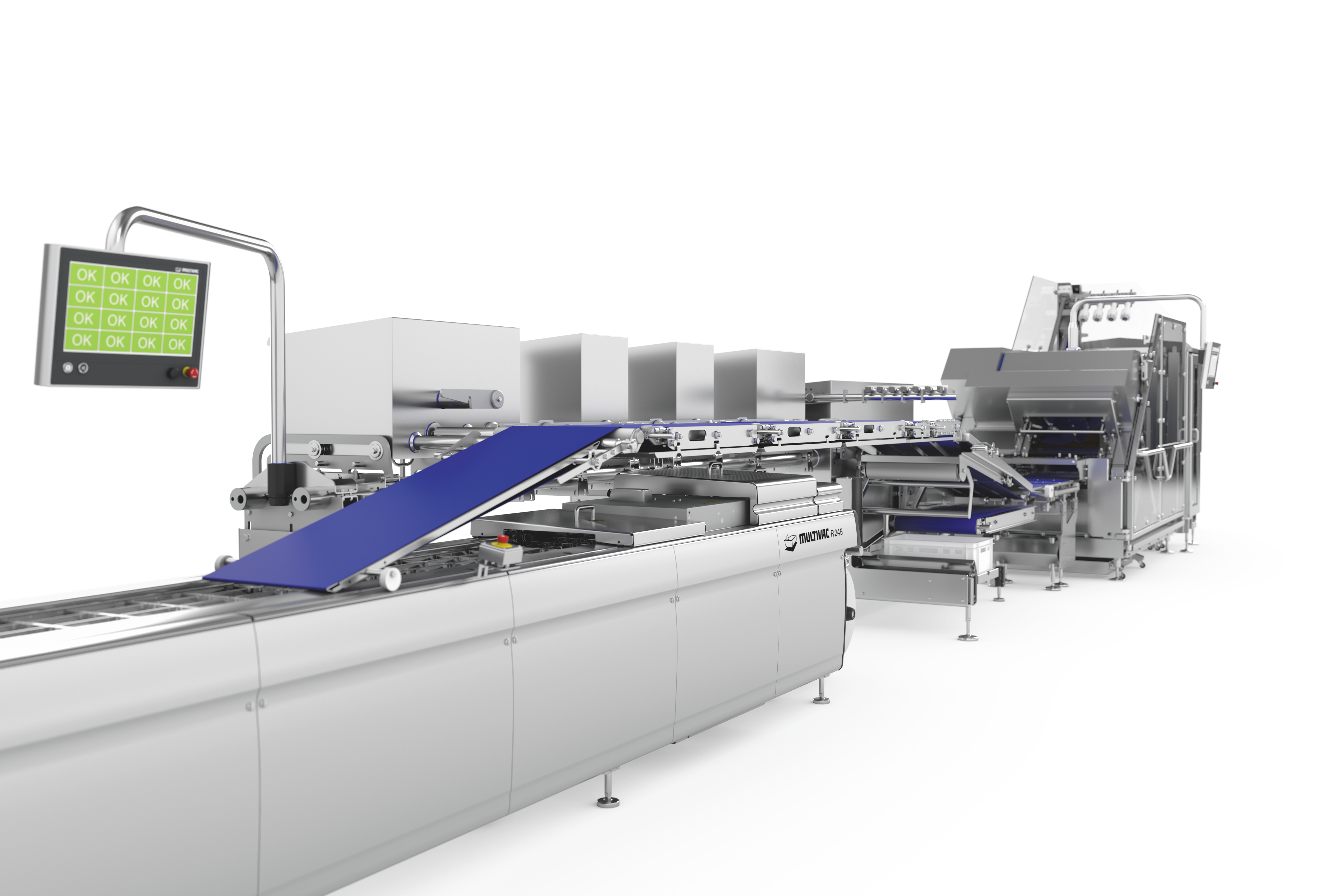

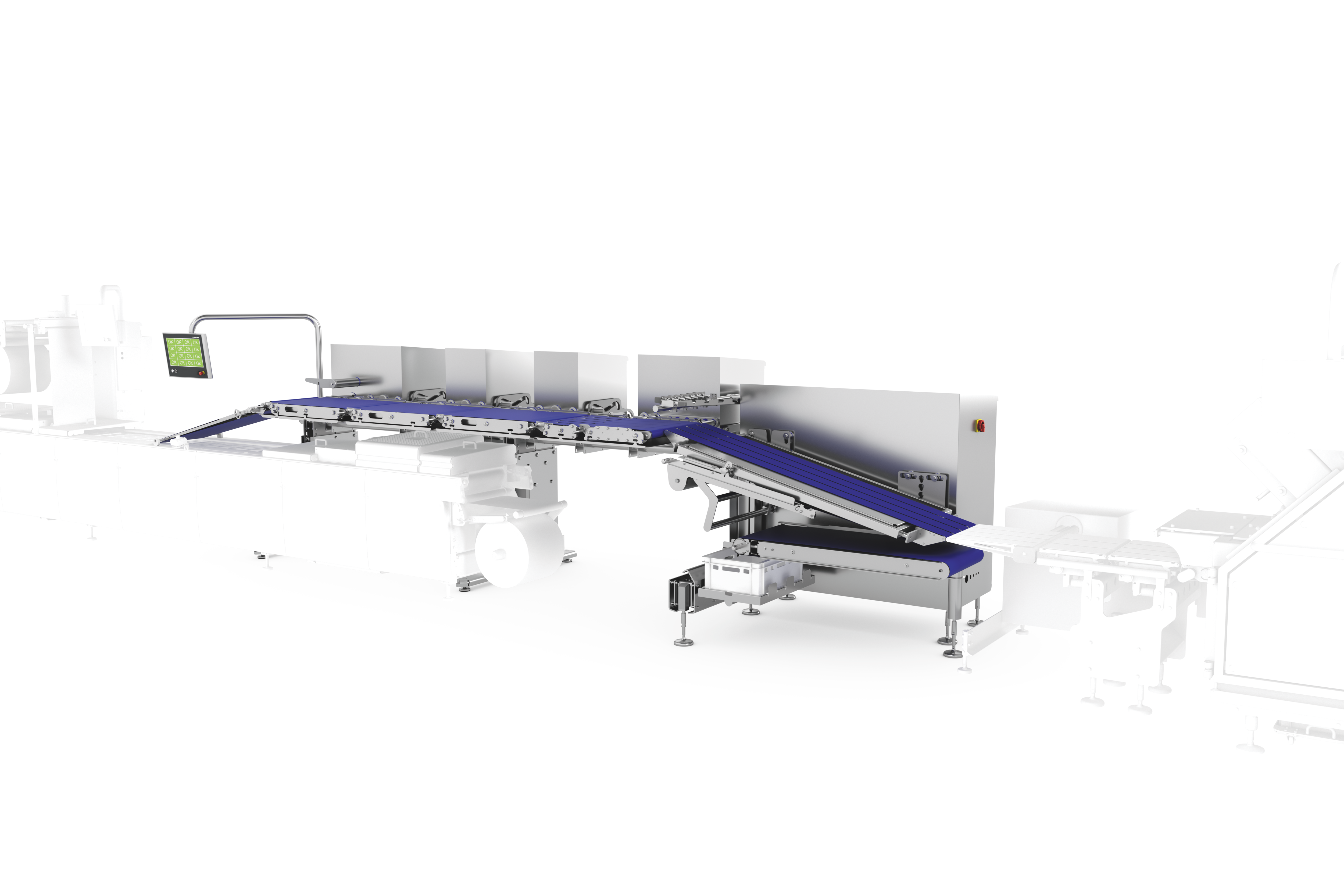

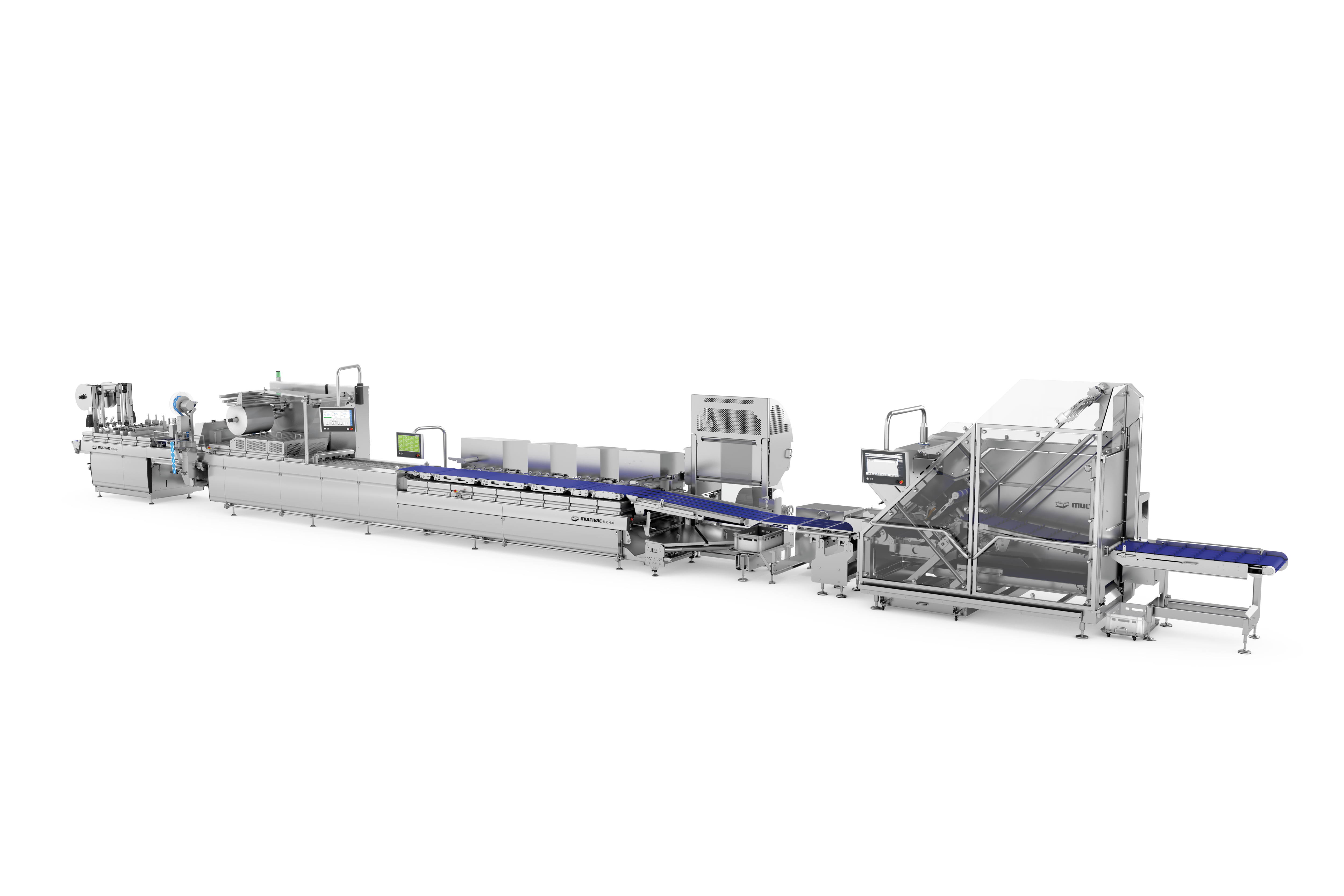

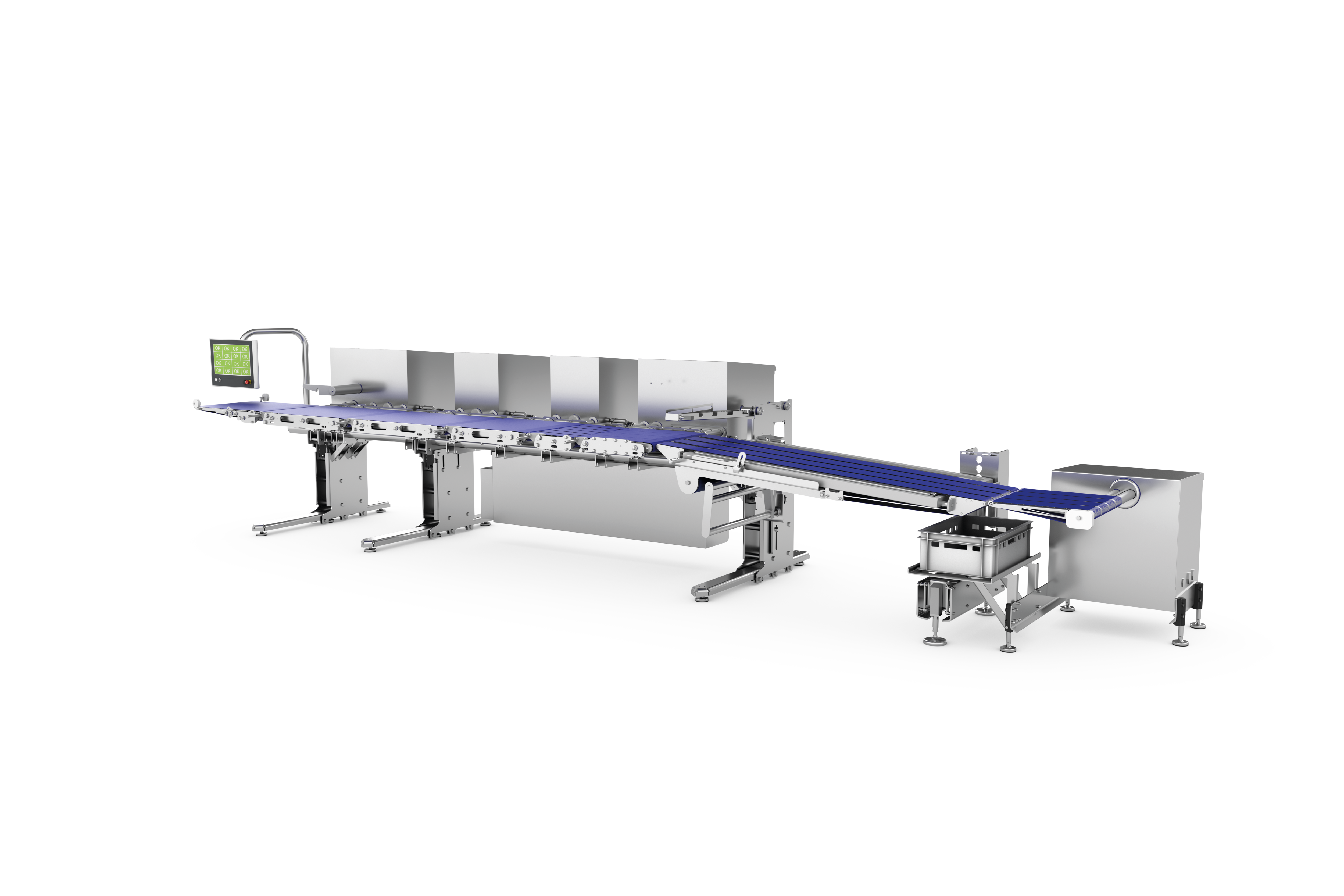

Features of the MULTIVAC Belt Loader Systems

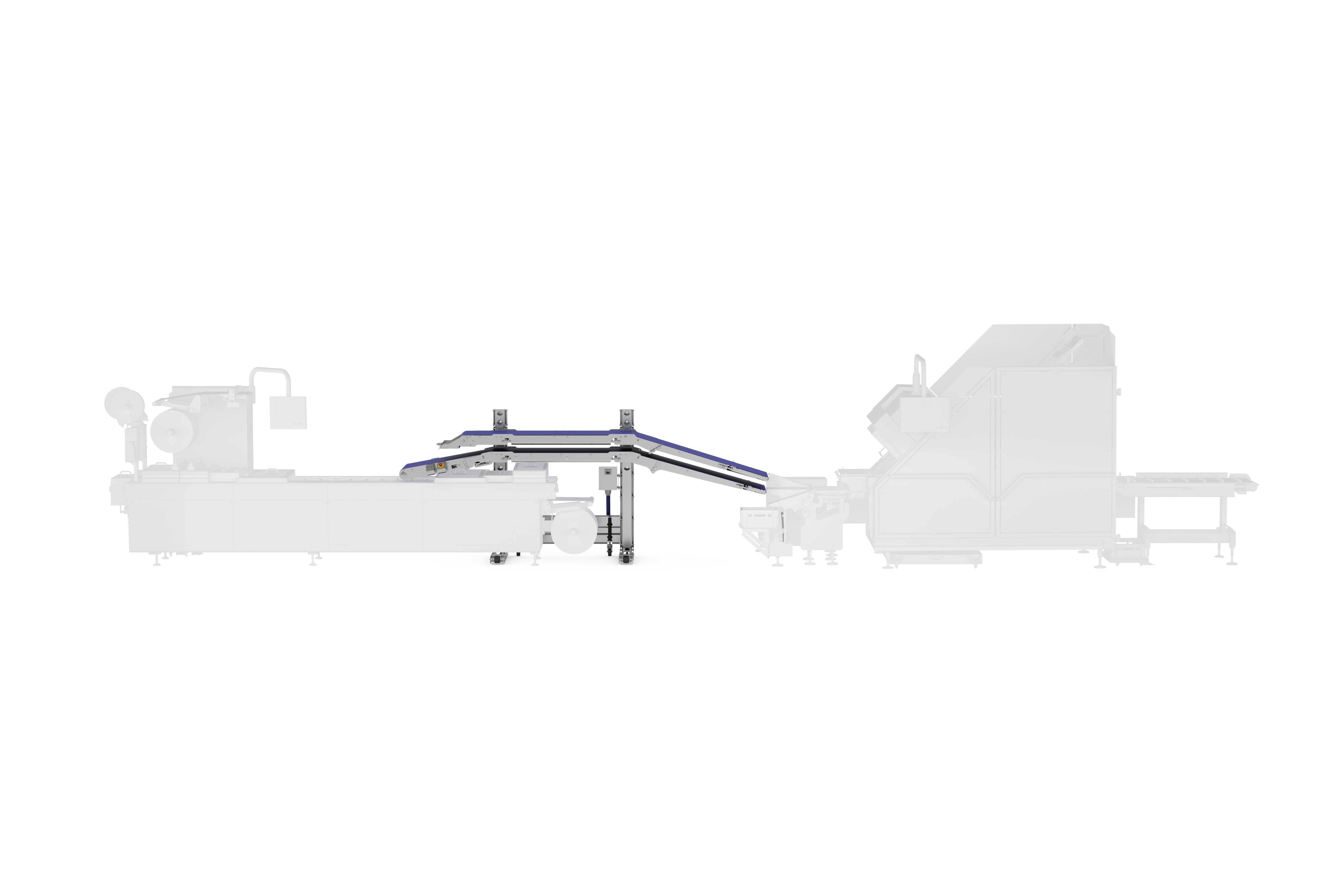

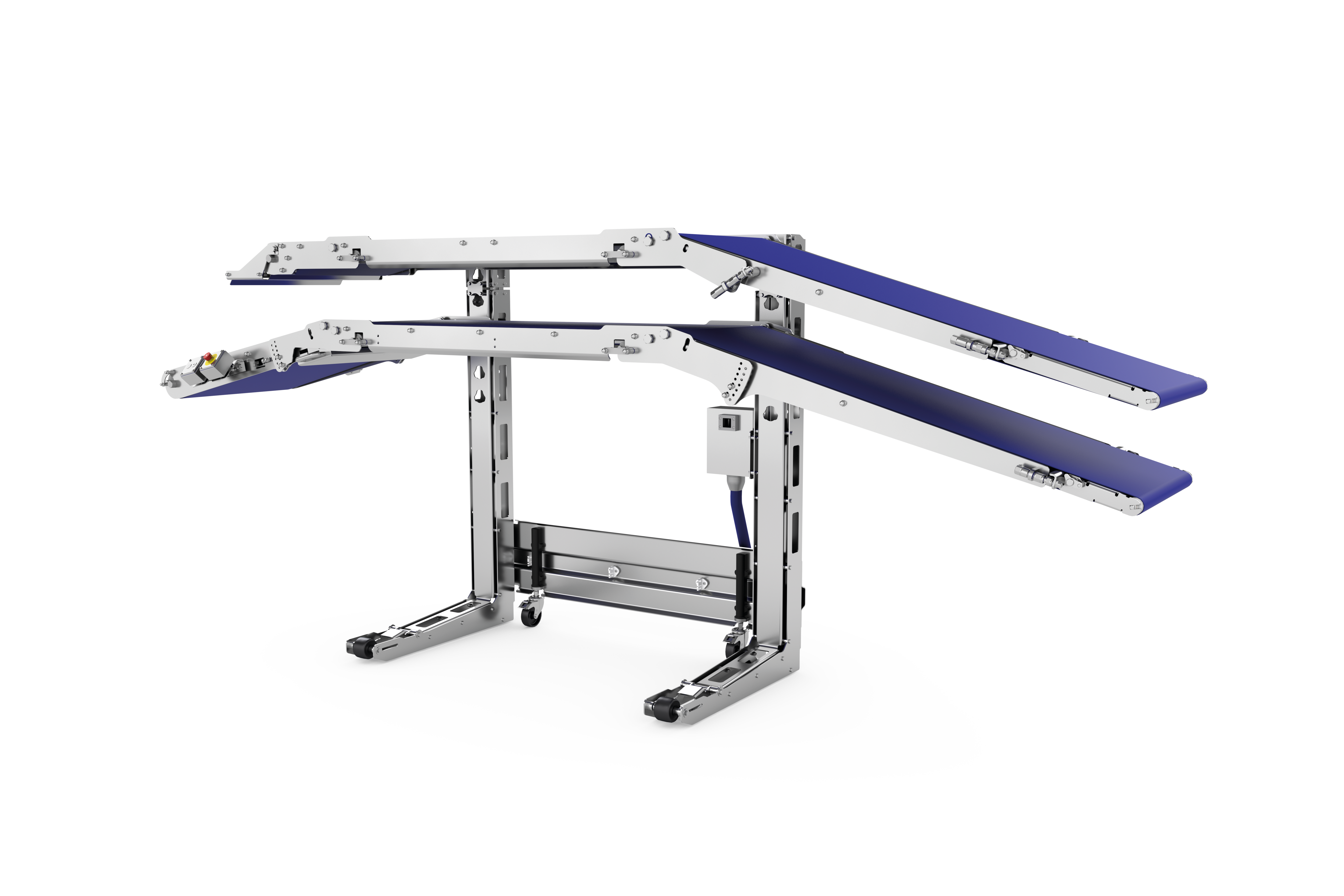

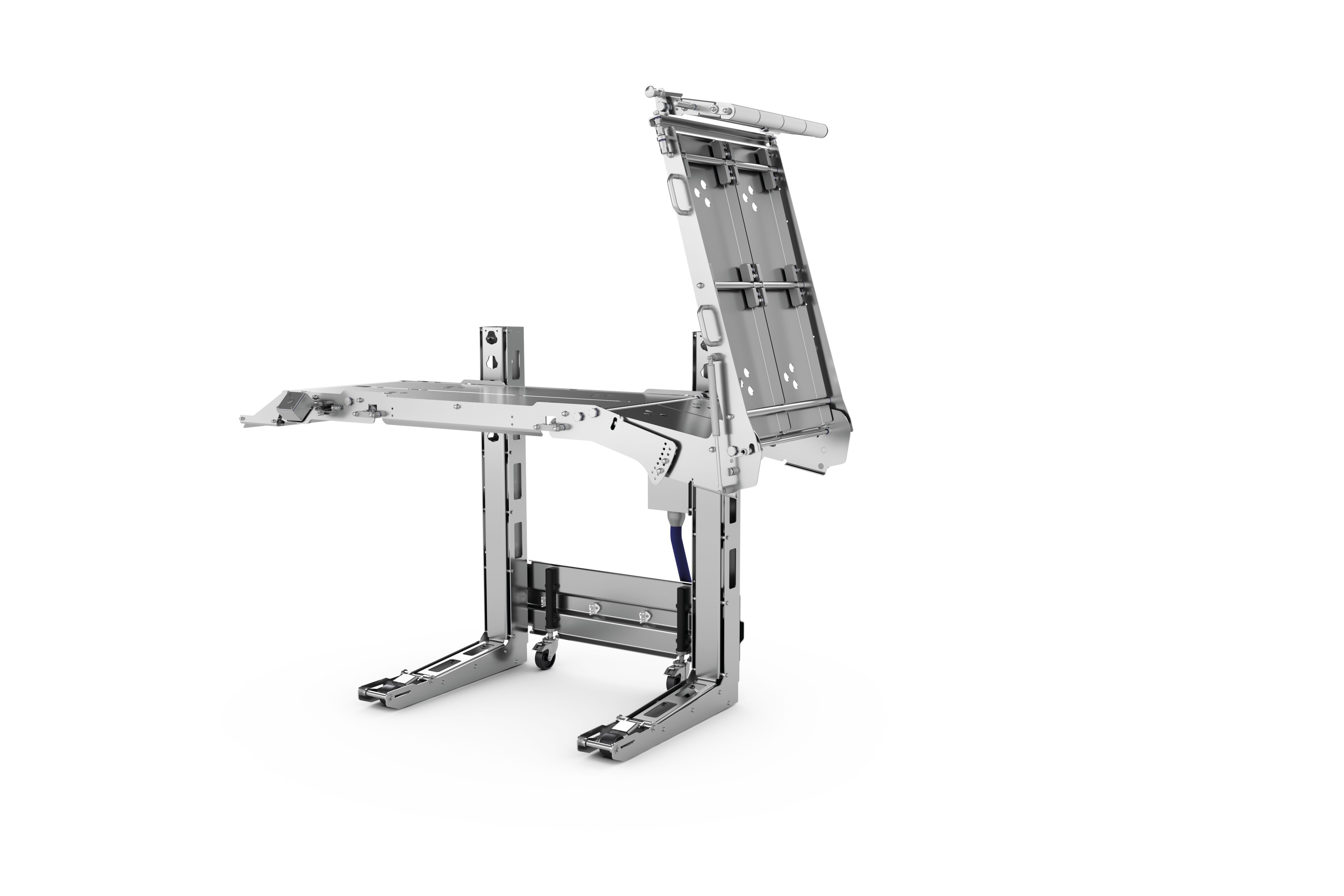

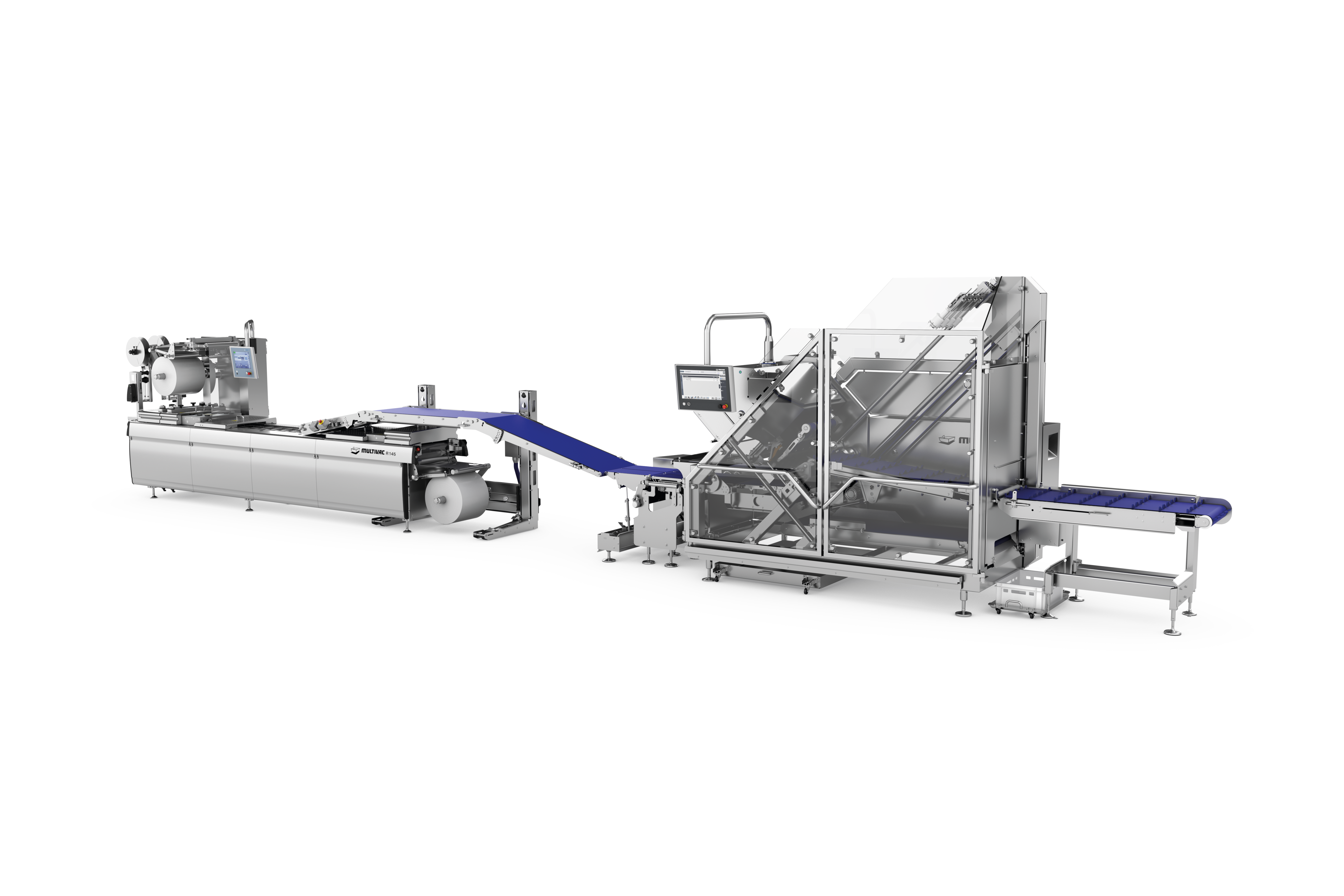

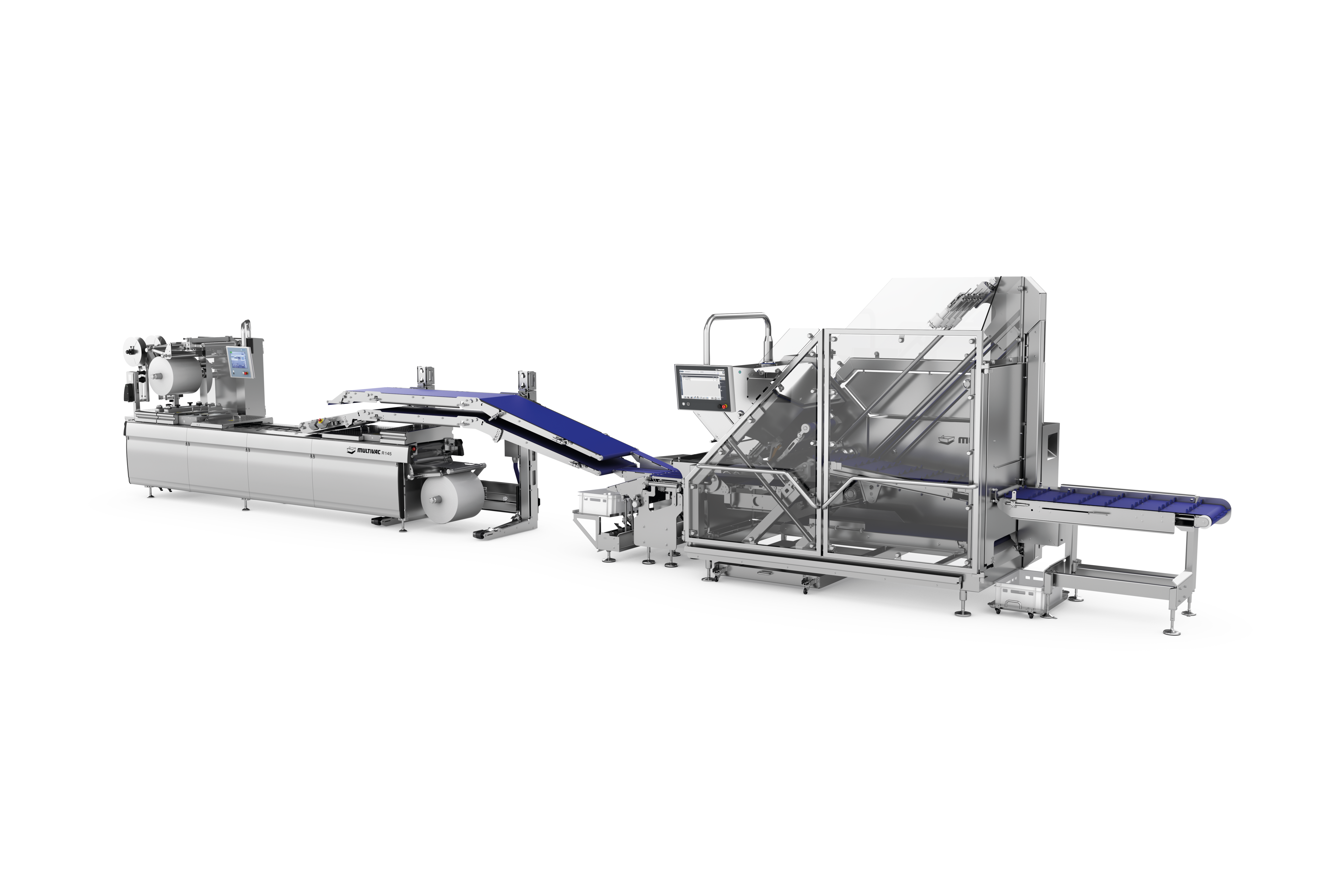

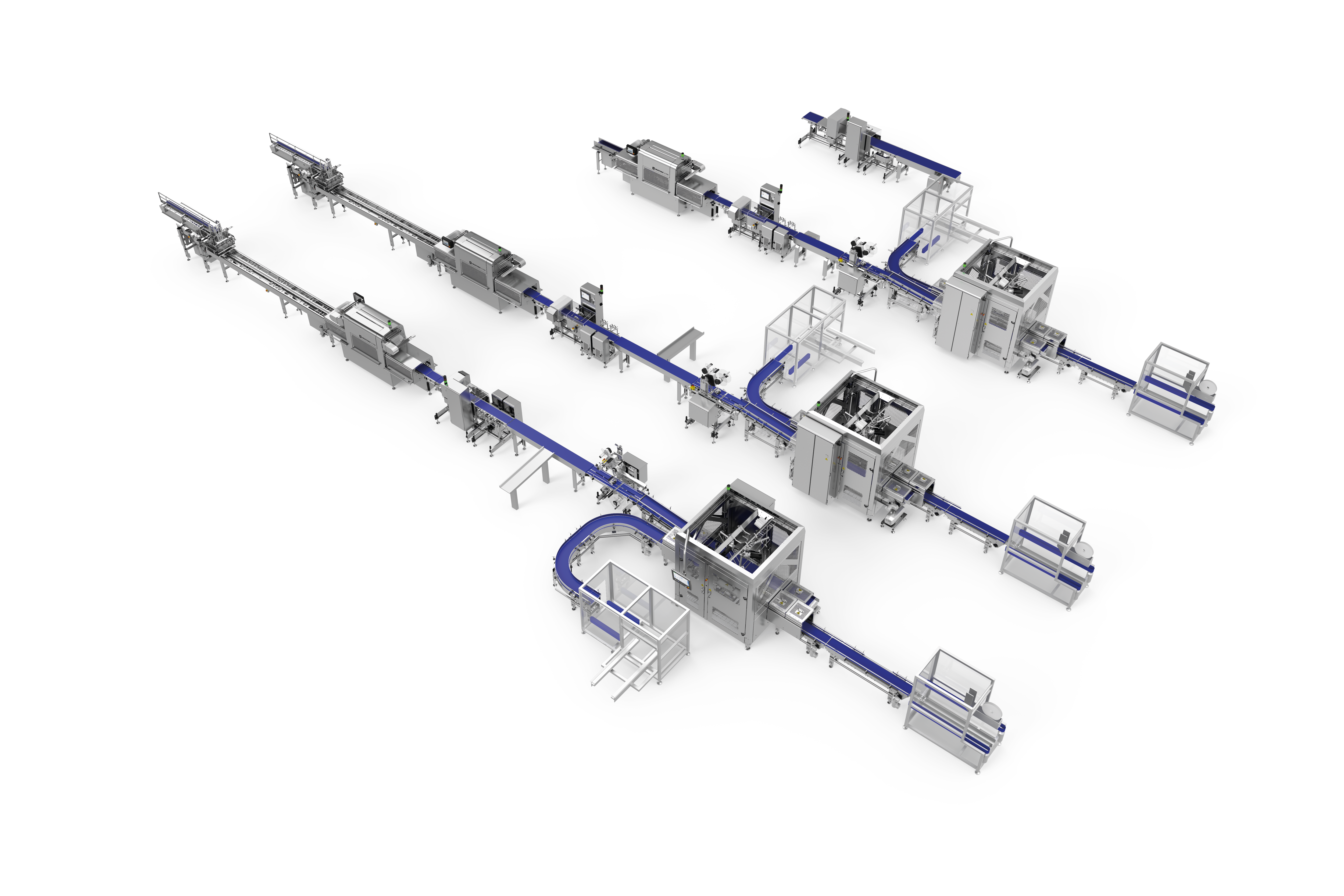

The MULTIVAC portfolio offers the best solution for linking slicers to packaging systems, allowing us to meet individualized customer requirements with different variants of high-performance belt loaders.

Whether you're seeking the highest possible output and maximum productivity with an automatic belt loader or simplifying your operation with a manual belt loader, our future-proof complete solutions feature high levels of efficiency, simple operation, and maximum hygiene.

MULTIVAC loading systems offer enormous time saving for your production process and can be integrated flexibly into your existing MULTIVAC equipment.