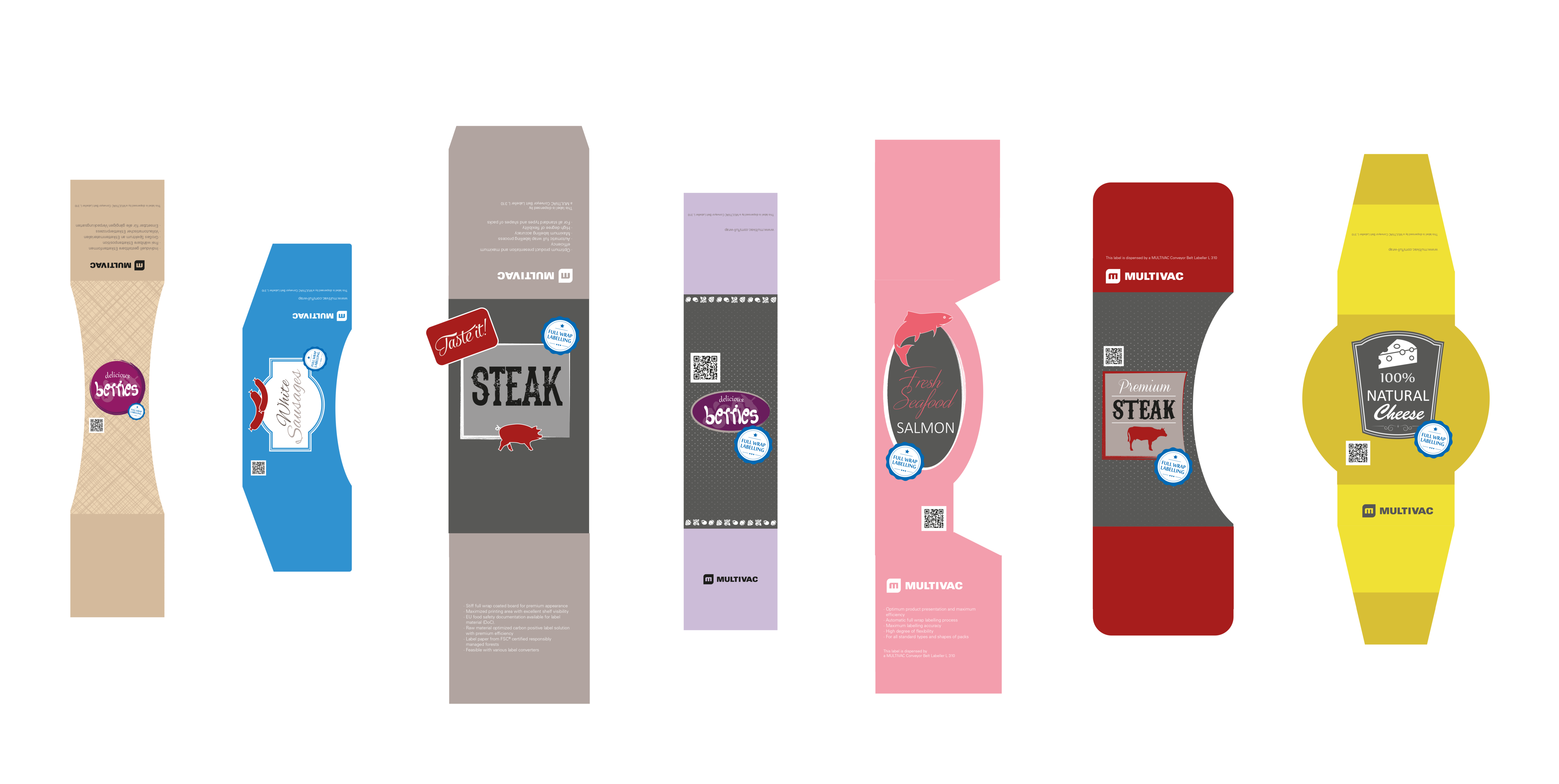

Seamlessly integrated - labelling and marking solutions with added value

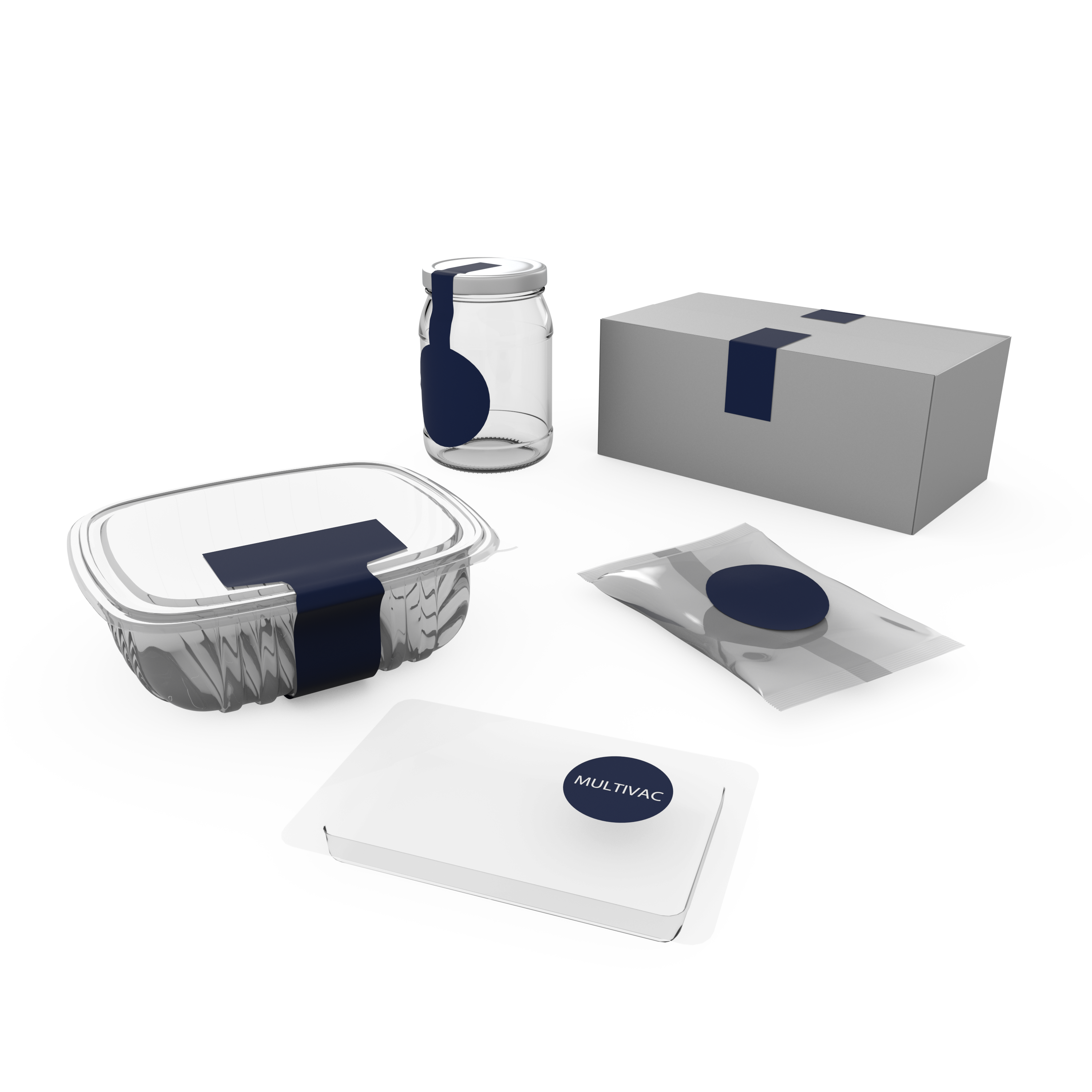

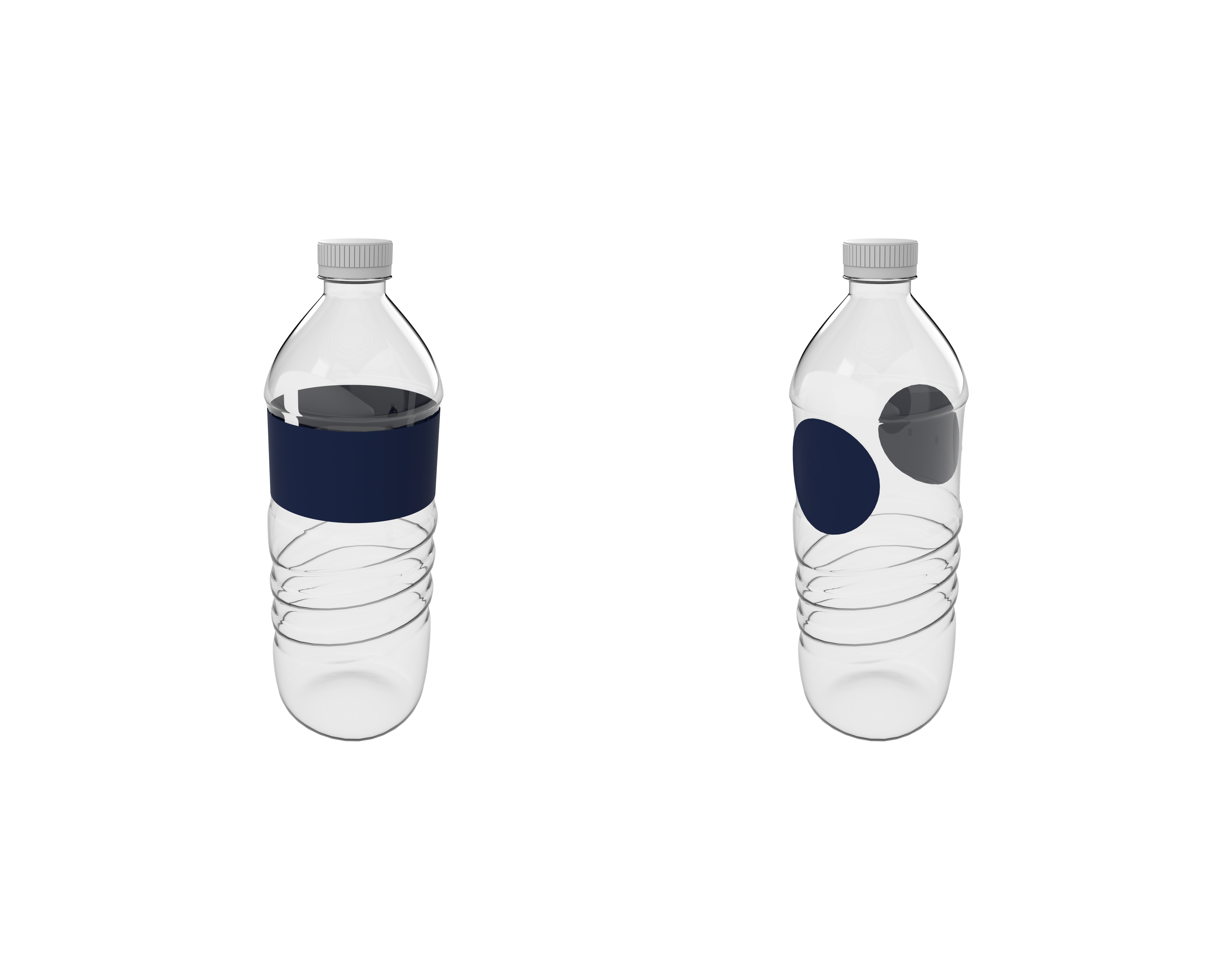

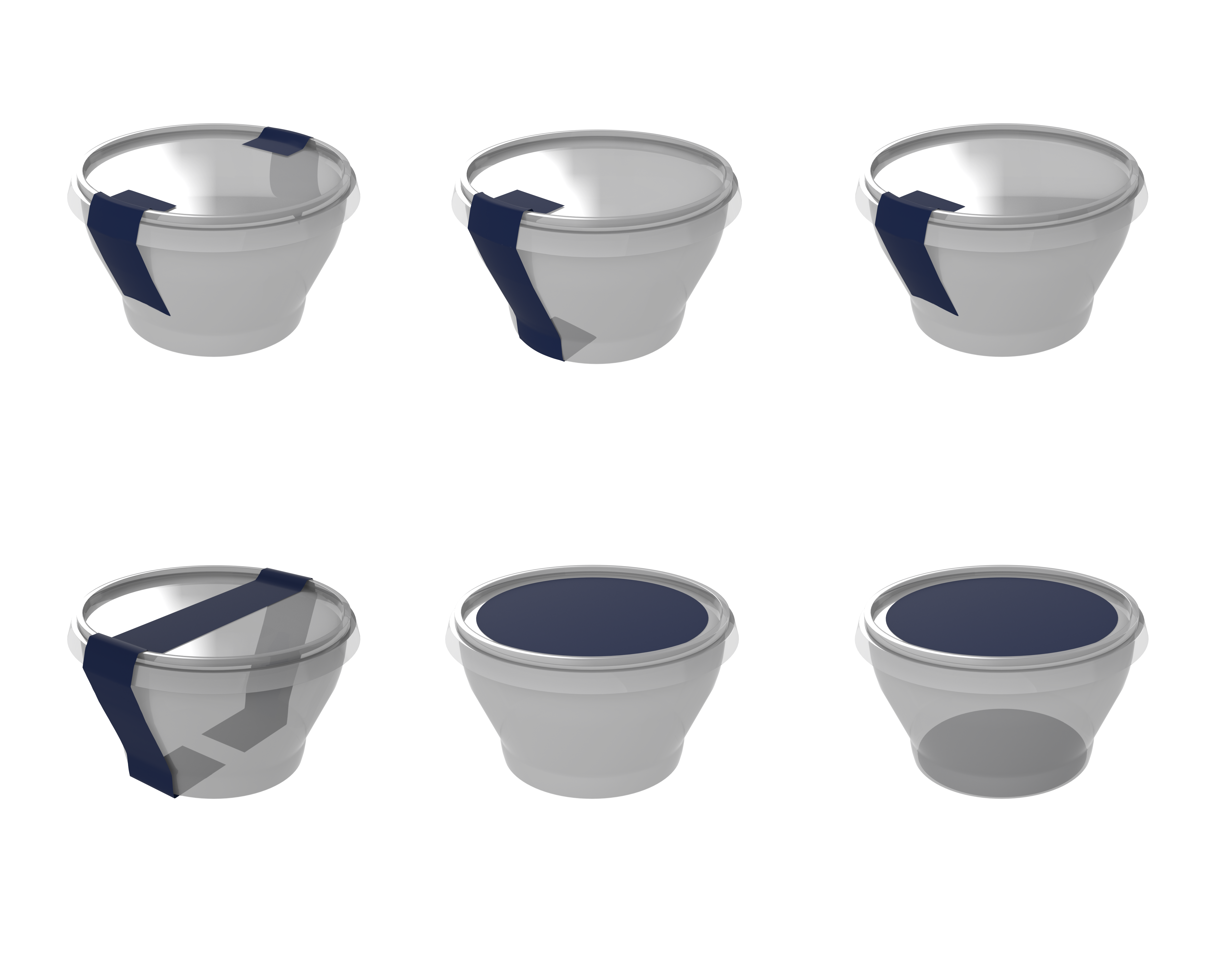

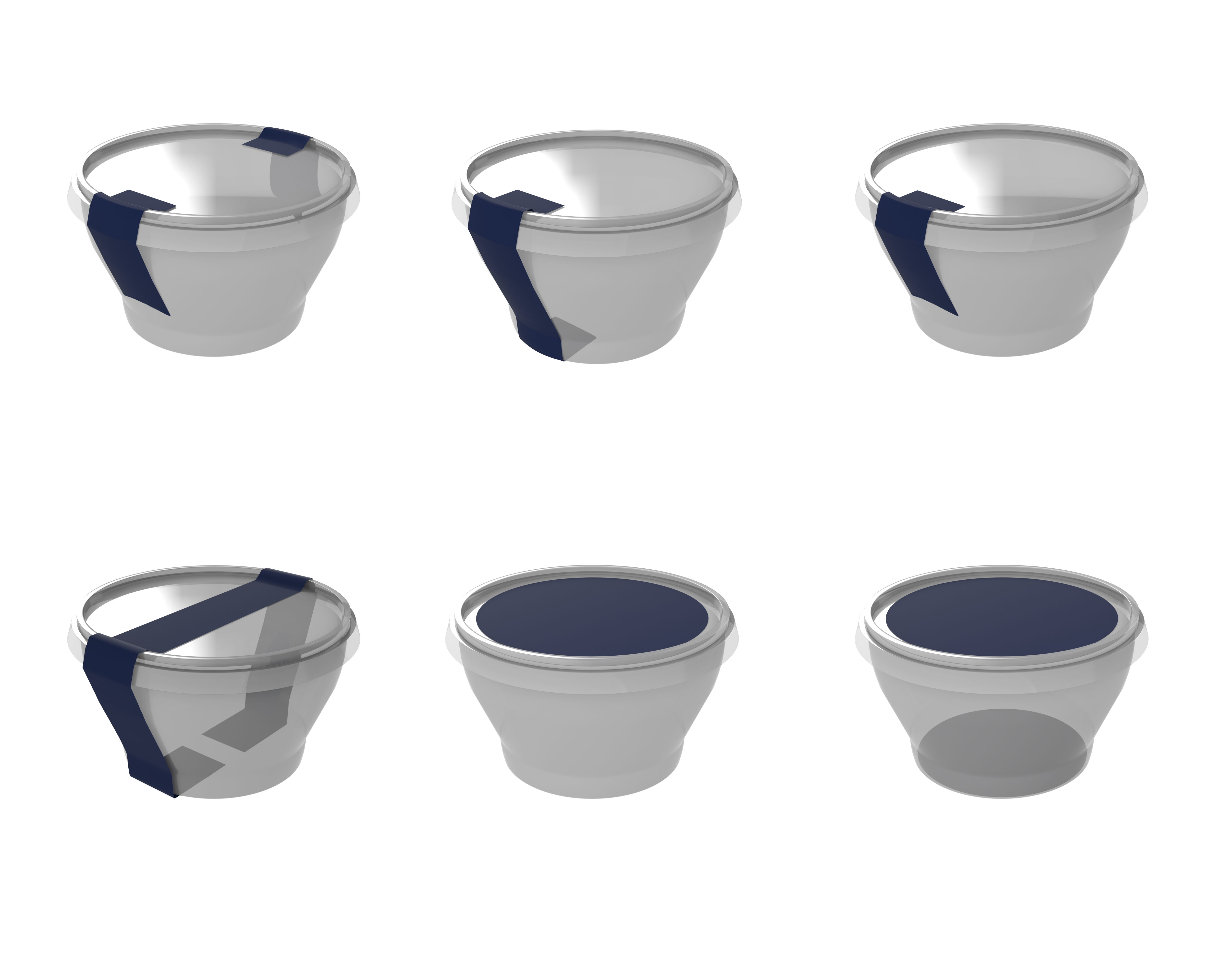

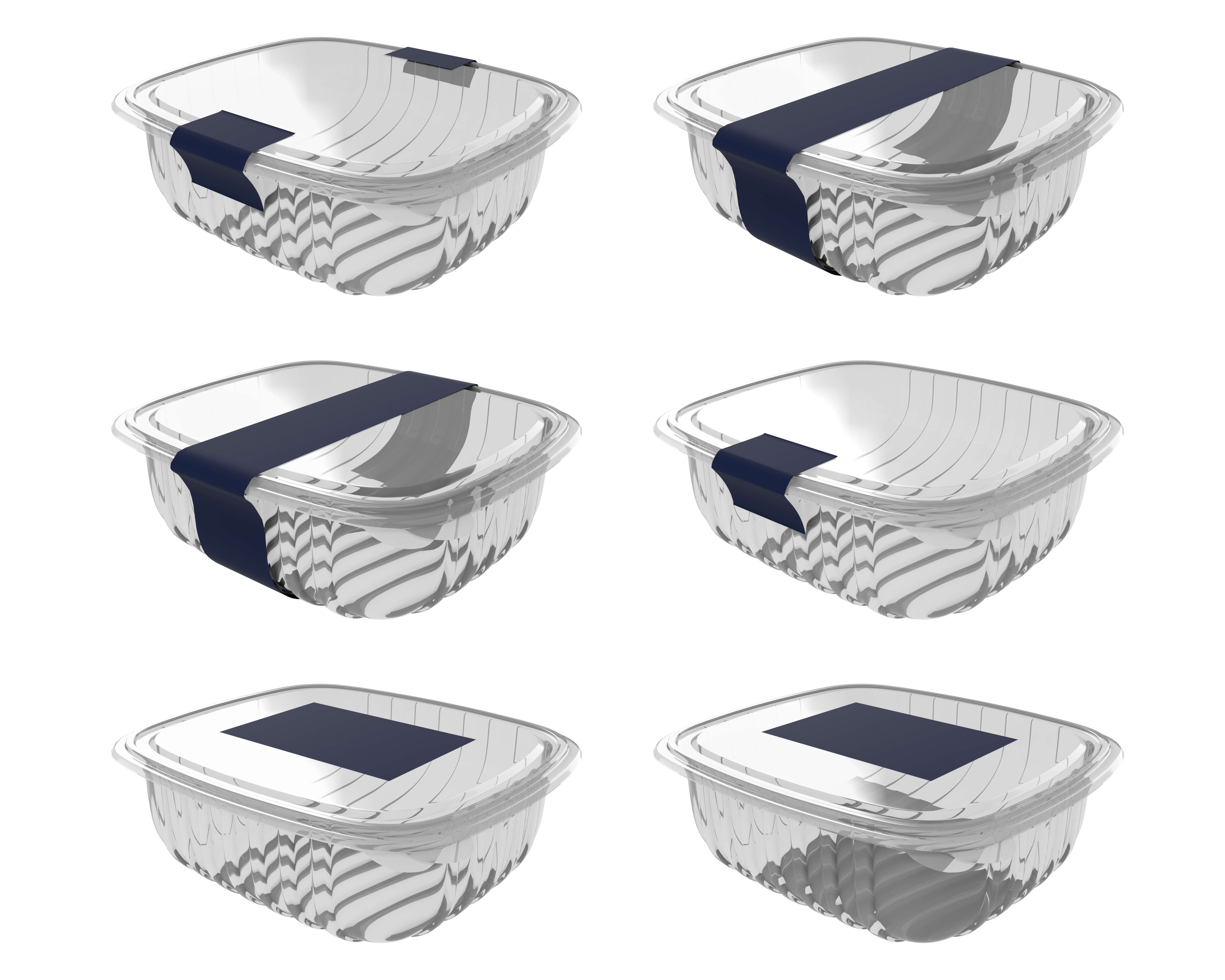

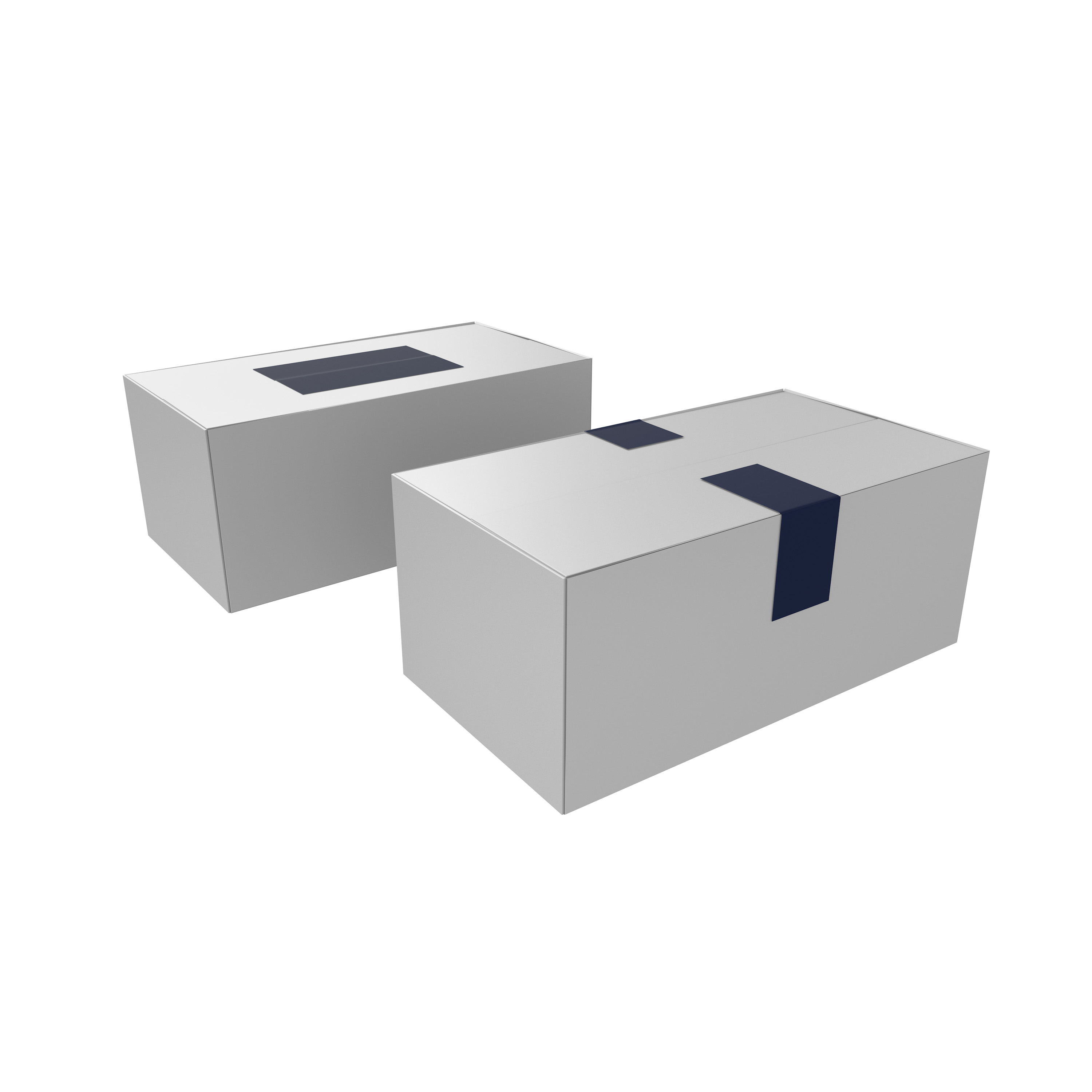

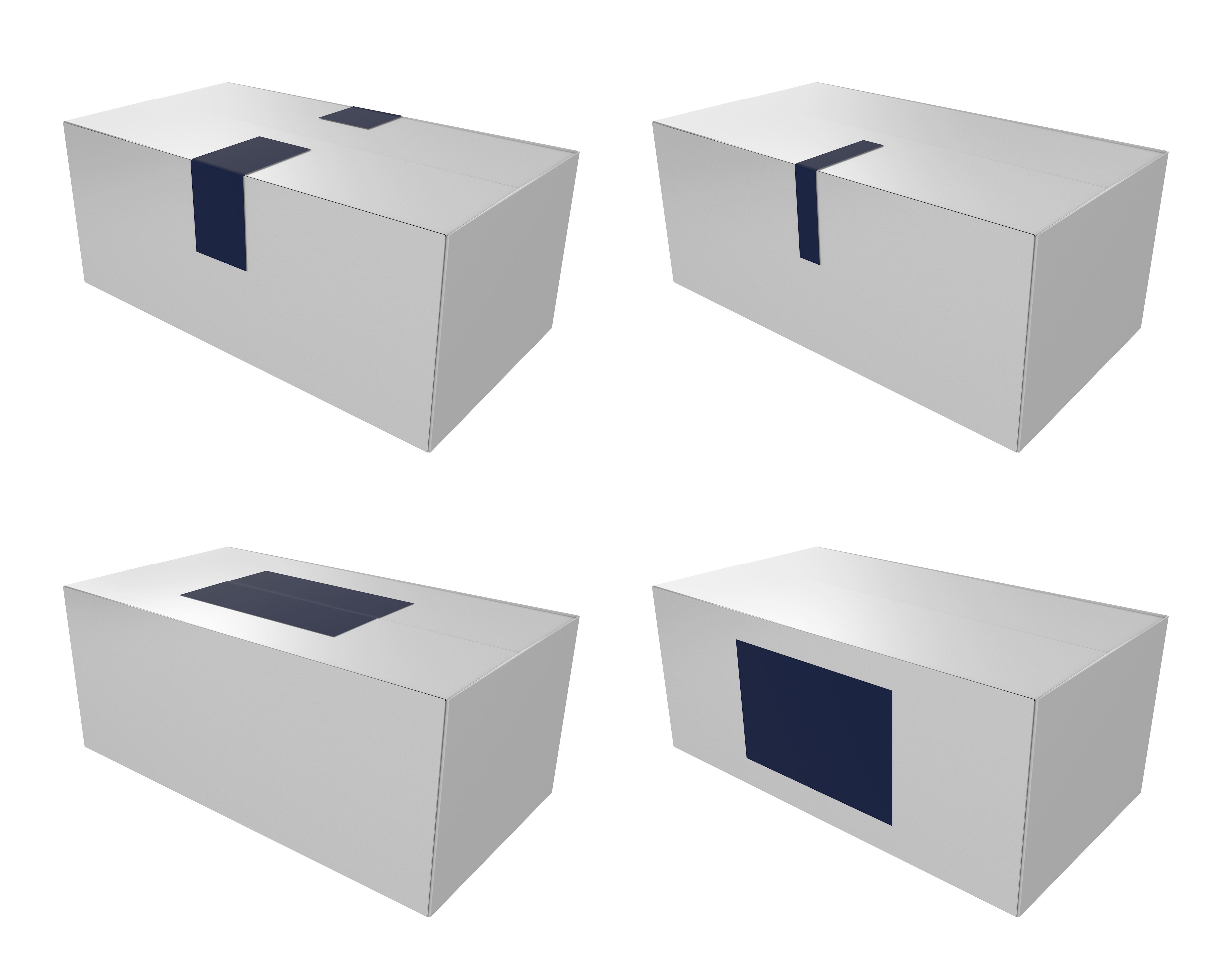

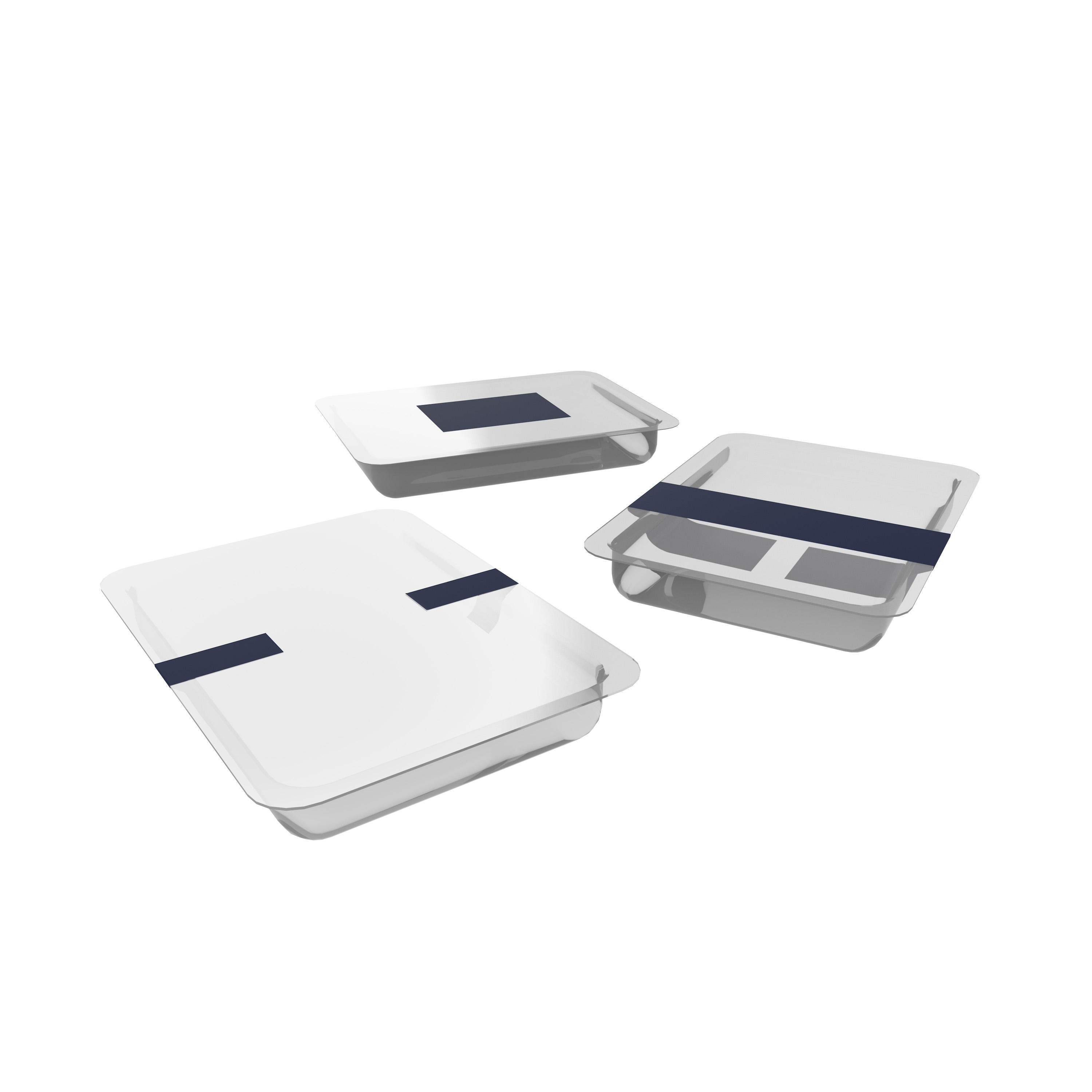

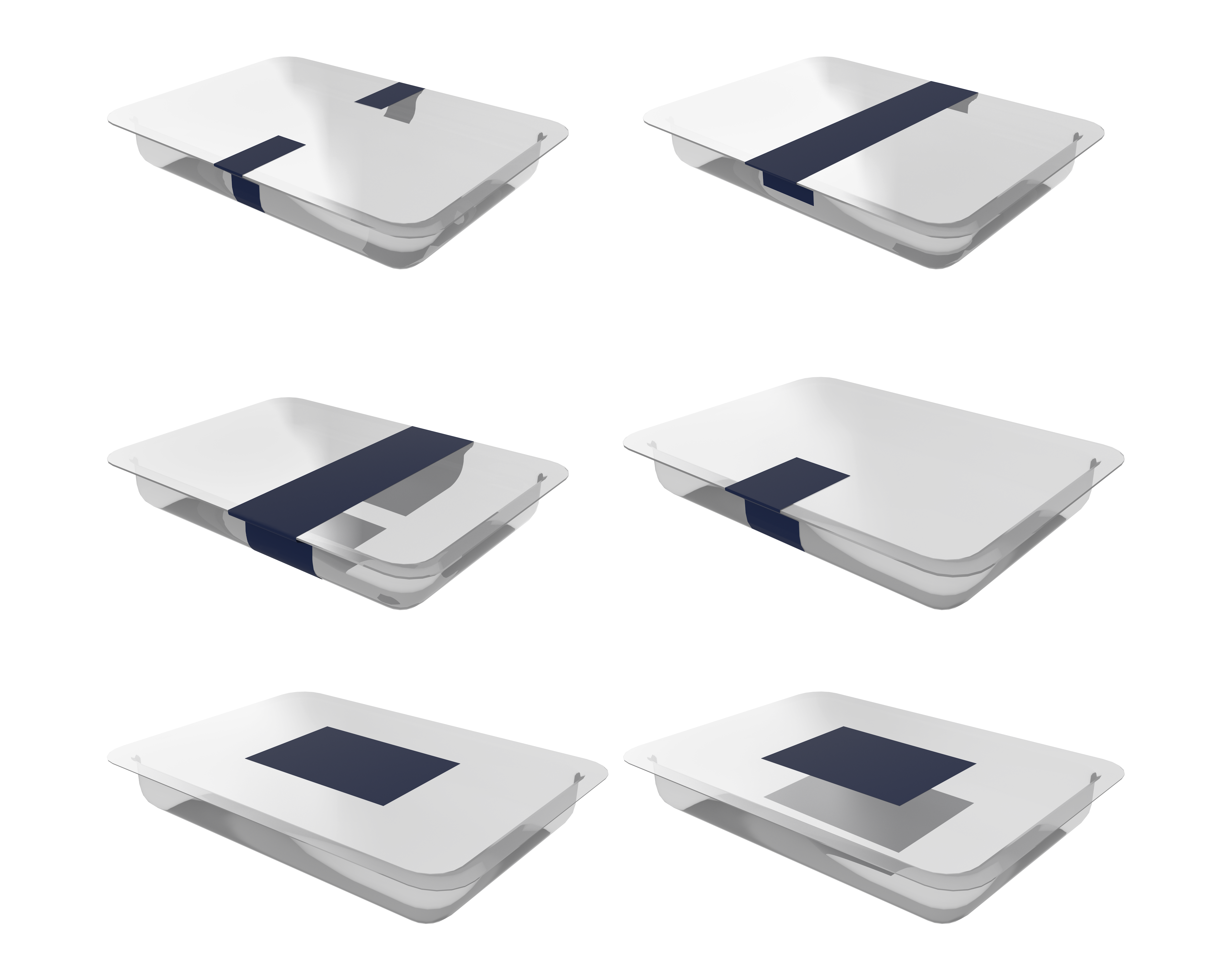

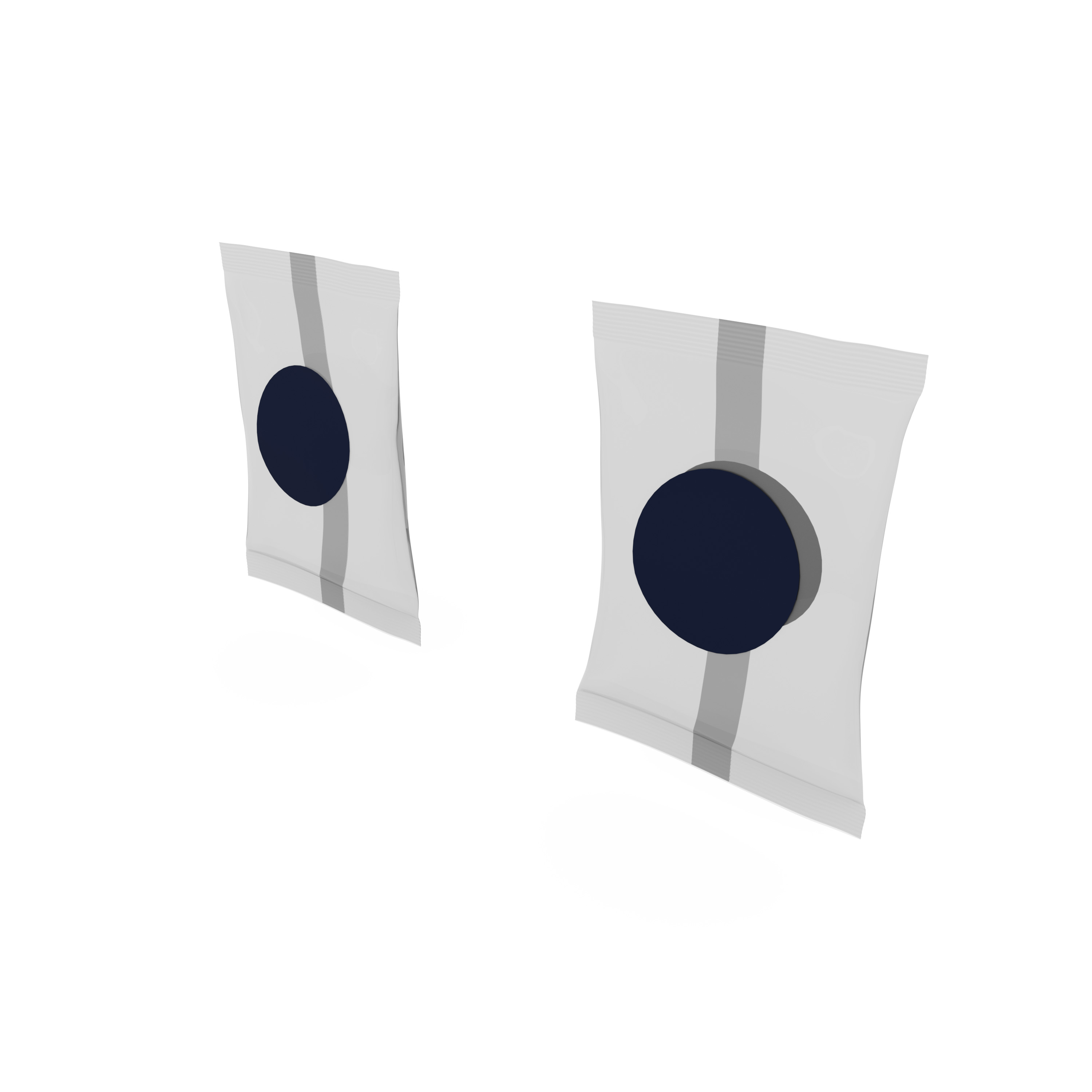

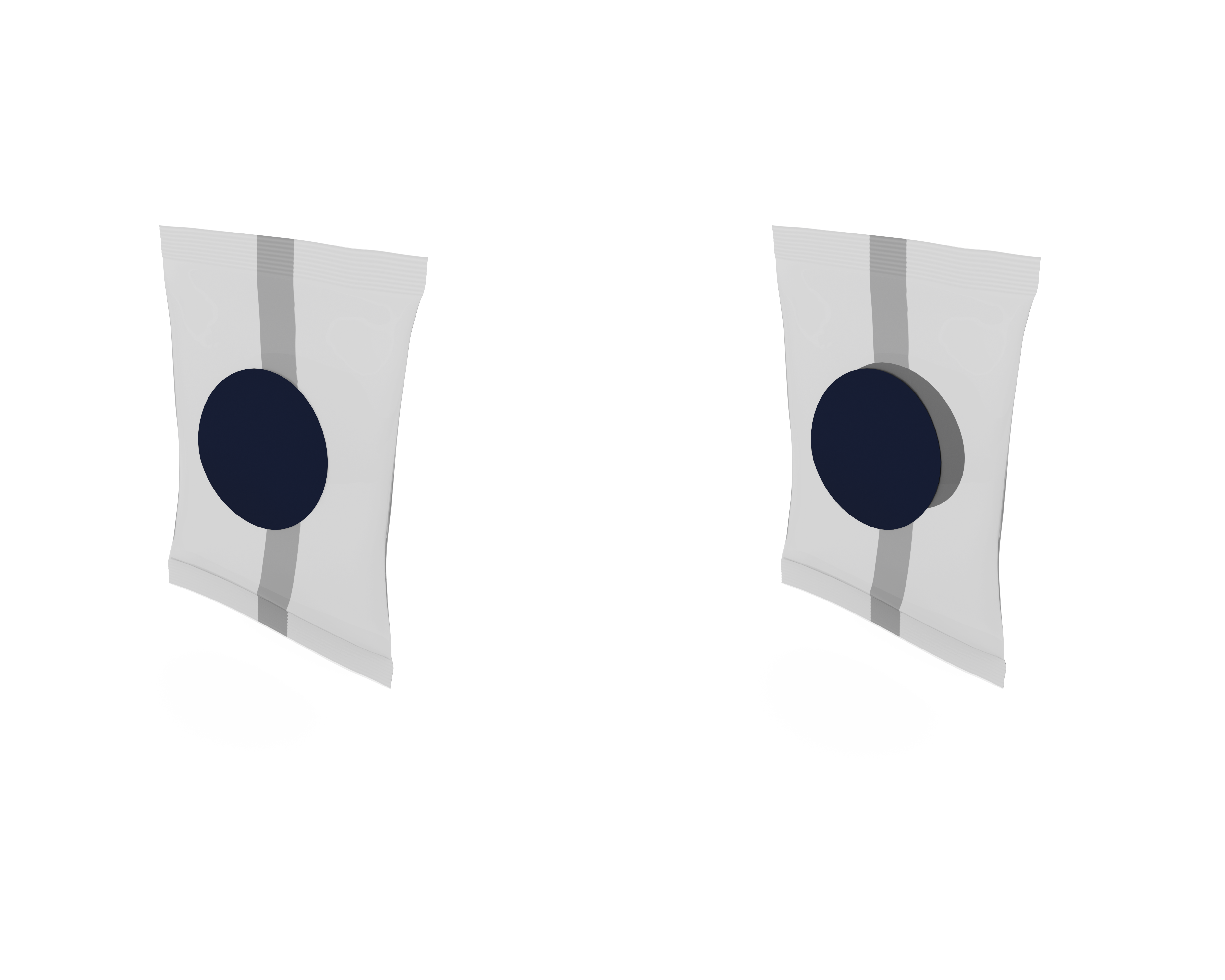

Yes, this is one of the key benefits of our labelling and marking solutions. The marking module fits precisely into your packaging line, and can be controlled centrally via the HMI. The MULTIVAC range of solutions is designed for the most common packaging formats and materials, and to perfectly match your specific requirements. Our labelling systems generate excellent results on various pack contours - independently of format or material.

A wide selection of labelling and marking solutions

MULTIVAC labelling and marking solutions are suitable for a multitude of pack shapes and types. The highest level of flexibility is of real benefit to you: product handling, label positioning, printing and inspection - always flawless and reliable. Our labelling and marking solutions can be seamlessly integrated into filling or packaging lines. They can also be used as a stand-alone solution with manual product infeed. You'll benefit from modular design. Our portfolio is ideally suited to a comprehensive range of labelling tasks, both technically and economically.