Inspection solutions - from simple to highly complex

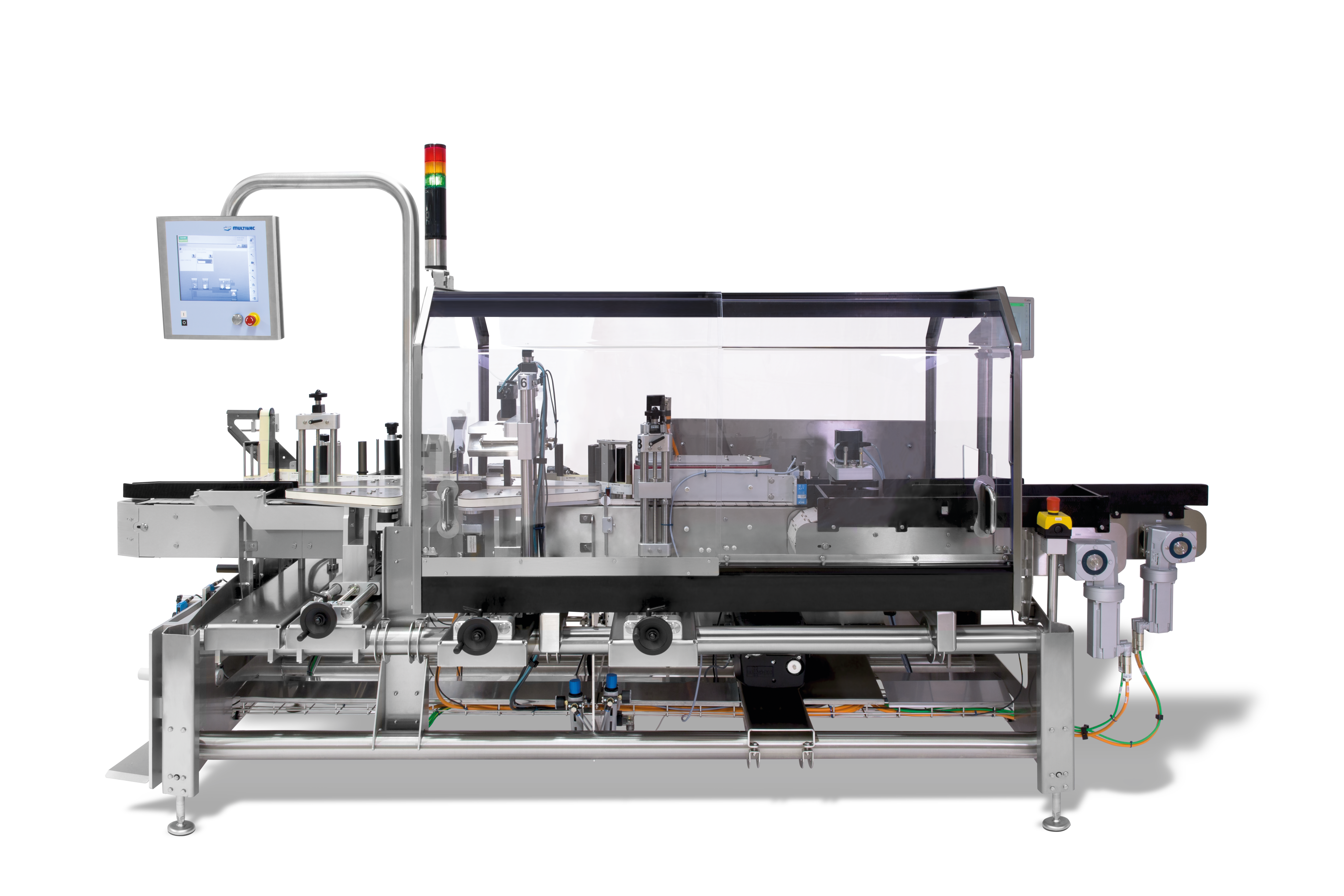

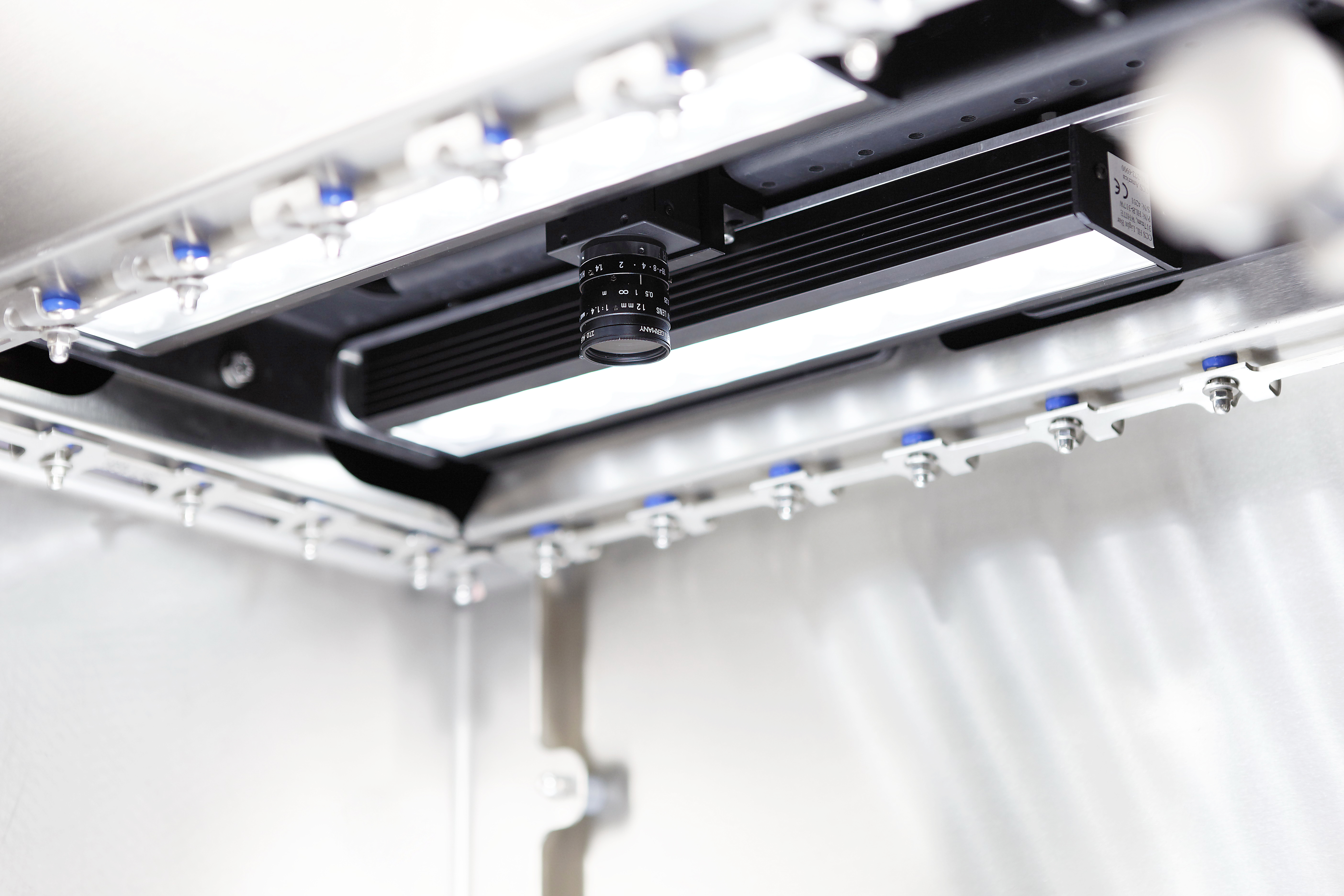

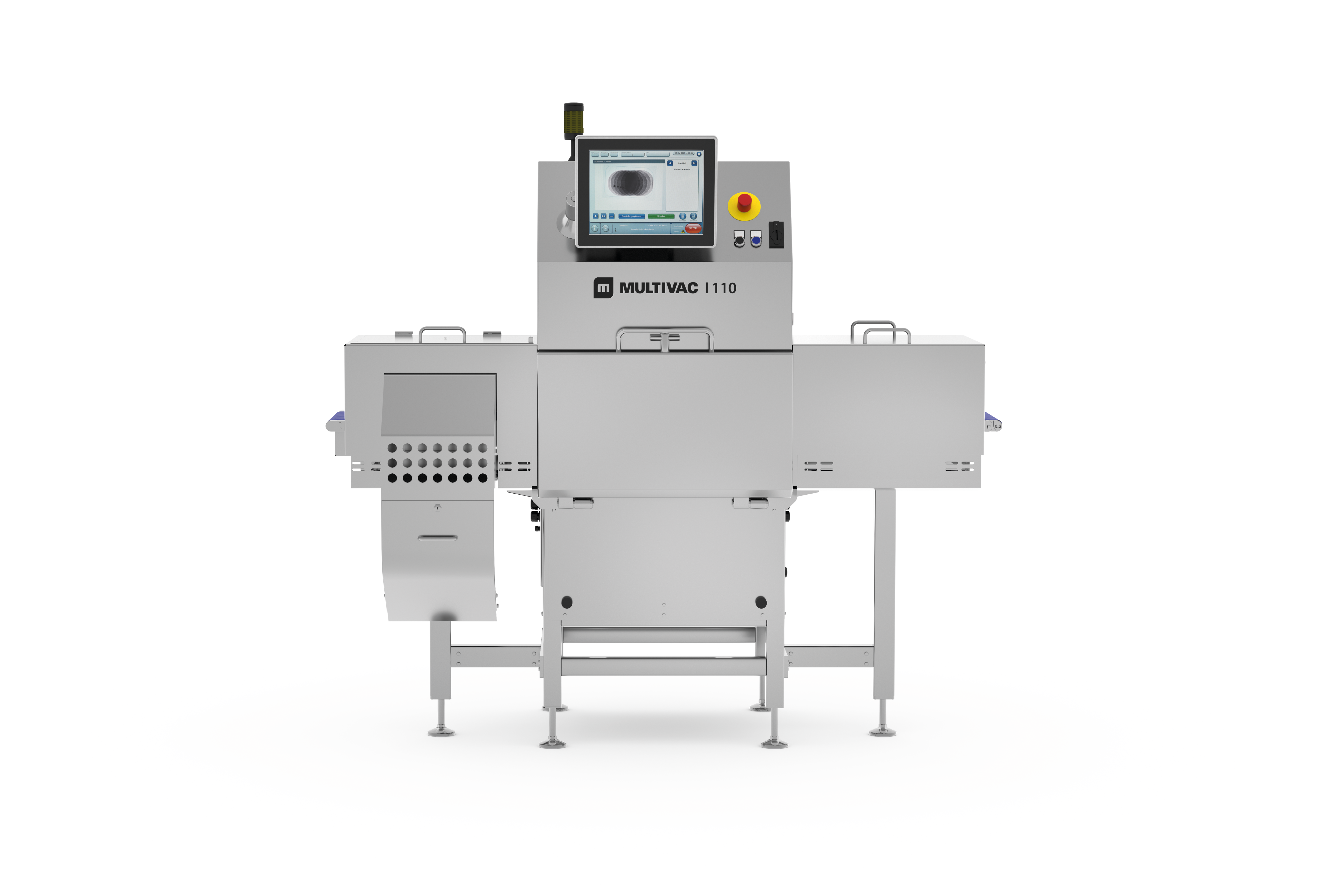

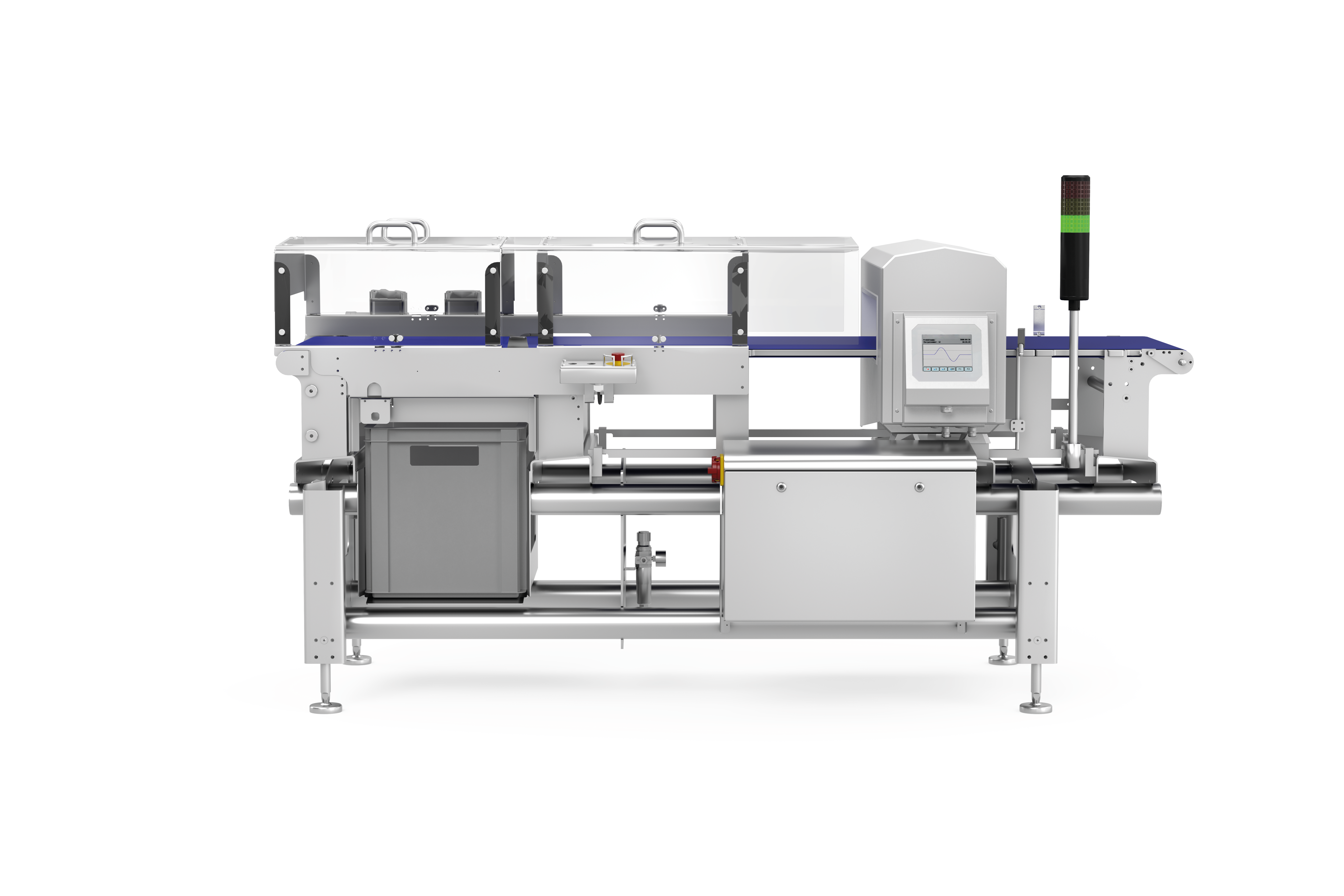

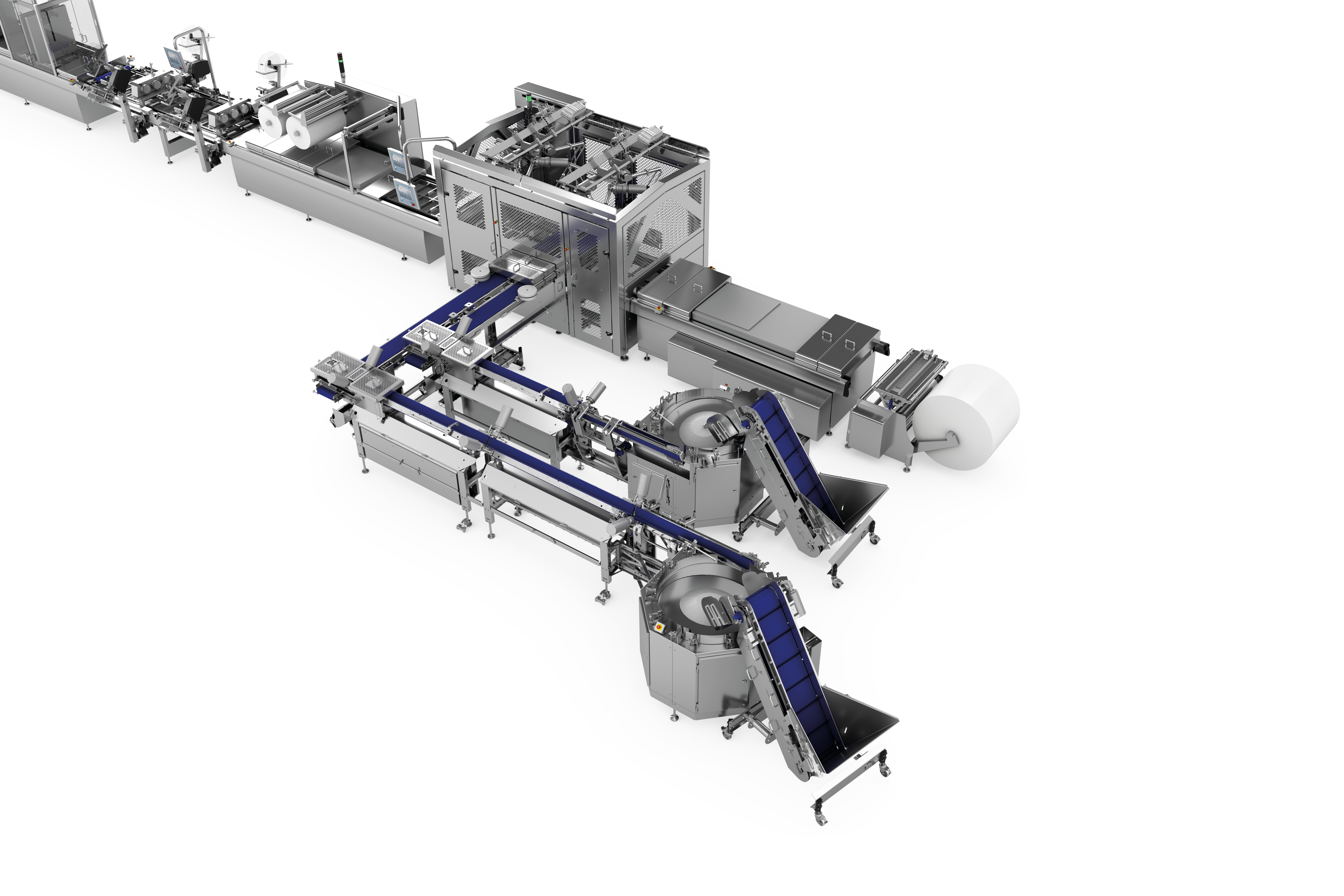

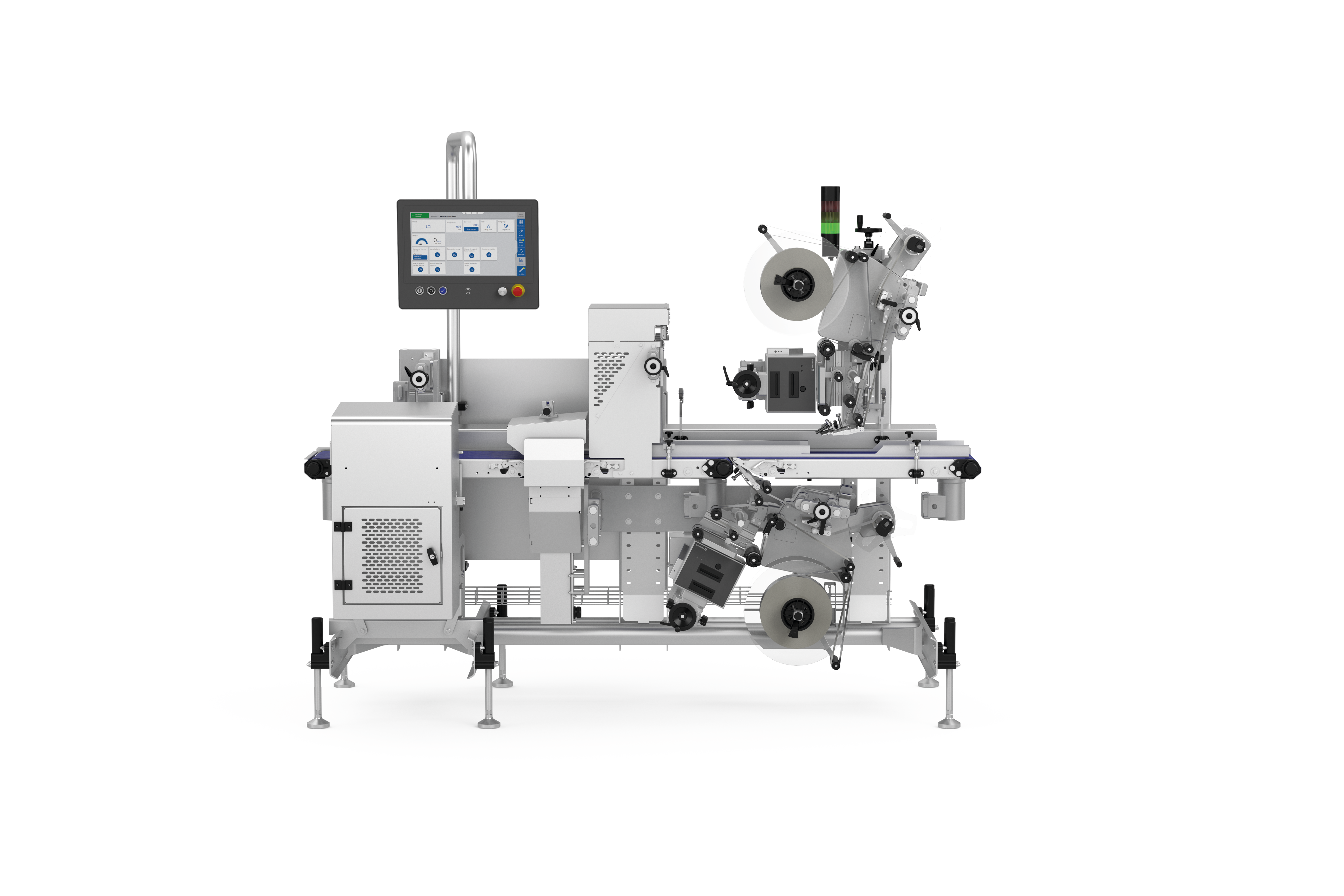

What type of inspection solution do you need for your quality assurance? Our range of services extends from automatic metal and foreign body detection to weight checking and visual inspection in challenging production and packaging processes. All our units are designed for efficiency and durability, to ensure reliable operation with maximum precision and reproducibility. We will advise you on an individual basis so that you can find the right solution for seamless integration in your production and packaging lines.

Innovative inspection technology for greater product safety

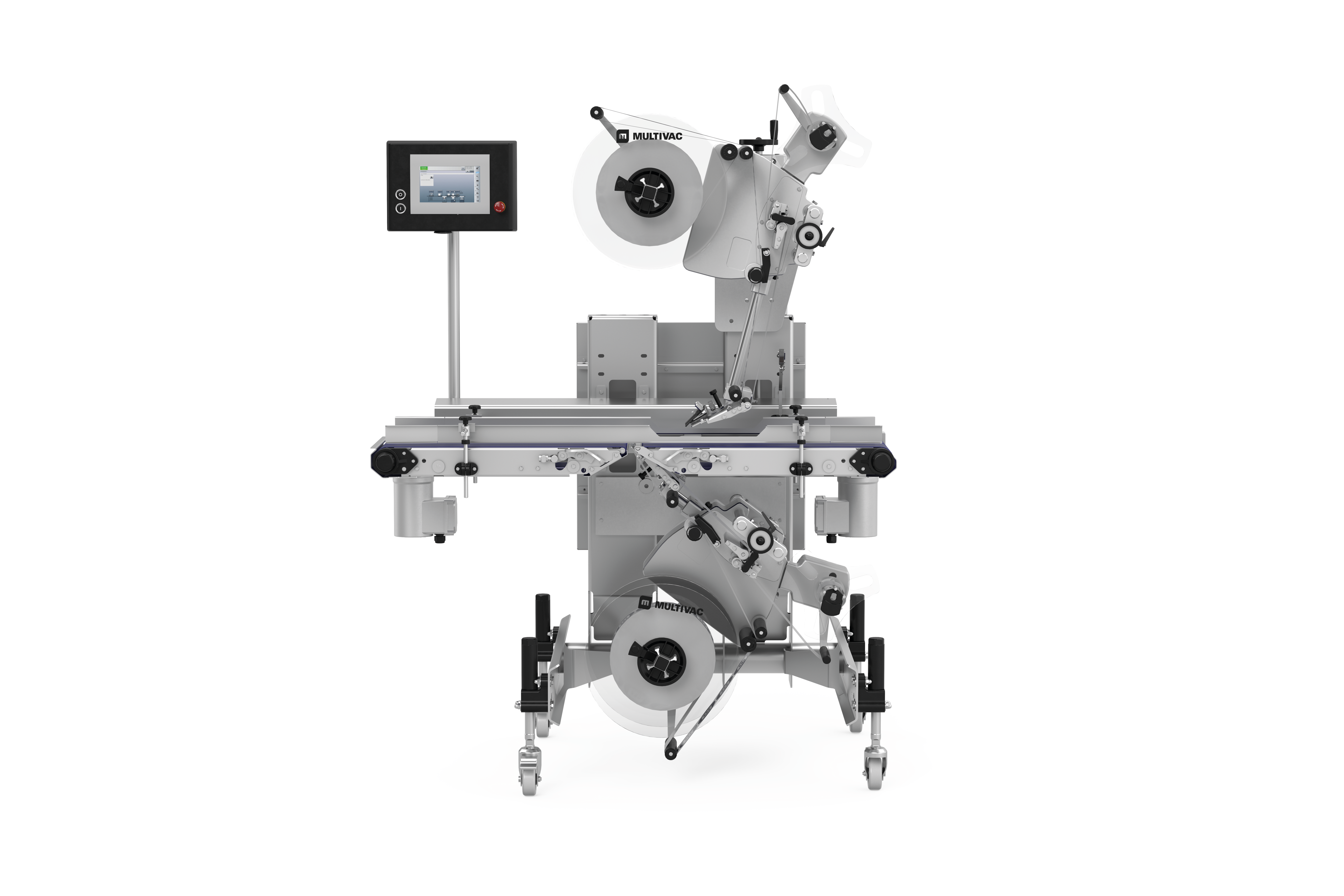

Our ideally matched modular solutions fit together in a single process - unbeatable for production reliability and packaging safety. This is primarily thanks to our various inspection technologies which eliminate faults alltogether. They can be integrated seamlessly into your packaging process with labelling solutions or expanded with additional functions. We also offer our inspection units to meet a variety of hygiene standards.

Success stories