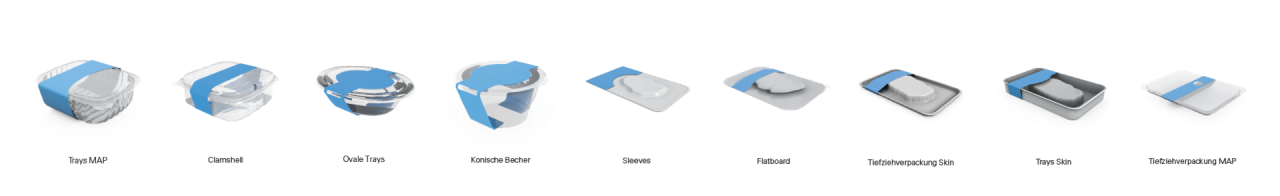

A typical application is skin packs with different product protrusion heights, or those where the product is below the tray height. Since unprinted upper webs are mostly used on skin packs, the label plays an important role with these packs in distinguishing the product. However, full wrap labelling is also used for MAP thermoformed packs or trays in a wide range of shapes. The even surface of these packs offers many opportunities for label placement. When it comes to hinged blister packs or clamshell trays, which are popular for ready-to-eat salads, fruit and bakery products, full wrap labelling can also contribute significantly to increasing the appeal of packs at the point of sale. The label also prevents the packs from springing open inadvertently.

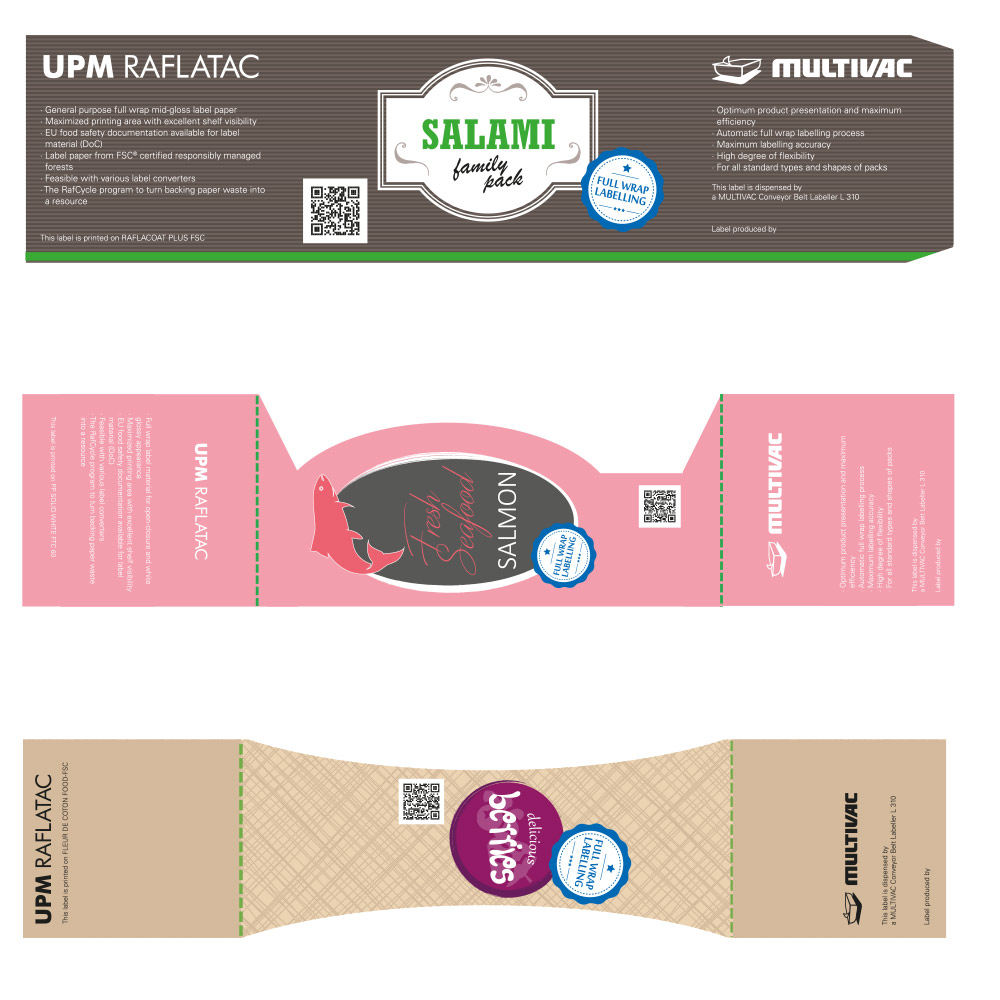

Thanks to their size and shape, full wrap labels offer a large area for product communication and information while leaving the product visible. They also enable the back of the label to be printed for special promotions, which are only visible after the product is purchased. Since food packs are often stacked on supermarket shelves, full wrap labelling also increases the visibility of the product on the shelf.

Transparent labels can also be used to present the product as completely as possible in the pack.

Full wrap labels can be designed in such a way, that they offer additional functions and increase the user-friendliness of the pack. Adhesive-free areas and perforations make it simple to remove the label and open the pack, for example. Additional information such as recipes, cooking tips, and advertising material can be placed on the back of the label. Full wrap labels can also provide anti-tampering protection, since the consumer would immediately recognize a pack, which had been tampered with or already opened.

The features of full wrap labelling with MULTIVAC conveyor belt labellers are a high level of automation and maximum labelling accuracy. If required, the conveyor belt labellers can also be equipped with extra label dispensers, so that additional labels beside the full wrap label can be applied to the pack. One example of this are promotional labels, which are increasingly being used for packs on the fresh food shelves.

With the RafCycle® program, the backing materials for full wrap labels are recycled and reused to manufacture paper and other materials. This offers processors, packers and brand owners many advantages, such as the reduction of disposal costs and the promotion of the recycling economy.

Card sleeves do of course convey a high-quality impression, but they are typically pushed manually over the pack and then fixed on the back by an additional label to the pack. Automatic full wrap labelling with paper labels, which have a higher grammage weight, is therefore an attractive alternative. Through the targeted integration of typical paper grooves and folds into the label design the high-quality impression can even be increased.

In addition to the high level of automation, full wrap labelling also offers benefits in terms of security. Self-adhesive labels adhere immeasurably better to the pack and remain securely in place during the subsequent logistical processes such as box loading, transporting, and shelf stacking. The customer is also unable to swap the labels from cheaper to more expensive products in the supermarket.

Self-adhesive labels offer greater flexibility as regards design and shape. Whereas linerless labels can only be produced in a rectangular format, all shapes can be considered for self-adhesive labels, since they are "held" in effect by the carrier paper. Labels with curves or cut-outs for example are possible with self-adhesive labels, which means they can be matched to the shape of the particular product or pack. It is the same story with the range of materials, which can be used for producing self-adhesive labels – this is much wider than for linerless labels, since the backing paper for the self-adhesive labels has a stabilising effect on the label material.

Another aspect, which restricts the efficiency of linerless labelling systems, is the fact that running these materials causes increased cleaning work on the machine. Labelling machines for running linerless labels also have to be equipped with knives, so the labels can be cut from the endless label stock. Residue of the adhesive or silicone layer on the labels builds up on these knives, which means they have to be cleaned regularly in order to maintain optimum labelling. The machine running time is therefore reduced significantly.

08.03.2020