MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

Communiqués de presse actuels

Vous trouverez ici les derniers communiqués de presse du groupe MULTIVAC.

MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

2327146963

2327146963

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

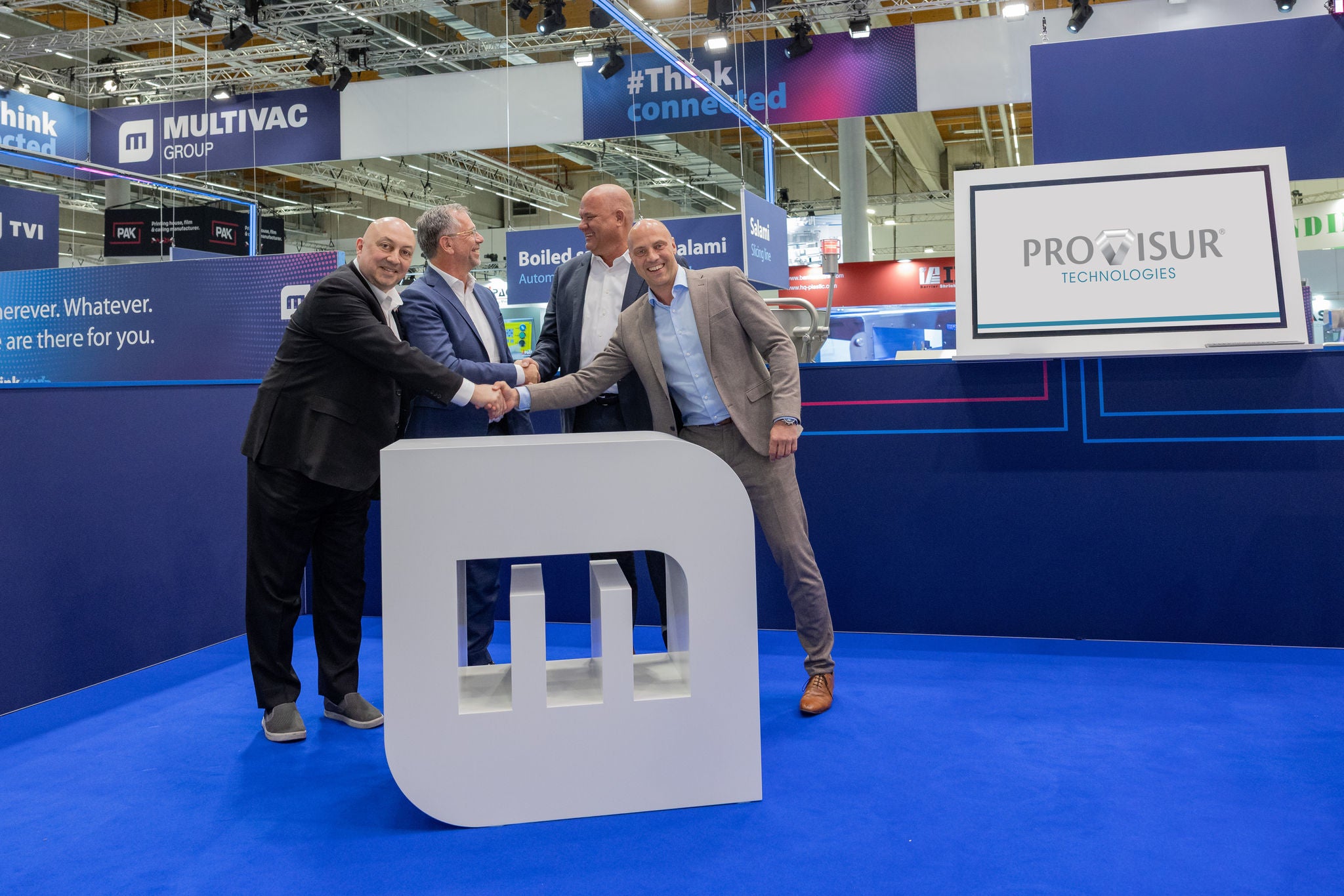

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

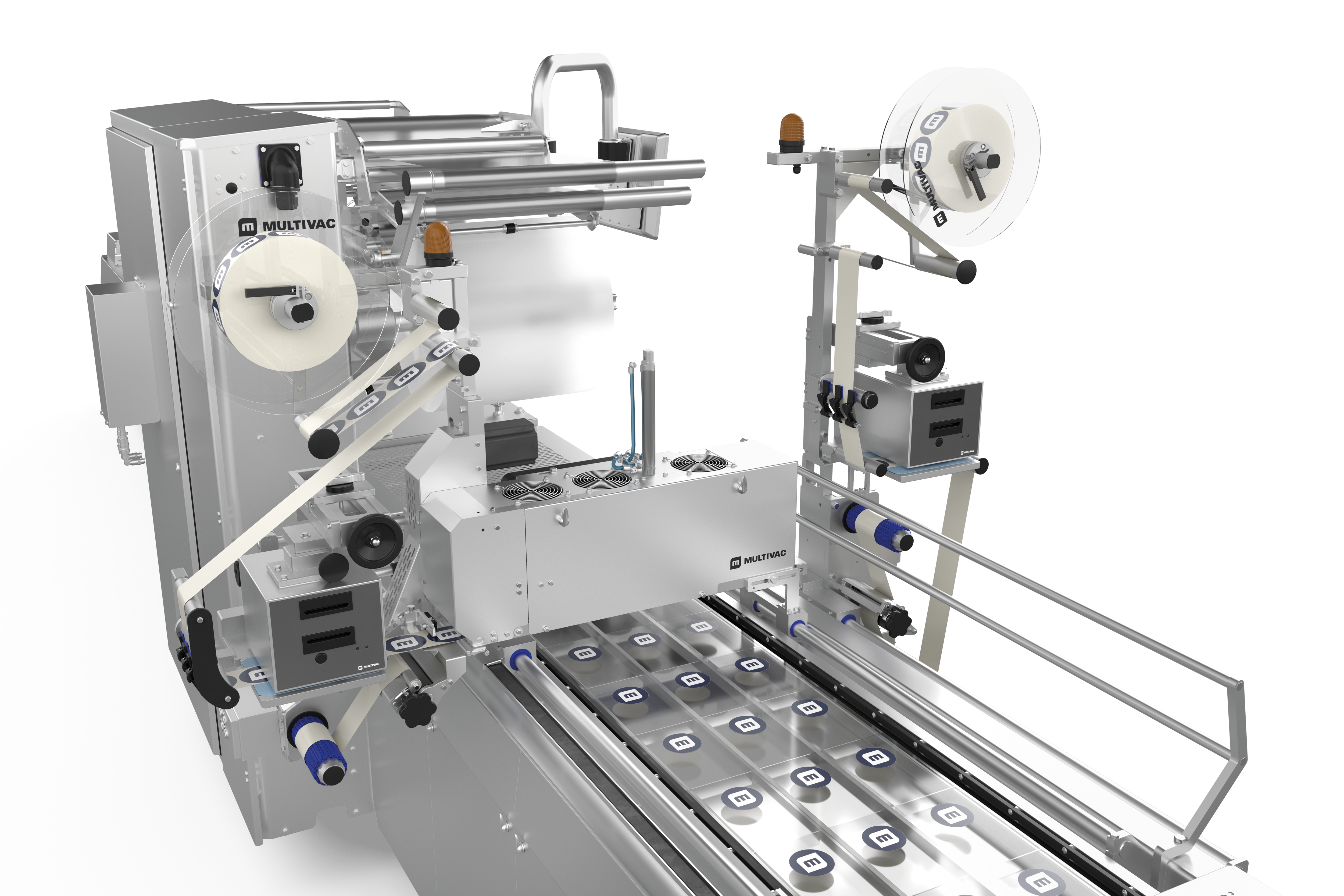

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

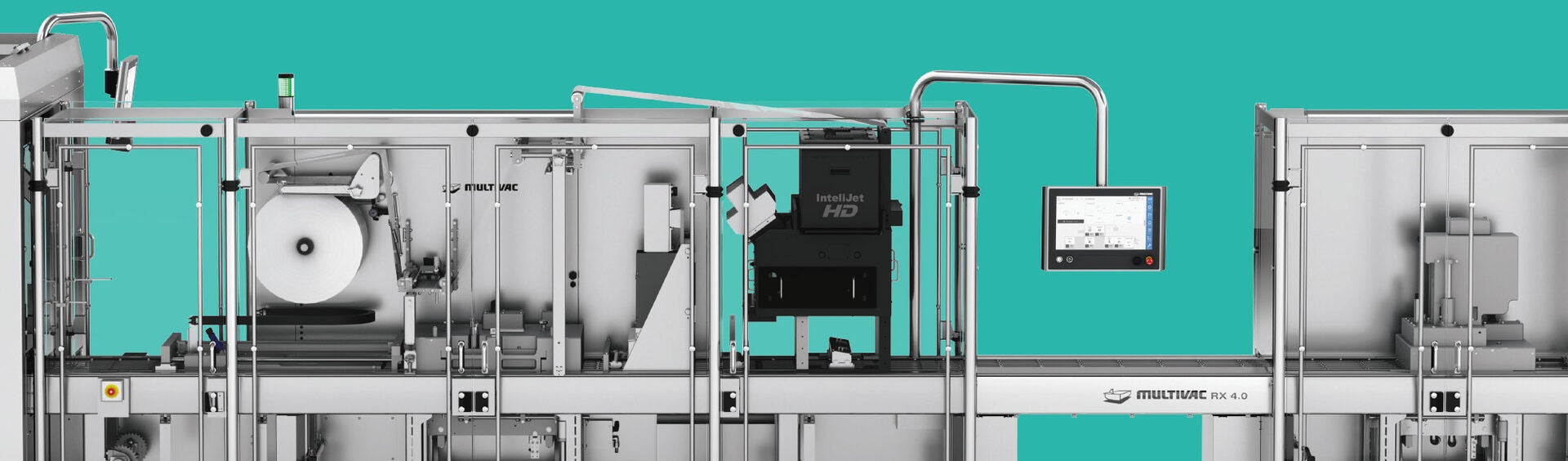

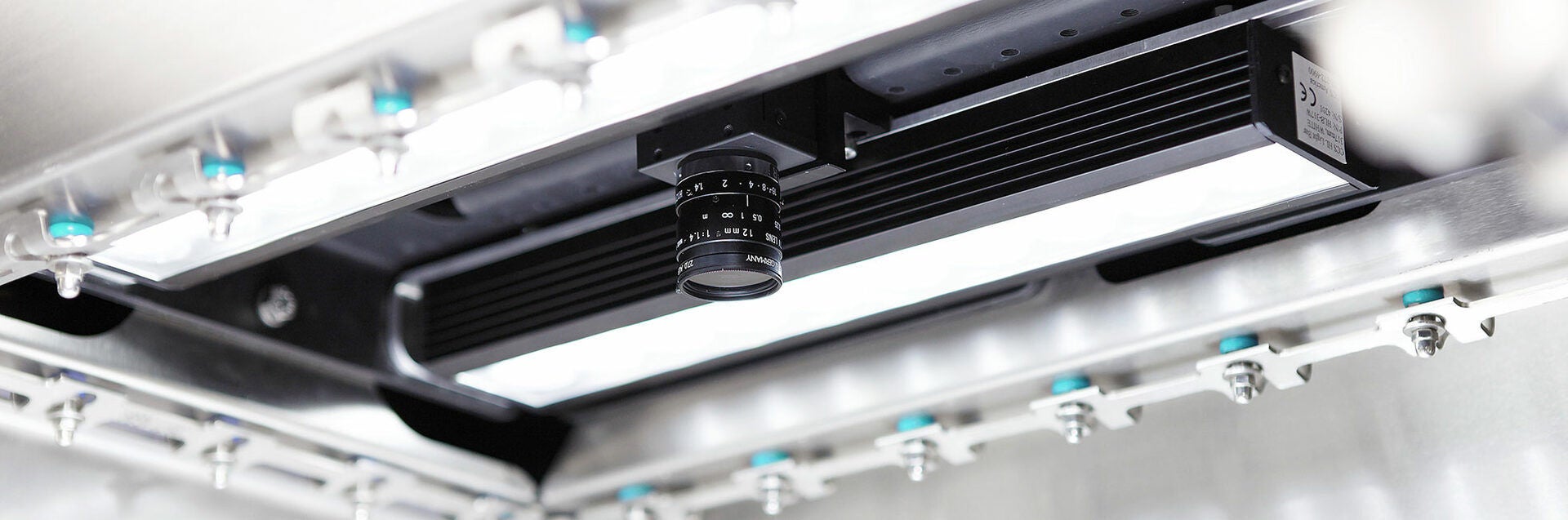

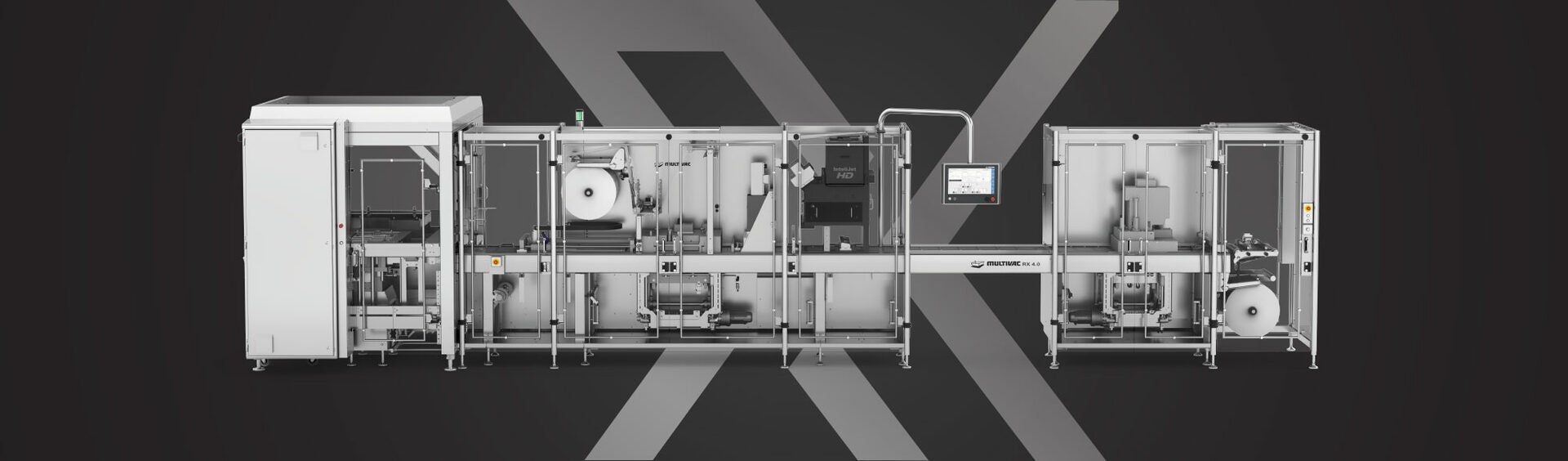

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC PDF

MULTIVAC PDF

MULTIVAC PDF

MULTIVAC PDF

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

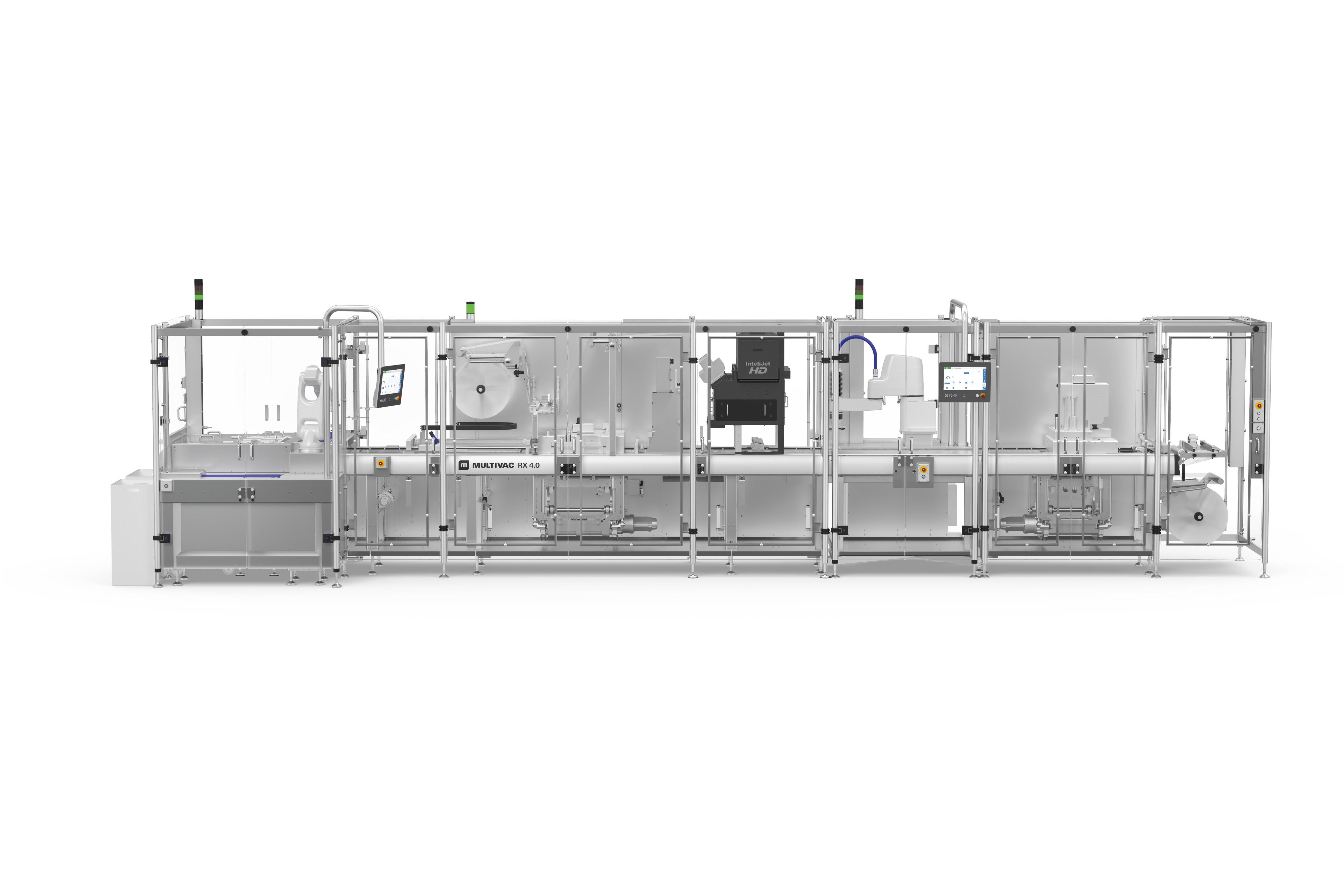

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

Business Professionals in Formal Attire

Business Professionals in Formal Attire

Beef Jerky Packaging by MULTIVAC Jalapeno Flavor

Beef Jerky Packaging by MULTIVAC Jalapeno Flavor

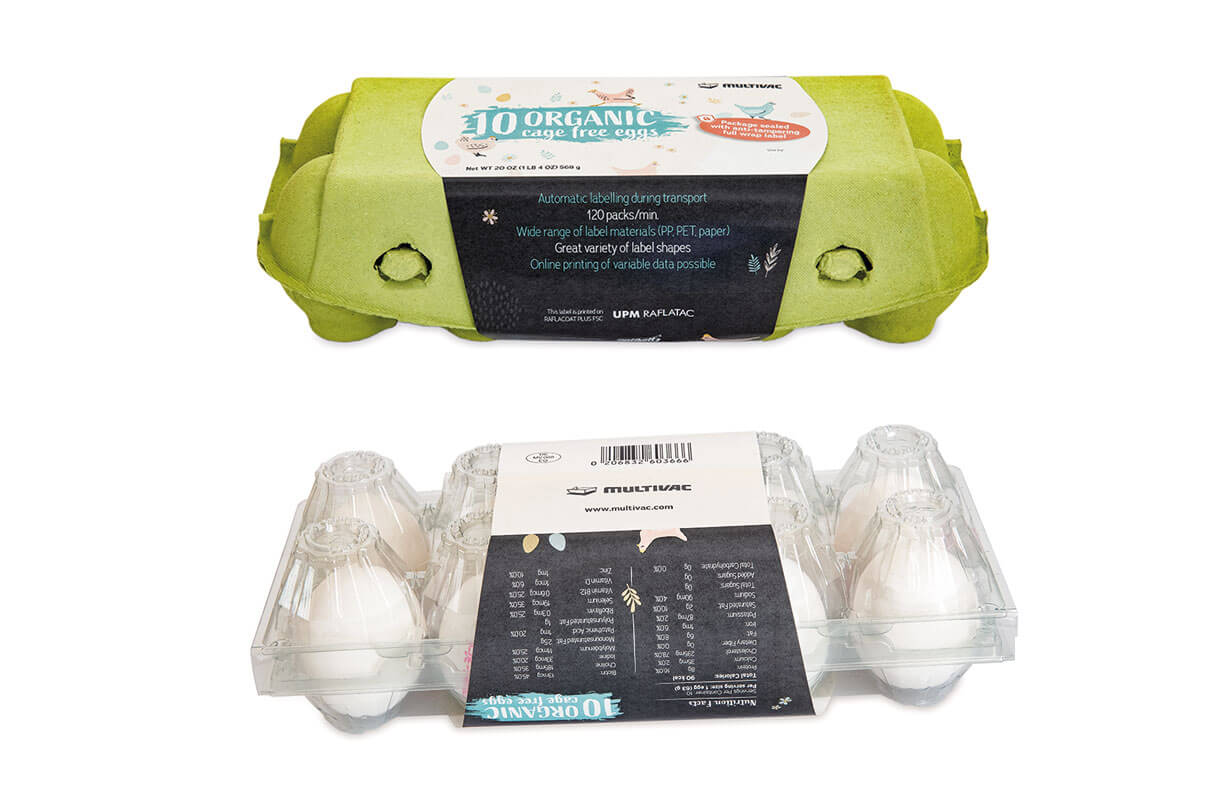

MULTIVAC Egg Packaging Machine Display

MULTIVAC Egg Packaging Machine Display

Articles techniques

MULTIVAC Food Packaging Machine with Patties

MULTIVAC Food Packaging Machine with Patties

MULTIVAC Machine Assembly in Industrial Setting

MULTIVAC Machine Assembly in Industrial Setting

MULTIVAC Factory Exterior with Green Landscape

MULTIVAC Factory Exterior with Green Landscape

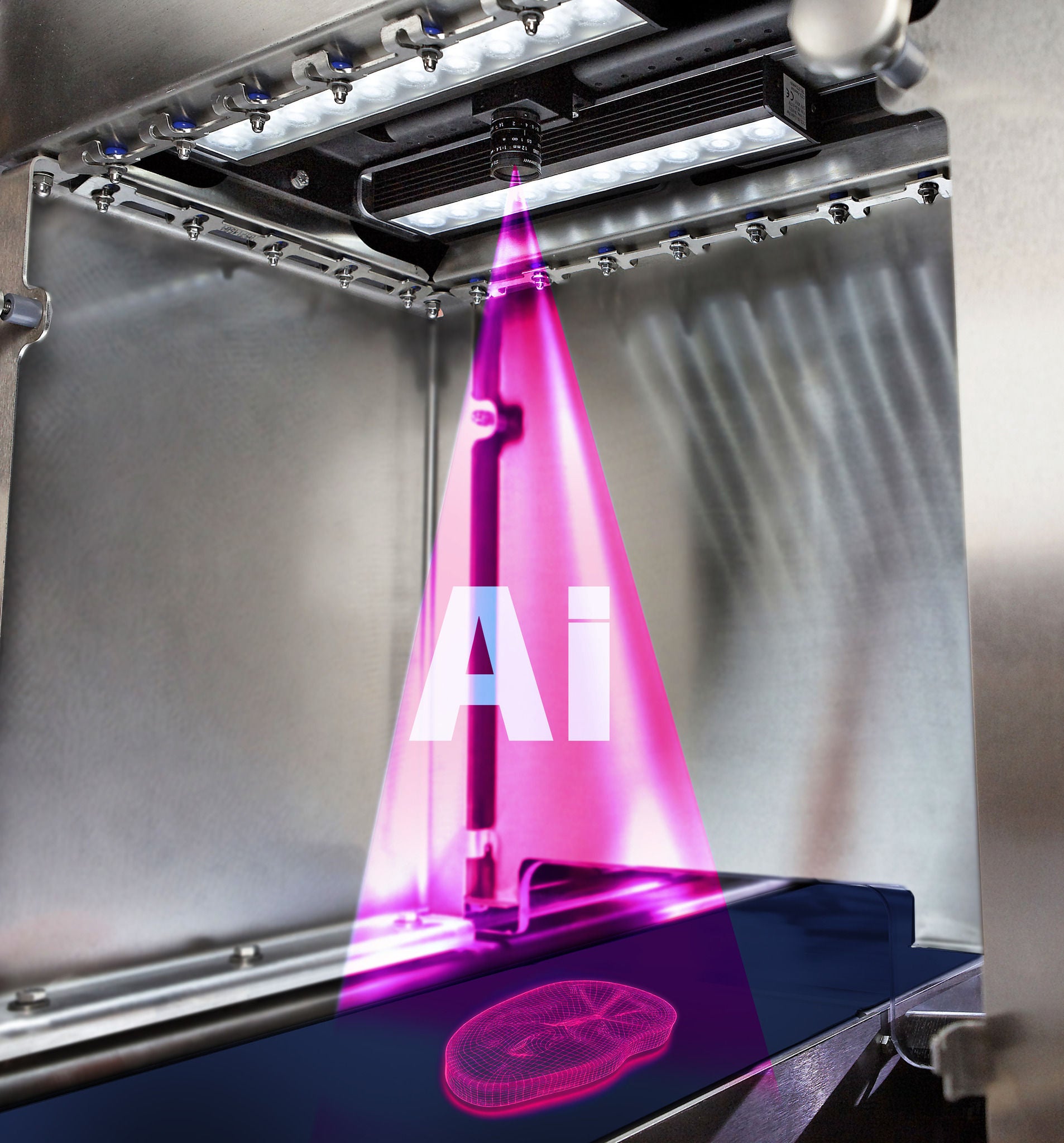

Digital Transformation with MULTIVAC Technology

Digital Transformation with MULTIVAC Technology

Businessman in White Shirt

Businessman in White Shirt

Business Executive Portrait Indoors

Business Executive Portrait Indoors

Businessman in Office Setting

Businessman in Office Setting

MULTIVAC Packaging Machine Industrial Equipment

MULTIVAC Packaging Machine Industrial Equipment

Healthcare Professionals Europe Overview

Healthcare Professionals Europe Overview

MULTIVAC Packaging Machine in Modern Office Setting

MULTIVAC Packaging Machine in Modern Office Setting

MULTIVAC Industrial Machine with Operator in Lab

MULTIVAC Industrial Machine with Operator in Lab

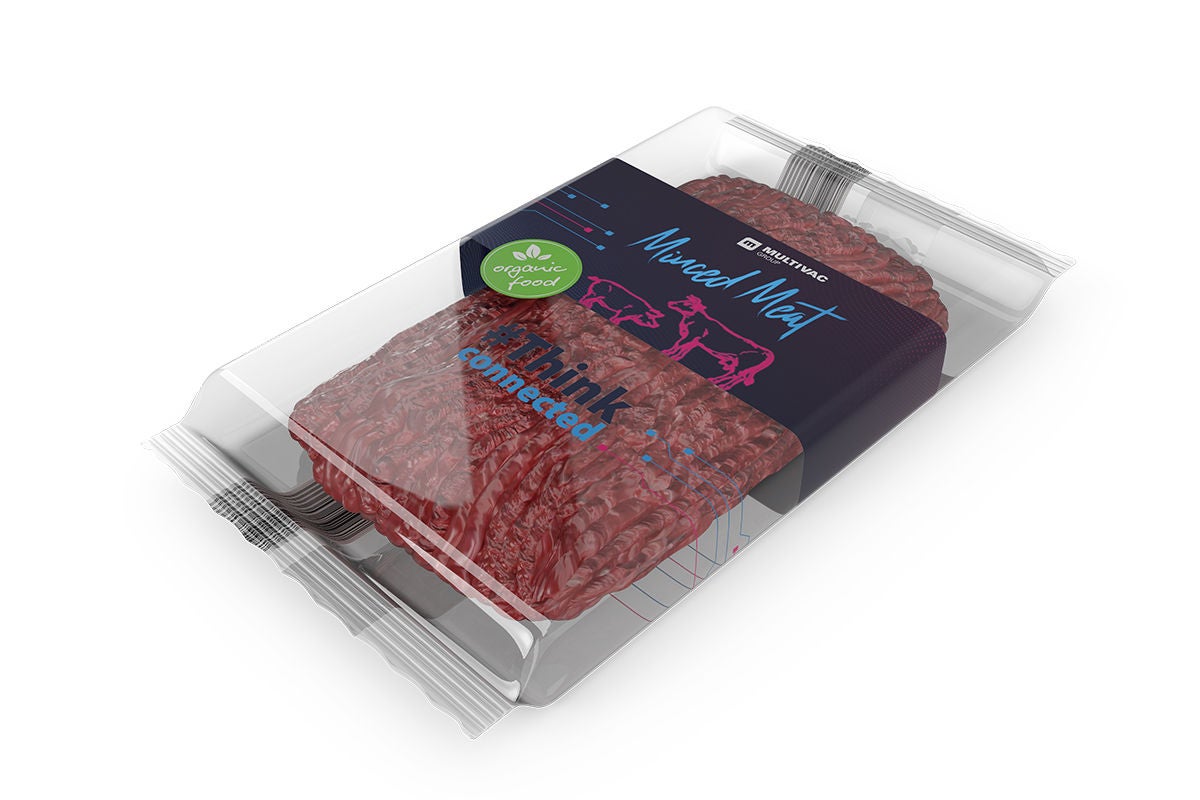

MULTIVAC Packaging Solutions for Meat Products

MULTIVAC Packaging Solutions for Meat Products

Vegetable Spread Packaging Design

Vegetable Spread Packaging Design

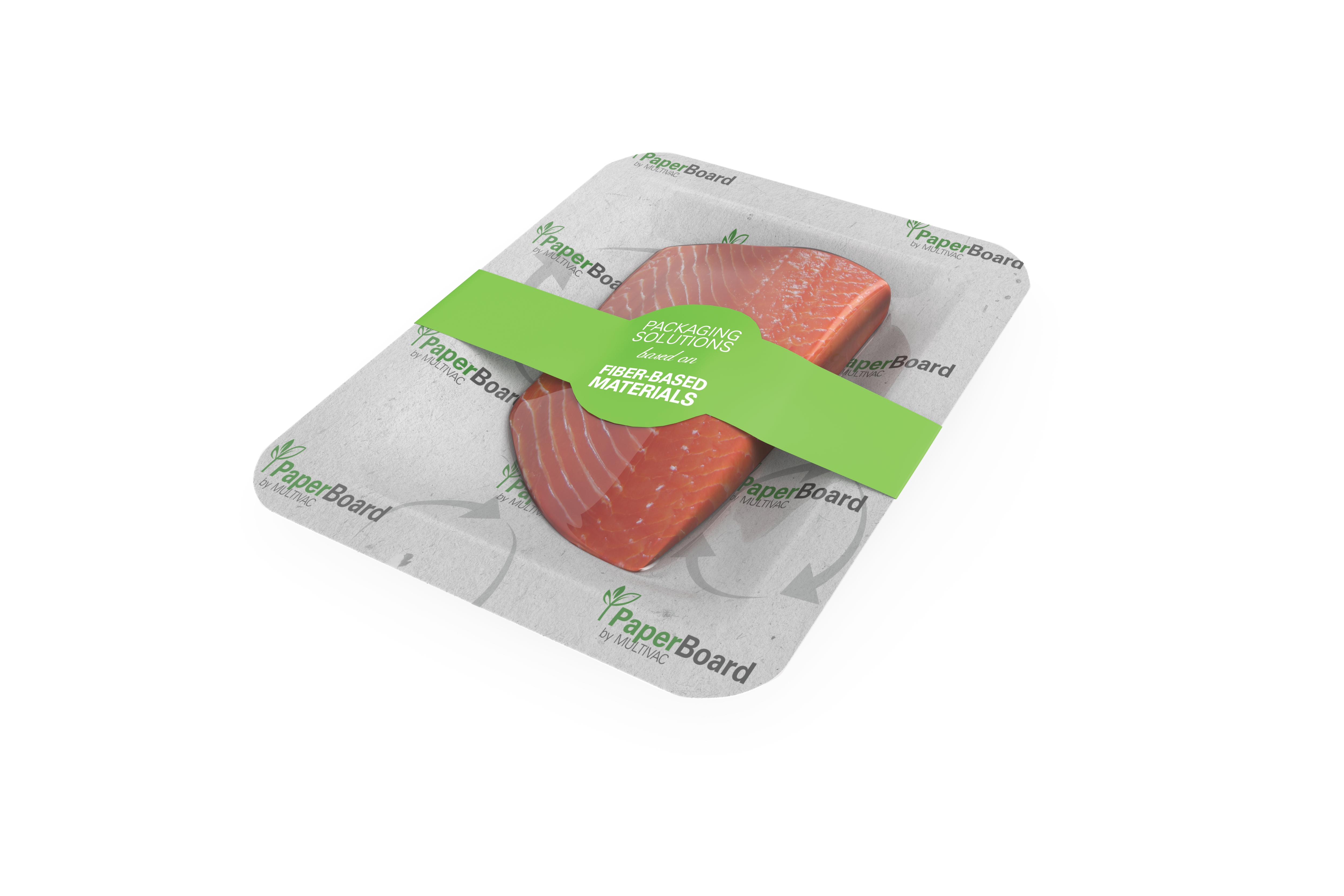

MULTIVAC PaperBoard Packaging Cycle Image

MULTIVAC PaperBoard Packaging Cycle Image

Beef Jerky with Sea Salt on Slate Background

Beef Jerky with Sea Salt on Slate Background

Frozen Meat Slice on White Background

Frozen Meat Slice on White Background

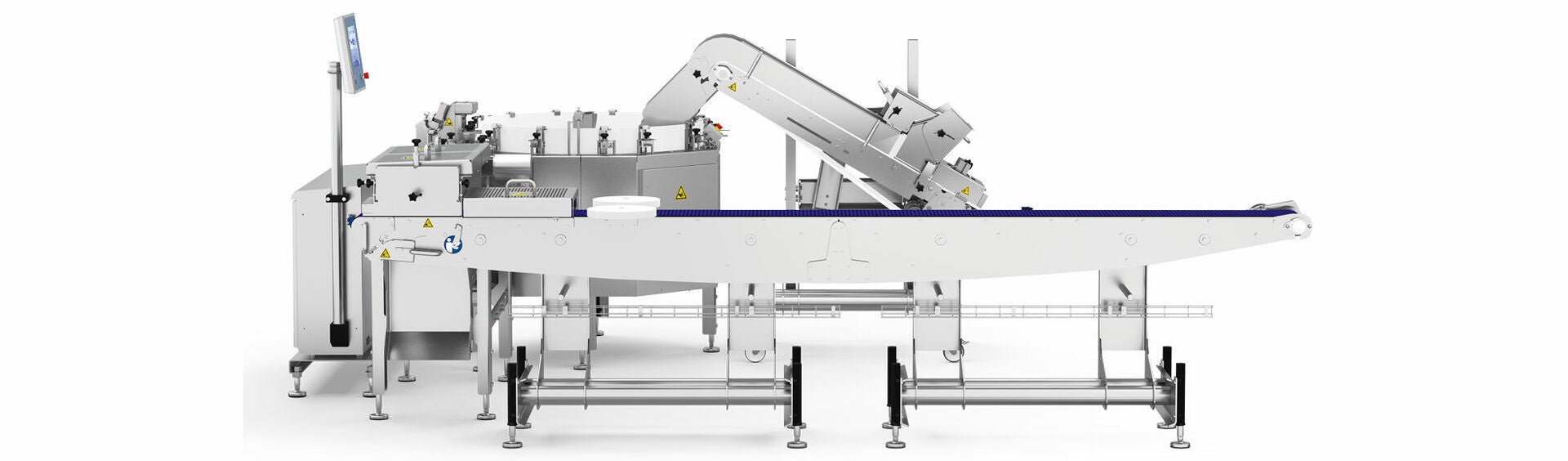

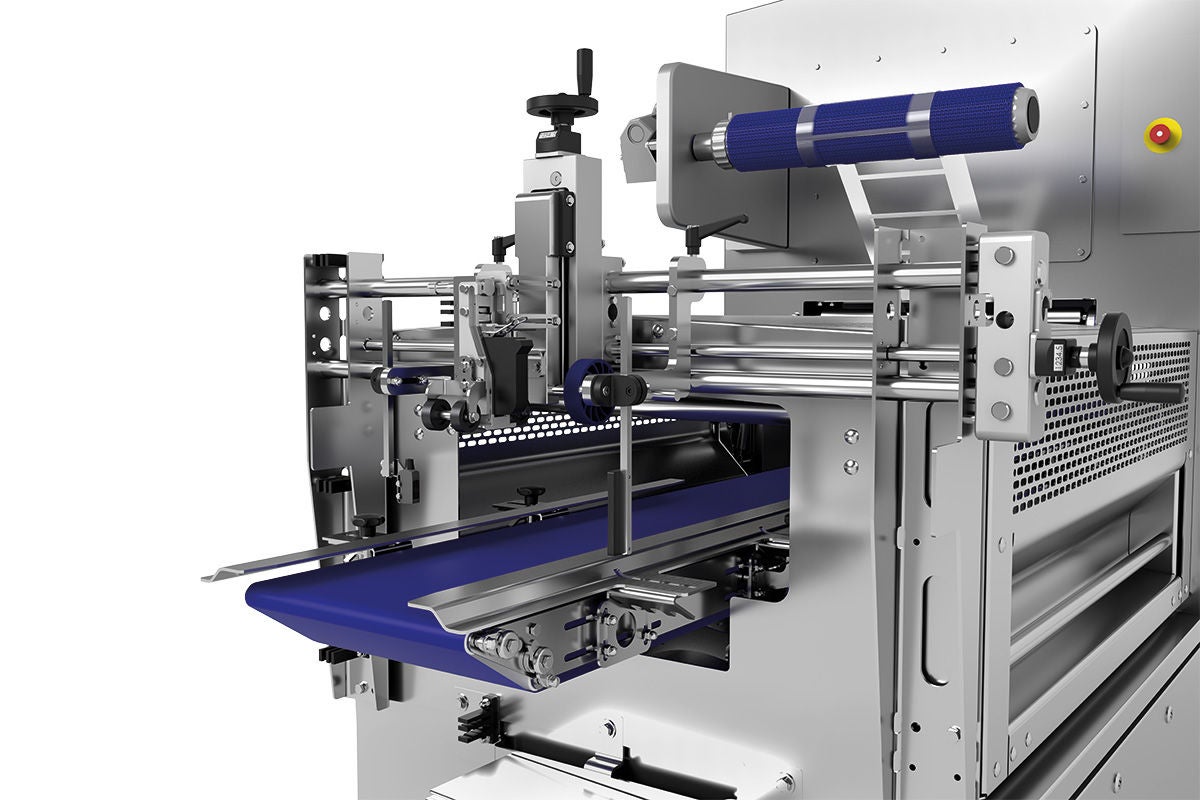

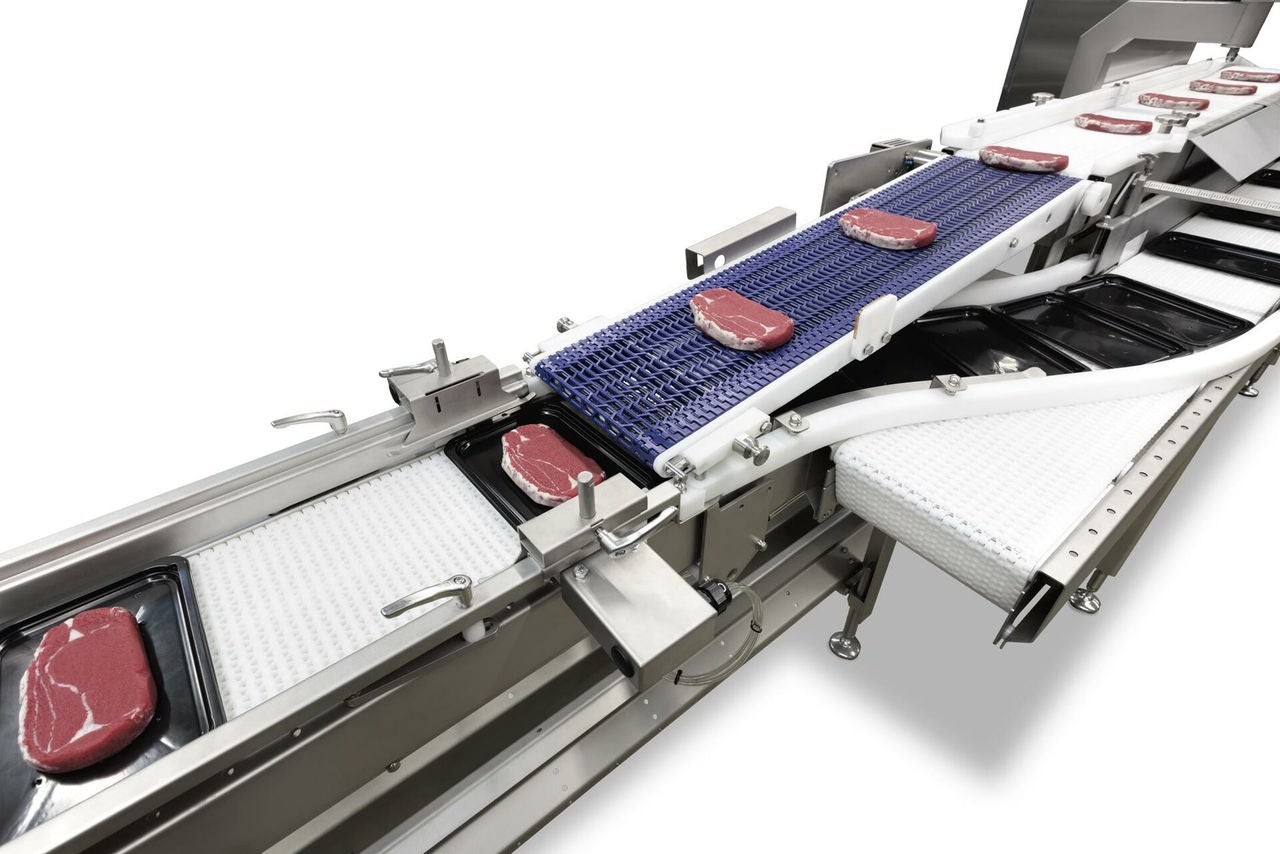

MULTIVAC Meat Packaging Conveyor System

MULTIVAC Meat Packaging Conveyor System

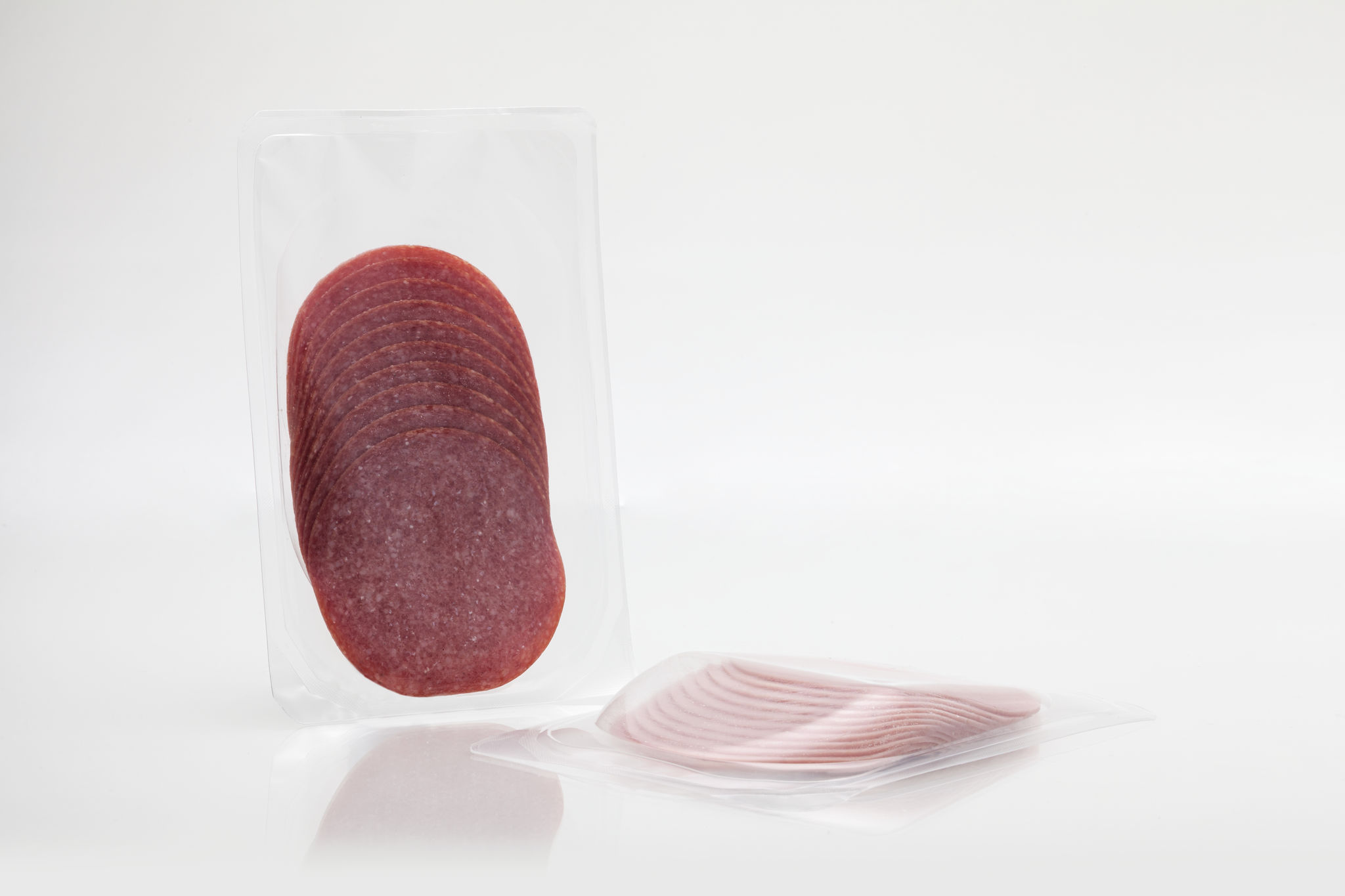

Vacuum Sealed Meat Packaging by MULTIVAC

Vacuum Sealed Meat Packaging by MULTIVAC

MULTIVAC Packaging Machine with Blue Crate

MULTIVAC Packaging Machine with Blue Crate

MULTIVAC Packaging Machine for Medical Supplies

MULTIVAC Packaging Machine for Medical Supplies

MULTIVAC Tray Sealer Machine Component

MULTIVAC Tray Sealer Machine Component

MULTIVAC Food Packaging Machine Honey Peppers

MULTIVAC Food Packaging Machine Honey Peppers

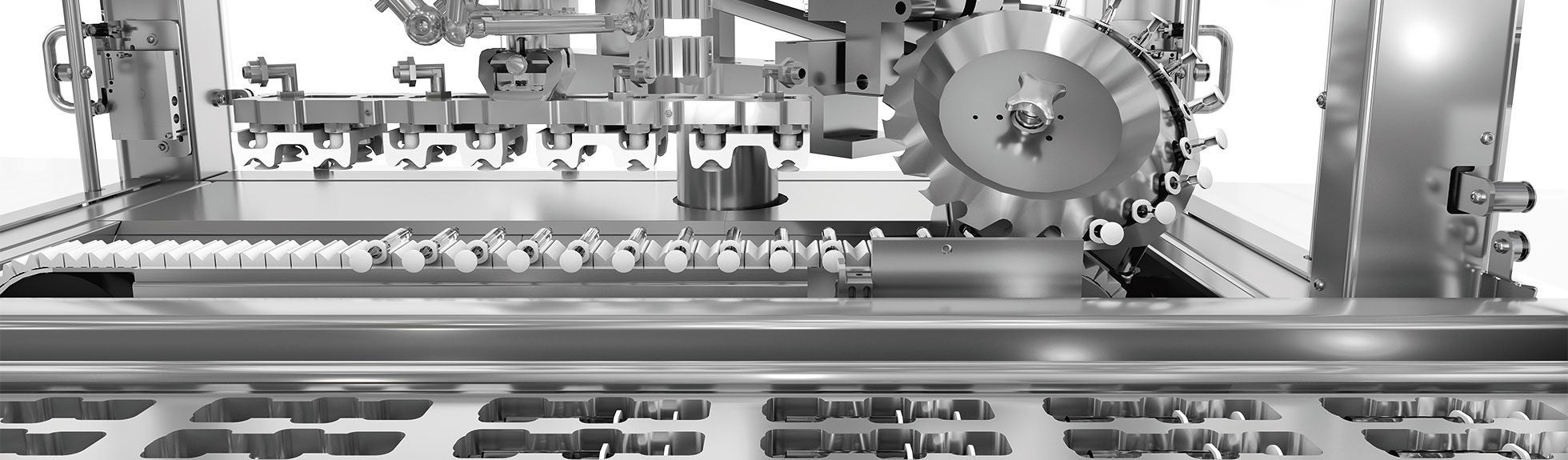

MULTIVAC Packaging Machine Close-Up View

MULTIVAC Packaging Machine Close-Up View

Syringes and Vaccine Vial Medical Supplies Image

Syringes and Vaccine Vial Medical Supplies Image

Téléchargements

SUSTAINABILITY

Rapport sur le développement durable

Notre premier rapport de développement durable basé sur les normes de la Global Reporting Initiative (GRI).

- Taille

- 50 MB

- Format

Verhaltenskodex

Code de conduite

Normes et spécifications internes du groupe MULTIVAC

- Taille

- 700 KB

- Format

Contact

Vous avez des questions sur nos communiqués de presse, ou vous souhaitez vous inscrire à notre liste de diffusion de la presse ? Prenez tout simplement contact avec nous. Nous serons heureux de vous entendre.

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com