Aktuelle pressemeddelelser

Her finder du de nyeste pressemeddelelser fra MULTIVAC-gruppen.

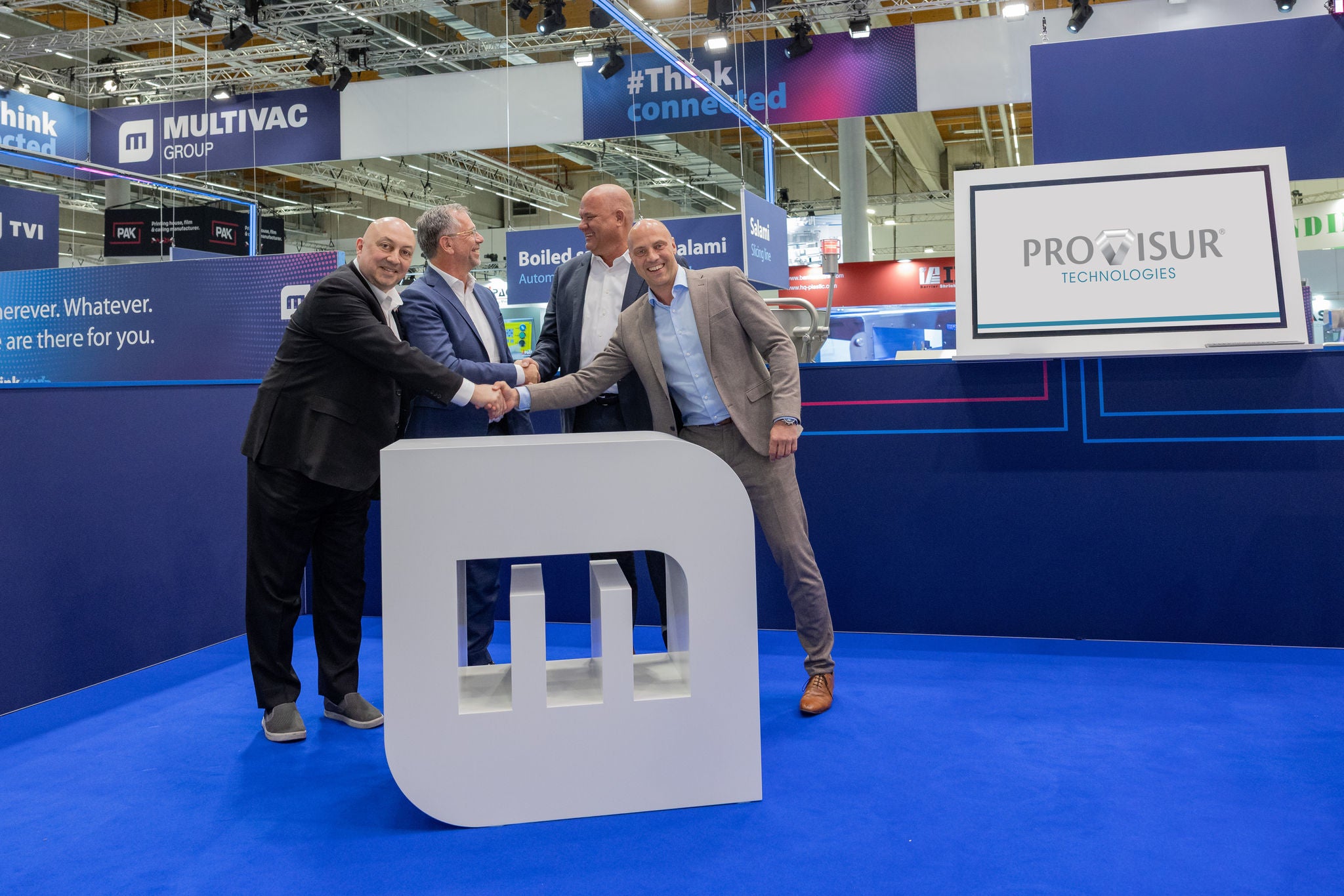

2327146963

2327146963

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

Snack a Fish Packaging Design by MULTIVAC

Snack a Fish Packaging Design by MULTIVAC

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC PDF

MULTIVAC PDF

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tekniske artikler

MULTIVAC Food Packaging Machine with Patties

MULTIVAC Food Packaging Machine with Patties

MULTIVAC Machine Assembly in Industrial Setting

MULTIVAC Machine Assembly in Industrial Setting

Packaging flat sterile products efficiently and reliably

When flat and sterile disposable products are being packed in large batch sizes, it is not only the pack quality but also the efficiency and cost-effectiveness of production which is of great importance.

When flat and sterile disposable products are being packed in large batch sizes, it is not only the pack quality but also the efficiency and cost-effectiveness of production which is of great importance.

Lær mere

MULTIVAC Factory Exterior with Green Landscape

MULTIVAC Factory Exterior with Green Landscape

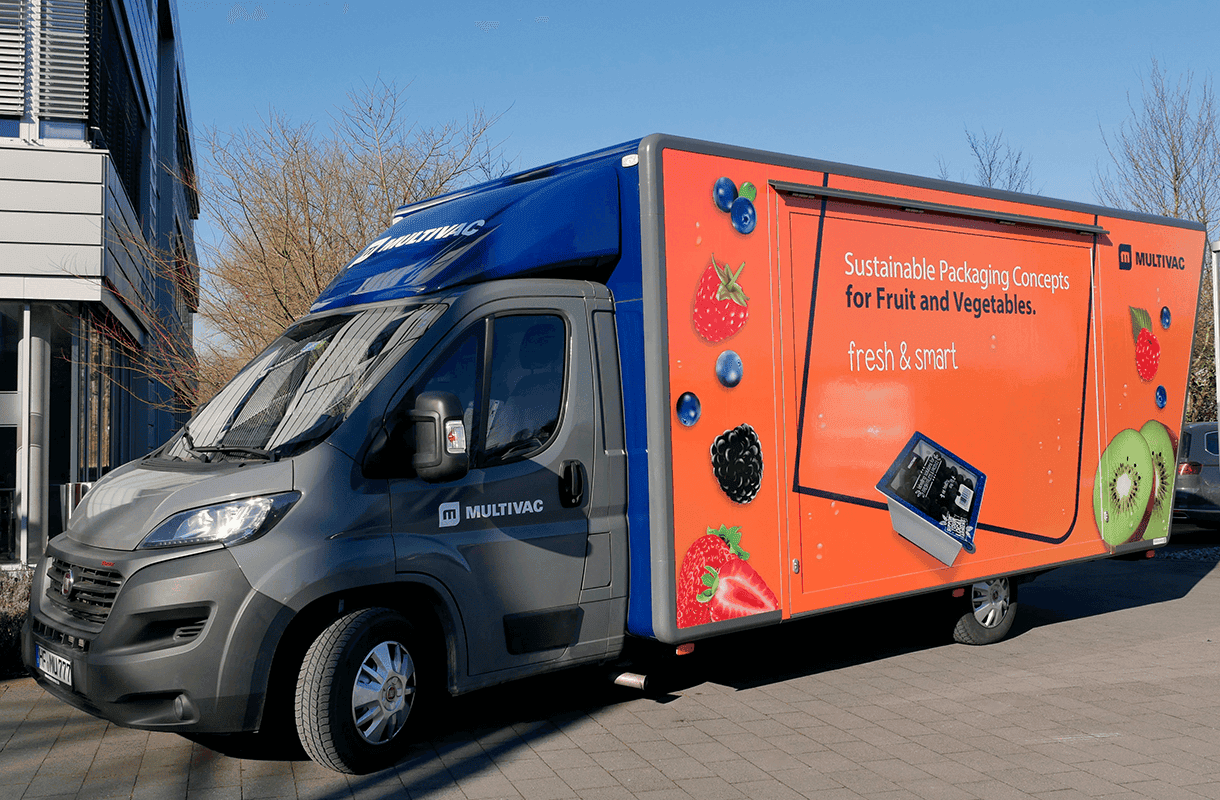

Less food wastage thanks to sustainable packaging and labelling concepts for fruit and vegetables

MULTIVAC adjusted to this trend at an early stage: Its solutions not only meet the sustainability requirements of customers, they also protect the packaged product perfectly, as well as reducing food wastage and appealing to retailers and consumers alike with their attractive design.

MULTIVAC adjusted to this trend at an early stage: Its solutions not only meet the sustainability requirements of customers, they also protect the packaged product perfectly, as well as reducing food wastage and appealing to retailers and consumers alike with their attractive design.

Lær mere

Digital Transformation with MULTIVAC Technology

Digital Transformation with MULTIVAC Technology

Businessman in White Shirt

Businessman in White Shirt

“We support manufacturers of medical technology as a partner.”

Product safety, reliability, sustainability and cost-effectiveness: To implement the best possible packaging lines for manufacturers of medical technology, MULTIVAC continues to advance as a solution provider in line with the increasing requirements of the industry. In this interview, Luc van de Vel, Executive Vice President of the Food, Medical & Consumer Solutions Business Unit at MULTIVAC, explains what the future holds.

Product safety, reliability, sustainability and cost-effectiveness: To implement the best possible packaging lines for manufacturers of medical technology, MULTIVAC continues to advance as a solution provider in line with the increasing requirements of the industry. In this interview, Luc van de Vel, Executive Vice President of the Food, Medical & Consumer Solutions Business Unit at MULTIVAC, explains what the future holds.

Lær mere

Business Executive Portrait Indoors

Business Executive Portrait Indoors

“60 years of MULTIVAC - Globalisation, digitalisation and sustainability”

Some 60 years after the company was founded, MULTIVAC has long been known as much more than just a producer of packaging machines. The company has now developed into a global systems supplier with an annual turnover of 1.2 billion euros. And it is treading new paths in digitalisation and sustainability. Discussion with Guido Spix, joint Group President of MULTIVAC.

Some 60 years after the company was founded, MULTIVAC has long been known as much more than just a producer of packaging machines. The company has now developed into a global systems supplier with an annual turnover of 1.2 billion euros. And it is treading new paths in digitalisation and sustainability. Discussion with Guido Spix, joint Group President of MULTIVAC.

Lær mere

Businessman in Office Setting

Businessman in Office Setting

“Digitalisation in the packaging process is gaining in dynamism”

Interview with Dr Marius Grathwohl, Vice President of Digital Products & Transformation at MULTIVAC

Interview with Dr Marius Grathwohl, Vice President of Digital Products & Transformation at MULTIVAC

Lær mere

Process validation as the basis for maximum product safety

The relevance of process precision and reproducibility continues to increase in the medical products industry. Process validation provides seamless documentation, that the defined quality features are being achieved with a high level of reliability and consistency over the entire life cycle of the product. As a supplier of integrated solutions, MULTIVAC has many years of well-grounded expertise in all types of projects and packaging solutions. It can, therefore, offer professional support to manufacturers of medical devices, when they are implementing a challenging process validation.

The relevance of process precision and reproducibility continues to increase in the medical products industry. Process validation provides seamless documentation, that the defined quality features are being achieved with a high level of reliability and consistency over the entire life cycle of the product. As a supplier of integrated solutions, MULTIVAC has many years of well-grounded expertise in all types of projects and packaging solutions. It can, therefore, offer professional support to manufacturers of medical devices, when they are implementing a challenging process validation.

Lær mere

MULTIVAC Packaging Machine Industrial Equipment

MULTIVAC Packaging Machine Industrial Equipment

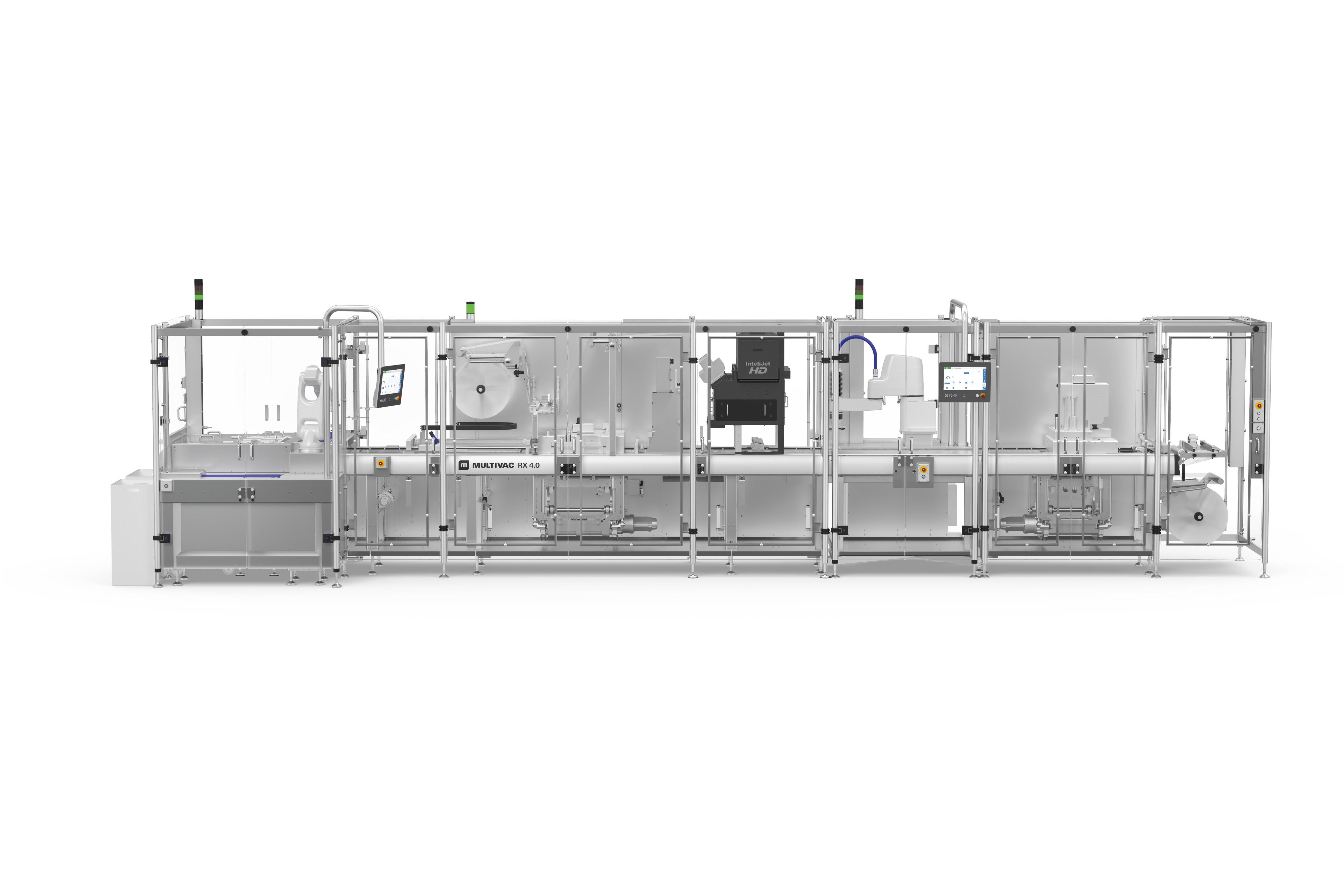

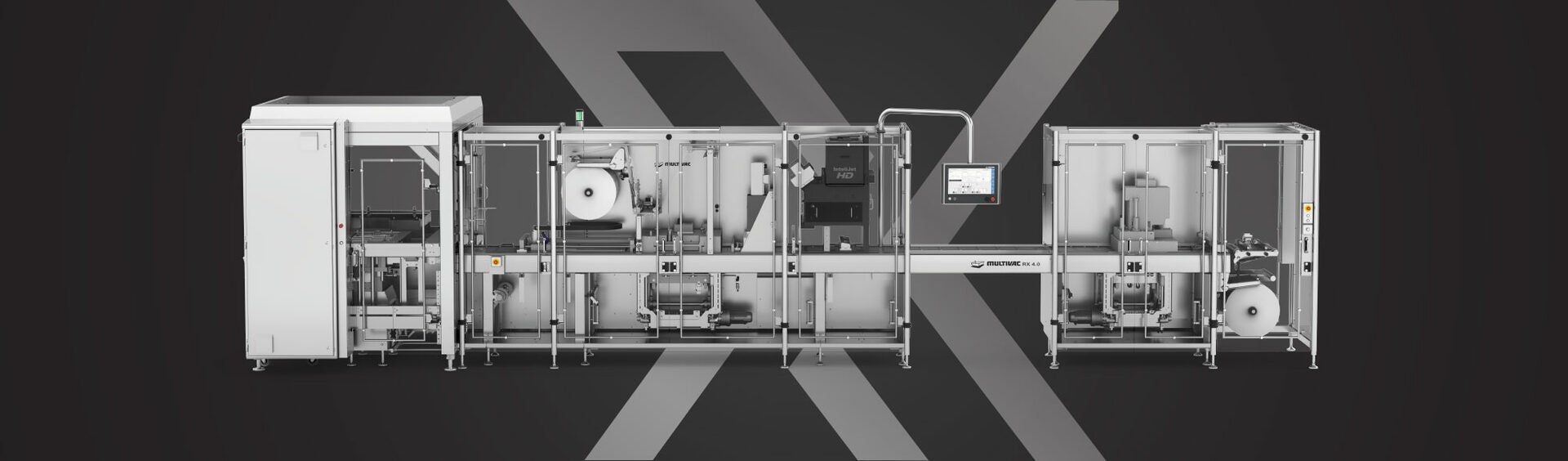

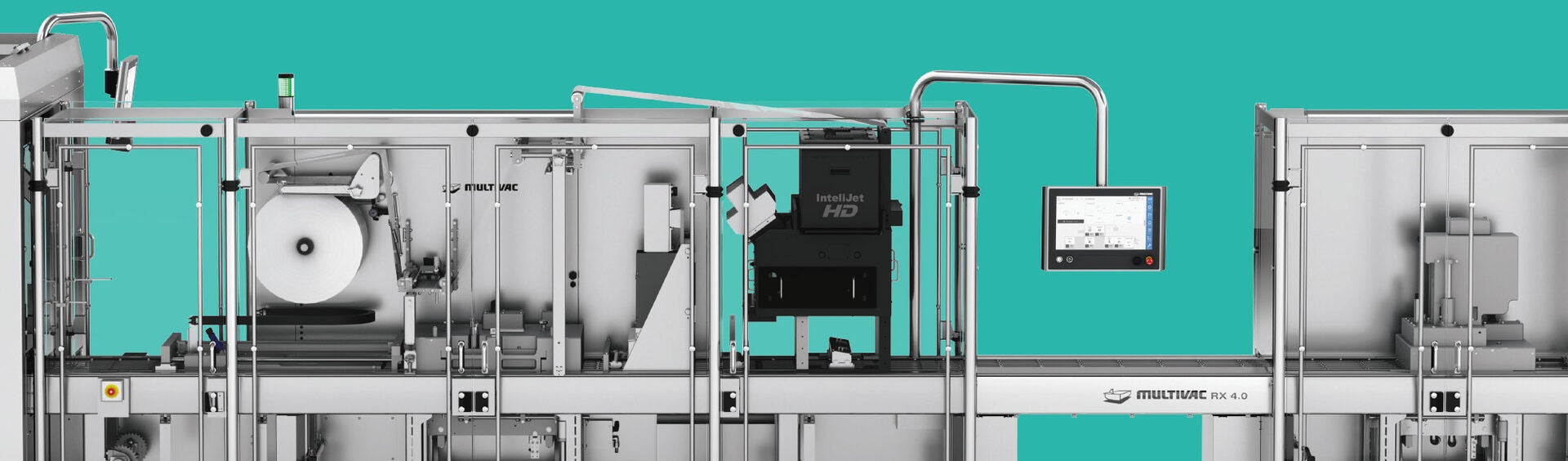

RX 4.0 offers maximum process reliability

The medical products and pharmaceutical industries place very great demands on the precision and reproducibility of processes when packing sensitive products - not least because of the new MDR and UDI regulations. The declared aims of both sectors also include improvements in throughput times, production efficiency and process flexibility.

The medical products and pharmaceutical industries place very great demands on the precision and reproducibility of processes when packing sensitive products - not least because of the new MDR and UDI regulations. The declared aims of both sectors also include improvements in throughput times, production efficiency and process flexibility.

Lær mere

Healthcare Professionals Europe Overview

Healthcare Professionals Europe Overview

“Manufacturers of medical products should approach their suppliers at an early stage.”

Dr Jan Havel, Global Director for General Essential Modules (GEM), Biocompatibility, Sterilization and Packaging at TÜV SÜD Product Services GmbH explains, what manufacturers of medical products must take into consideration in the light of MDR.

Dr Jan Havel, Global Director for General Essential Modules (GEM), Biocompatibility, Sterilization and Packaging at TÜV SÜD Product Services GmbH explains, what manufacturers of medical products must take into consideration in the light of MDR.

Lær mere

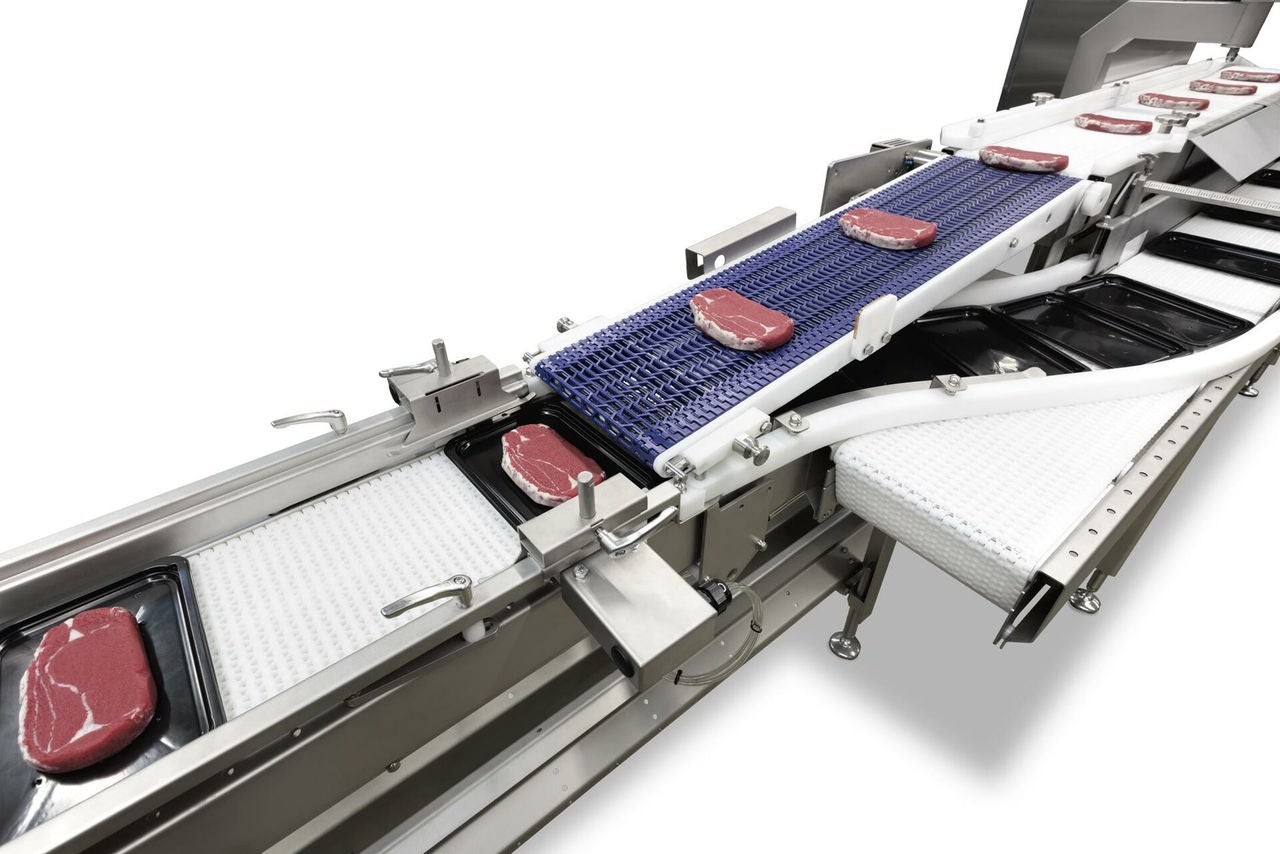

Maximum flexibility in the portioning of fresh meat

Producers of sausage and meat products are being required, now more than ever, to provide a wide range of varieties for the market.

Producers of sausage and meat products are being required, now more than ever, to provide a wide range of varieties for the market.

Lær mere

FRITSCH - A strong MULTIVAC brand

The integration of FRITSCH into the MULTIVAC Group is proceeding very rapidly. The joint CEOs, Andreas Eyd and Frank Gabriel, report in this interview on the current state and prospects of the family company, which was founded in 1926.

The integration of FRITSCH into the MULTIVAC Group is proceeding very rapidly. The joint CEOs, Andreas Eyd and Frank Gabriel, report in this interview on the current state and prospects of the family company, which was founded in 1926.

Lær mere

MULTIVAC Packaging Machine in Modern Office Setting

MULTIVAC Packaging Machine in Modern Office Setting

Digitalisation in the food industry

In many business sectors, digitalisation is already well advanced. However, the food processing industry is still in the early stages, although it is clear that digitalisation can make a major contribution to greater efficiency, process reliability, and transparency, as well as higher pack and product quality. The current situation is illustrated for us by Dr Marius Grathwohl, Vice President of Digital Products and Transformation at MULTIVAC.

In many business sectors, digitalisation is already well advanced. However, the food processing industry is still in the early stages, although it is clear that digitalisation can make a major contribution to greater efficiency, process reliability, and transparency, as well as higher pack and product quality. The current situation is illustrated for us by Dr Marius Grathwohl, Vice President of Digital Products and Transformation at MULTIVAC.

Lær mere

MULTIVAC Industrial Machine with Operator in Lab

MULTIVAC Industrial Machine with Operator in Lab

The digital challenge

One of the most important drivers for progress and development in the medical and pharmaceutical industries is digitalisation along the entire process chain. In order to benefit from digitalisation and the resulting added value, a clear digital strategy is essential and must be in harmony with the whole company strategy.

One of the most important drivers for progress and development in the medical and pharmaceutical industries is digitalisation along the entire process chain. In order to benefit from digitalisation and the resulting added value, a clear digital strategy is essential and must be in harmony with the whole company strategy.

Lær mere

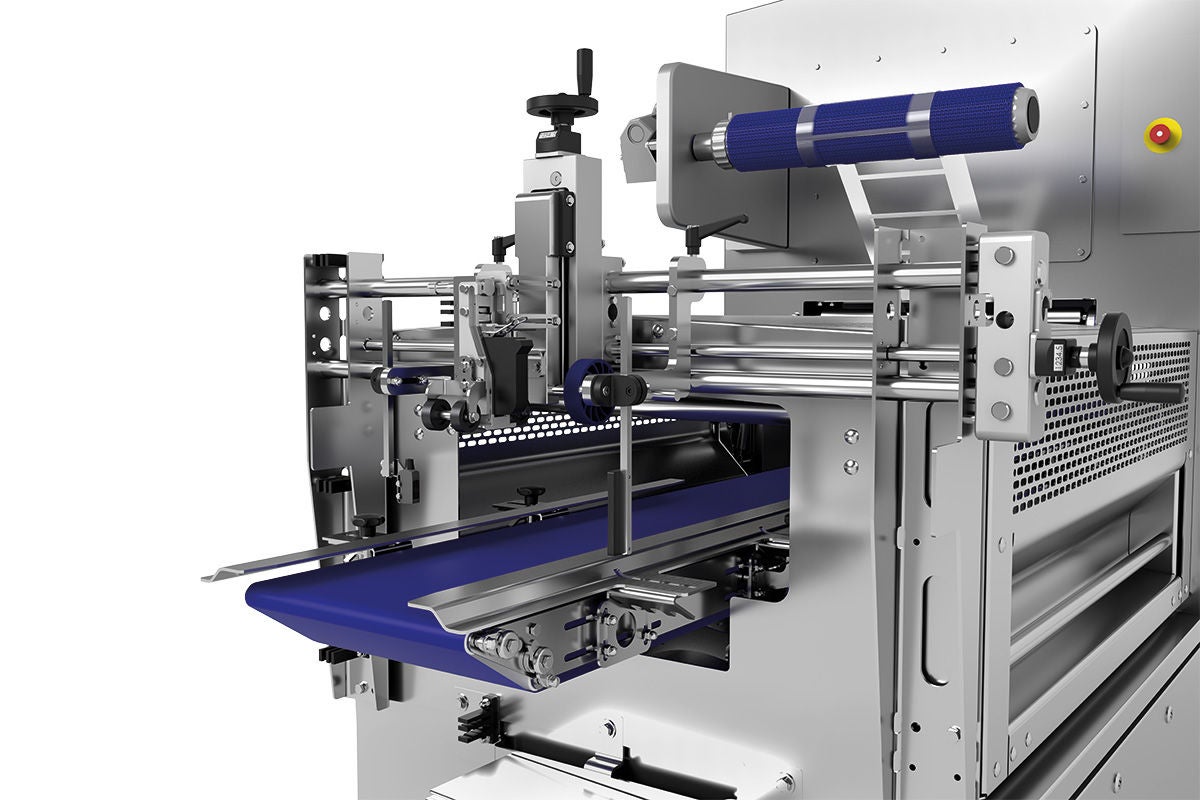

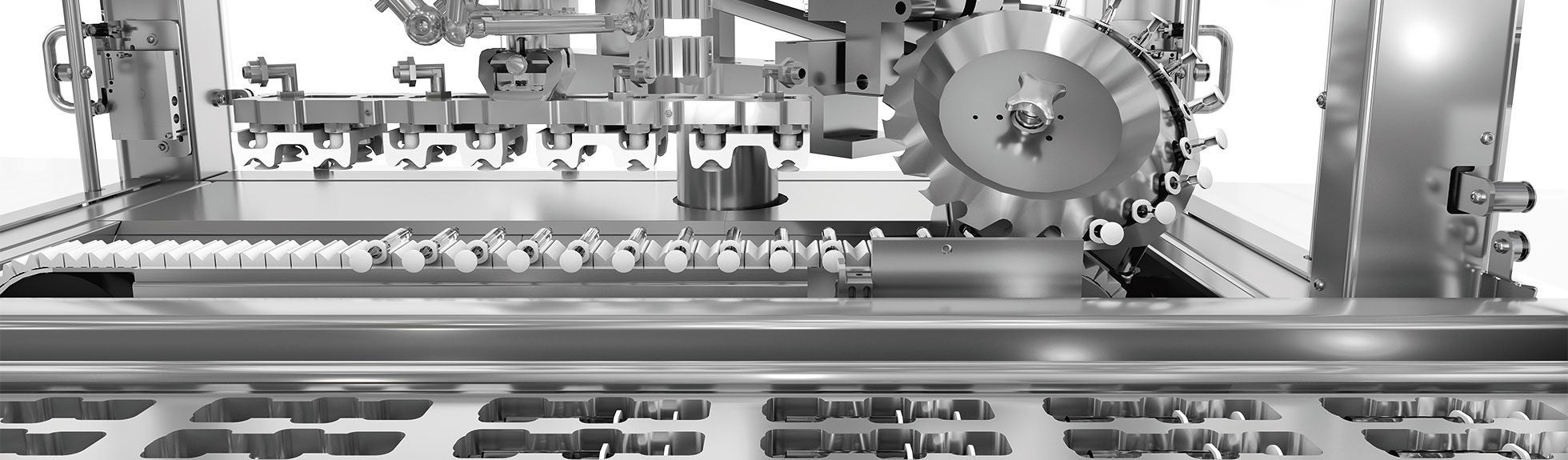

Carrier concepts as an important building block for automation in the packaging process

Today, packaging machines in the medical and pharmaceutical industries are generally a central component of an increasingly complex system solution, which is invariably complemented by customised conveyor and infeed systems, handling modules, labellers, printing solutions and inspection systems. Automation makes it possible to have more stable, transparent, efficient and above all reliable processes throughout the line, particularly if at the same time there is an integrated transfer of all the process data. This article will shed light on the benefits that automation solutions offer, as well as the opportunities that are currently available in the area of product infeed and generally throughout the packaging process.

Today, packaging machines in the medical and pharmaceutical industries are generally a central component of an increasingly complex system solution, which is invariably complemented by customised conveyor and infeed systems, handling modules, labellers, printing solutions and inspection systems. Automation makes it possible to have more stable, transparent, efficient and above all reliable processes throughout the line, particularly if at the same time there is an integrated transfer of all the process data. This article will shed light on the benefits that automation solutions offer, as well as the opportunities that are currently available in the area of product infeed and generally throughout the packaging process.

Lær mere

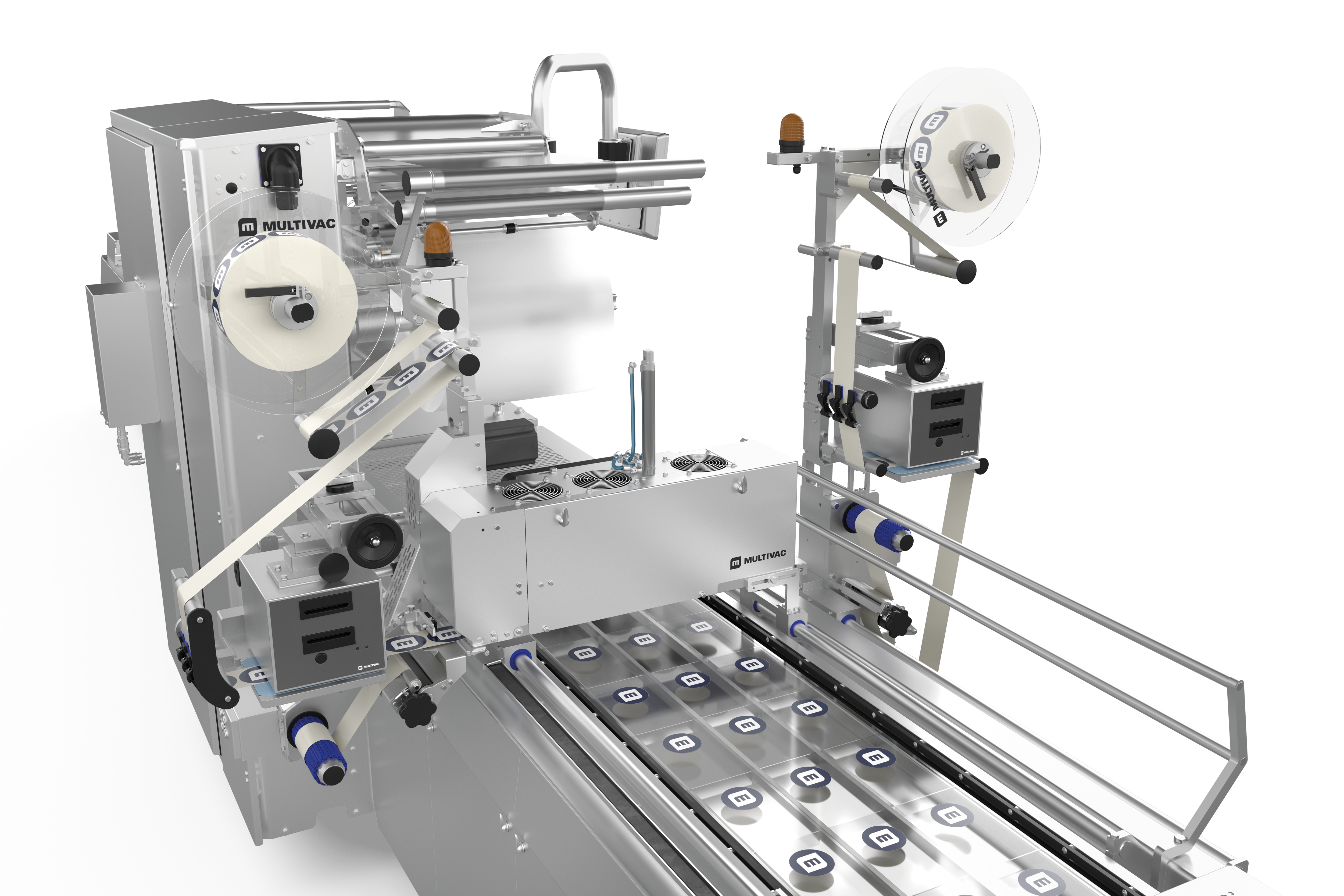

Digital printing systems fulfil challenging pack marking requirements

The UDI Directive applies to all companies, which manufacture medical products or bring these into circulation. From 25 April 2020 all products of Class III together with implants must be marked with a distinct and unique identification number, and this applies from May 2023 to products of Class IIa and IIb, as well as from 2025 to products of Class I. This distinct product identification is allocated by various bodies - these are currently GS1, HIBCC and ICCBBA. The products together with their master data and a so-called Basic UDI are registered in a new, central database (Eudamed) covering all of Europe.

The UDI Directive applies to all companies, which manufacture medical products or bring these into circulation. From 25 April 2020 all products of Class III together with implants must be marked with a distinct and unique identification number, and this applies from May 2023 to products of Class IIa and IIb, as well as from 2025 to products of Class I. This distinct product identification is allocated by various bodies - these are currently GS1, HIBCC and ICCBBA. The products together with their master data and a so-called Basic UDI are registered in a new, central database (Eudamed) covering all of Europe.

Lær mere

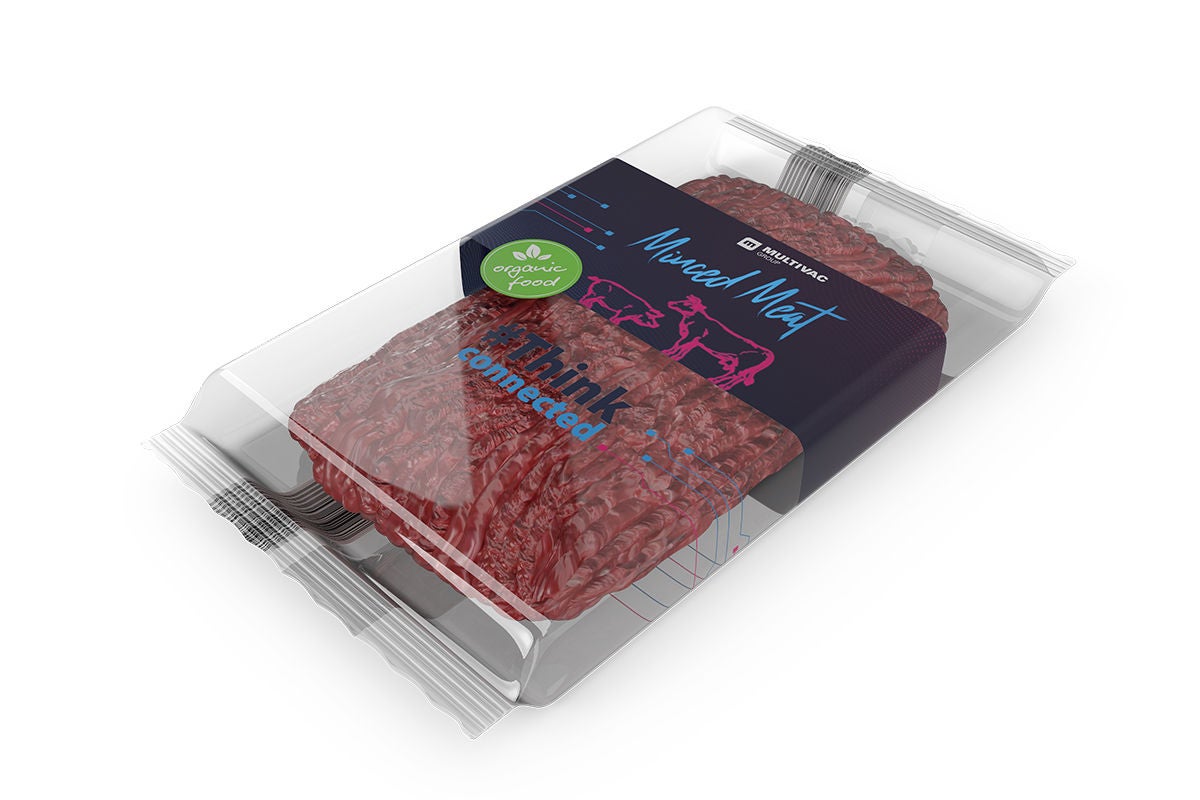

MULTIVAC Packaging Solutions for Meat Products

MULTIVAC Packaging Solutions for Meat Products

Full wrap labelling for maximum pack attractiveness at the POS

Full wrap labels, which enclose all four sides of a pack like a banderole, feature a whole range of competitive advantages over other solutions for labelling and marking. In addition to their function as information carriers, full wrap labels are today also an essential design feature for increasing the appeal of packs on the shelf. They support manufacturers in optimal presentation of their brand and offer consumers real added value.

Full wrap labels, which enclose all four sides of a pack like a banderole, feature a whole range of competitive advantages over other solutions for labelling and marking. In addition to their function as information carriers, full wrap labels are today also an essential design feature for increasing the appeal of packs on the shelf. They support manufacturers in optimal presentation of their brand and offer consumers real added value.

Lær mere

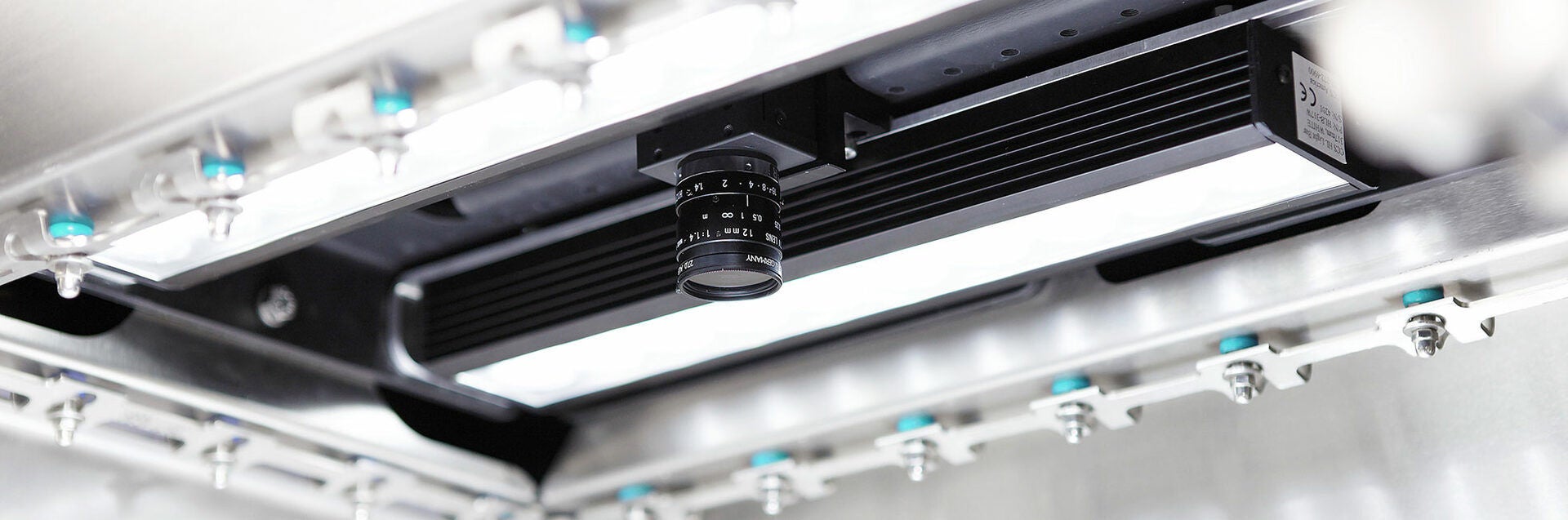

Automated label and print inspection in the food industry

Rising demands in food labelling increase the complexity of information that has to be printed on labels. As the throughput of packaging lines continues to increase, it is no longer possible for the human eye to inspect label print thoroughly. Although present legislation does not yet stipulate the use of visual inspection systems for checking labels, investment in automatic inspection systems can be very beneficial for many reasons.

Rising demands in food labelling increase the complexity of information that has to be printed on labels. As the throughput of packaging lines continues to increase, it is no longer possible for the human eye to inspect label print thoroughly. Although present legislation does not yet stipulate the use of visual inspection systems for checking labels, investment in automatic inspection systems can be very beneficial for many reasons.

Lær mere

Optimum slicing quality and weight accuracy when producing cheese slices

Today a large variety of sliced cheese is sold in chill cabinets in every supermarket. The different sorts, such as Appenzeller, Edam, Gouda, Leerdammer, or Tilsiter are either packed as shingled or wafer-thin slices, which are folded and presented attractively in the pack. While also maintaining the highest hygienic standards, producers today must operate with the maximum efficiency, flexibility, weight accuracy, and yield, if they are to remain competitive in the market. But how can these requirements be met? And what in particular must be taken into account when slicing cheese?

Today a large variety of sliced cheese is sold in chill cabinets in every supermarket. The different sorts, such as Appenzeller, Edam, Gouda, Leerdammer, or Tilsiter are either packed as shingled or wafer-thin slices, which are folded and presented attractively in the pack. While also maintaining the highest hygienic standards, producers today must operate with the maximum efficiency, flexibility, weight accuracy, and yield, if they are to remain competitive in the market. But how can these requirements be met? And what in particular must be taken into account when slicing cheese?

Lær mere

Sustainable packaging concepts for sliced cheese

Thanks to the driving force of the EU's Plastics Strategy and new packaging legislation, the issue of sustainability is now gaining increasing importance in the packing of dairy products. At the same time the strict hygiene regulations must however continue to be observed, while also maintaining the maximum shelf life for the food products. Innovative packaging concepts can help to master the difficult balancing act between sustainability, product protection, and retaining quality.

Thanks to the driving force of the EU's Plastics Strategy and new packaging legislation, the issue of sustainability is now gaining increasing importance in the packing of dairy products. At the same time the strict hygiene regulations must however continue to be observed, while also maintaining the maximum shelf life for the food products. Innovative packaging concepts can help to master the difficult balancing act between sustainability, product protection, and retaining quality.

Lær mere

Vegetable Spread Packaging Design

Vegetable Spread Packaging Design

Labelling of dairy products

The range of dairy products is very large - it extends from hard cheese, semi-hard sliced cheese or soft cheese through to butter and cream cheese and right up to liquid or creamy products such as milk, whipped cream, and yogurt. In this article you will learn how the labelling process for the different product groups can be performed as reliably, efficiently, and cost-effectively as possible.

The range of dairy products is very large - it extends from hard cheese, semi-hard sliced cheese or soft cheese through to butter and cream cheese and right up to liquid or creamy products such as milk, whipped cream, and yogurt. In this article you will learn how the labelling process for the different product groups can be performed as reliably, efficiently, and cost-effectively as possible.

Lær mere

Use automation to master modern challenges in the food industry

Intelligently used automation solutions can make a major contribution in the food industry to designing an efficient, hygienic, and cost-effective packaging process. Automation is particularly worthwhile for product loading, even if this process represents a real challenge for some applications due to the diverse nature of the products. This article will throw light on those systems, which are available for the most common tasks in this sector.

Intelligently used automation solutions can make a major contribution in the food industry to designing an efficient, hygienic, and cost-effective packaging process. Automation is particularly worthwhile for product loading, even if this process represents a real challenge for some applications due to the diverse nature of the products. This article will throw light on those systems, which are available for the most common tasks in this sector.

Lær mere

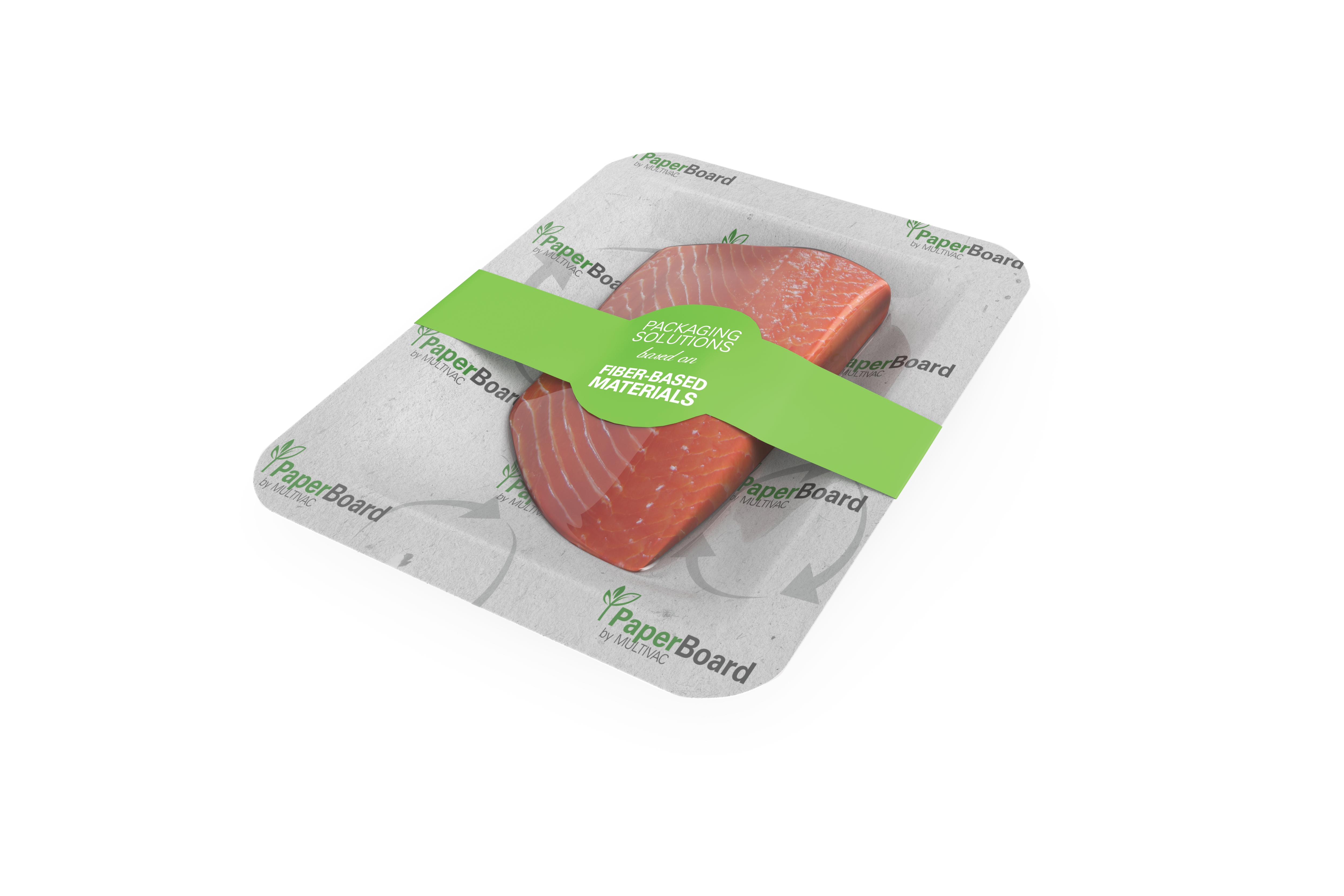

MULTIVAC PaperBoard Packaging Cycle Image

MULTIVAC PaperBoard Packaging Cycle Image

Packing sustainably

The new Packaging Legislation has been in force in Germany since the start of 2019. Among other things, it lays down challenging quotas for the recycling of materials and the reusability of packs. The introduction of a functioning closed-loop system for the packaging industry, as well as establishing that plastics are a reusable and therefore valuable resource, are important steps in the right direction. In parallel with this, the packaging industry is also driving forward the development of packs made from alternative materials. In addition to the introduction of a closed-loop system for plastics, the reduction in the consumption of plastics in the production of packs also represents another sensible approach to the sustainable development of the packaging industry.

The new Packaging Legislation has been in force in Germany since the start of 2019. Among other things, it lays down challenging quotas for the recycling of materials and the reusability of packs. The introduction of a functioning closed-loop system for the packaging industry, as well as establishing that plastics are a reusable and therefore valuable resource, are important steps in the right direction. In parallel with this, the packaging industry is also driving forward the development of packs made from alternative materials. In addition to the introduction of a closed-loop system for plastics, the reduction in the consumption of plastics in the production of packs also represents another sensible approach to the sustainable development of the packaging industry.

Lær mere

Beef Jerky with Sea Salt on Slate Background

Beef Jerky with Sea Salt on Slate Background

Beef jerky in attractive aluminium packs

Dried meat is one of the most popular snacks in China. But jerky has now also become one of the top sellers in the USA, and even recently in Germany. The market for the spicy, long-life strips and pieces of beef, duck, and ostrich meat is booming worldwide. The sales figures in the snacks segment are strongly driven by marketing. The Chinese company, Zhangfei Beef, recognized this trend at an early stage and now presents its high-quality beef snacks at the point of sale in attractive aluminium packs.

Dried meat is one of the most popular snacks in China. But jerky has now also become one of the top sellers in the USA, and even recently in Germany. The market for the spicy, long-life strips and pieces of beef, duck, and ostrich meat is booming worldwide. The sales figures in the snacks segment are strongly driven by marketing. The Chinese company, Zhangfei Beef, recognized this trend at an early stage and now presents its high-quality beef snacks at the point of sale in attractive aluminium packs.

Lær mere

“A holistic approach to retail thinking, management, and processes”

In Germany food still arrives at the consumer in the classic way via traditional physical retailing. Only one percent of significant market volume is handled online. But the market potential is huge - as are the challenges presented to online retailers, particularly as regards the logistics. We spoke to Dr. Reinhard Grandke, Head of the German Agricultural Society (DLG) about the challenges and opportunities for digitalisation in food retailing.

In Germany food still arrives at the consumer in the classic way via traditional physical retailing. Only one percent of significant market volume is handled online. But the market potential is huge - as are the challenges presented to online retailers, particularly as regards the logistics. We spoke to Dr. Reinhard Grandke, Head of the German Agricultural Society (DLG) about the challenges and opportunities for digitalisation in food retailing.

Lær mere

Frozen Meat Slice on White Background

Frozen Meat Slice on White Background

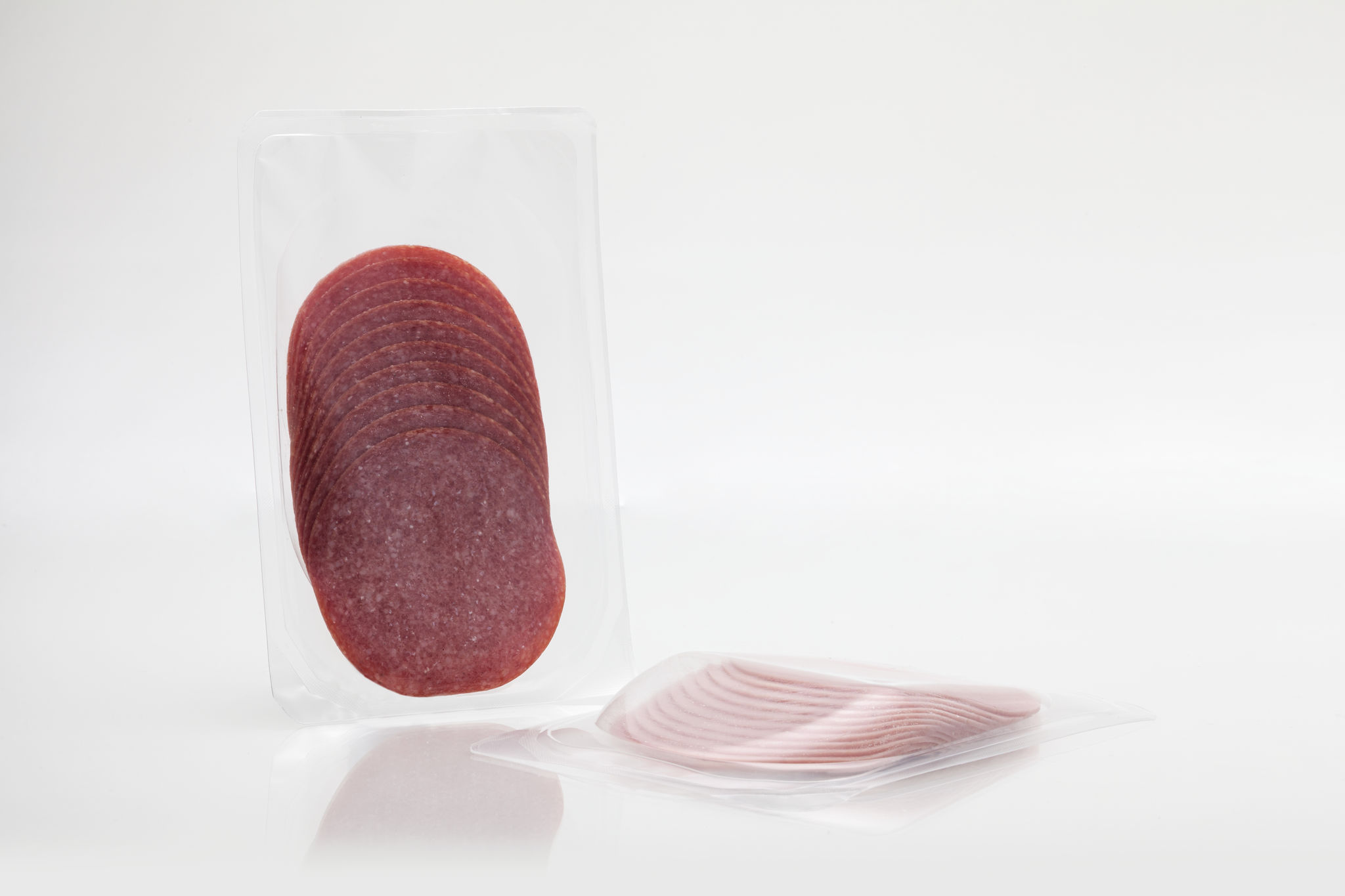

Perfect slicing results for fresh meat and processed products

Precise weight control in the portioning and slicing of meat or sausage products is one of the standard requirements in industrialised processing of fresh food. The slicing quality of the finished product is influenced significantly by the tempering and forming of the raw product, as well as by the slicing technology used. In this article we have compiled those aspects, which need to be taken into account with slicing, depending on the particular product and the outline conditions.

Precise weight control in the portioning and slicing of meat or sausage products is one of the standard requirements in industrialised processing of fresh food. The slicing quality of the finished product is influenced significantly by the tempering and forming of the raw product, as well as by the slicing technology used. In this article we have compiled those aspects, which need to be taken into account with slicing, depending on the particular product and the outline conditions.

Lær mere

MULTIVAC Meat Packaging Conveyor System

MULTIVAC Meat Packaging Conveyor System

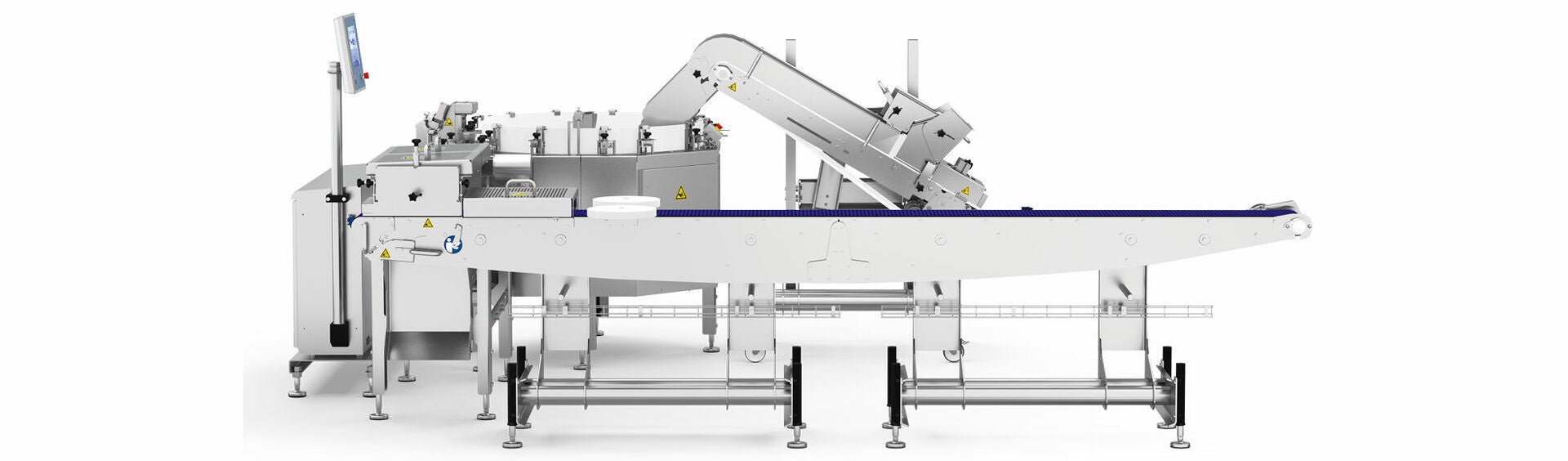

Automatic loading of sausage and meat products into the packaging machine

Today practically every stage in the processing and packing of meat and sausage products can be automated. But different products such as sliced meats, sausages or fresh meat require individual solutions. In the following article there are descriptions of the possible options for feeding and loading products efficiently and gently into the pack cavities.

Today practically every stage in the processing and packing of meat and sausage products can be automated. But different products such as sliced meats, sausages or fresh meat require individual solutions. In the following article there are descriptions of the possible options for feeding and loading products efficiently and gently into the pack cavities.

Lær mere

Vacuum Sealed Meat Packaging by MULTIVAC

Vacuum Sealed Meat Packaging by MULTIVAC

Different packaging concepts and methods for preserving meat quality

There are different packaging concepts depending on the particular product and the processing stage within the added value chain. This means that different technology and packaging materials are required, when transport or maturation packs for example are being produced, from those required for retail packs for the end consumer. In addition to the high demands placed on hygiene and functionality, one of the most important objectives of a pack is to provide extended shelf life for the product.

There are different packaging concepts depending on the particular product and the processing stage within the added value chain. This means that different technology and packaging materials are required, when transport or maturation packs for example are being produced, from those required for retail packs for the end consumer. In addition to the high demands placed on hygiene and functionality, one of the most important objectives of a pack is to provide extended shelf life for the product.

Lær mere

Automation solutions for the bakery product industry

The bread and bakery product industry finds itself in a far-reaching transition. Cost pressure, product diversity in the market, altered consumer habits, and hygiene regulations require companies not only to adapt their product range but also to optimise their production processes. One important approach as regards packaging are solutions with a high degree of automation.

The bread and bakery product industry finds itself in a far-reaching transition. Cost pressure, product diversity in the market, altered consumer habits, and hygiene regulations require companies not only to adapt their product range but also to optimise their production processes. One important approach as regards packaging are solutions with a high degree of automation.

Lær mere

Automation in meat processing offers a wide range of benefits

The food industry is booming. An ever increasing number of fresh and processed food products, snacks, ready meals, and convenience products have to be manufactured and packed. But it has become more difficult to find suitable or qualified staff. There is currently an acute lack of personnel in the meat processing sector. At the same time, hygiene and quality requirements are increasing. Automation solutions provide one way out of the dilemma. However, robots have been used to a very limited extent in the meat industry up to now.

The food industry is booming. An ever increasing number of fresh and processed food products, snacks, ready meals, and convenience products have to be manufactured and packed. But it has become more difficult to find suitable or qualified staff. There is currently an acute lack of personnel in the meat processing sector. At the same time, hygiene and quality requirements are increasing. Automation solutions provide one way out of the dilemma. However, robots have been used to a very limited extent in the meat industry up to now.

Lær mere

MULTIVAC Packaging Machine with Blue Crate

MULTIVAC Packaging Machine with Blue Crate

MULTIVAC solutions for secondary packaging – highly efficient and reliable to the end of the line

When it comes to loading packs into boxes or crates, and grouping or converging packs, MULTIVAC offers a wide range of end-of-line solutions, which are very flexible to use and which are individually designed to customer requirements. They can be used to automate quickly and precisely a wide range of tasks for a variety of products, pack formats, weights, and cycle times. They are also very reliable in their targeted ejection of empty or reject packs, and this contributes significantly to increasing process reliability and line efficiency.

When it comes to loading packs into boxes or crates, and grouping or converging packs, MULTIVAC offers a wide range of end-of-line solutions, which are very flexible to use and which are individually designed to customer requirements. They can be used to automate quickly and precisely a wide range of tasks for a variety of products, pack formats, weights, and cycle times. They are also very reliable in their targeted ejection of empty or reject packs, and this contributes significantly to increasing process reliability and line efficiency.

Lær mere

MULTIVAC Packaging Machine for Medical Supplies

MULTIVAC Packaging Machine for Medical Supplies

Automated production of combi packs

Packaging procedures with a high degree of complexity are often used to produce combi packs for pharmaceutical products. Infeed systems, which have to be tailored precisely to the particular components, and also integrated into the packaging line, are required for the automated infeed and loading of the various product components. This means the top priority is the precise and secure positioning of the product components, which are usually very small.

Packaging procedures with a high degree of complexity are often used to produce combi packs for pharmaceutical products. Infeed systems, which have to be tailored precisely to the particular components, and also integrated into the packaging line, are required for the automated infeed and loading of the various product components. This means the top priority is the precise and secure positioning of the product components, which are usually very small.

Lær mere

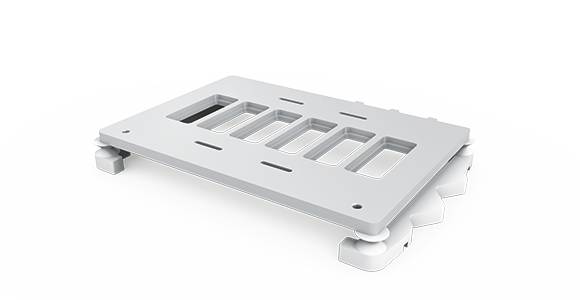

MULTIVAC Tray Sealer Machine Component

MULTIVAC Tray Sealer Machine Component

MULTIVAC Tray Carrier as a solution for packing in small series of batches

Comprehensive quality control

Comprehensive quality control

Lær mere

For maximum security - Product monitoring in the packaging procedure

Thanks to a wide range of inspection solutions, capable of seamelss integrationd into the packaging line, automated quality control can be performed very reliably, even for high-output applications.

Thanks to a wide range of inspection solutions, capable of seamelss integrationd into the packaging line, automated quality control can be performed very reliably, even for high-output applications.

Lær mere

MULTIVAC Food Packaging Machine Honey Peppers

MULTIVAC Food Packaging Machine Honey Peppers

Attractive solutions for full-wrap labelling of packs

MULTIVAC Marking & Inspection has continually expanded its range of conveyor belt labellers in recent years. The spectrum now includes a wide range of solutions for many different labelling requirements and output categories – from the simple BASELINE conveyor belt labellers to 2-track labelling systems with up to ten label dispensers.

MULTIVAC Marking & Inspection has continually expanded its range of conveyor belt labellers in recent years. The spectrum now includes a wide range of solutions for many different labelling requirements and output categories – from the simple BASELINE conveyor belt labellers to 2-track labelling systems with up to ten label dispensers.

Lær mere

MULTIVAC Packaging Machine Close-Up View

MULTIVAC Packaging Machine Close-Up View

Syringes and Vaccine Vial Medical Supplies Image

Syringes and Vaccine Vial Medical Supplies Image

Downloads

SUSTAINABILITY

Rapport om bæredygtighed

Vores første bæredygtighedsrapport baseret på standarderne fra Global Reporting Initiative (GRI).

- Størrelse

- 50 MB

- Format

Verhaltenskodex

Ordensreglerne

Interne standarder og specifikationer for MULTIVAC-gruppen

- Størrelse

- 700 KB

- Format

Har du spørgsmål til nogen af vores pressemeddelelser, eller ønsker du at registrere dig til vores distributionsliste? Kontakt os. Vi glæder os til at høre fra dig.

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com