This product diversity and the associated competition are a real challenge. Another major challenge is being able to push through commercially viable market prices for the particular products. The solution is automation - even for smaller companies. This can be done in individual process stages, or alternatively for the overall processing and packaging procedure. The compact and high-performance portioning solutions from TVI support smaller and medium-sized meat processing companies in meeting these daily challenges effectively.

Although meat consumption has seen a constant rise since the 1960's, the potential for further growth has largely been exhausted. Meat has long since developed from a luxury item to a generally accessible product, which is usually consumed several times a week. The market is now essentially saturated - and experts reckon that in the immediate future there will not be any significant rise in production quantities. On the contrary, consumer awareness of sustainability, expressed in a conscious move by many vegetarian or vegan diets, is creating a backward trend in meat consumption. The per-capita consumption in Germany is stagnating and even showing a slightly falling trend. Whereas the annual consumption in 1991 was around 63.9 kilograms, it has remained more or less stable since 2000 at approx. 60 kilograms. The compact and high-performance portioning solutions from TVI support smaller and medium-sized meat processing companies in meeting these daily challenges effectively.

Since increased sales can not be achieved - or only to a limited extent - through growth in this market environment, competition is increasingly being waged through the selling price. At the same time however, the customer's expectations in terms of quality, product presentation and diversity are increasing. In order to be able to produce meat products under these conditions in the required quality and at competitive prices, while still maintaining an acceptable margin, it is necessary to have a production process, which is as efficient and flexible as possible with the maximum process reliability. These objectives can be achieved with the help of high-output machines and automated processes. Traditionally these were reserved primarily for large-scale producers, who were able through their large volumes to amortise the high investment costs within a reasonable period of time. In the meantime however, even meat processing companies of only a moderate size are able to source suitable solutions on the market, which offer the maximum cost-effectiveness, resource efficiency and flexibility at a manageable price. This means the return on investment can be achieved after a relatively short time.

Portioning is a crucial factor in the efficient production of fresh meat. If optimum results are not achieved here, this will produce many negative effects, which can generally not be overcome in the downstream process stages. These include, for example, a lower level of resource efficiency and impaired product quality, as well as costly and labour-intensive reworking. There are many requirements of a portioning solution, and these are examined below in more detail.

The basic precondition for the sale of a product is that it looks as presentable as possible. Consumers expect pieces of meat, which look the same and have a virtually identical weight. If several meat slices are packed in one package, a uniform slice thickness also plays a significant role to ensure cooking times for the individual portions do not vary. Just as important as the portioning accuracy is a clean and smooth cutting result without any frayed meat fibres. A major challenge is the fact that meat becomes deformed at room temperature by the force of the cutting process. In order to prevent this, the raw material is often tempered before portioning. If deformation of the product is to be excluded completely, the temperature throughout the entire piece of meat should be below 0 °C. However, this results in the problem that ice crystals form inside the meat due to the freezing of the raw material, and these ice crystals destroy the cell structure of the meat. This means the product quality can be adversely affected - and this is reflected in increased drip loss, or in undesirable changes to the consistency and colour.

Therefore, one productive approach is to chill the raw material throughout to a low temperature just above freezing point (0 C to max. 4 C), and then to give the material a small freezer crust of approx. 2-5 millimetres thickness. The freezer crust stabilizes the meat during the cutting process, and it also facilitates the clean entry and exit of the cutting blade. Since the freezer crust has a dry surface when compared to meat at room temperature, the risk of contamination through bacteria is significantly reduced. When taken together with the constant chilling of the raw material right up to the packaging process, this makes a major contribution to the extension of product shelf life.

In order to achieve a long product shelf life, high standards of hygiene are also a crucial precondition. In addition to the machine design, which is laid out for simple, quick and thorough cleaning, the shortest possible path along the entire production process is also another critical factor. This means contact between the food and the mechanical components of the production line can be minimised, as is the intervention by the production personnel.

Weight accuracy and cutting quality during the portioning process can also contribute indirectly to a significant improvement in hygiene standards. If individual portions with a virtually identical weight are achieved, there is no requirement for further reworking stages. This reduces the risk of contamination, meaning that production lines can also be simplified. Better results in terms of product and pack quality can be achieved with a smaller footprint and reduced effort by staff.

Intelligent linking of the meat portioning system to the downstream packaging machine also helps to reduce the path along the production process. As part of the MULTIVAC Group, TVI has access to the parent company's expertise in packaging lines. Thanks to the seamless linking of the TVI portioning systems to MULTIVAC traysealers, resource efficiency and cost-effectiveness are just some of the features of MULTIVAC packaging solutions for portioned fresh meat. These solutions ensure high yields and low give-away are achieved with lower packaging material costs and reduced staff effort.

Meat is by far the biggest cost factor in a meat processing company. The most efficient use possible of this costly resource is therefore a critical factor in the commercial viability of a company. Its trading results can be crucially and positively influenced by precise and consistent portioning, which leads to an increase in yield by minimising the first end cut and give-away (with a high level of weight accuracy for fixed-weight packs).

As a natural product, meat has an irregular shape. Maximum yield can therefore only be achieved by targeted forming of the meat pieces. Thanks to its three-dimensional forming of the raw material, TVI's 3D forming system creates an even cross section over the entire product length. This means evenly large and evenly thick slices can be cut over the whole piece of meat. Depending on the desired shape and required quality expectations, it may even be possible to virtually eliminate the first end cut and give-away completely. Only if there are special requirements for the shape of the portions, are a first end cut and give-away necessarily required. And even this can be limited to a few millimetres with TVI's portioning solutions.

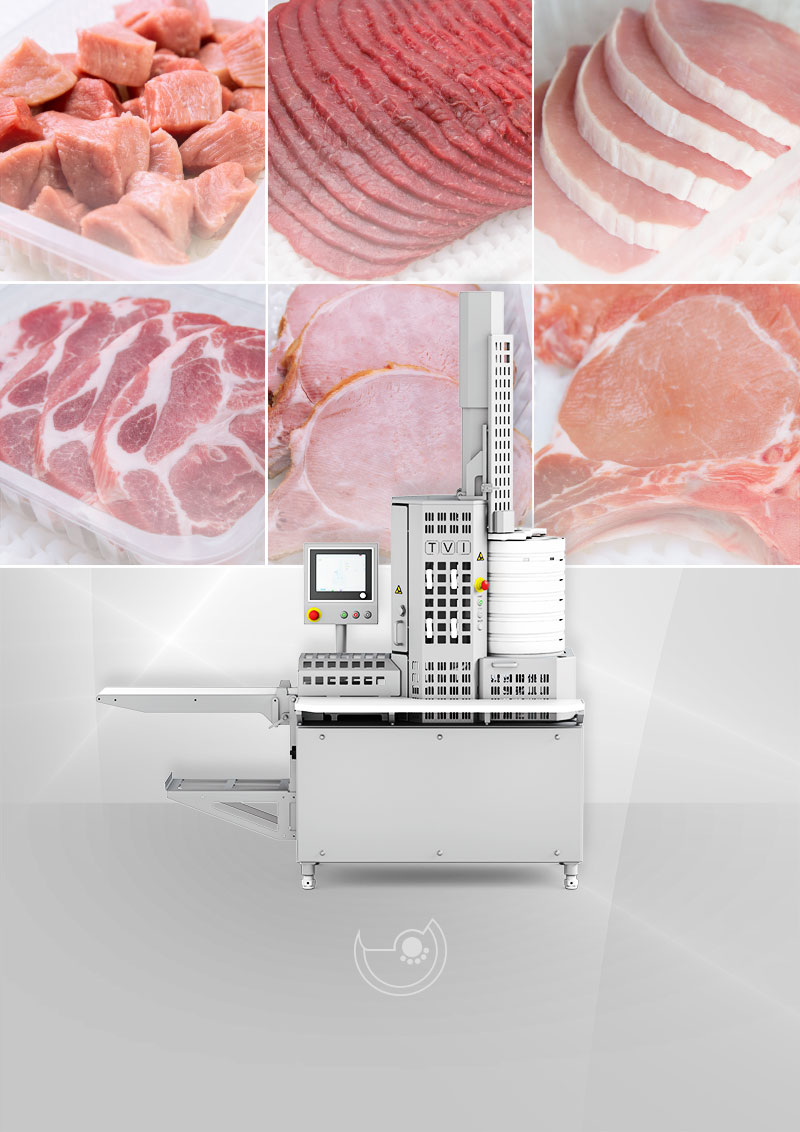

Portioning solutions should be as flexible as possible. A multifunctional meat portioning machine should be able to consistently process all types and consistencies of meat to the optimum degree: beef, pork and poultry, with and without bone, with freezer crust or frozen.

Compact and high-performance models like the multifunctional GMS 520 singlecut portioning system from TVI can meet all these requirements. But they can also process smaller batch sizes efficiently and cost-effectively. From small pork medallions to large beef roulades, from thin carpaccio to thick roasts, from goulash to goujons: even meat with bone, for example pork chops or neck cutlets of calf and lamb, can be cut into very even slices. A wide range of forming sets and easy conversion enable changes between different products to be made very quickly.

21.10.2020