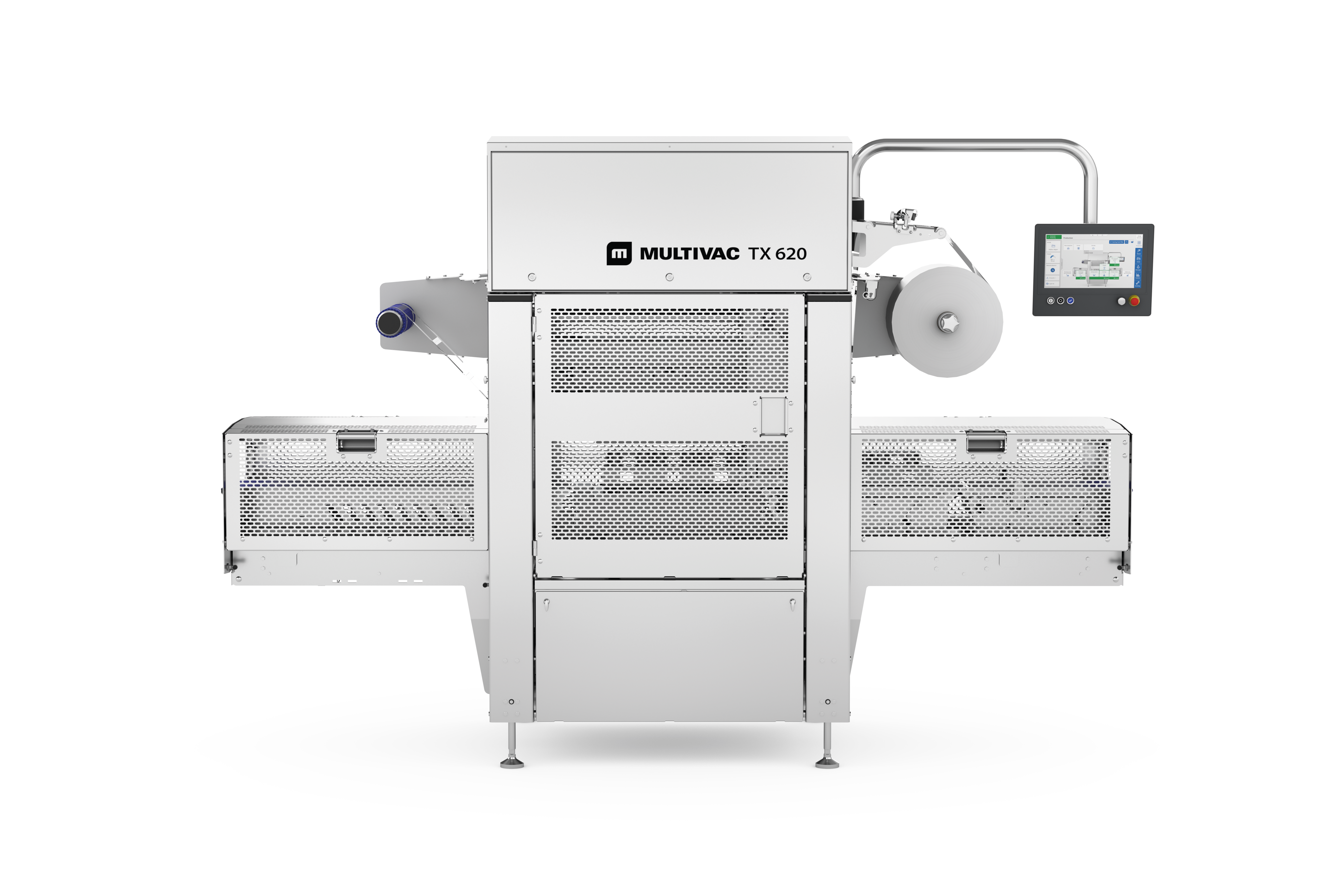

The new TX 6 series from MULTIVAC

Compact, versatile, networked: The new MULTIVAC traysealers are highly impressive in their outstanding performance with ex-ceptionally efficient use of the available production space. Just like the existing high-output TX 7 and TX 8 series, the space-saving new arrivals in the product range offer everything that customers could expect from a trend-setting machine generation. Also in terms of reliability, hygiene and ease of operation.

Maximum output with minimum use of resources

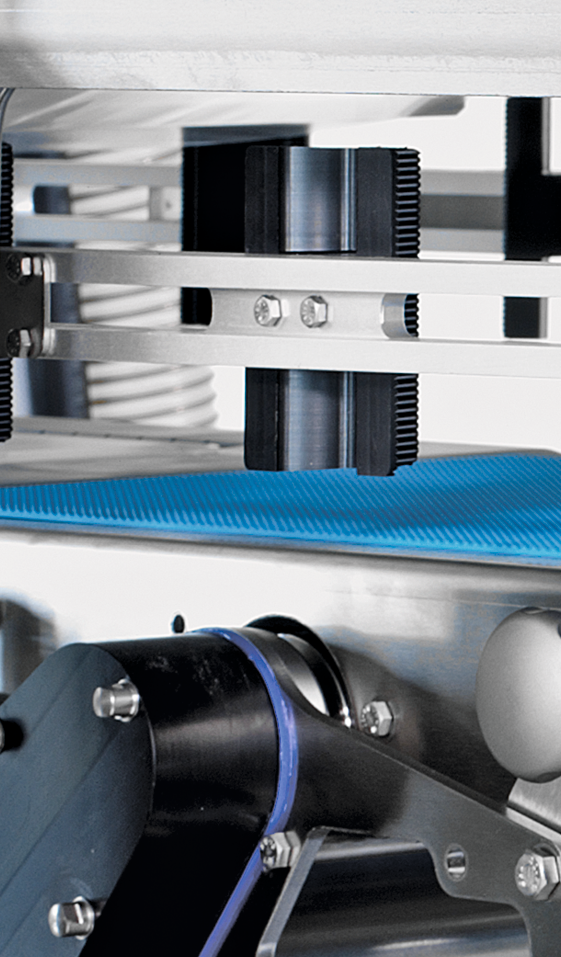

What makes our traysealers special? They provide maximum output for your application while consuming fewer resources and optimizing the use of your production space. MULTIVAC traysealers are efficient, flexible, durable, and particularly cost-effective as regards investment and operating costs. In addition to the economic aspects, safety is our first priority. Thanks to its intuitive operating concept, your machine can easily be controlled reliably.

Safe and reliable processes for maximum machine availability

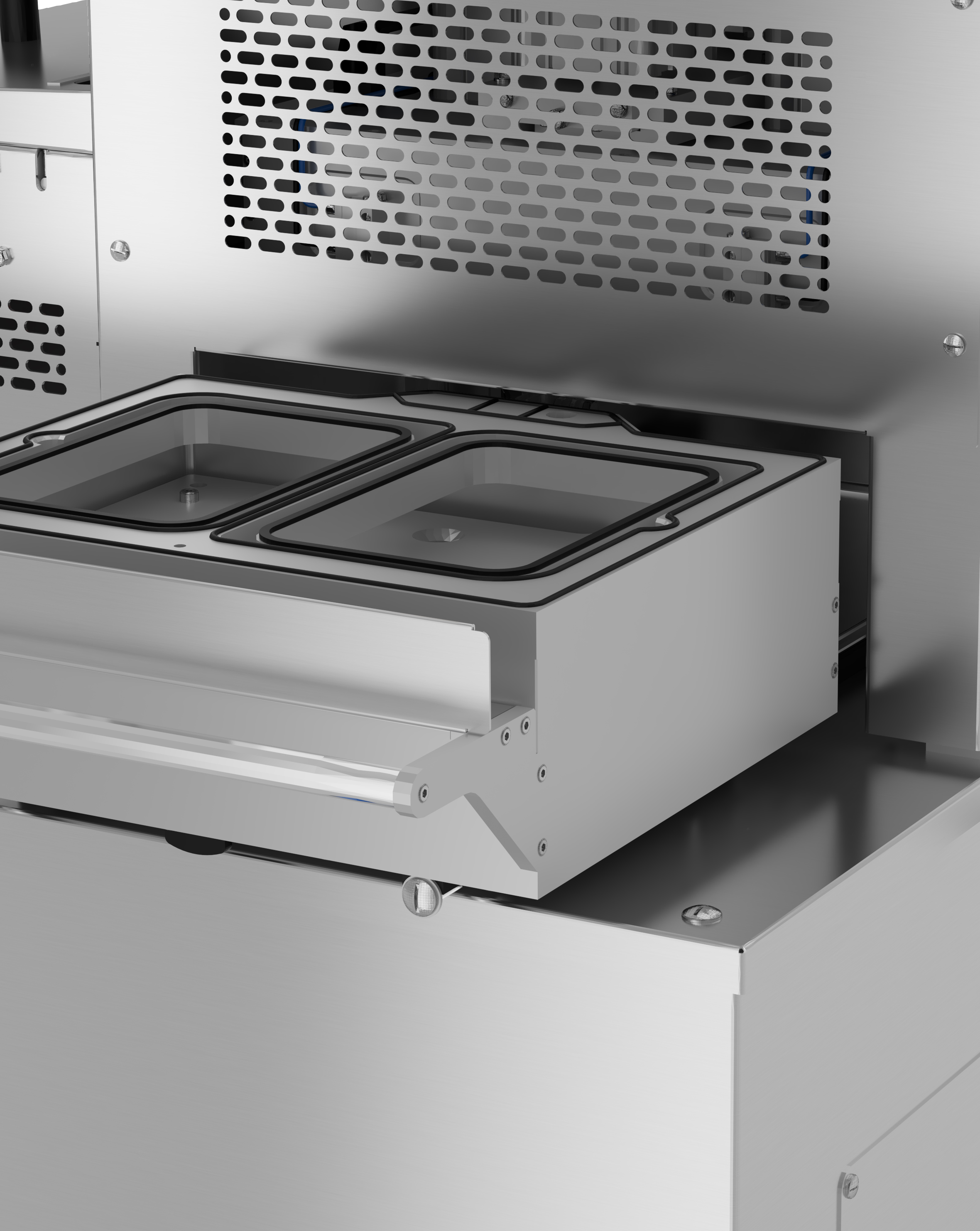

Consistent high pack quality and reproducibility, as well as the MULTIVAC Hygienic Design™, ensure the highest level of process reliability is achieved.

Our range is comprehensive and innovative. Each machine is designed to fit the customer's specific requirements regarding the product and tray, ensuring every traysealer fits seamlessly into a new or existing production environment, as a stand-alone machine, or as part of a fully automated packaging line solution.

Optimum packaging results

We are a supplier of integrated solutions with outstanding expertise in materials and applications. In addition, we ensure the perfect interaction of packaging material, machine, product, and atmosphere – and we systematically match the machines to the packaging technology and materials—the result: a pack that meets the highest demands.

As the leading manufacturer of packaging machines, our focus is on our customers. With our innovative technologies, we contribute to ensuring that you can consolidate your future market position with your products. Would you like to learn more about the benefits of MULTIVAC traysealers? Please contact us.

Interested?

Success stories

Poultry Farm Chickens in a Modern Facility

Poultry Farm Chickens in a Modern Facility

Beef Jerky with Sea Salt on Slate Background

Beef Jerky with Sea Salt on Slate Background

MULTIVAC Tray Sealer Machine Component

MULTIVAC Tray Sealer Machine Component

Hayter's Farm Event Display

Hayter's Farm Event Display

Cater Food Meat Preparation with Fresh Ingredients

Cater Food Meat Preparation with Fresh Ingredients

MULTIVAC Meat Skewer Packaging Machine Display

MULTIVAC Meat Skewer Packaging Machine Display

MULTIVAC Packaging Machine in Modern Kitchen Setting

MULTIVAC Packaging Machine in Modern Kitchen Setting

Spicy Marinated Olives with Red Peppers

Spicy Marinated Olives with Red Peppers