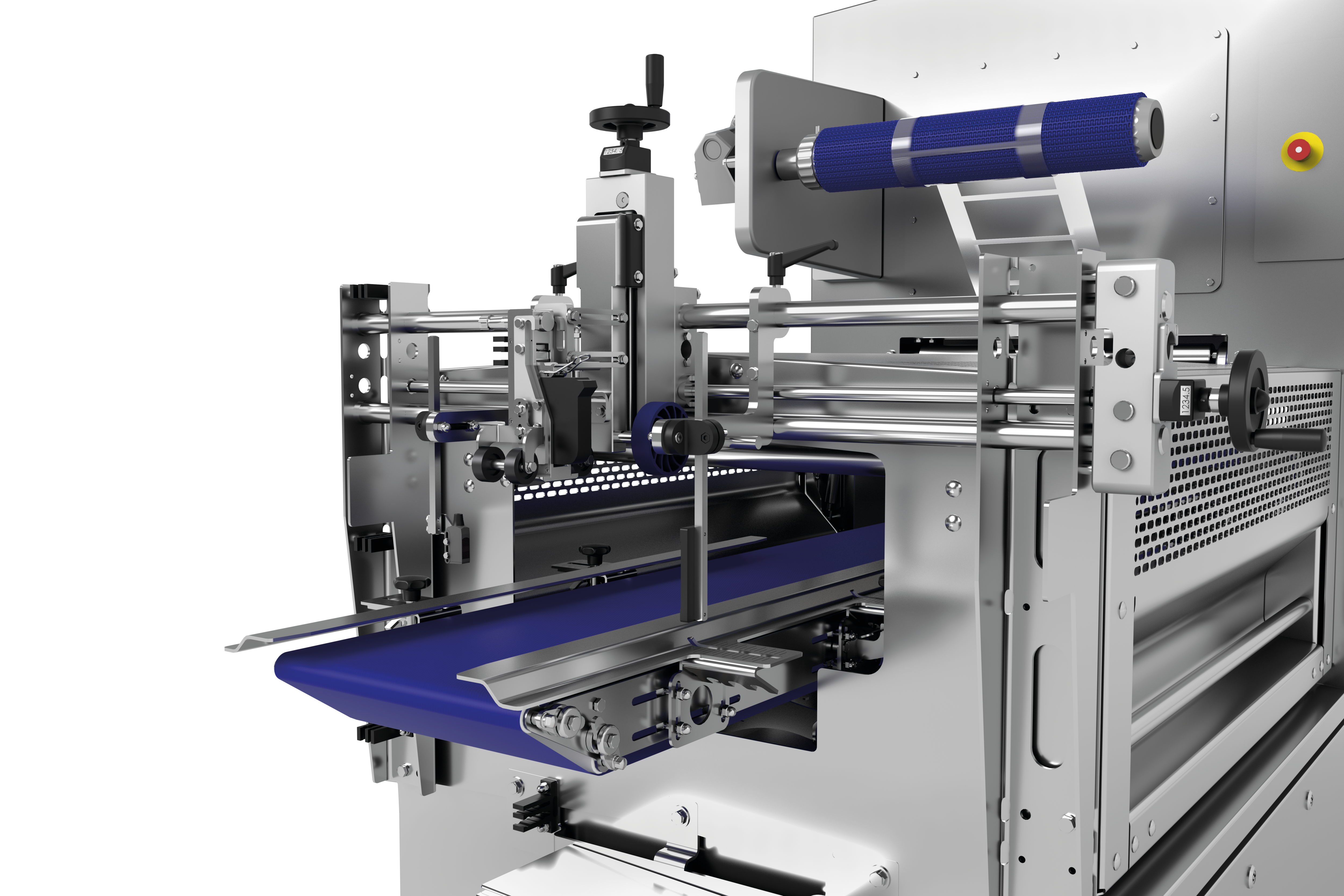

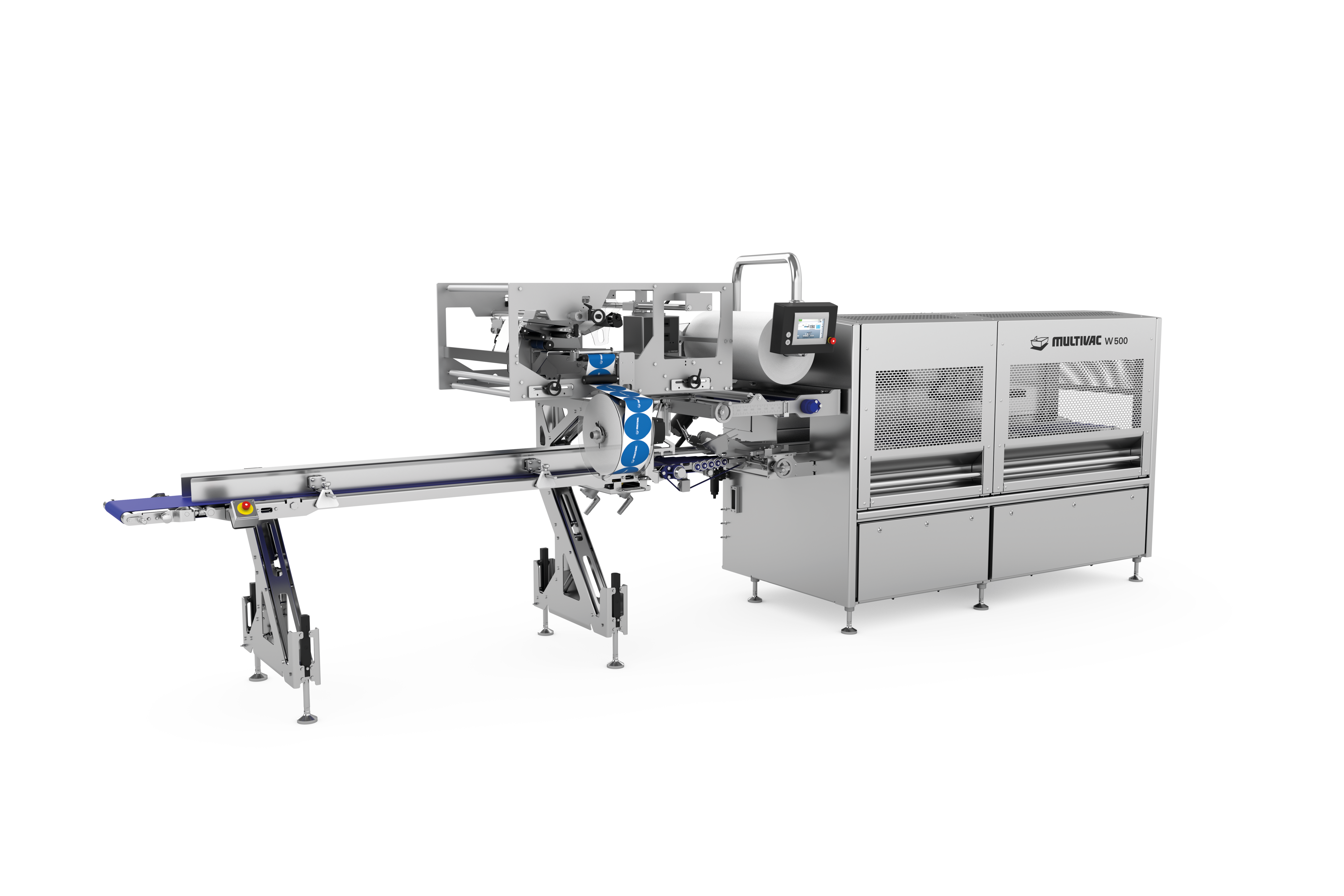

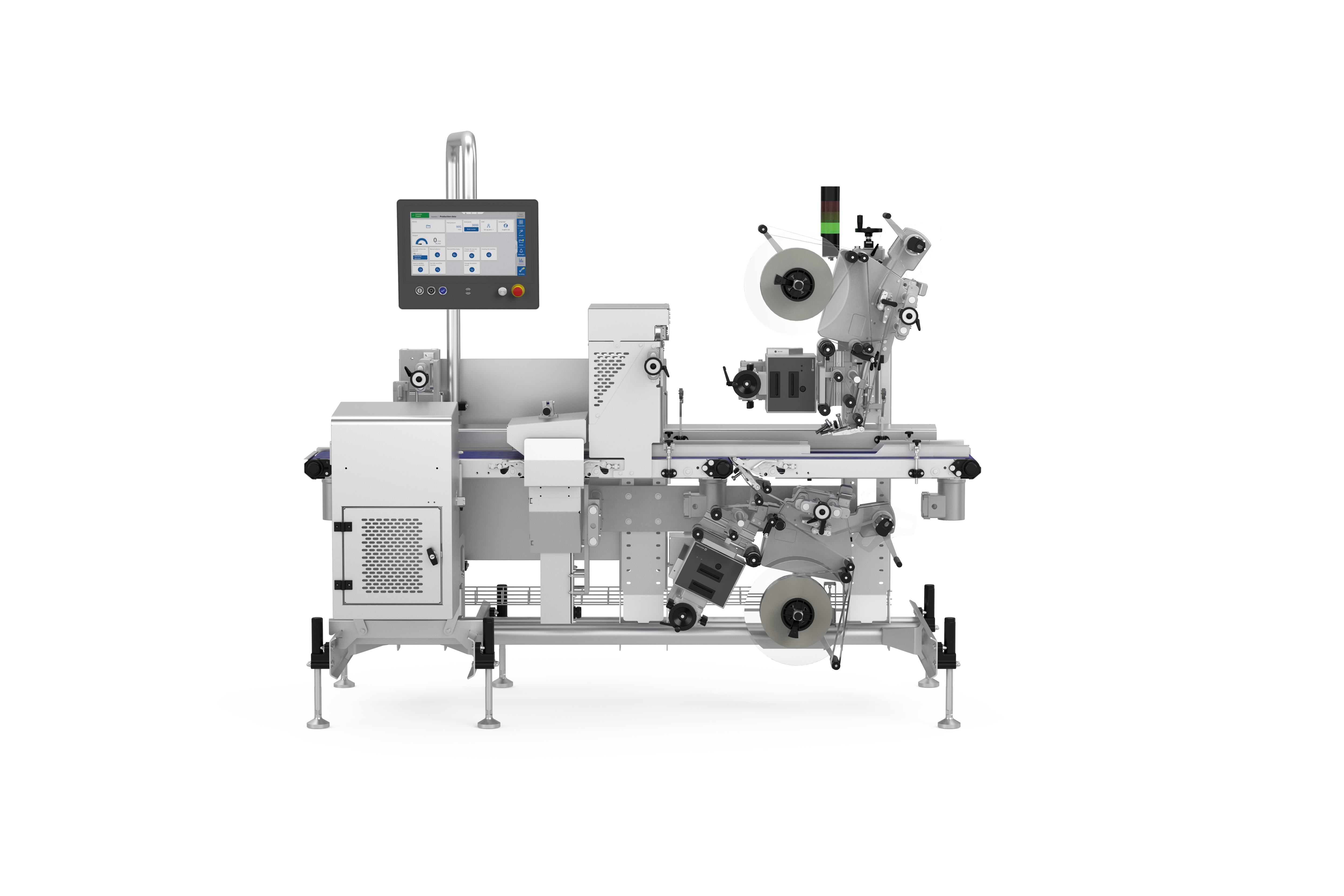

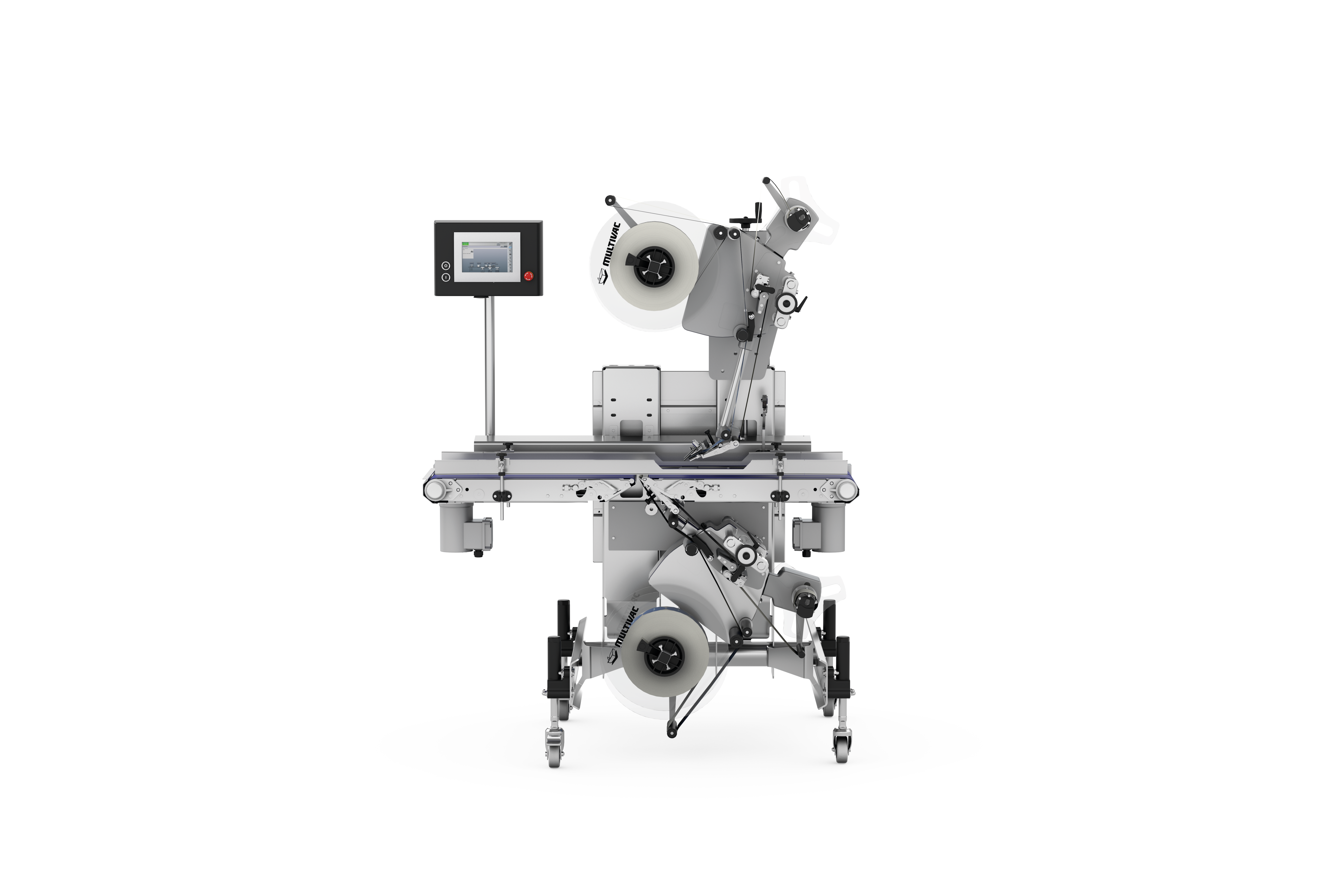

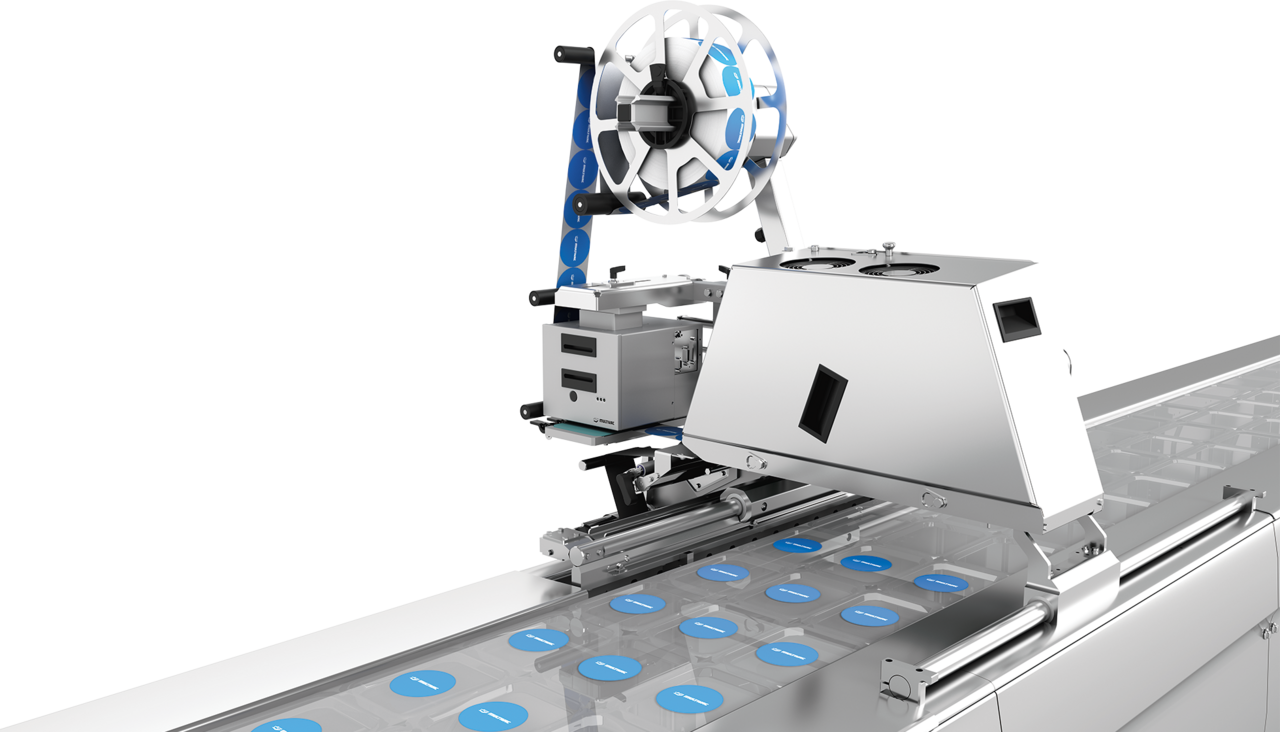

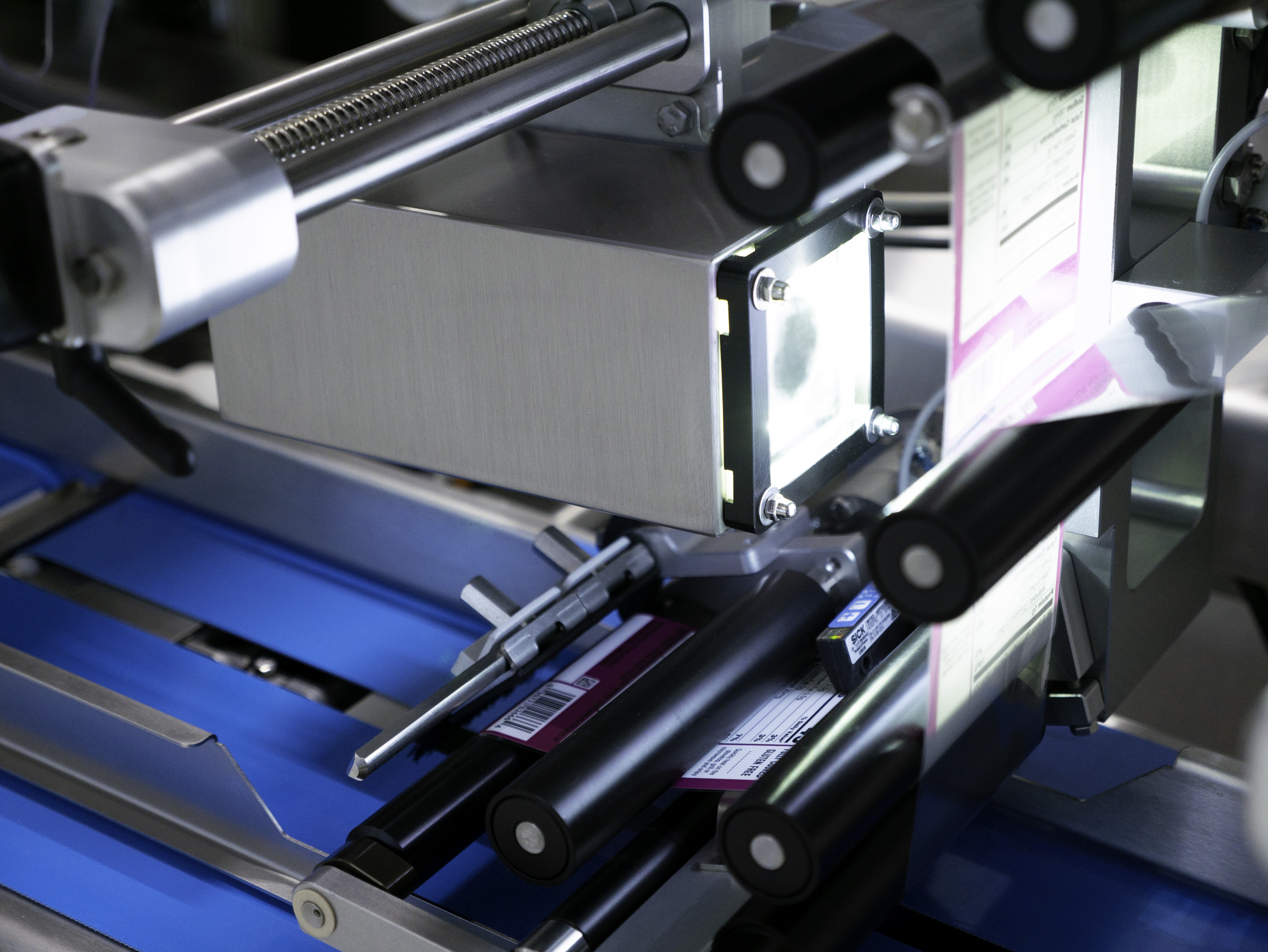

Flexible printing solutions to meet a wide range of requirements

MULTIVAC offers you a wide range of printing solutions for perfect results on labels, films and packs. Thanks to complete integration into the machine control of the packaging machine or labeller, they offer significant benefits when it comes to efficient, reliable operation. We also supply a range of consumable materials of the highest quality so that all components required in the printing process are ideally matched.