The two brothers, Samuel and Charles Gosselin, specialise in smoked salmon, and lately they have been making a great impression on customers both old and new with attractive vacuum skin packs, which exert a magical attraction for the consumer thanks to their colourful full wrap label.

The salmon comes from sustainable sources and is of the highest quality. It is only smoked with piquantly aromatic maple wood, and at Fumoirs Gosselin in Quebec they allow themselves just one thing: time. “This means that the fish is desiccated in a very gentle way. And this preserves the nutrients as well as the antioxidant properties. It also produces a delicate texture and an appetising red colour,” explains Samuel Gosselin.

The fish must first however undergo dry salting after having been cleaned. “This enables us to reduce the natural moisture as well as the growth of bacteria. At the same time we are creating an important precondition for the salmon to absorb the smoke aroma at a later stage,” emphasizes his brother Charles. In order to achieve the desired taste for the various product varieties, the raw salmon is first marinated in brown sugar, salt and different herbs, before being smoked for two hours. The smoking temperature is always between 50 and maximum 70 °C.

The first product, which Fumoirs Gosselin brought onto the market, and which began the company's success story, was "Maple" smoked salmon. This classic and top seller in the product range is seasoned with parsley, tarragon and chives, and it is captivating with its powerful maple overtones and delicate glaze. It is sold in packs of 200 and 320 grams. But large-scale users and catering outlets can also buy whole fillets. In addition to this, the very versatile salmon specialists also offer their smoked salmon in "Natural" or "Honey seasoned" varieties.

When it comes to small snacks, starters or fish additions to salads, the salmon is now also available in bite-size portions as "Natural", "Spicy" and of course "Maple Smoked" salmon nuggets.

catches the eye immediately with all the product varieties. The recyclable lower web, which is formed into a rigid tray on a MULTIVAC R 105 MF packaging machine, is coloured black, while the very thin flexible upper web on the other hand is highly transparent. The bright red salmon is showcased particularly vividly. The quality, freshness, colour and texture are presented in a natural way.

These very attractive packs are MultiFresh™ packs. These particularly appealing vacuum skin packs are produced on MULTIVAC's uniquely developed MultiFresh™ machines, using special MultiFresh™ packaging materials from MULTIVAC. The upper web encloses the product tightly and free of tension without affecting the shape of the product. The product is also firmly located in the pack, so that it can be presented at the point of sale either standing up or hanging as well as lying flat. The escape of liquid from the product is also reduced very effectively - another important aspect in terms of quality and shelf life.

The decision was made very consciously by Fumoirs Gosselin for the MultiFresh™ process, because it wanted to underline the top quality of the fish with an appropriate packaging design, as well as achieving the longest possible shelf life. In the view of the two company founders, epicureans and visionaries, the MULTIVAC R 105 MF thermoforming packaging machine is a “very intelligent investment”: The compact, cost-effective and highly flexible entry-level machine can run different types of film, such as flexible and rigid films, as well as paper composites, and also enables fast changeover to vacuum and MAP packs. Thanks to the unique interaction of machine and packaging material, vacuum skin packs of ground-breaking quality and perfection are produced.

The packaging process is a smart combination of technology and "handcrafting": After the smoking is completed, the salmon sides are placed manually on an infeed conveyor and cut into portions of equal weights on a portioning machine. When the lower web from the roll has been formed into rigid pack cavities in the thermoforming station of the R 105 MF, the cavities are filled with the individual fish pieces by the staff in the loading area of the machine. In order to achieve a high pack throughput, these process stages are performed in a three-track format. The filled packs are then allover sealed around the product by the upper web under vacuum. A cutting system then gives the pack the desired contour.

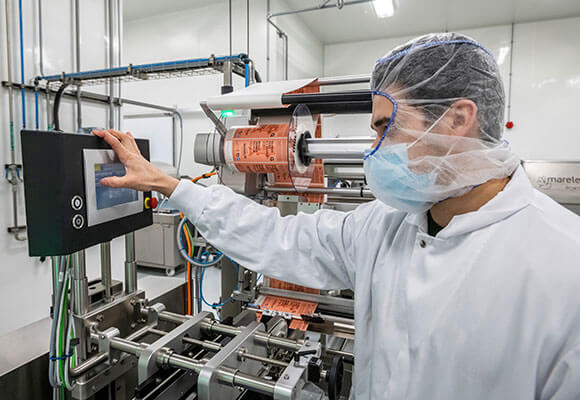

In order that the packs can also be labelled efficiently and reliably, they must next be converged and fed with the correct spacing to the L 310 full wrap labeller. This space-saving and high-output model from MULTIVAC Marking & Inspection is integrated into the line and, like all MULTIVAC line modules, it can be controlled reliably and conveniently from the HMI of the packaging machine. It is easily able to achieve the throughput of the upstream R 105 MF.

This conveyor belt labeller with its patented, servo-driven press-on brushes makes it possible to automatically apply a pre-printed self-adhesive label on up to four sides of a pack. The maximum label width is 500 mm, and the labelling output is up to 120 packs per minute. Depending on the requirements, a wide range of thermal transfer or thermal inkjet printers can be integrated into the labeller, so that just as at Fumoirs Gosselin variable data like use-by date, ingredients and weight can also be printed on the label.

Each product can be recognized at first glance by its label colour: The packs for the "Natural" smoked salmon are wrapped on the left side of the pack with a light blue full wrap label over all sides, while the "Honey" salmon can be recognized by the consumer from its golden yellow label colour, and the salmon with the maple aroma from the autumn red colour of its label. The right side of the pack remains uncovered and allows the content of the pack to be viewed.

In Quebec the very conscious decision was made to opt for simple, straight-line full wrap labels. Even though the design variants and applications for the process range from full wrap labels with cut-outs right up to allover labels, and also including additional functions such as perforation, opening aids, viewing window or adhesive-free zones. “Ultimately the smoked salmon still plays the central role for us,” says Samuel Gosselin with slight irony in his voice.

Michael Reffke, Product Manager at MULTIVAC Marketing & Inspection, adds: “Even where a fairly "simple" label design, such as that at Fumoirs Gosselin, or the lowest-cost material is used, our concept is still highly impressive with its high-quality look and feel, since the print design, shape and type of material can be individually adapted to the product and brand.”

Charles and Samuel Gosselin are in agreement: “Full wrap labelling meets all our expectations in terms of high quality and design. And thanks to the automated process, it is also significantly more efficient, as well as being more environmentally-friendly than cardboard sleeves due to the much reduced material input. It underlines our company philosophy perfectly, which is reflected primarily in our sustainable fish specialities, and which we of course want to highlight in our marketing.”

The labelling expert at MULTIVAC also adds something: “Full wrap labelling is an excellent alternative, particularly when natural or bio products are involved. When compared with cardboard sleeves, the weight of the banderole can be reduced by half. And in many cases even higher material savings over cardboard sleeves are possible.” The light label material therefore saves resources and also reduces the transport weight of the packs throughout the entire supply chain. Ultimately this also contributes to an improvement in the CO2 balance.

20.10.2022