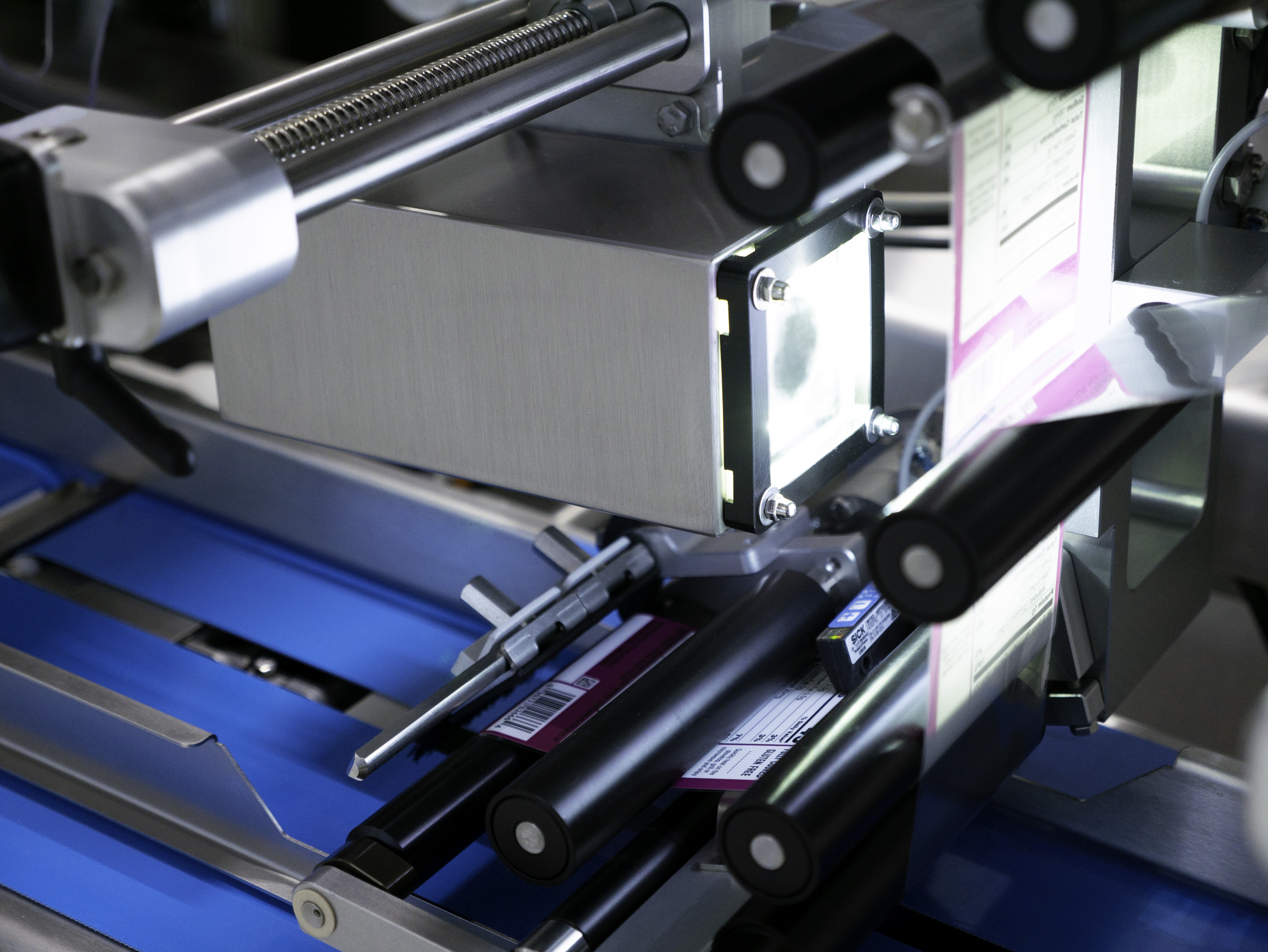

Avoid product recalls and ensure consumer safety and brand protection

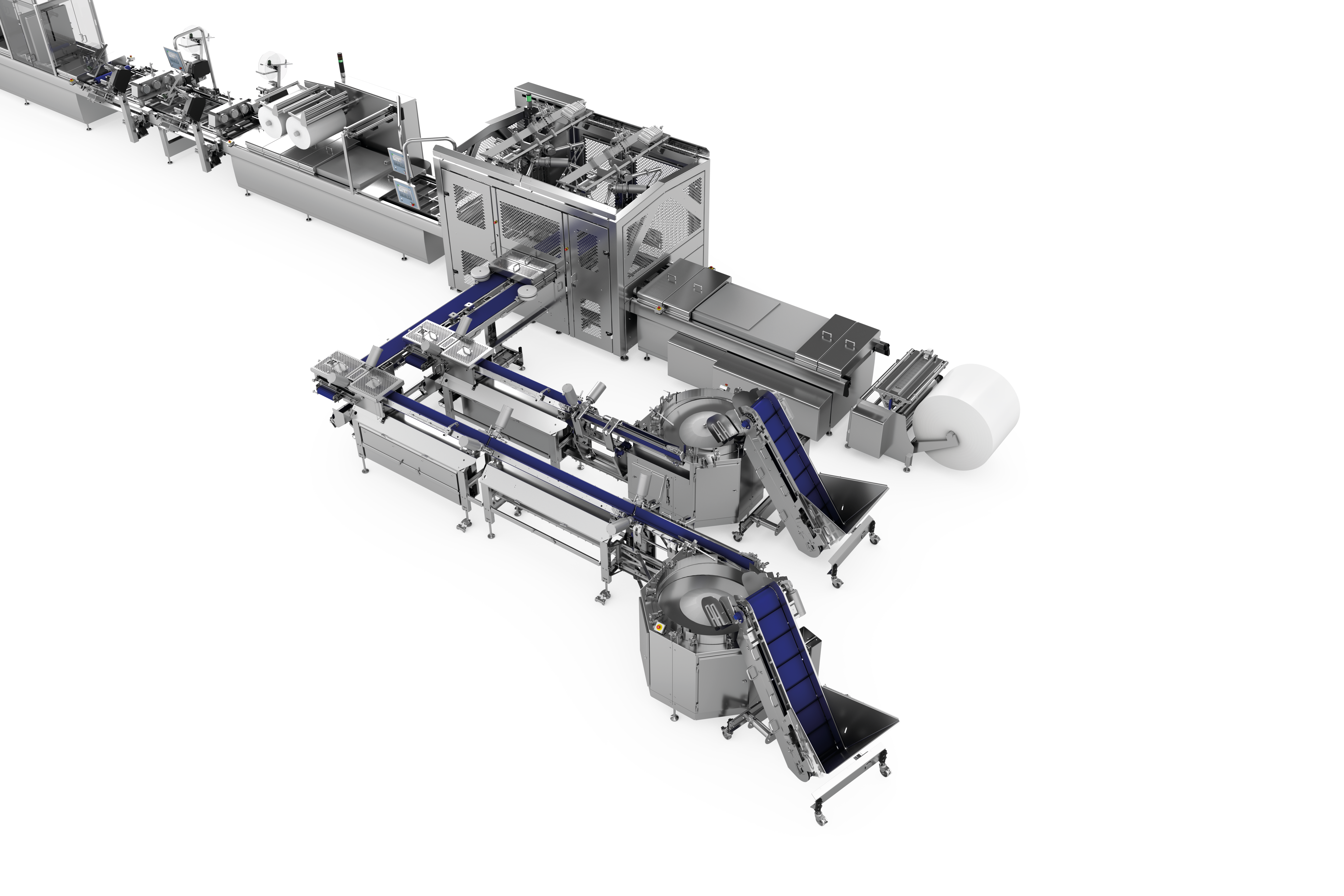

MULTIVAC offers inspection solutions that are designed to a high technical level while meeting all market requirements. They ensure that statutory regulations are met and the highest quality standards are maintained. Their hygienic design makes cleaning easy since the relevant modules are easily accessible. Our inspection solutions comply with all the requirements of the food industry and medical technology.

We are in constant dialogue with our customers and we understand their requirements and wishes. We will find the right inspection solution for you! For example, a module which can be seamlessly integrated into your packaging process. Easy handling, maximum operating safety and reliable inspection results are guaranteed.

You avoid errors, brand-damaging product recalls and benefit from products and packs that appeal to the consumer. And all this with high levels of efficiency and cost-effectiveness.