Protecting what protects health – secure and reliable packaging solutions

Health Packaging: MULTIVAC at COMPAMED (17 - 20 November 2025)

24.09.2025

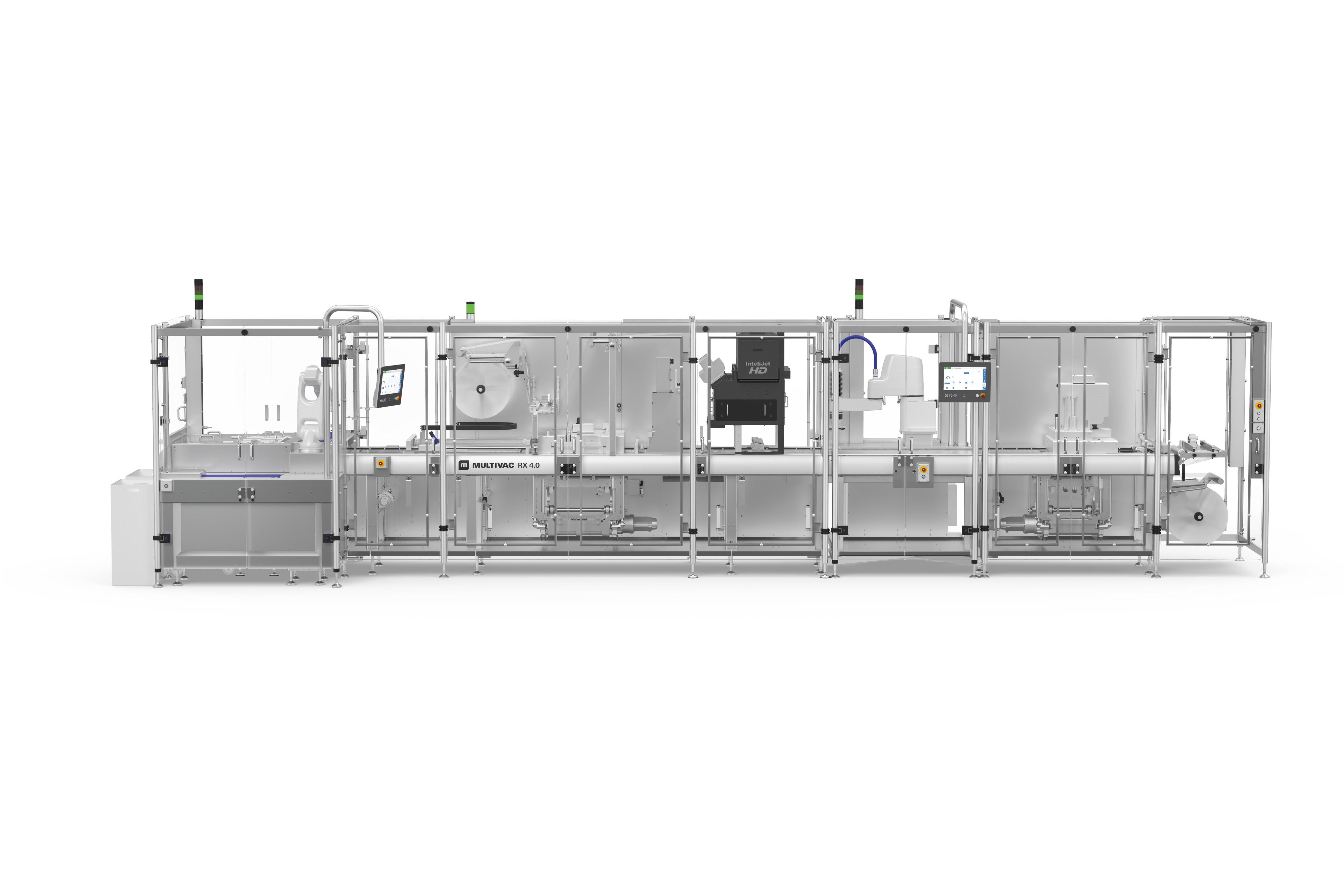

Wolfertschwenden, 24 September 2025 – Whether it is disposable syringes, catheters or implants, MULTIVAC will be showing at this year's Compamed (Hall 8a, Stand H01), how medical items can be packaged securely and efficiently. The focus will be on the R3 thermoforming packaging machine, designed with a modular concept that enables medical products to be packaged costeffectively and with process reliability. In addition to this, a semiautomatic traysealer and chamber machine for packaging medical items will also be exhibited, as well as various inspection solutions for inspecting products, labels and print. The company will be exhibiting at the trade fair under the name of MULTIVAC Health Packaging for the first time – the new segment branding for medical and pharmaceutical packaging solutions. MULTIVAC has repositioned itself with a clear focus on the current requirements of the health market, so that it can support its customers in an even more comprehensive and targeted manner

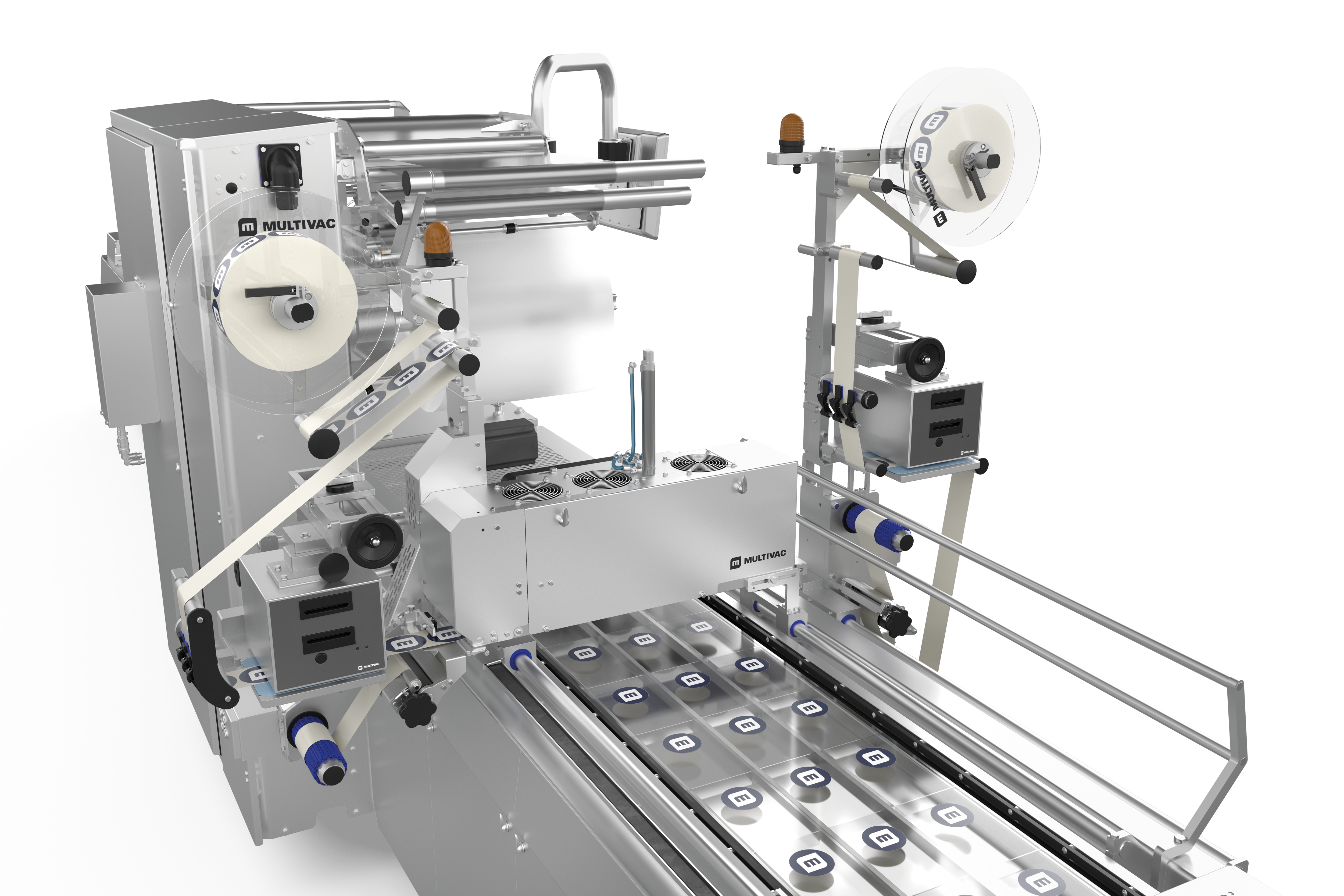

R3 thermoforming packaging machine: Large batch sizes can be packaged very efficiently

The R3 thermoforming packaging machine is designed for packing a wide spectrum of medical products – from disposable syringes through to laboratory items and right up to medical connectors. It is particularly suitable for large batch sizes, which are packaged in conventional thermoformed packs. In addition to an outstanding price-toperformance ratio, the main feature of the machine is its simple servicing and maintenance. At Compamed the machine demonstrated by MULTIVAC will be packaging disposable items in recyclable flexible film packs, which comply with the PPWR requirements. The packaging made of polyethylene is printed in two colours by a Bell-Mark printer prior to sealing. The print image is then checked by a MULTIVAC visual inspection system – this ensures that the printing is UDI-compliant.

T 260 traysealer: Precision for sensitive products packed in tray

The semi-automatic T 260 traysealer was developed for packaging sensitive medical products in small batch sizes, such as implants for example. The mobile and compact model, which can be used very flexibly, is ideal for a wide range of trays and upper webs. The GMP-compliant stainless steel construction meets all the requirements of the medical industry in terms of cleanroom compatibility and ease of cleaning. Thanks to its small space requirement, the T 260 is also ideally suited to use where space is limited

C 400 TC chamber machine: Secure packaging of medical items

With the C 400 TC chamber machine, MULTIVAC will be presenting a packaging solution for sterile medical products in pre-made film pouches. At Compamed the machine demonstrated will feature heart catheters packaged in Alu-PE film pouches. The machine has permanently heated sealing bars. These are available in various lengths and positioning variants, so that it is possible to package larger products or several smaller products on the same machine.

Thanks to their monitored sealing pressure and precise temperature distribution, as well as processes that can be calibrated and validated, both the traysealer and the chamber machine ensure that the packaging process is reliable, reproducible and traceable. The IPC control on the machine monitors and controls the entire process, as well as integrating peripheral equipment such as a scanner or printer, and it can also document all the batch data very clearly in a batch report, if this is required. Critical parameters such as sealing pressure, cooling water and sealing temperature are controlled and monitored constantly by sensors.

Inspection technology for seamless quality

In addition to this, MULTIVAC Health Packaging also offers a wide range of innovative inspection solutions for inspecting the product, label or print. Cameras, code readers or sensors are used depending on the requirement – either integrated seamlessly into the packaging machine or labeller, or installed as a free-standing system. All the components are tailored perfectly to each other, and they enable one uniform operating system to be created. This holistic system integration ensures that efficient, reliable and seamless processes are achieved.

Different solutions for a range of inspection tasks will be shown on a demonstration stand at the trade fair. Here visitors will receive comprehensive advice about the possibilities and capabilities of the individual systems.

Press release

Protecting what protects health – secure and reliable packaging solutions

- Size

- 143 KB

- Format

Image

Health Packaging: MULTIVAC at COMPAMED (17 - 20 November 2025

- Size

- 861 KB

- Format

- jpeg

Current News

MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

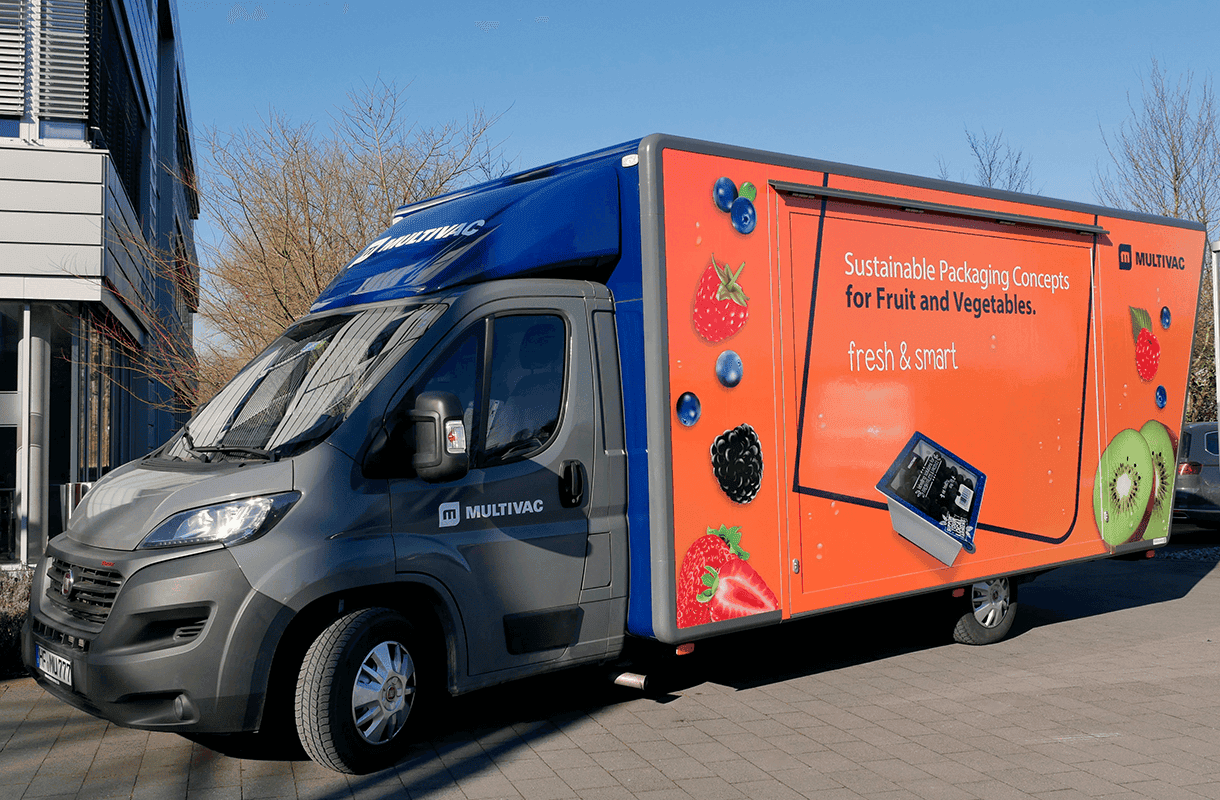

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com