MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

Cooling@Packing from MULTIVAC receives the Sustainable Packaging News Award

Award in the category for Sustainable Packaging Machinery

24.01.2025

Wolfertschwenden, 24 January 2025 – Outstanding innovation: In December the jury of the Sustainable Packaging News magazine selected the innovative Cooling@Packing System from MULTIVAC as the winner in the category for Sustainable Packaging Machinery. The Sustainable Packaging News Award is bestowed annually in six categories.

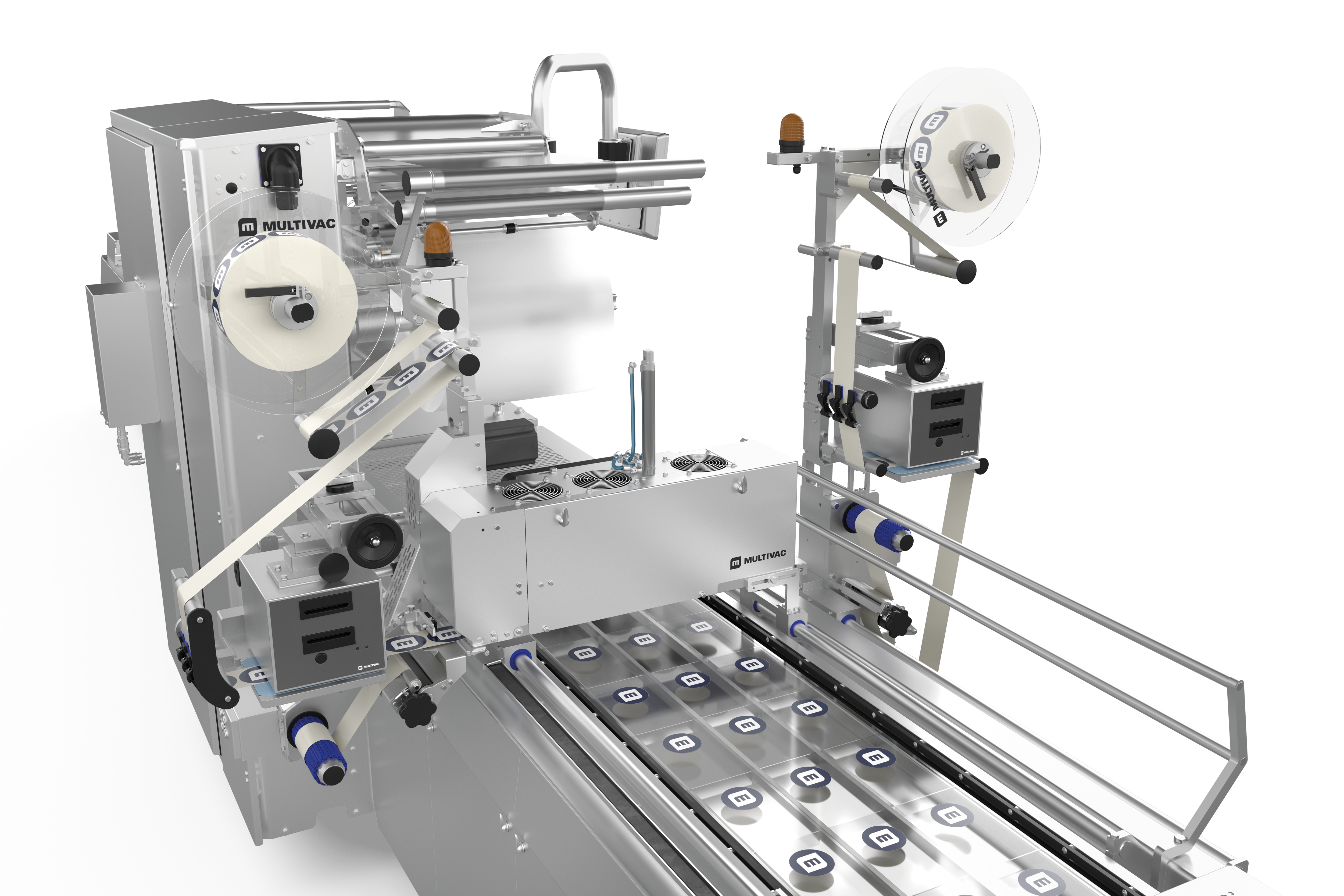

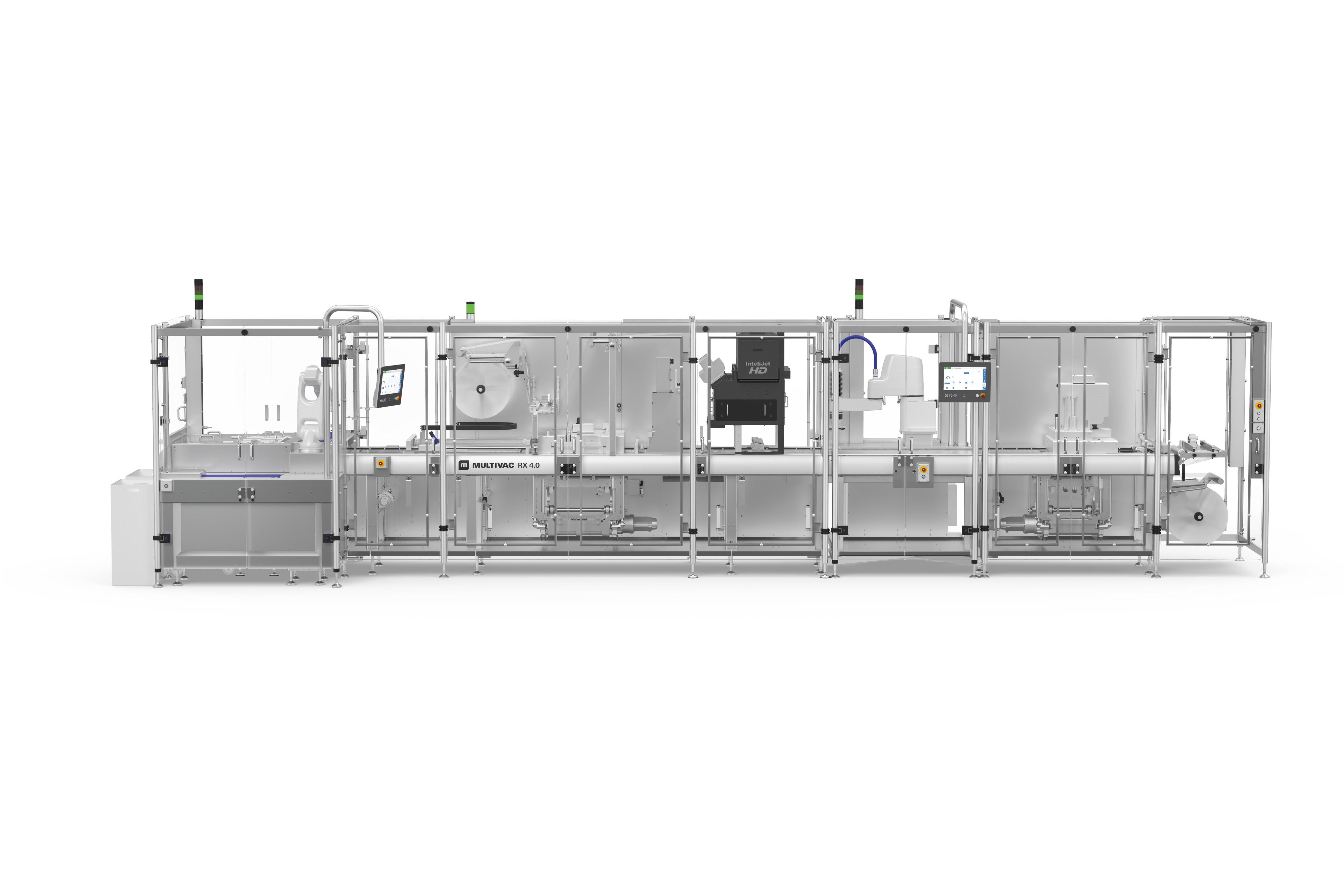

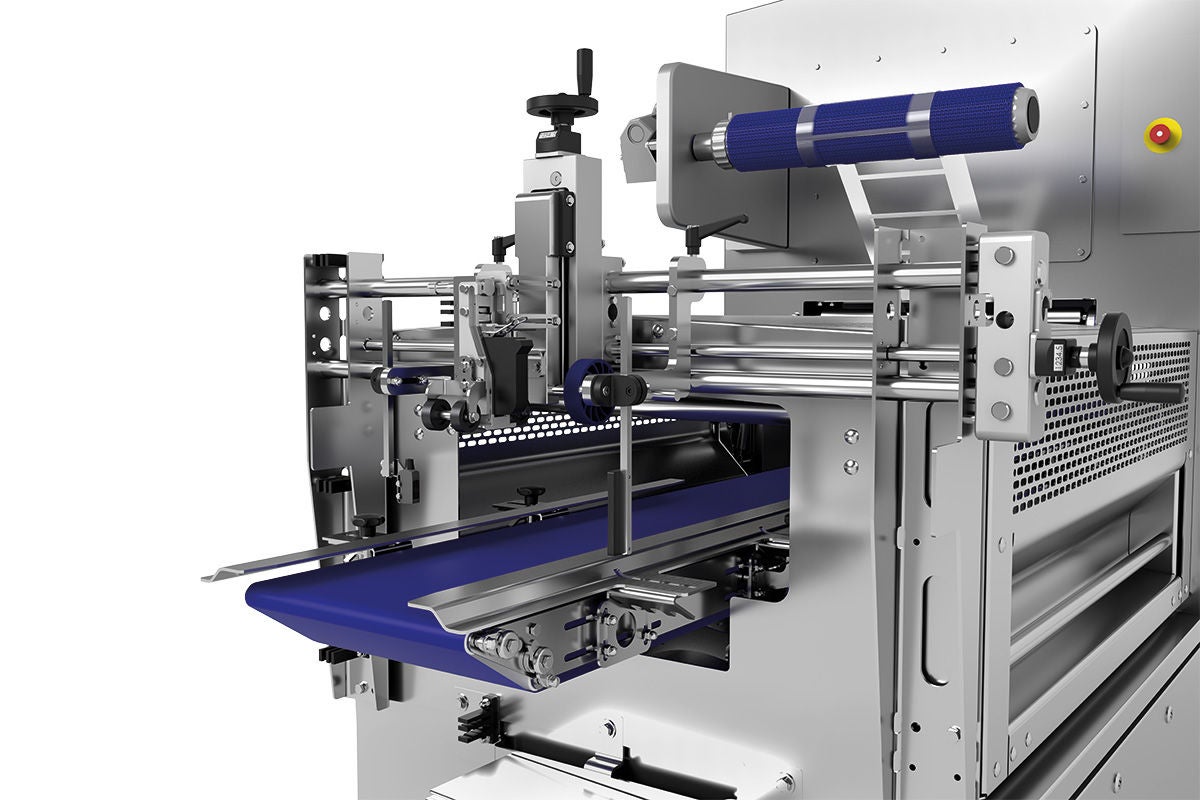

The MULTIVAC Cooling@Packing System is a vacuum application, which integrates the cooling process for bakery products into the thermoforming packaging machine. This enables the bakery products to be packed immediately after baking, so that they remain fresher for longer and have an extended shelf life. Bakery products are traditionally cooled by means of cooling spirals at ambient temperature, or alternatively by passing through cooling tunnels. Both procedures take up a lot of space in the production area, as well as requiring a high level of investment.

„By using our Cooling@Packing system, which is about to be launched on the market, bakery products can be placed directly from the oven into the open pack cavities on the thermoforming packaging machine – and even automatically by means of loading robots,” explains Thomas Fickler, Product Manager at MULTIVAC. “Thanks to the evacuation process in the chambers of the packaging machine, the bakery products are cooled down within a few seconds from 95°C to approximately 30°C. The evacuation process produces vaporisation energy, which is released by the evaporation of the bakery products' own moisture, and which then cools down the bakery products.“

The MULTIVAC Cooling@Packing System enables savings to be made by companies: firstly thanks to the smaller space requirement for cooling the bakery products, and secondly due to the reduced energy consumption during product cooling. The risk of product contamination during the cooling process is also minimised. And the production capacity can be increased thanks to shorter baking times, without the product quality suffering. The new solution can be integrated into MULTIVAC thermoforming packaging machines in the high-output range.

“We are continually developing new and groundbreaking technology, which helps our customers to produce even more efficiently and sustainably,” says Thomas Fickler. “We are highly delighted with this award, which confirms our commitment to efficient and sustainable packaging solutions,” says Thomas Fickler.

Press Release

Cooling@Packing from MULTIVAC receives the Sustainable Packaging News Award

- Size

- 84 KB

- Format

Latest News

MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com