AI optimises packaging processes: highest quality, maximum efficiency

MULTIVAC at IFFA 2025 (Hall 12.1, Stand A 41): AI-supported vision systems

18.03.2025

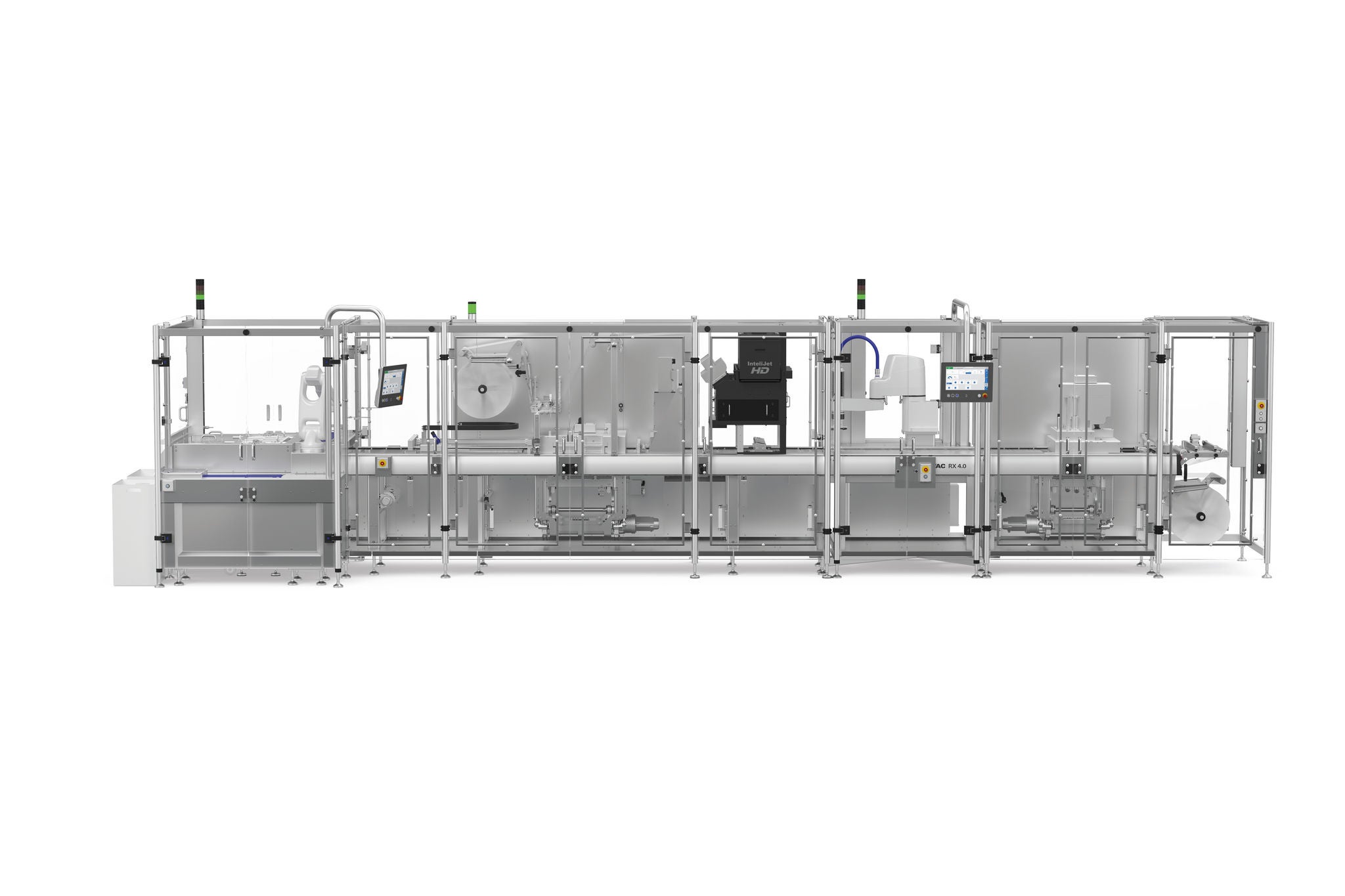

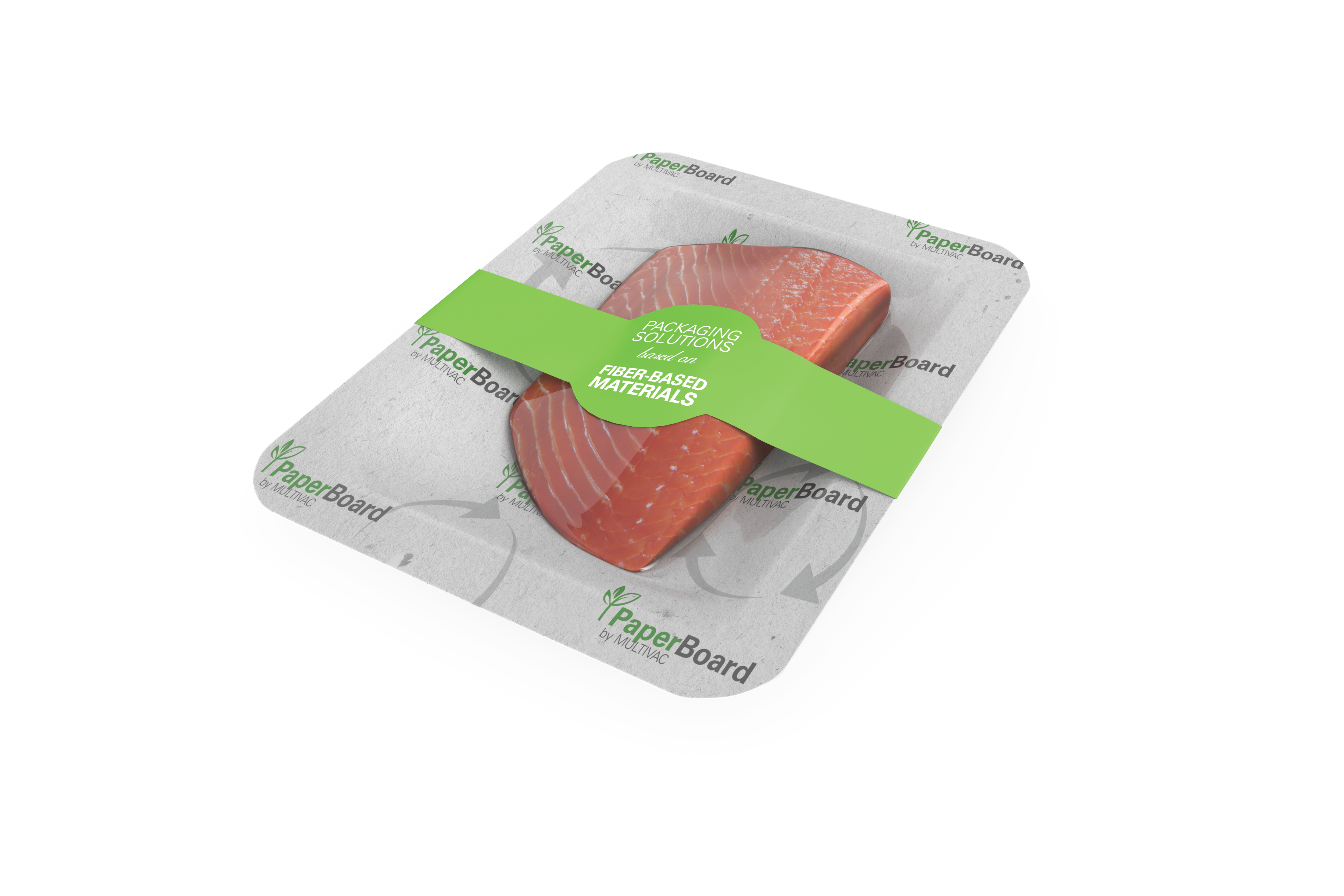

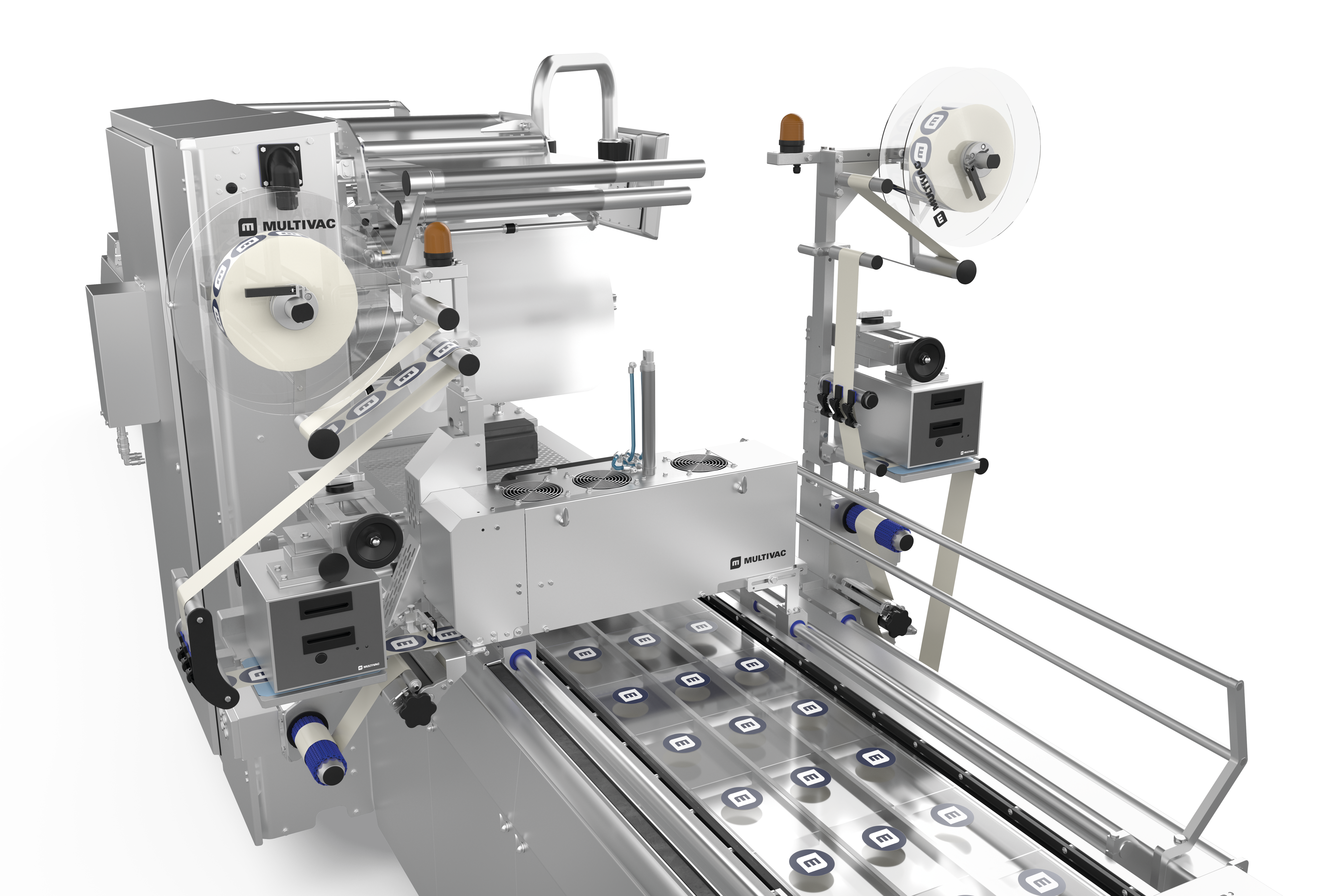

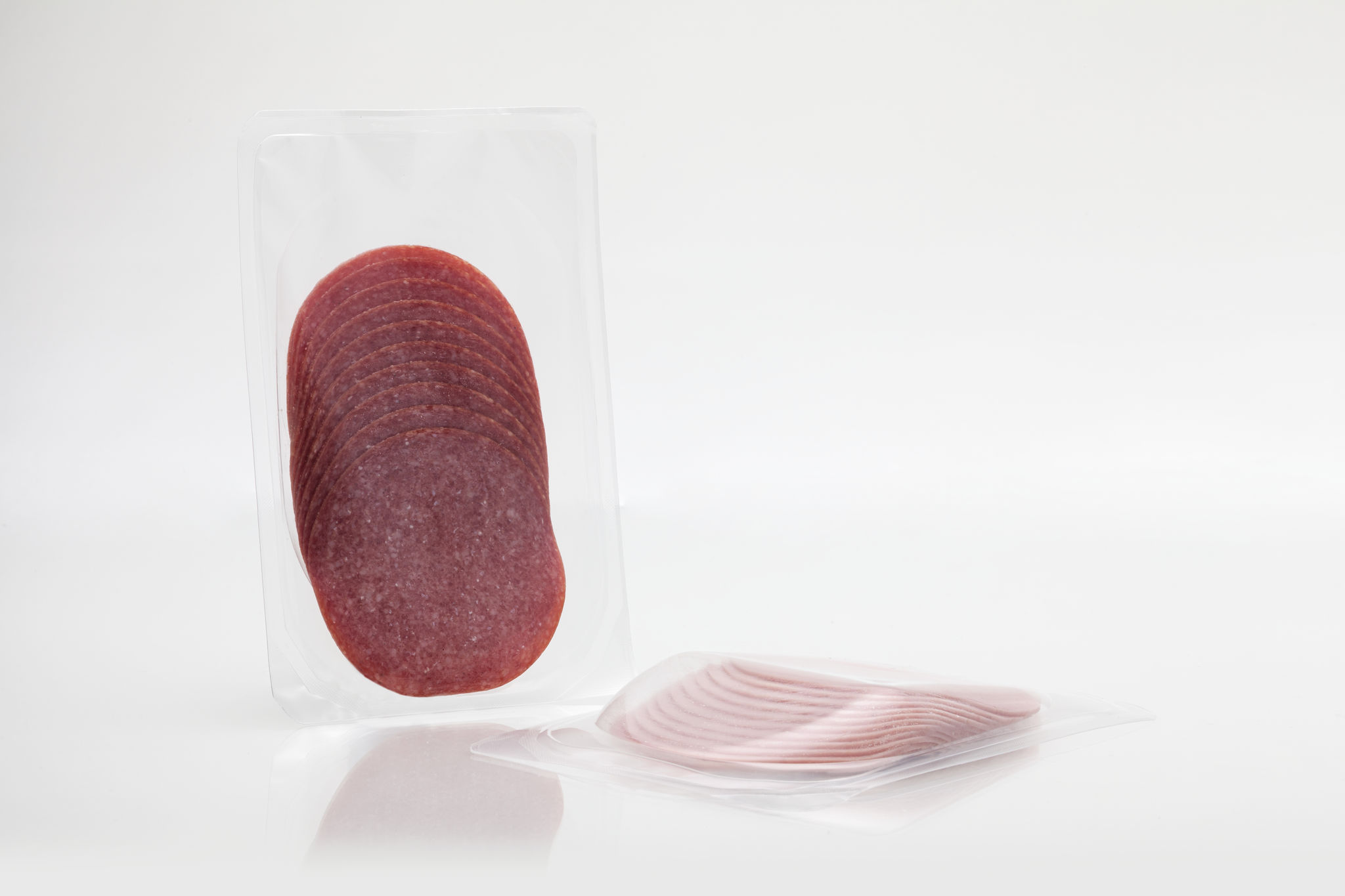

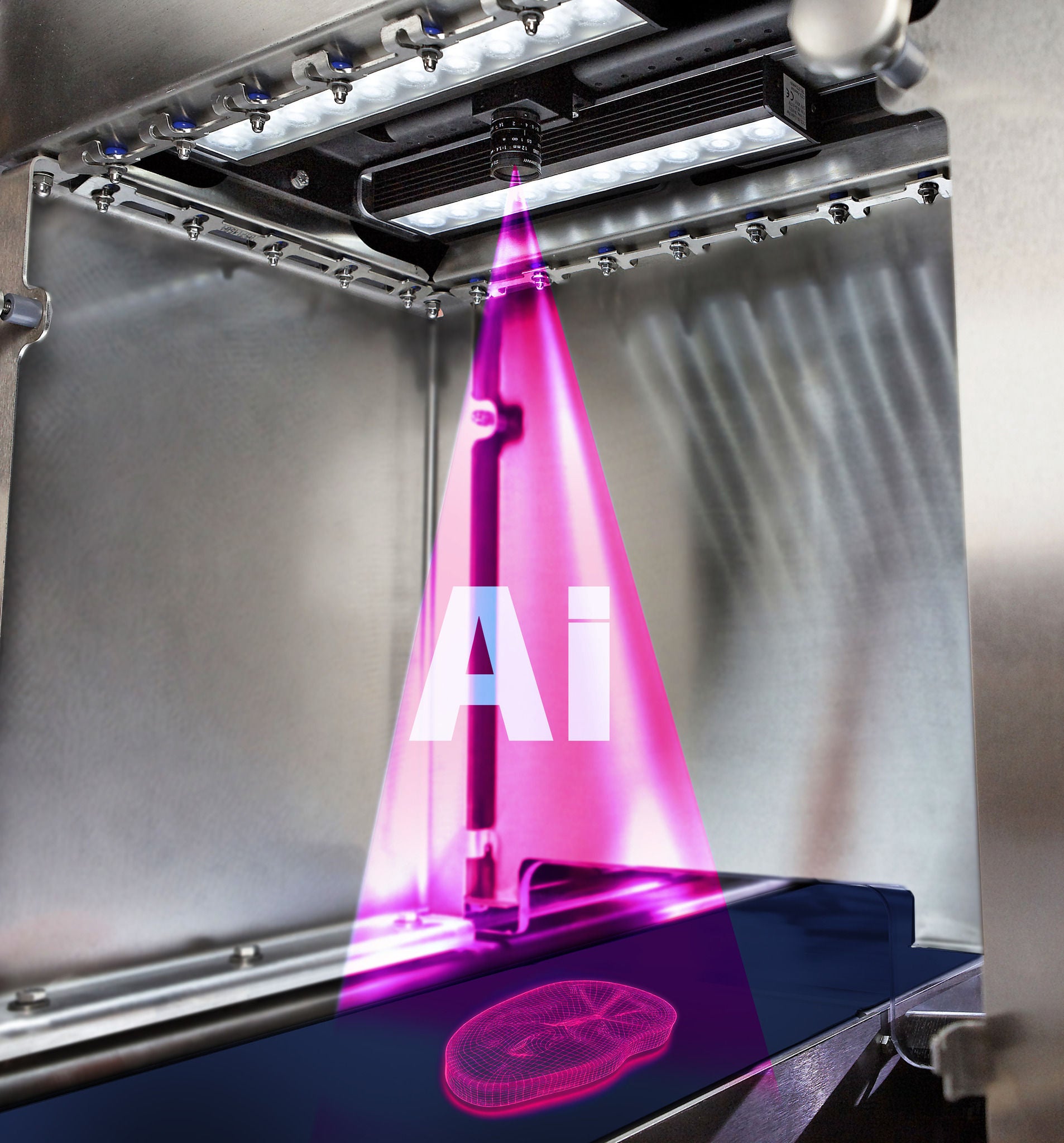

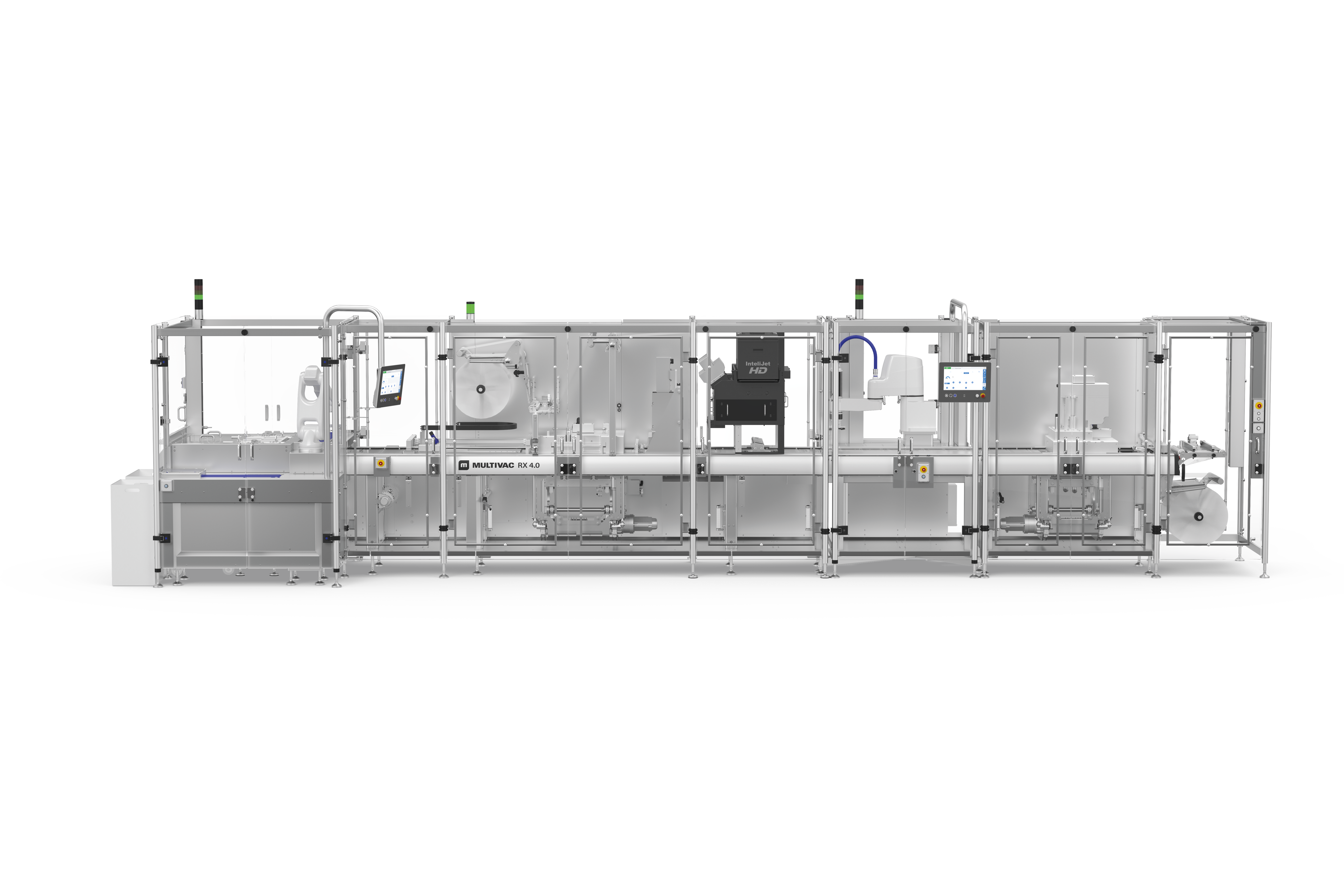

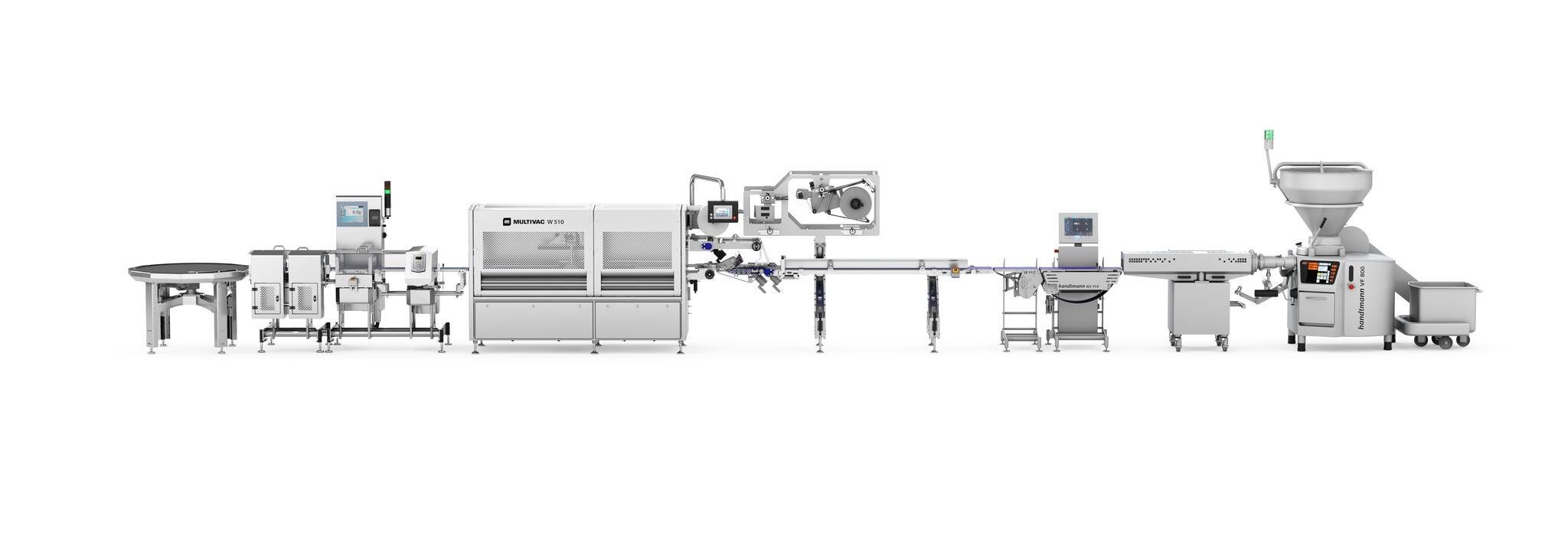

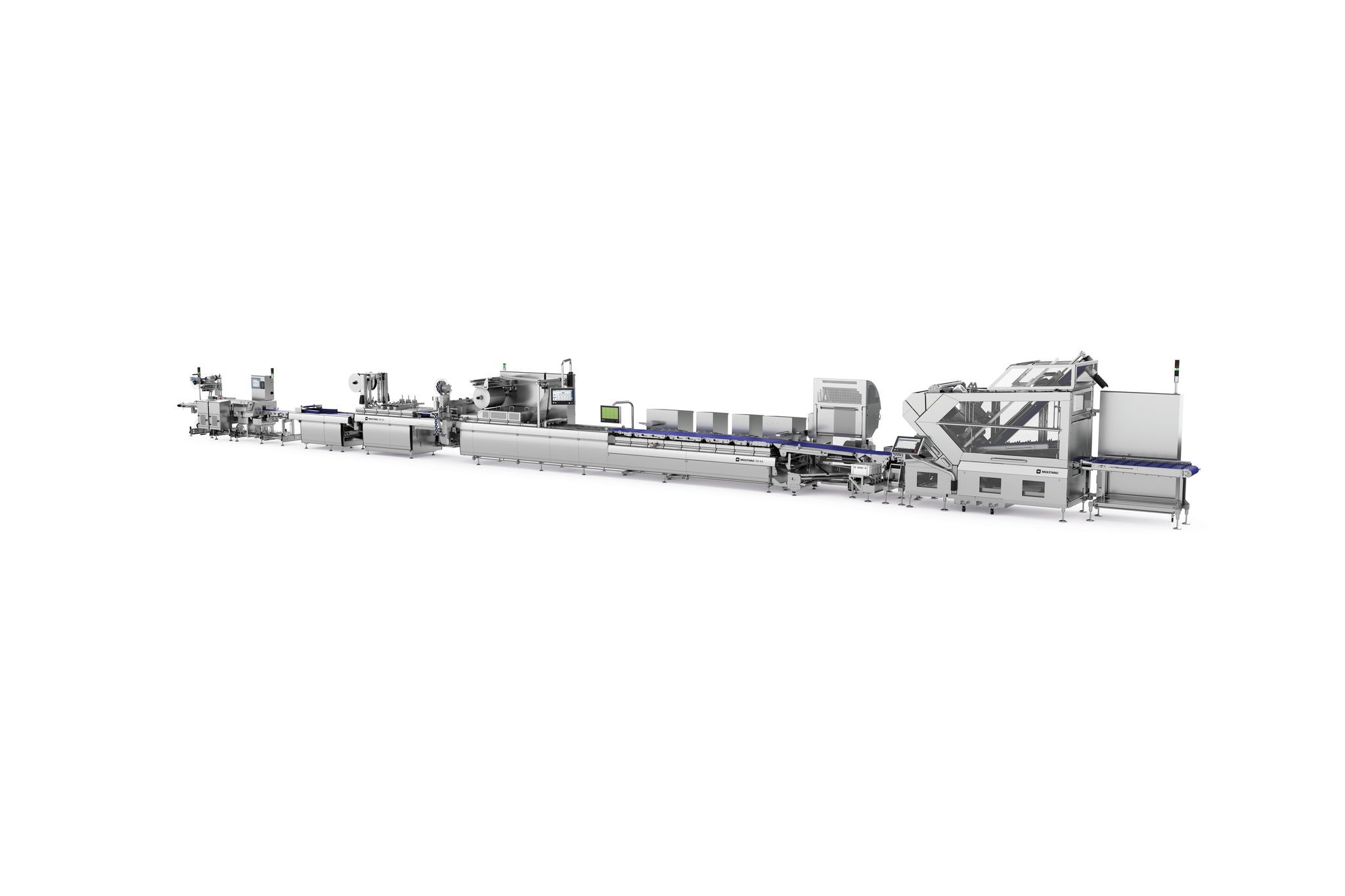

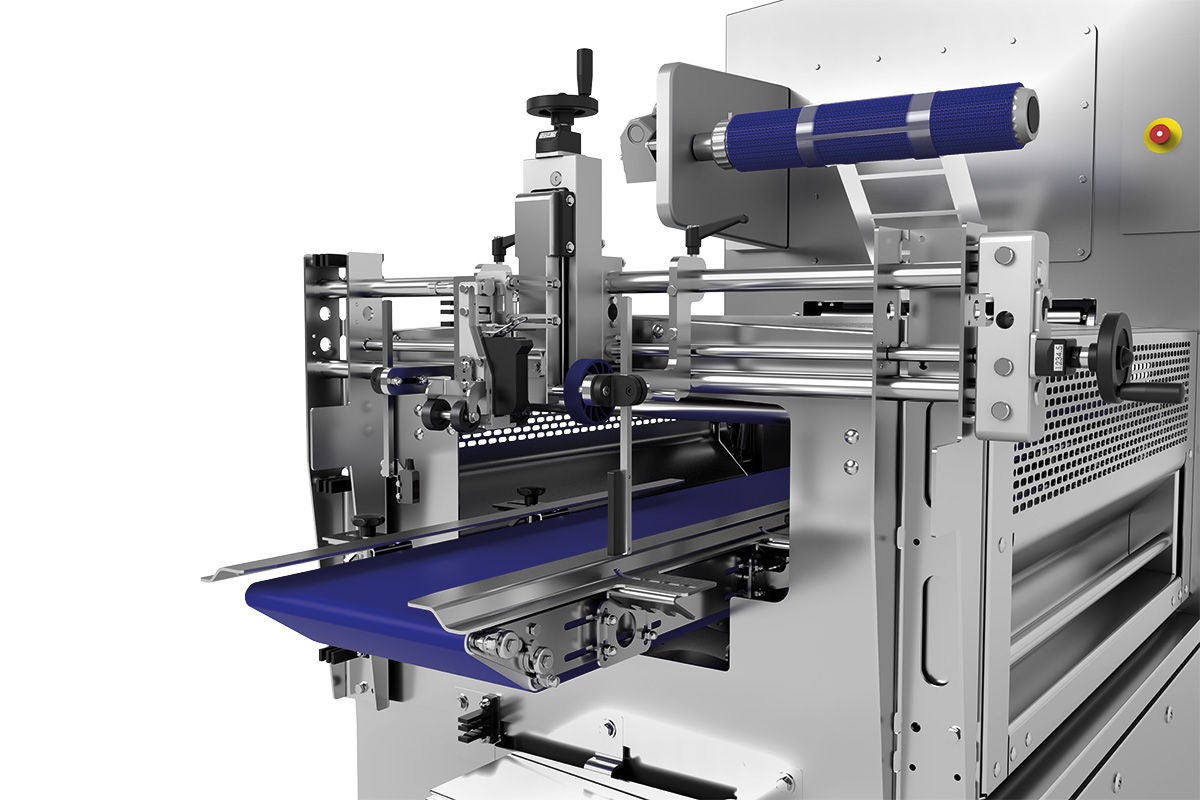

Wolfertschwenden, 18 March 2025 – Rising quality demands and high processing speeds, as well as the need to meet ever more complex labelling requirements, provide the food industry with challenges, which make automated inspection systems essential. By using artificial intelligence (AI), the efficiency and precision of such systems can be maximised – and even very complex inspection or classification tasks can be mastered quickly and reliably. At this year's IFFA in Frankfurt, MULTIVAC will be presenting an AI-supported vision system, which identifies packs with different pieces of meat. Depending on the content of the pack, the corresponding information is relayed to the MULTIVAC labelling and printing system, so that each pack is labelled correctly.

In addition to the inspection of packs, labels and print, AI-supported vision systems can also meet the requirements for quality control and identification of food products. They can even classify products according to defined criteria, as well as inspect portions and check packs for correct content and completeness. This means that they make a crucial contribution to increasing line efficiency, and therefore also raising the production capacity.

Precise and consistently reliable inspection and identification of products or packs

“Our AI-supported vision systems are configured individually, and they are integrated seamlessly into the customer's processing or packaging operation,“ explains Christine Oehls, Product Manager for VisionSystems at MULTIVAC Marking & Inspection. “The path to an AI-supported vision solution begins with intensive consultation and a feasibility study for the particular application. The data is then collected when the machine is put into service: Examples of the images are taken under actual production conditions and classified. An AI model is trained and perfected based on this classified data collection. We accompany the customer throughout the entire life cycle of the system, by adjusting the existing models or creating new AI models.“

One of the advantages of an AI-supported vision solution from MULTIVAC is the automated, precise and consistently reliable inspection and identification of products or packs. The production capacity can also be raised by increasing the line efficiency. The brand and image are protected thanks to the faultless quality of the packs at the point of sale. Early detection of even the smallest discrepancies, as well as rapid intervention to eliminate the problem, ensure that the maximum process reliability is achieved. And last but not least, all the line modules, which are matched perfectly to each other, offer a uniform operating concept.

Press Release

AI optimises packaging processes: highest quality, maximum efficiency

- Size

- 159 KB

- Format

Latest News

MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

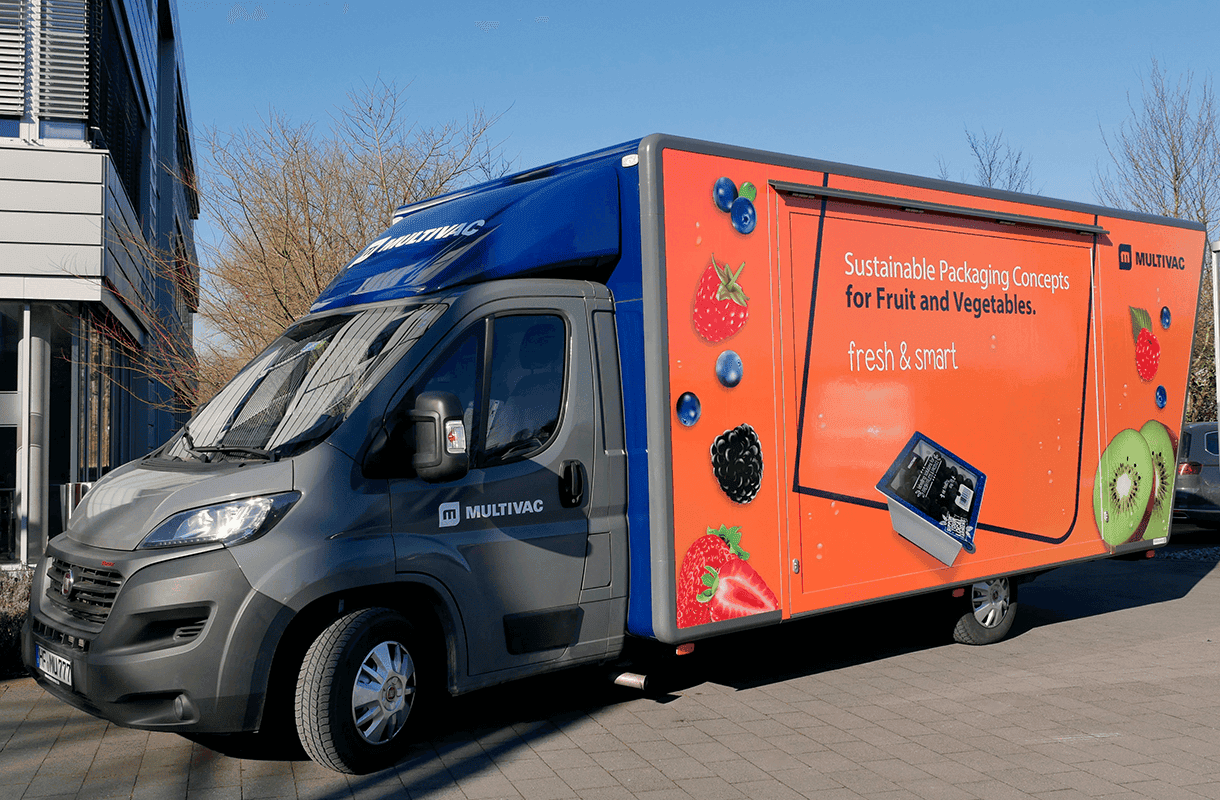

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

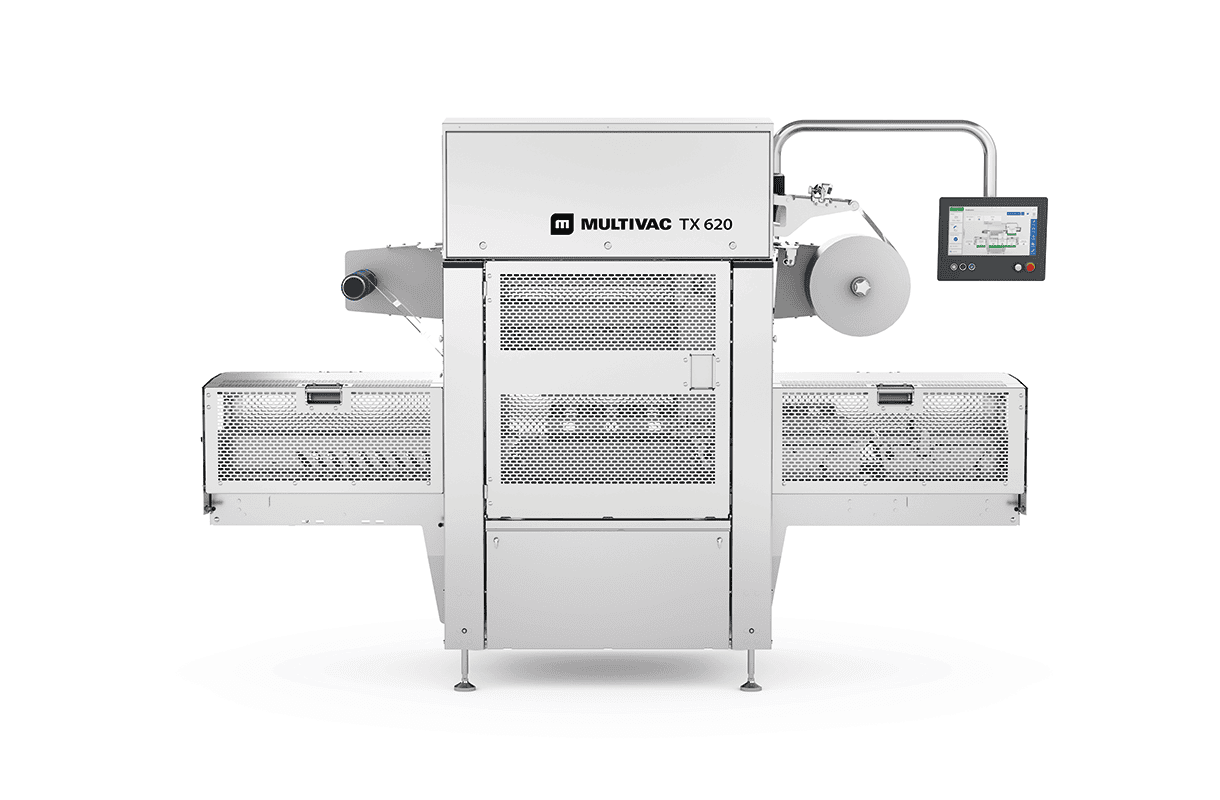

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com