Beyond Automation: Building a Smarter, Connected Packaging Line for Long-Term Success

Data-driven packaging solutions for future-ready manufacturers.

Automation is standard in modern food and life sciences manufacturing — but is it delivering all the value it could? Leading manufacturers are looking beyond basic automation to build smart, connected packaging ecosystems that integrate equipment, data, and people for continuous improvement and long-term resilience.

At MULTIVAC Group, we believe automation should do more than move products down a line — it should empower you to adapt faster, optimize performance, and secure a competitive edge.

Integration: The Next Frontier in Packaging Automation

Many packaging lines today are a patchwork of automated components that don’t fully communicate — especially when upstream and downstream systems are sourced separately. This lack of integration can limit your ability to:

- Pinpoint bottlenecks or inefficiencies.

- Switch formats quickly to meet shifting demand.

- Capture complete traceability and compliance data.

“We upgraded from piecemeal automation to a fully integrated MULTIVAC line and immediately saw smoother changeovers, faster line clearance times, and greater confidence in our traceability reporting.” — Director of Operations, Global Food Manufacturer

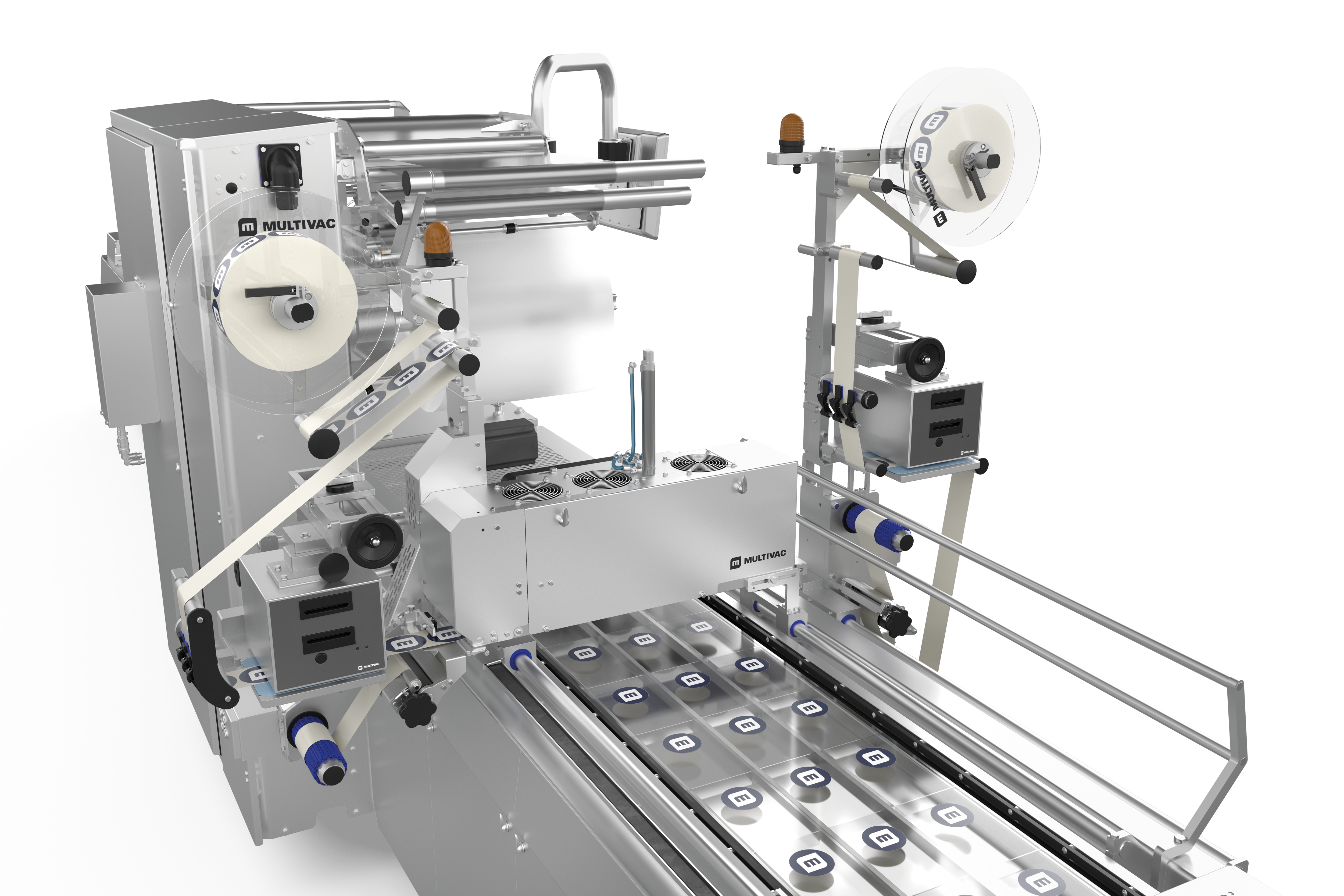

MULTIVAC Group’s one line, one control technology ensures seamless connectivity — not only across forming, filling, labeling, inspection, and end-of-line processes, but also with:

- Upstream product sorting and placement systems

- Slicing and portioning equipment

- Downstream cartoning, case packing, and palletizing solutions

This holistic integration provides true line-wide visibility and control in real time — from the moment a product enters your facility to the moment it’s ready for shipment.

From Data Collection to Actionable Insight

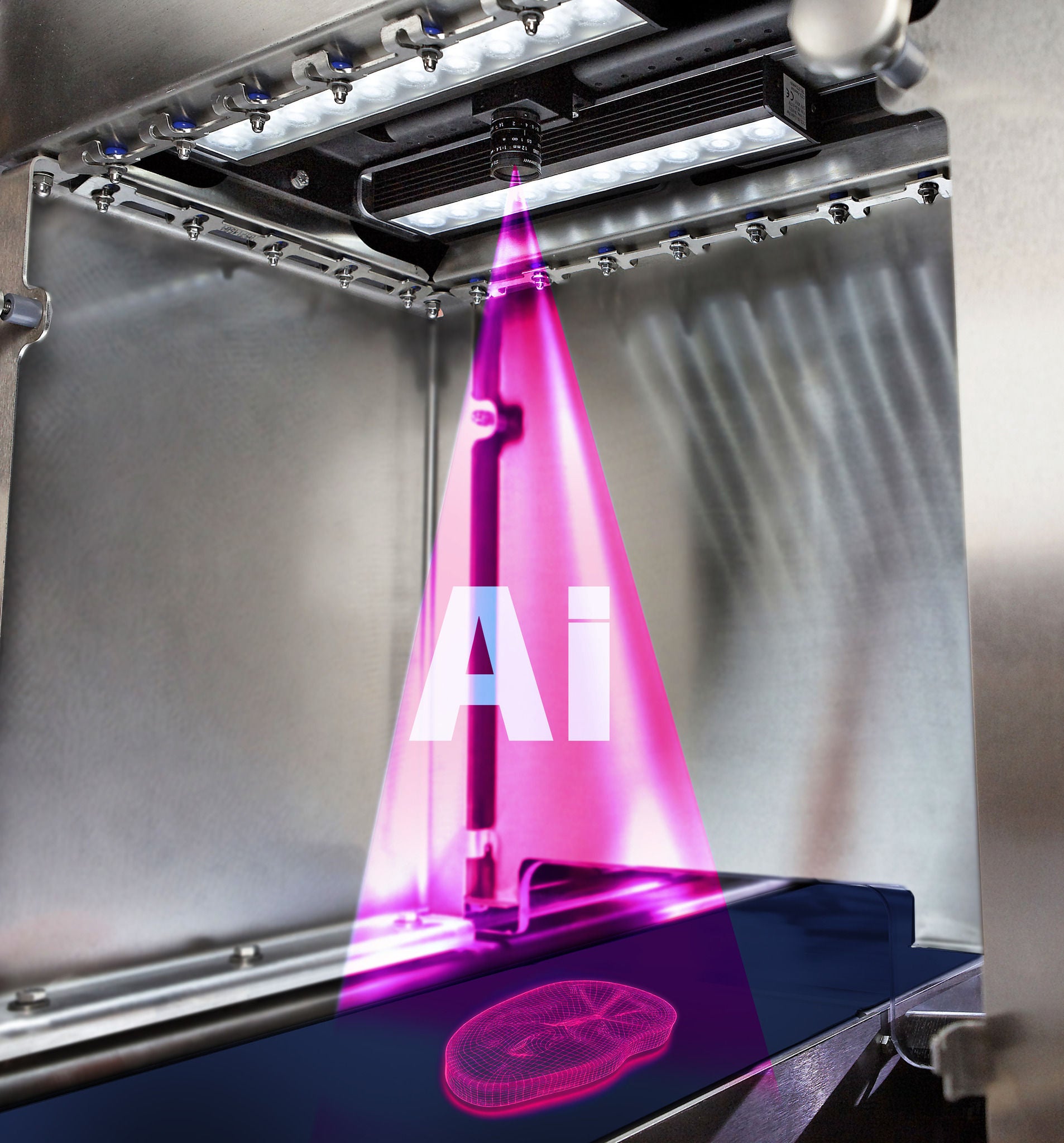

Your line already generates data — but are you turning it into value? With MULTIVAC Smart Services, you can:

- Monitor real-time OEE (Overall Equipment Effectiveness) and detect micro stops before they become hours of lost production.

- Receive predictive maintenance alerts — studies show predictive maintenance can reduce equipment breakdowns by up to 70% (McKinsey).

- Use dashboards to align output with market demand, optimize staffing, and reduce material waste.

“MULTIVAC’s Smart Services helped us identify small inefficiencies that were adding up to 6–8 hours of lost production each month.” — Senior Engineer, Major Medical Device Manufacturer

Flexibility to Future-Proof Your Operations

Markets change. Regulations tighten. Consumers demand more sustainability and transparency. Your packaging automation must evolve just as quickly. MULTIVAC solutions are built to help you:

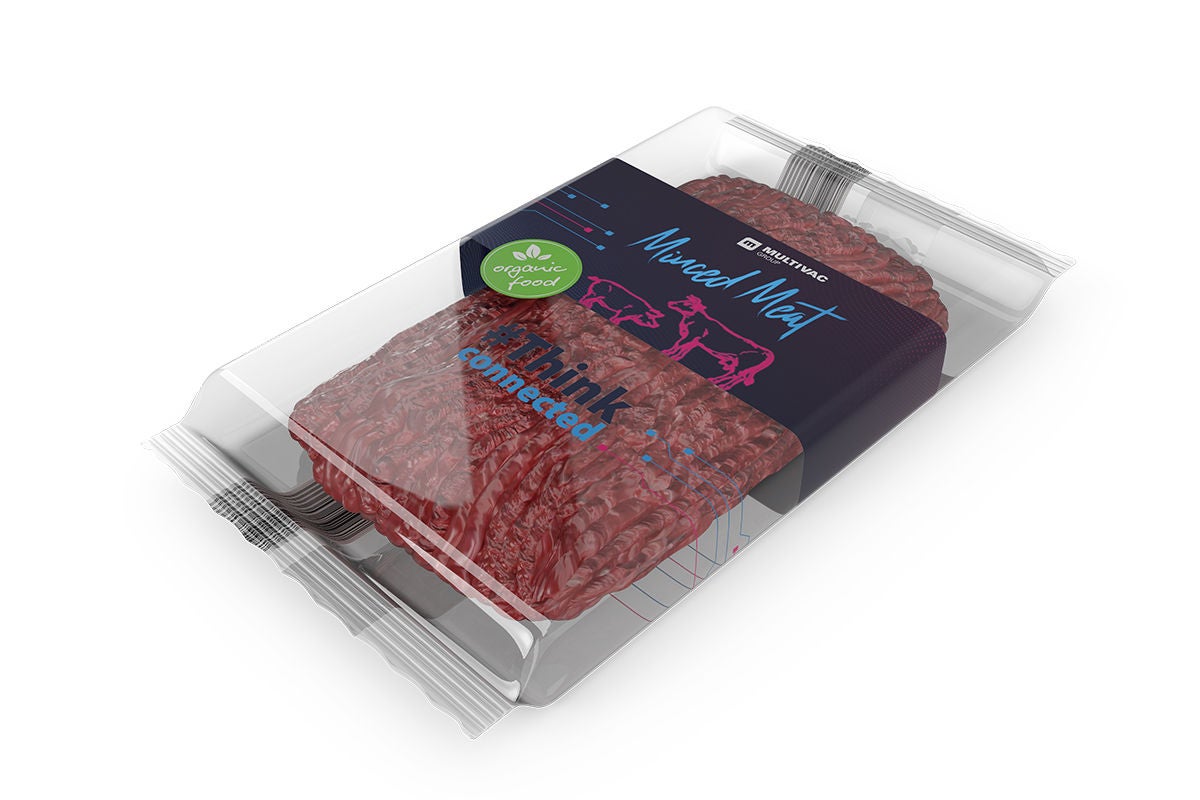

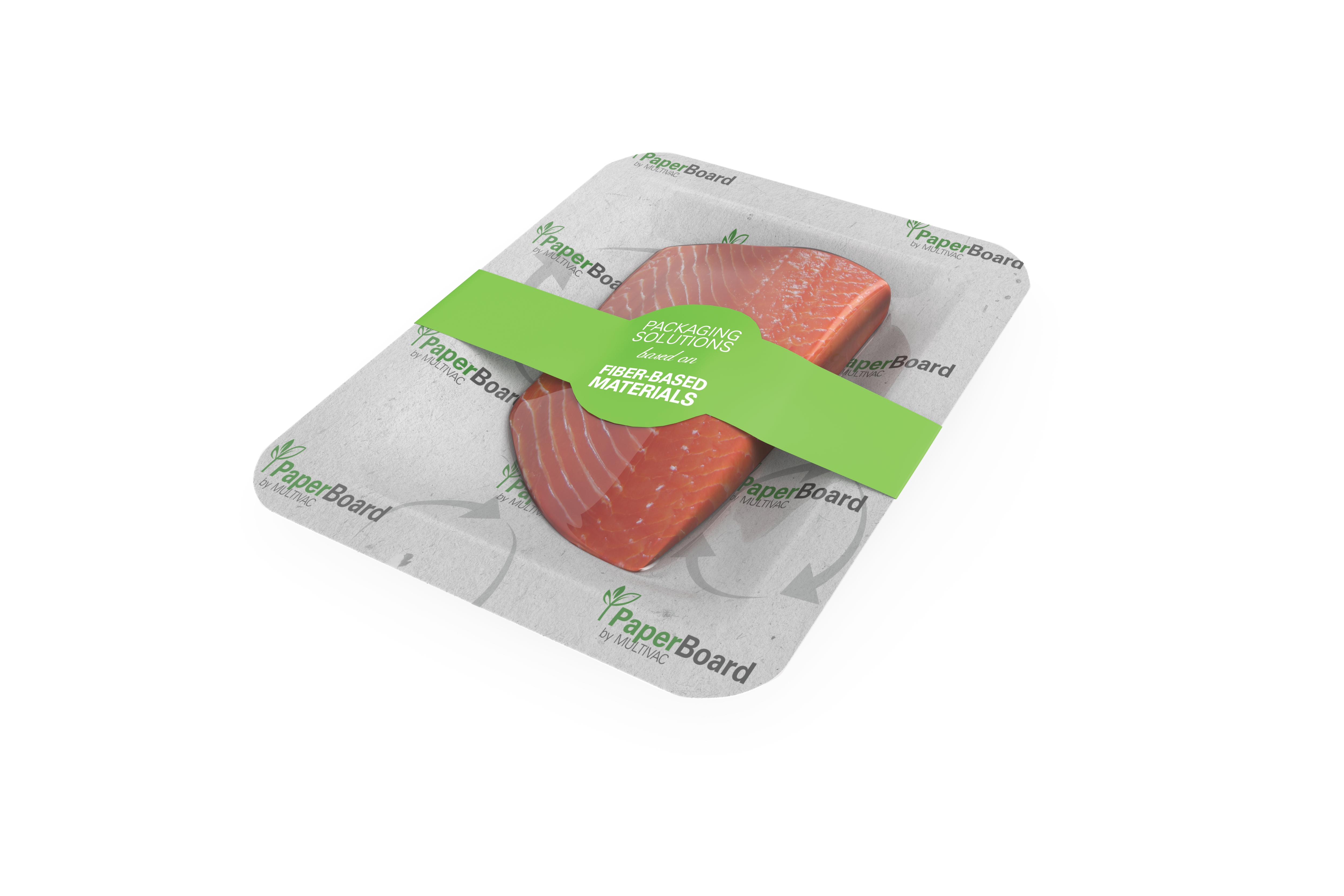

- Switch formats and packaging materials easily — including sustainable trays and films.

- Maintain compliance with integrated inspection and traceability systems.

- Scale your line as your product portfolio or production needs grow.

“Our packaging lines can now change formats 30% faster — that’s helped us meet tighter retail delivery windows and reduce overtime.” — Production Manager, Regional Food Processor

Why MULTIVAC Group? We Are Your Partner in Smarter Automation

- One partner for integrated automation - from product sorting and slicing to forming, labeling, vision, case packing, and palletizing.

- Smart technology that provides real-time insight and proactive control.

- Global expertise with local support - 115+ field technicians dispersed across the U.S.

- Flexible, future-ready systems designed for the demands of modern food and life sciences manufacturing.

Industry benchmark: Integrated packaging lines can boost efficiency by up to 25% compared to isolated automation cells (Source: PMMI).

See What's Possible Beyond Automation

The future belongs to manufacturers who move beyond simply automating - and build packaging lines that are connected, intelligent, and continuously improving. Let MULTIVAC Group help you take the next step.

Contact us today to schedule a packaging line assessment - and discover how smarter automation can drive measurable results for your operation.

Latest news

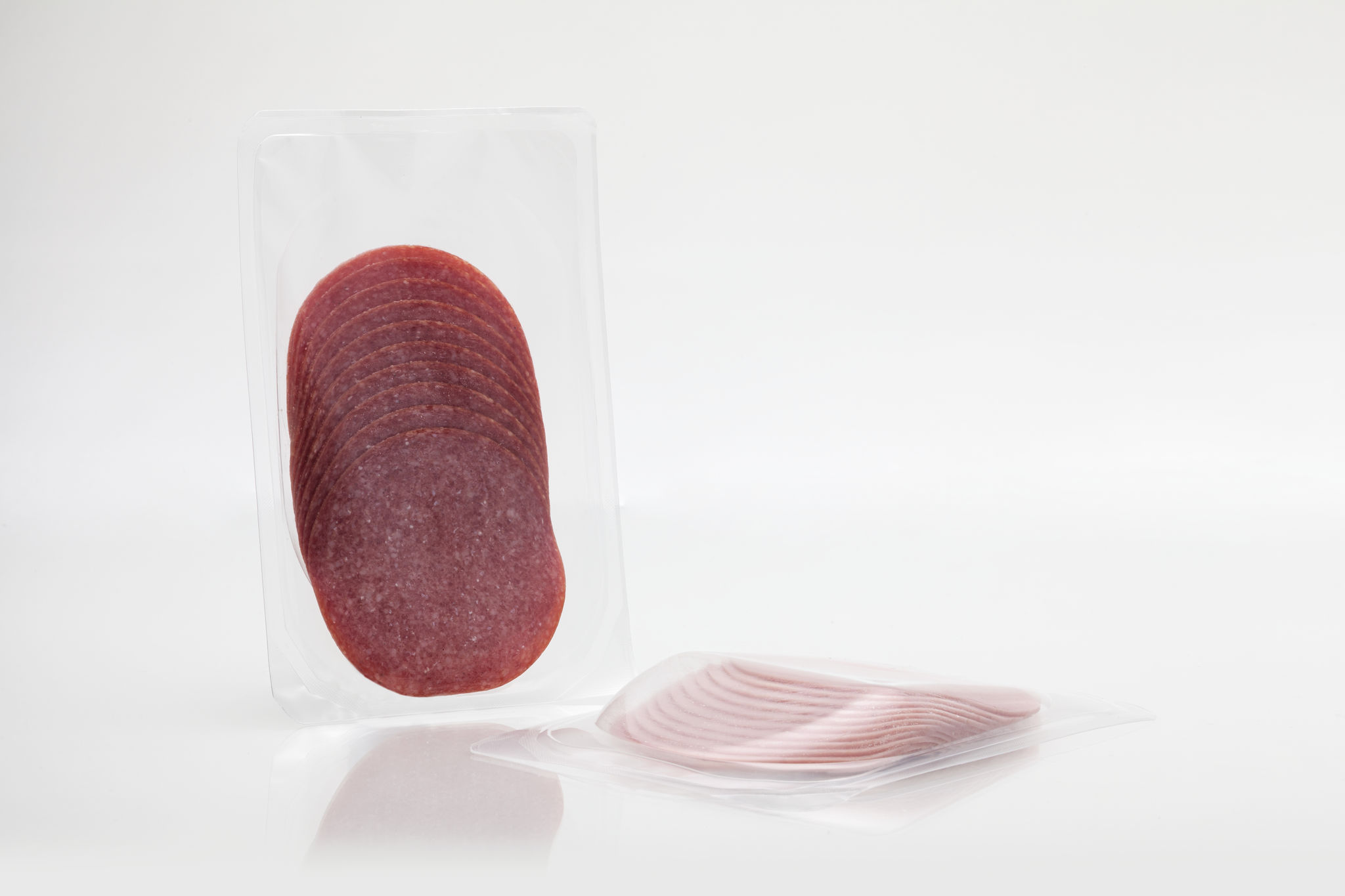

MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

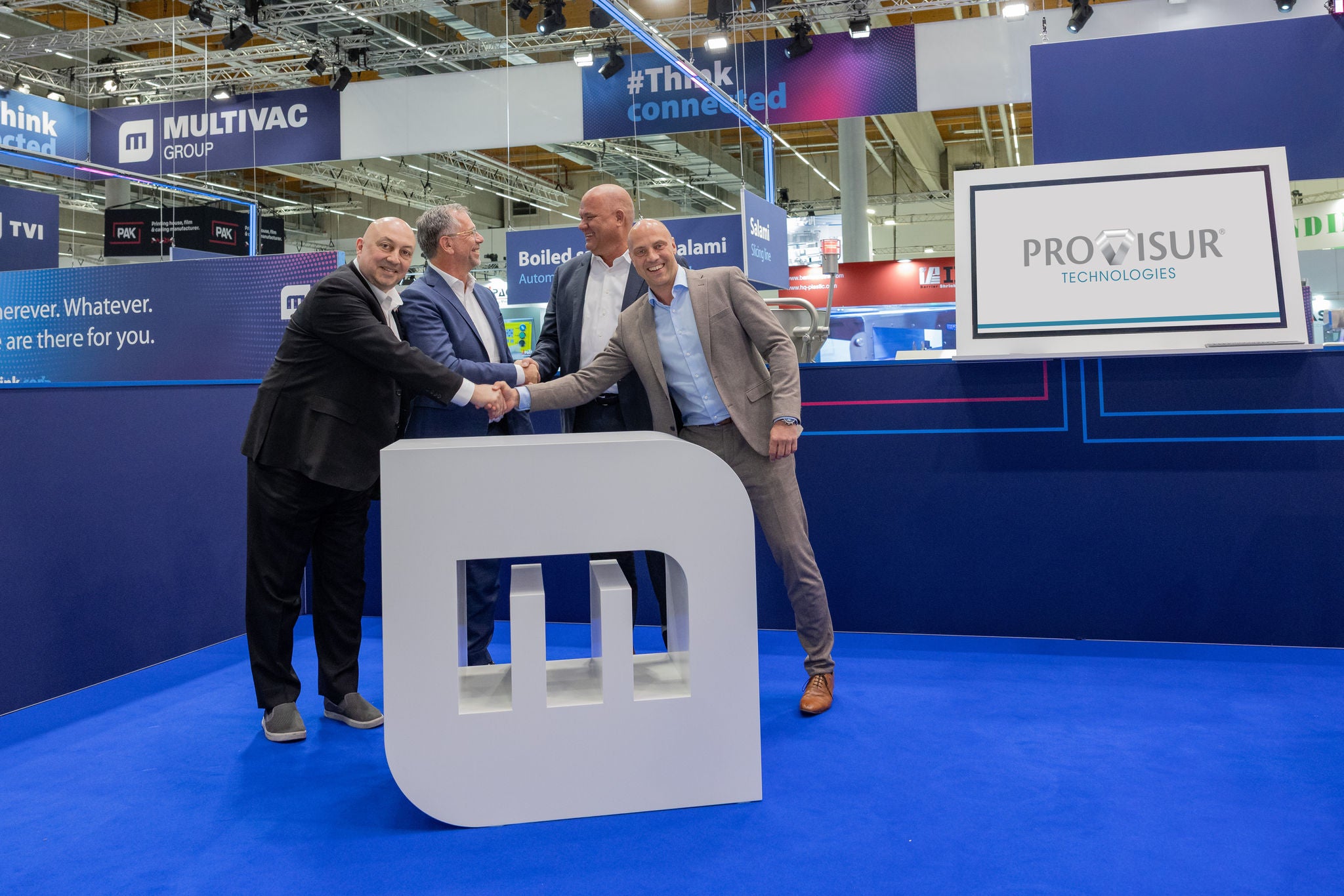

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

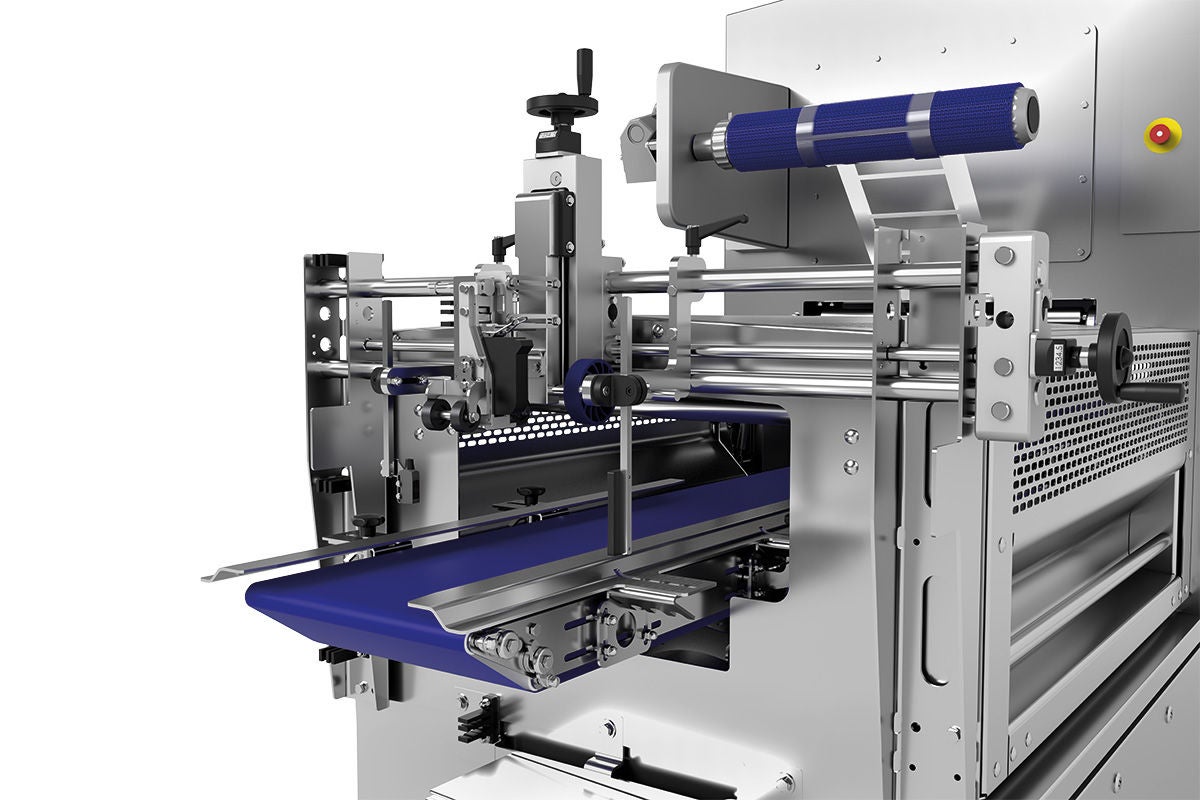

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

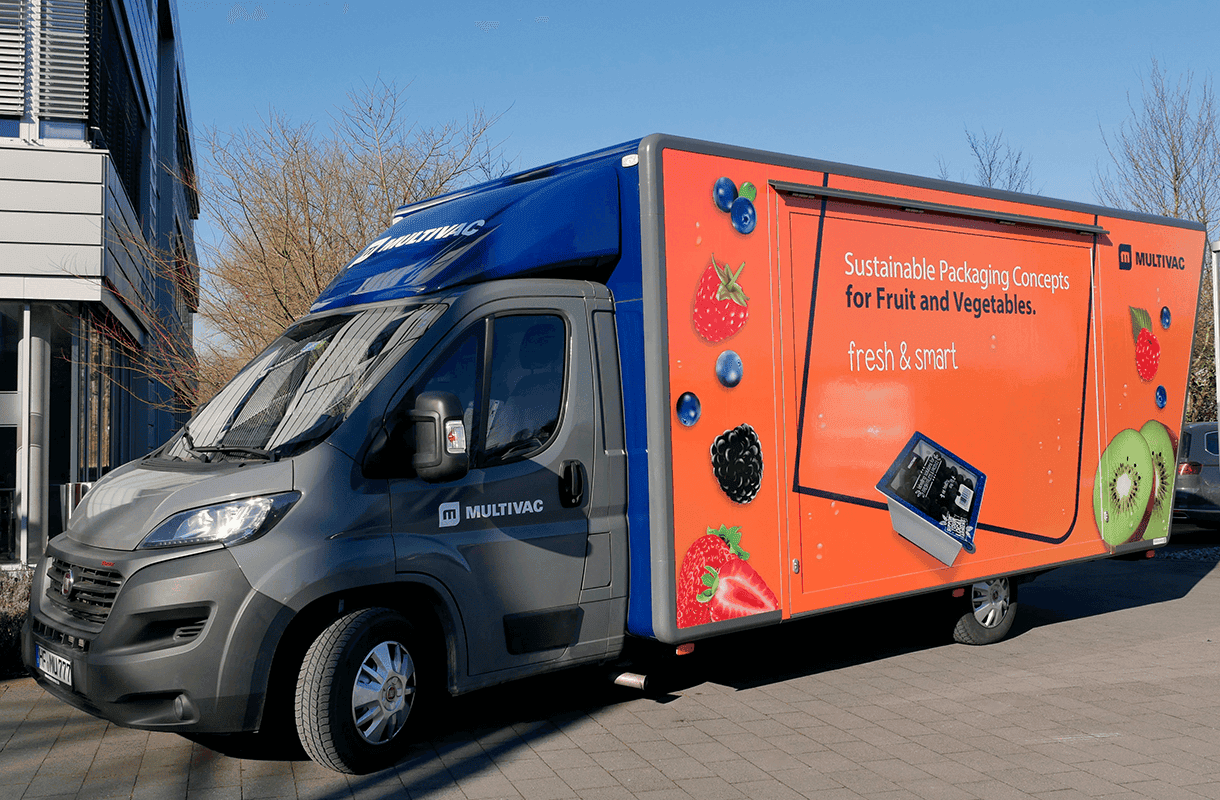

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

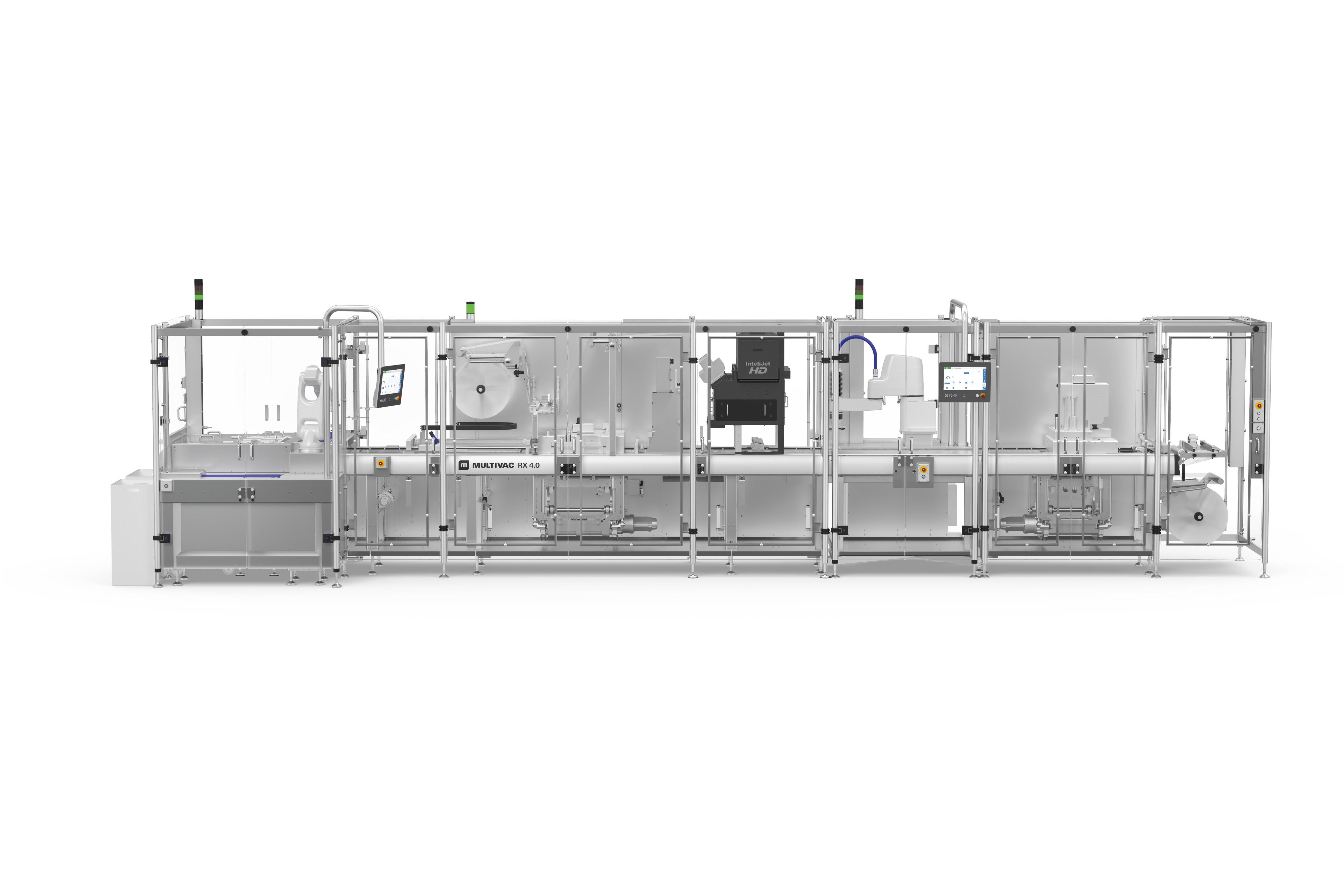

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com