Always performing better..

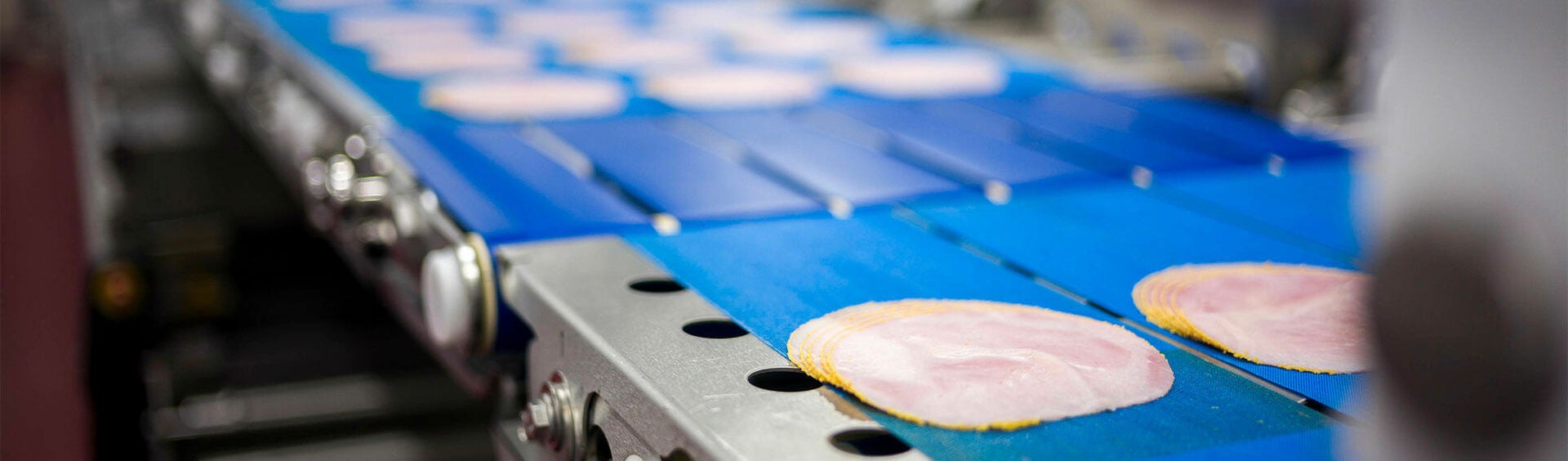

The future of slicing: With the new SLX generation.

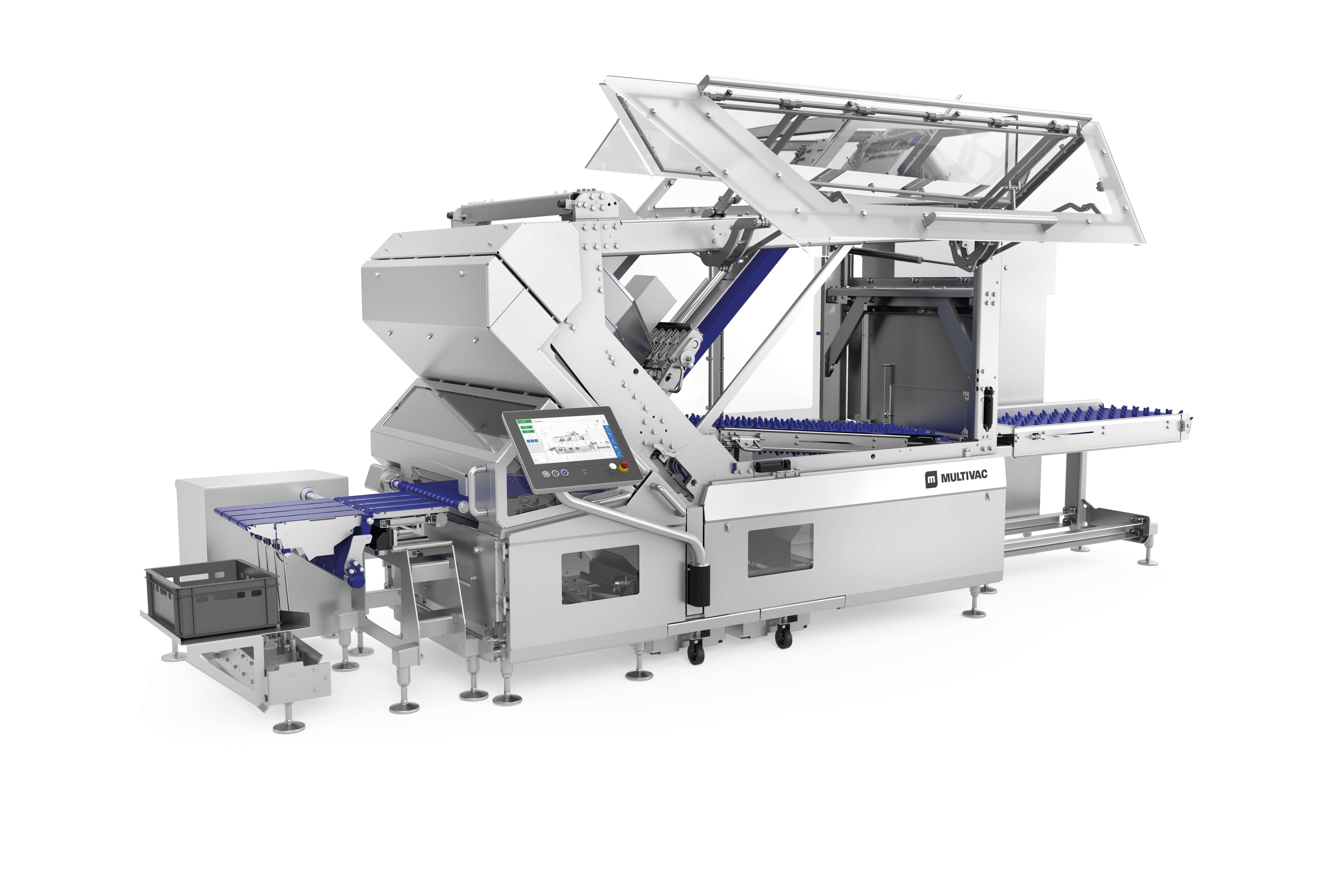

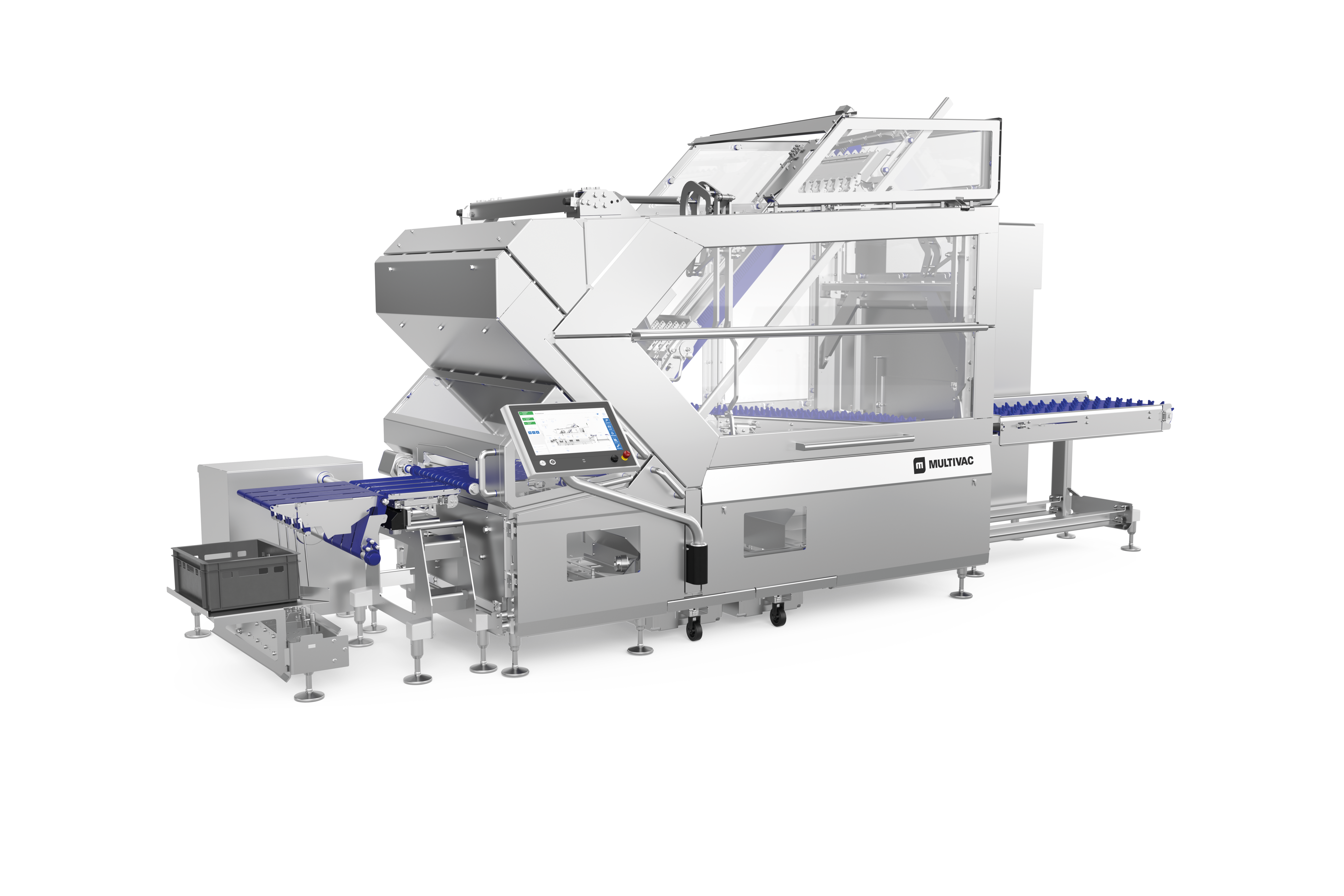

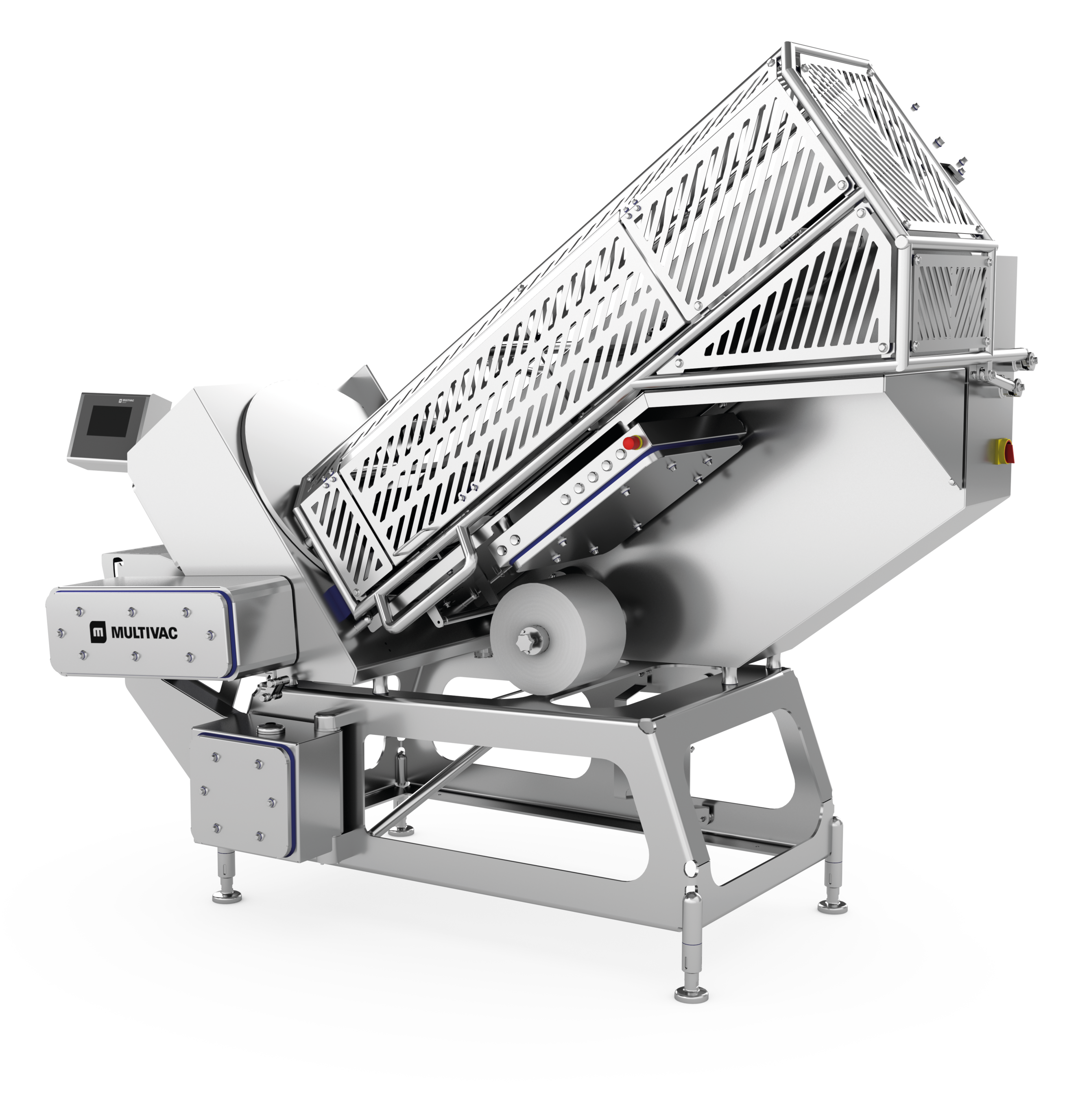

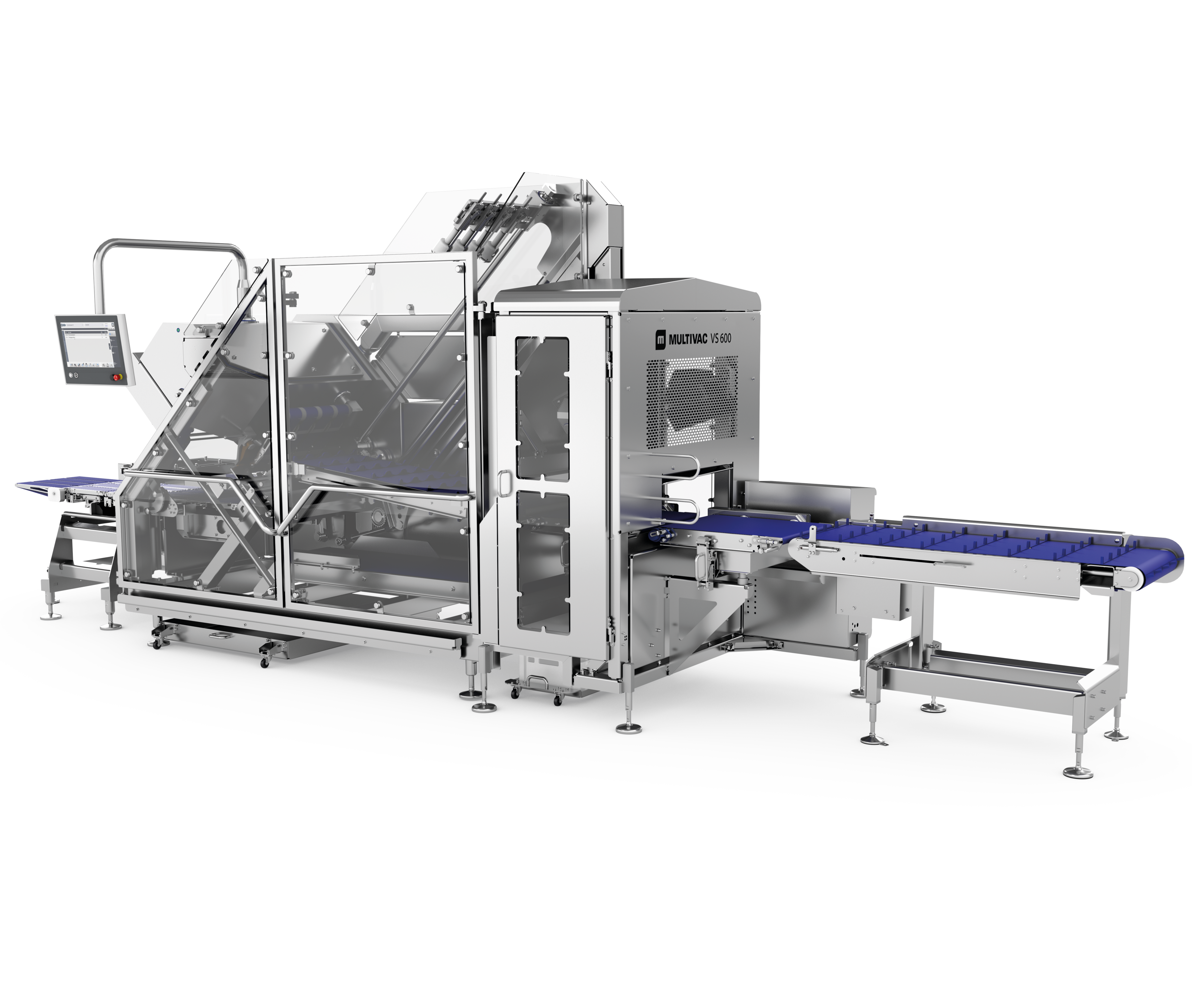

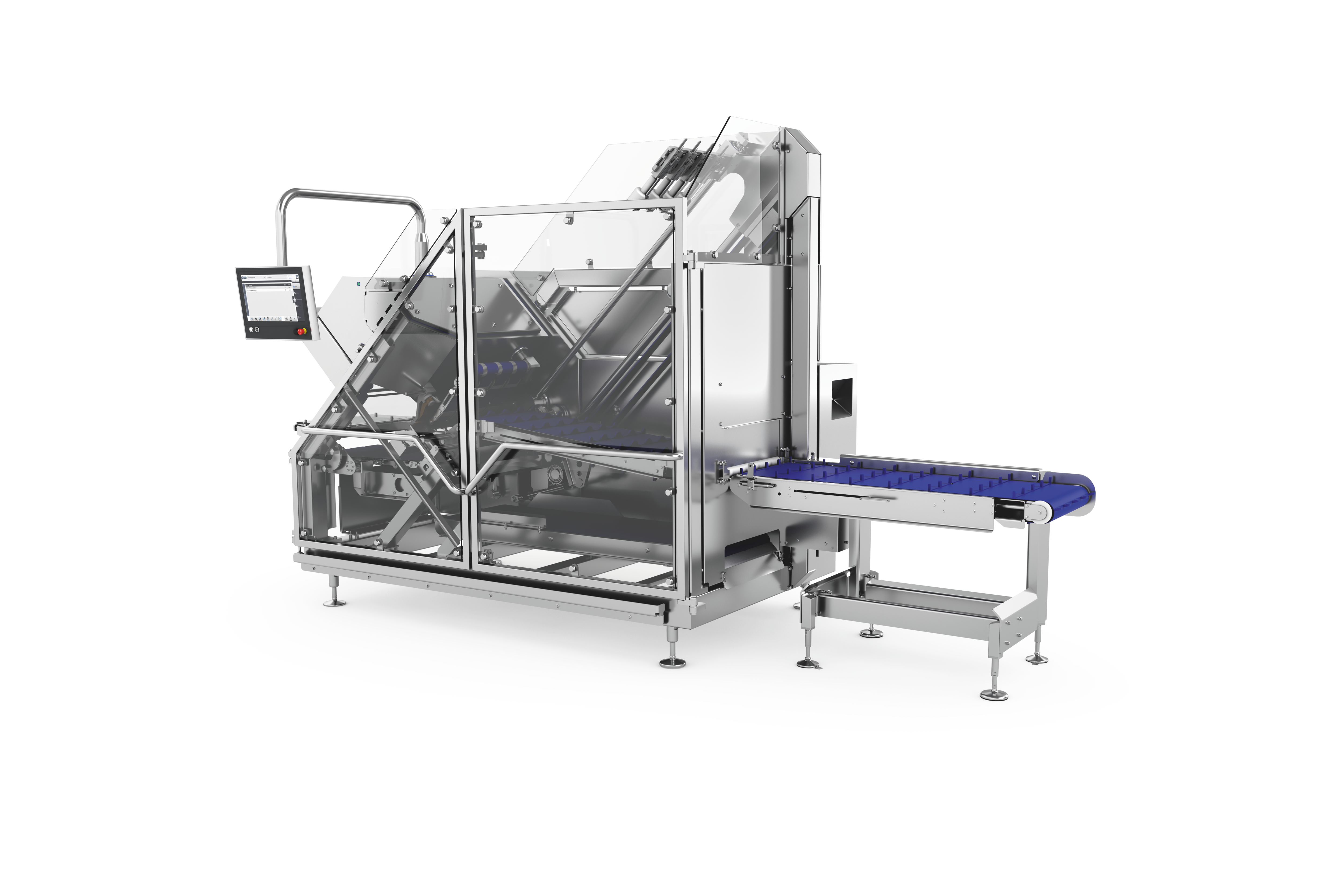

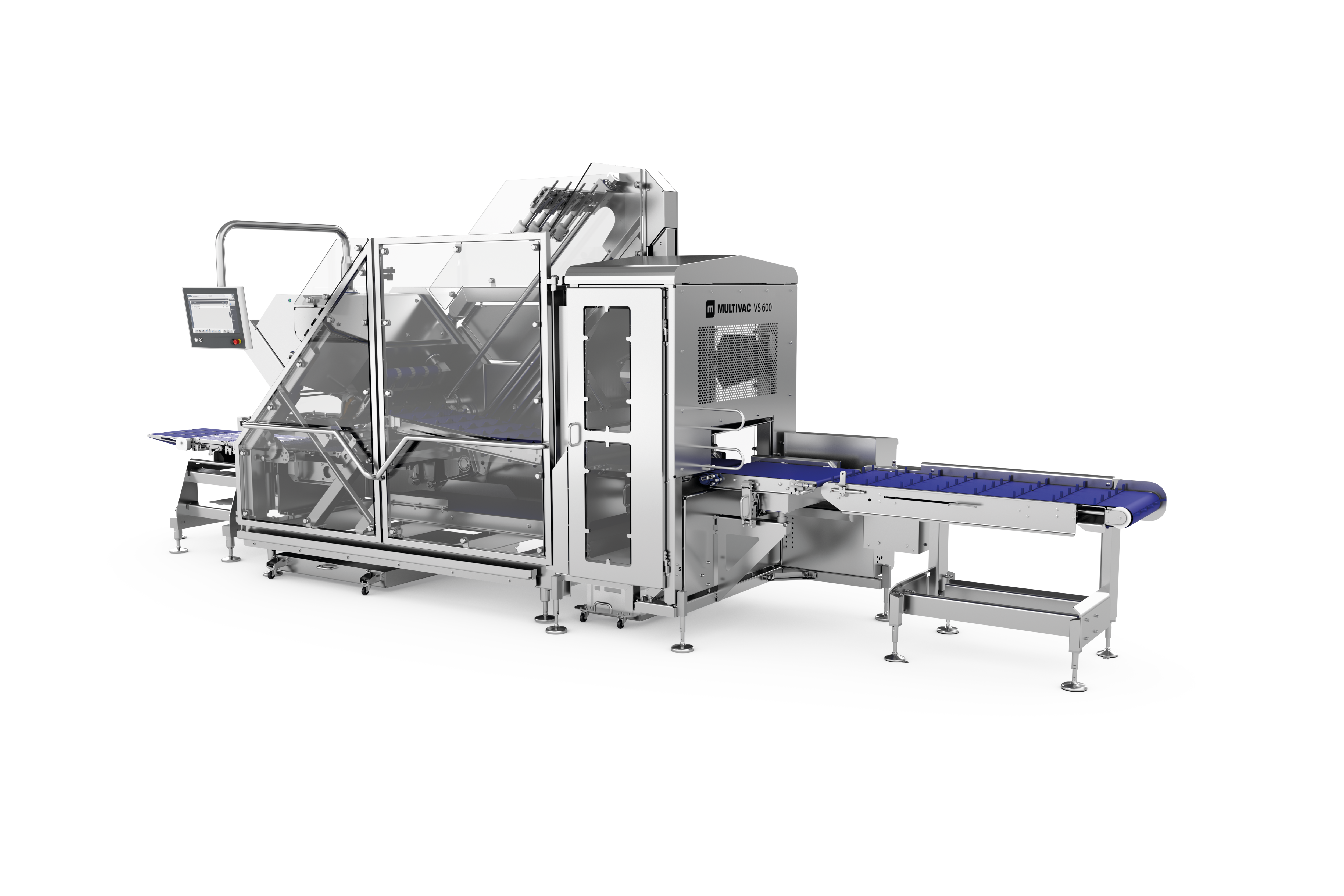

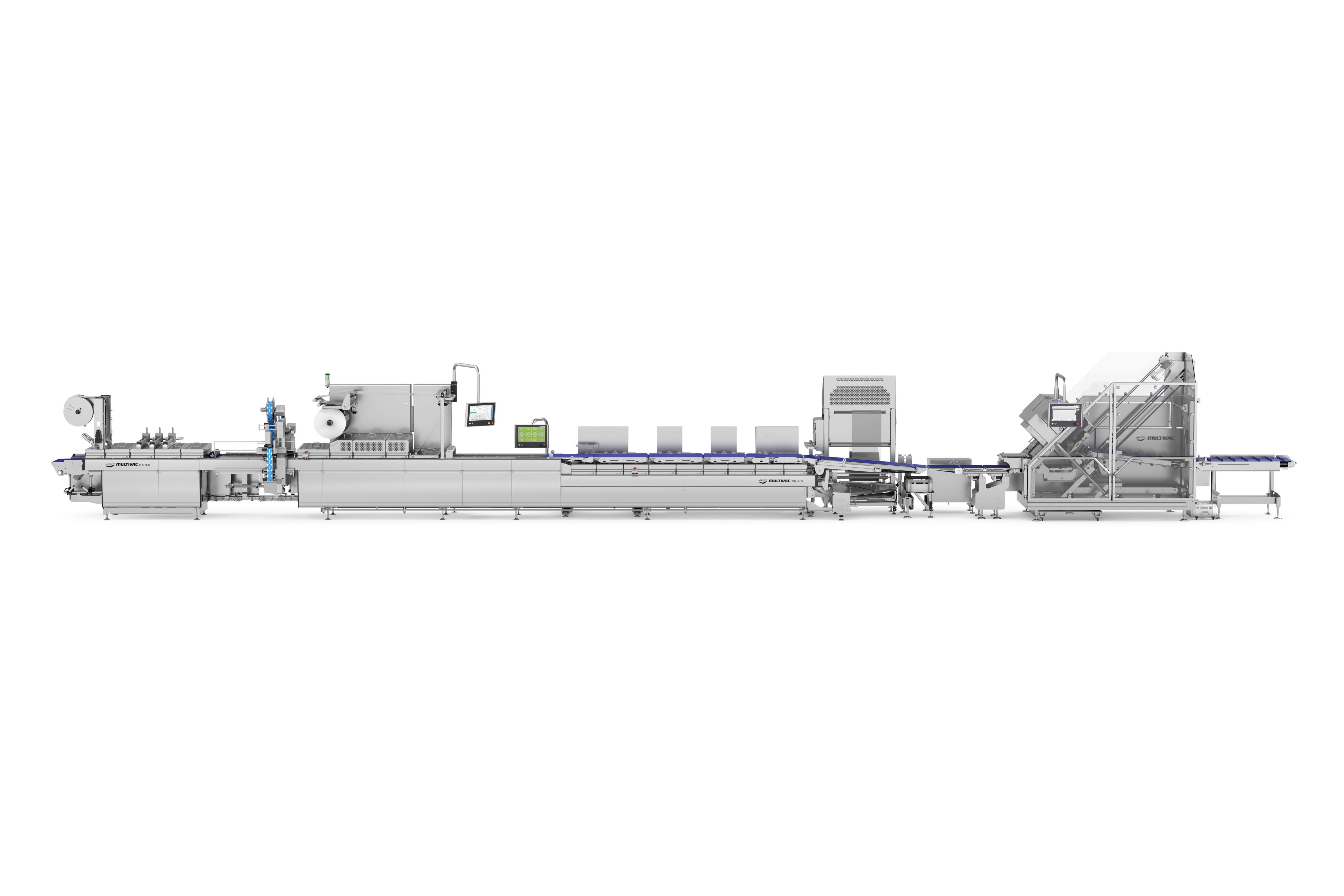

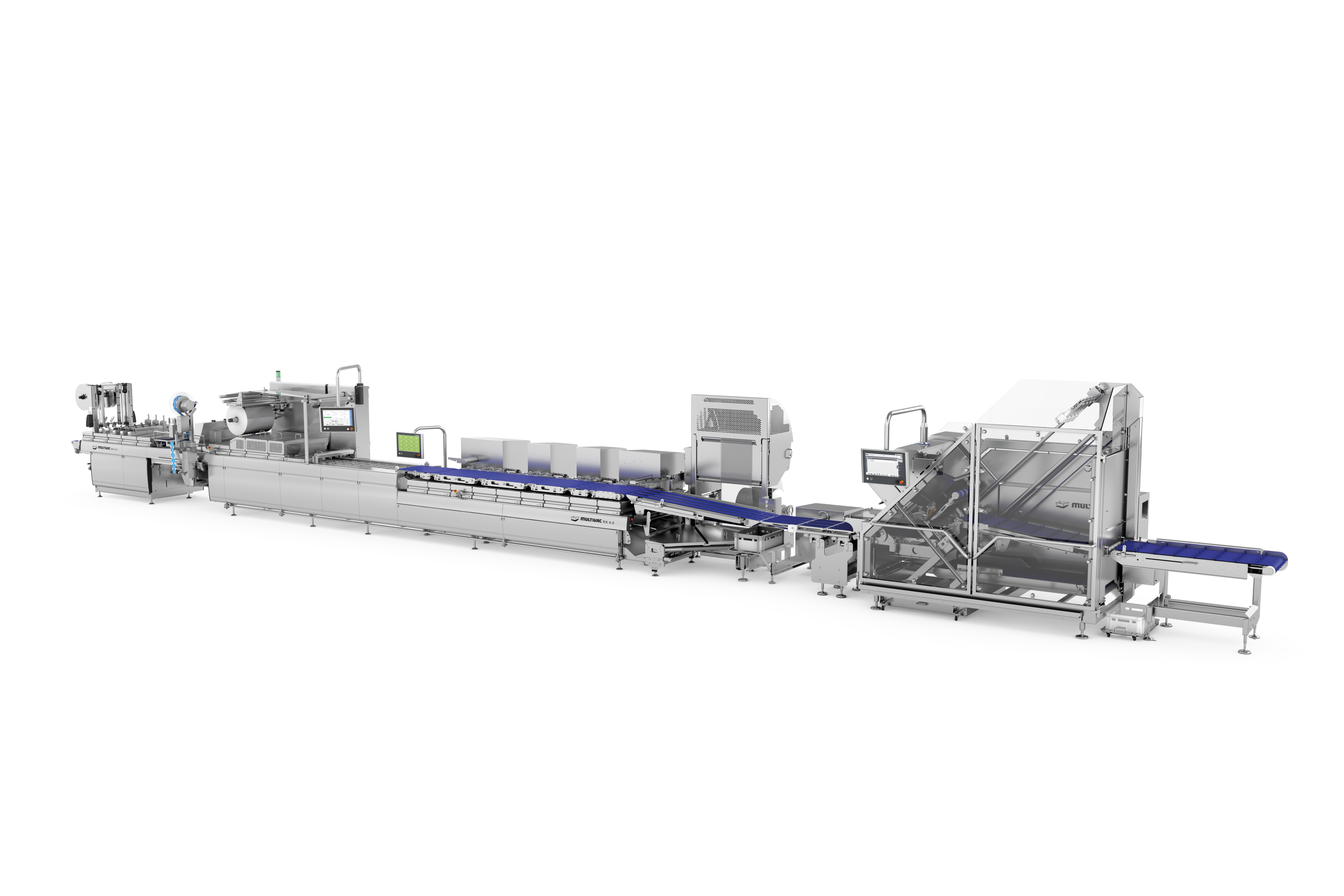

The new and advanced generation of MULTIVAC slicers – state-of-the-art and designed using our proven expertise in integrated processing and packaging solutions. Separating the machines into different slicer series enables perfect solutions in terms of performance, flexibility, footprint and functionality.

Forward-thinking MULTIVAC customers can expect excellent slicing quality even at warmer product temperatures, perfect slicing and portioning results and simple, intuitive operation thanks to the latest IPC control with HMI 3. MULTIVAC Smart Services monitors, controls and optimises processes in real time, which simplifies production sequences.

Short set-up times and rapid conversion, as well as excellent access to the machine for easy maintenance and cleaning, guarantee a high level of machine availability. The machines can be used both as stand-alone units and integrated with MULTIVAC Line Control (MLC) in fully automatic slicing and packaging lines. Ideal for ensuring particularly efficient machine and system operation.

- Teaser 1

- Teaser 2

- Teaser 3

- Teaser 4

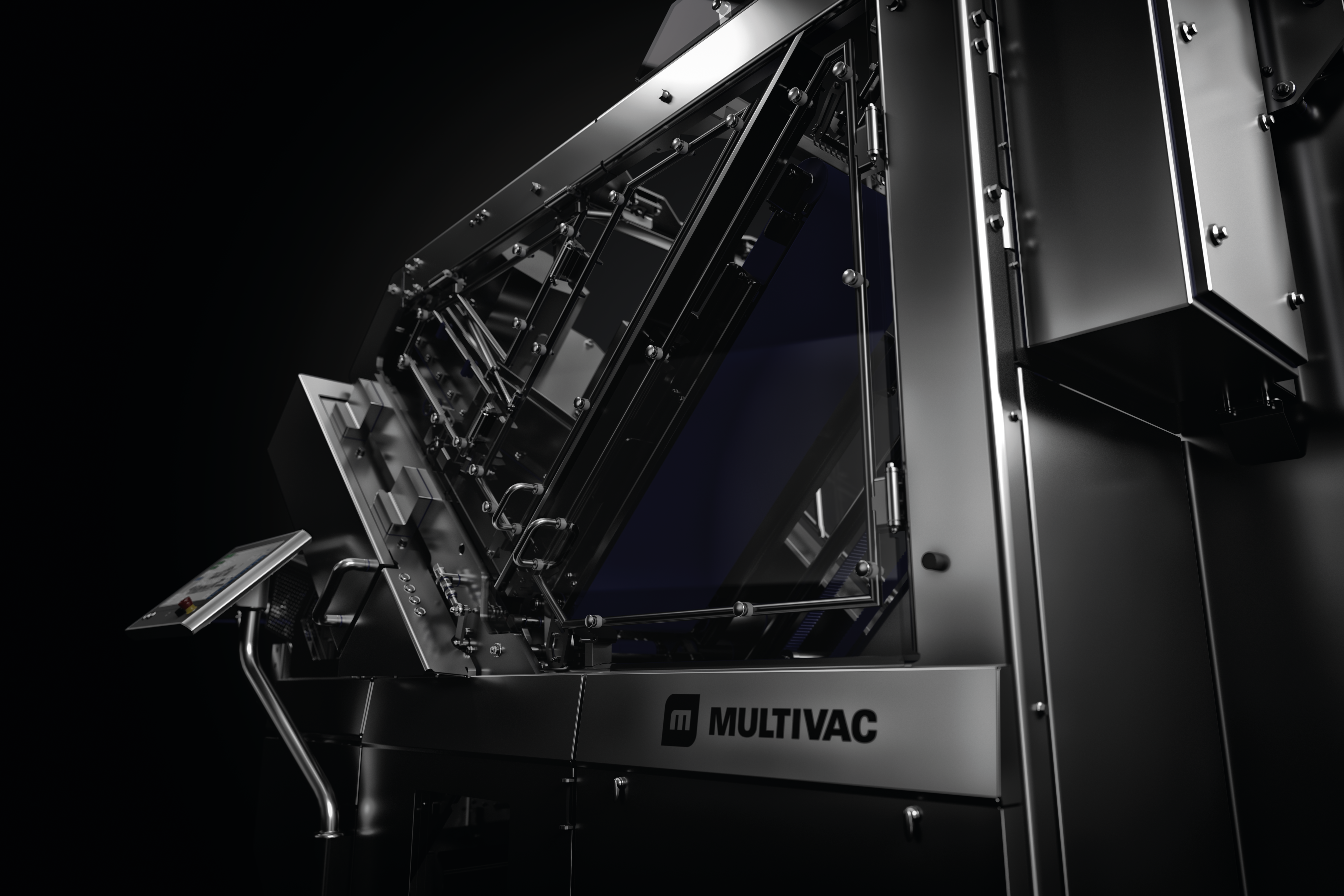

Highest level of precision for the best slicing results

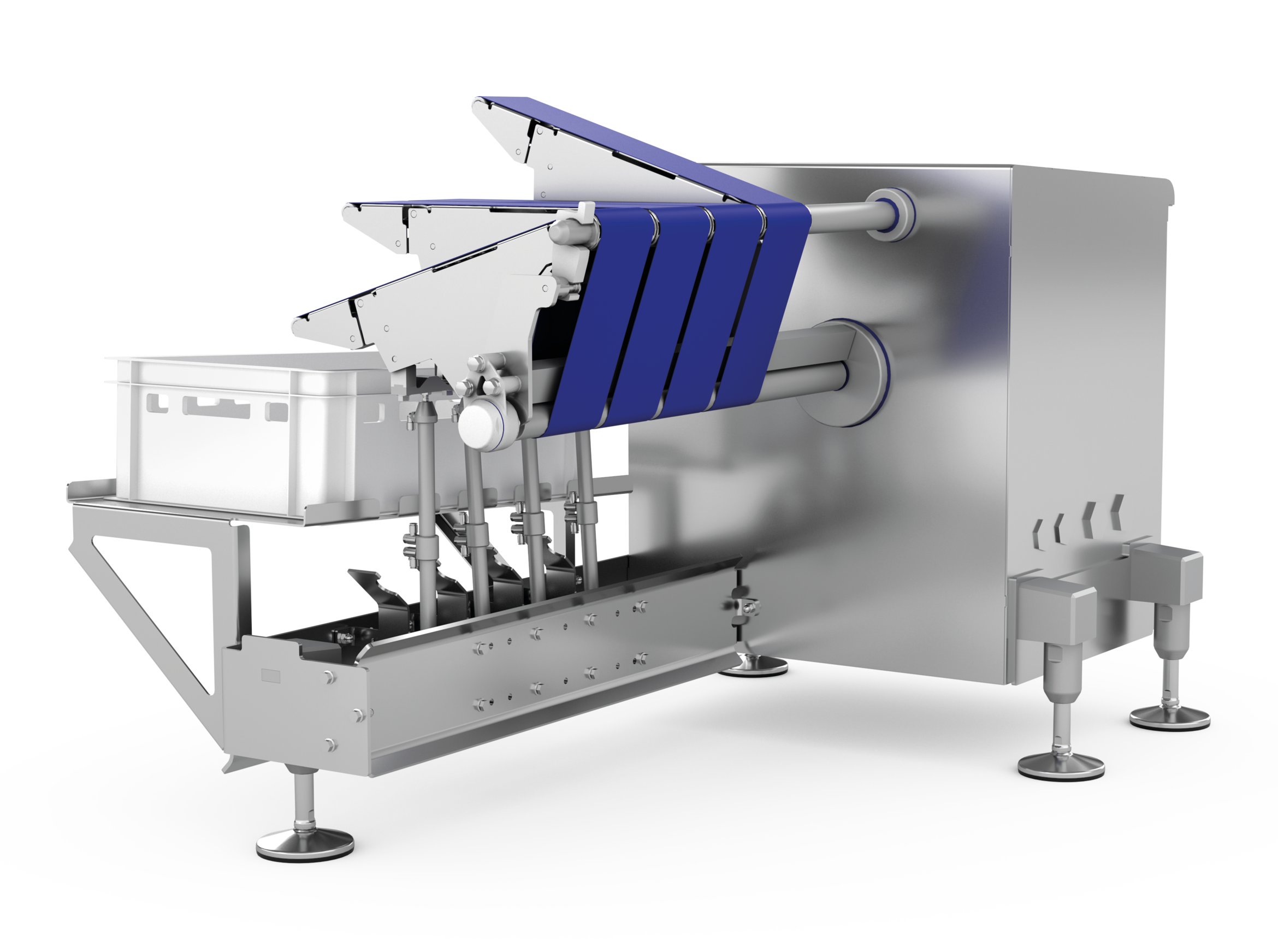

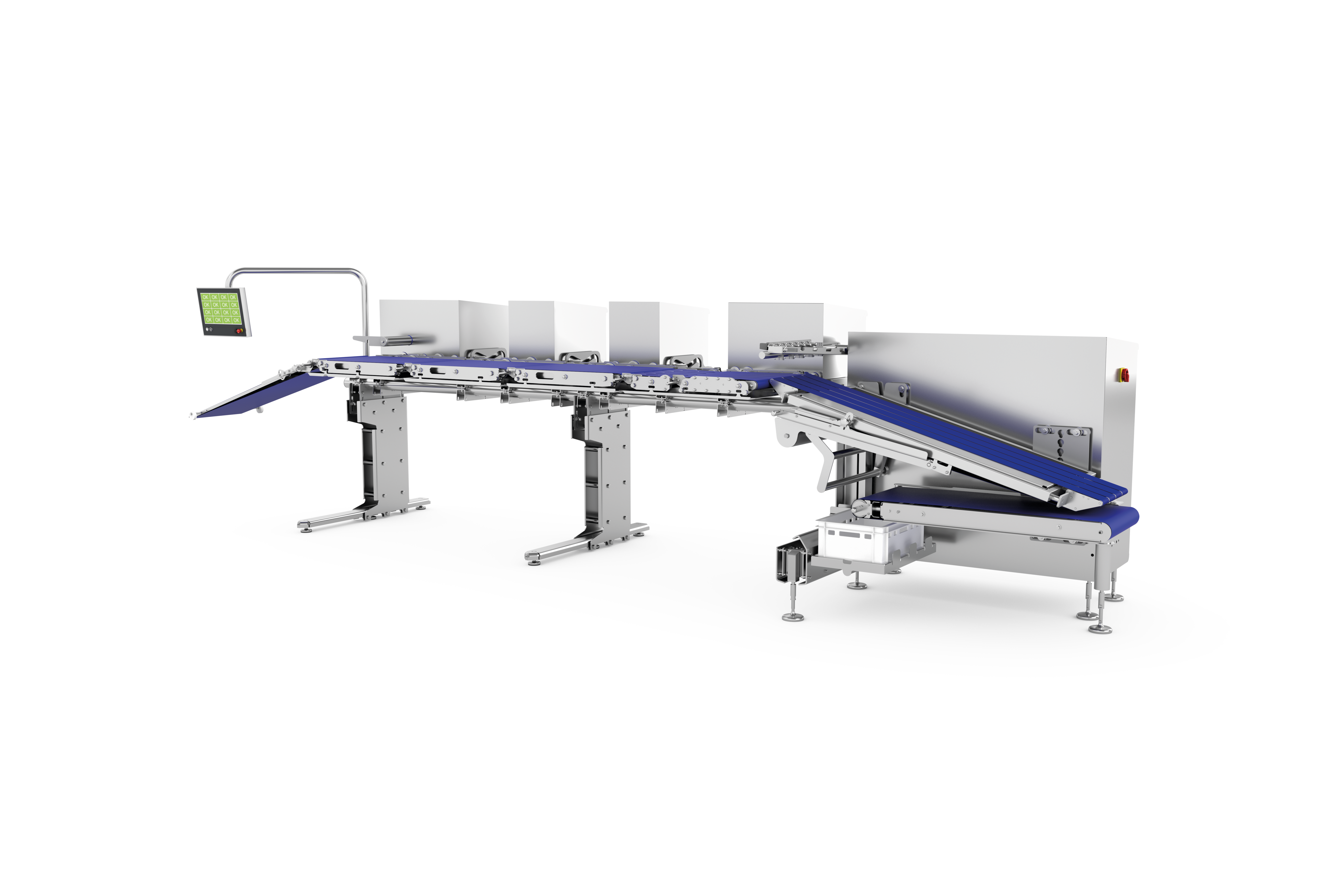

MULTIVAC slicers stand out with their reliable precision and high level of flexibility for quick product and format changes.

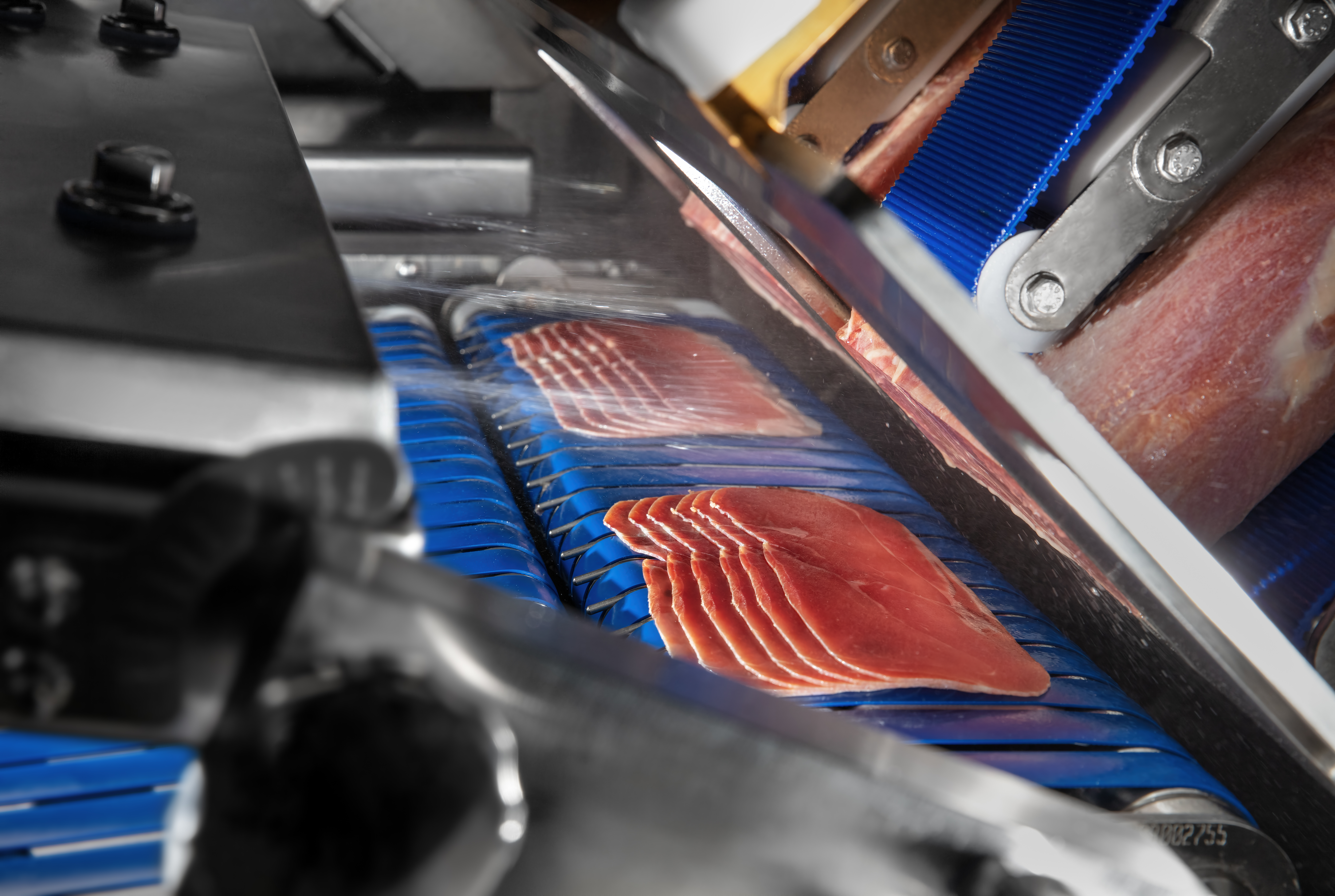

The slicing quality remains constant, both with challenging consistencies or complex products. Our range of high-quality slicers offers outstanding slicing results for your sausage and meat products, ham, cheese, and even alternative protein products.

Our focus is always on your product. Together, we will find the right solution to present your products attractively and maximize your output with optimized portions.

MULTIVAC slicers are also perfectly designed for integration into our line concepts. Thanks to the seamless processing and packaging, your product's quality and taste are fully protected. The shelf life increases for your consumers and the positive experience with your product remains constant right through to the very last portion. We will be happy to advise you and look forward to meeting your requirements.

Cost-effectiveness thanks to high-level efficiency

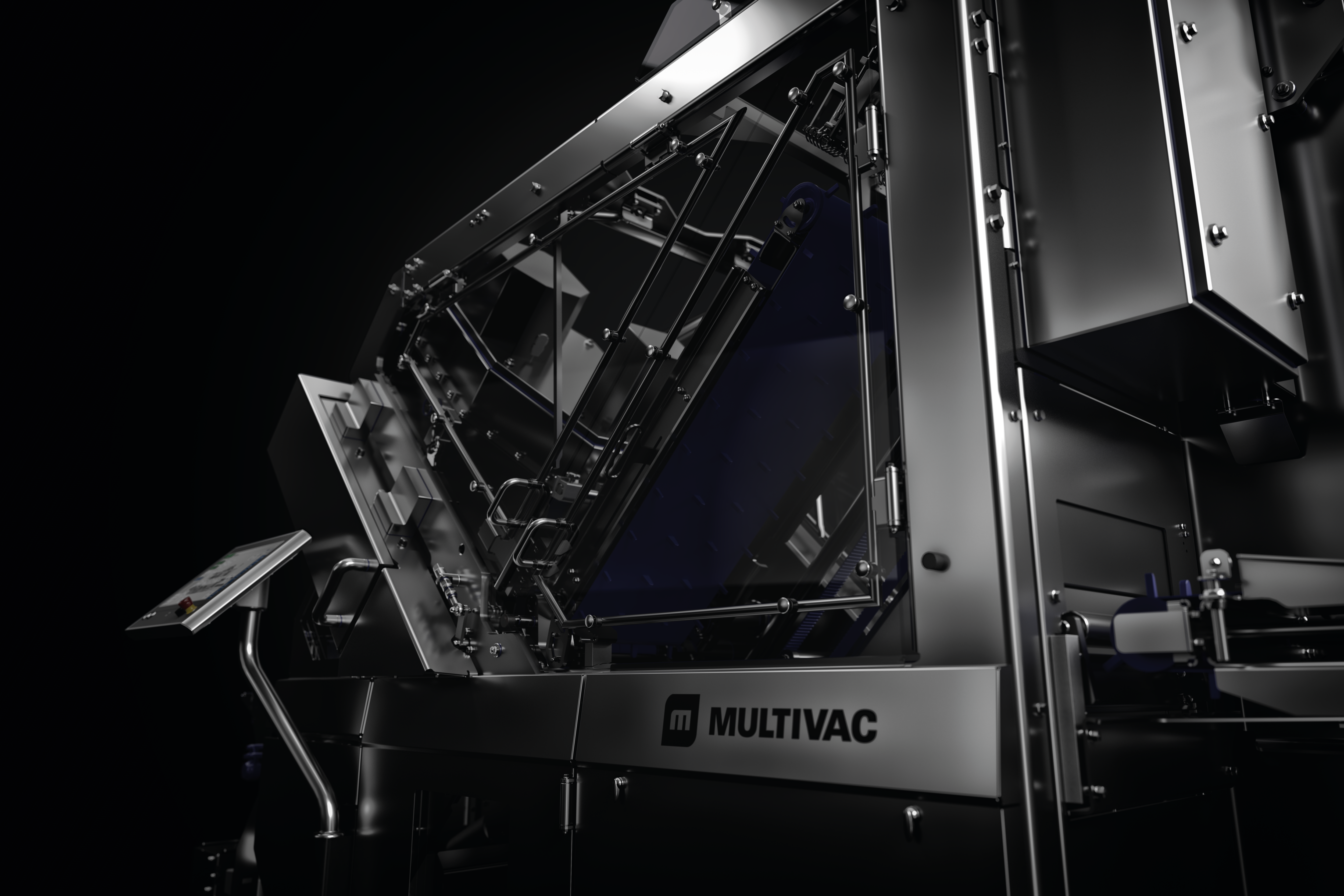

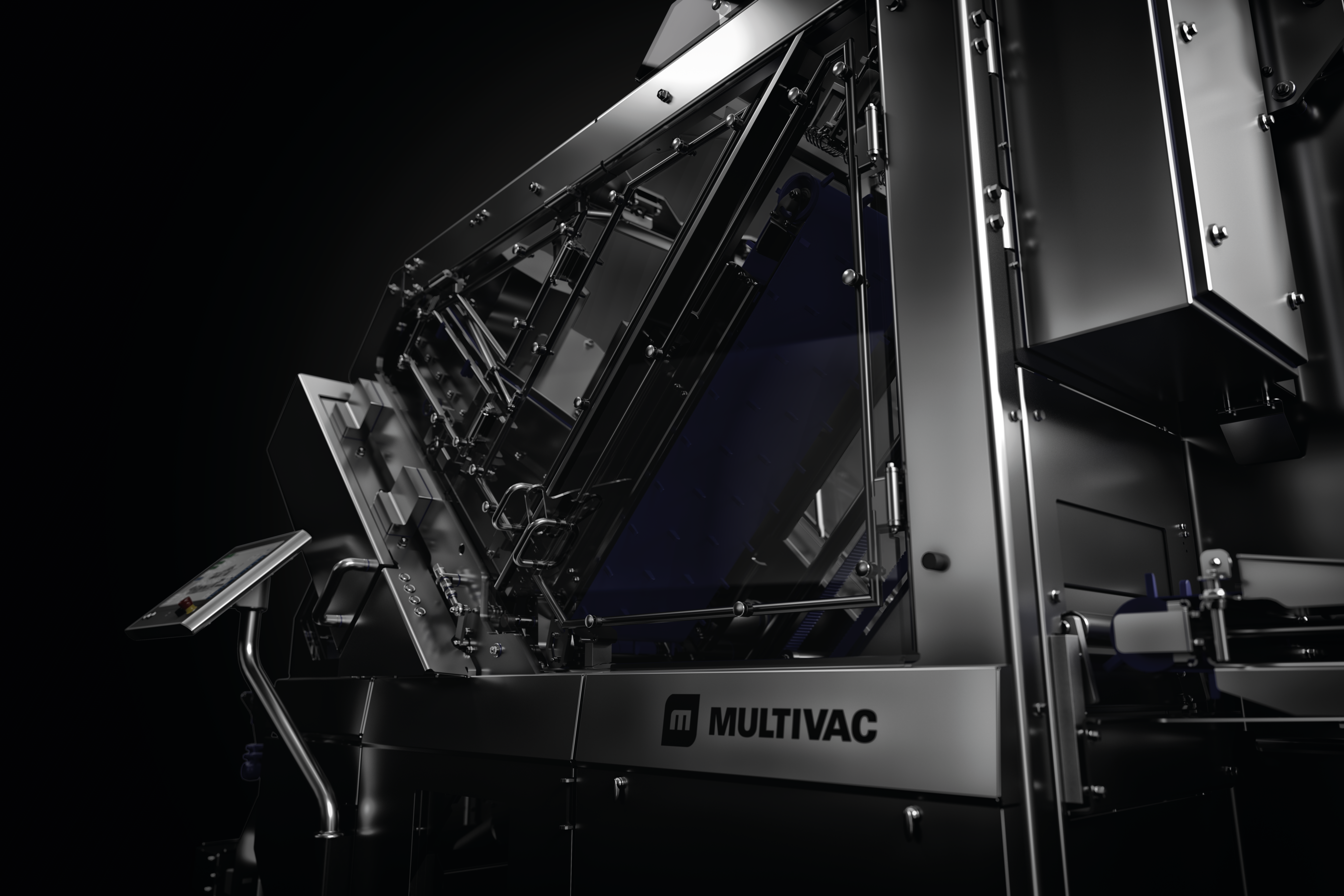

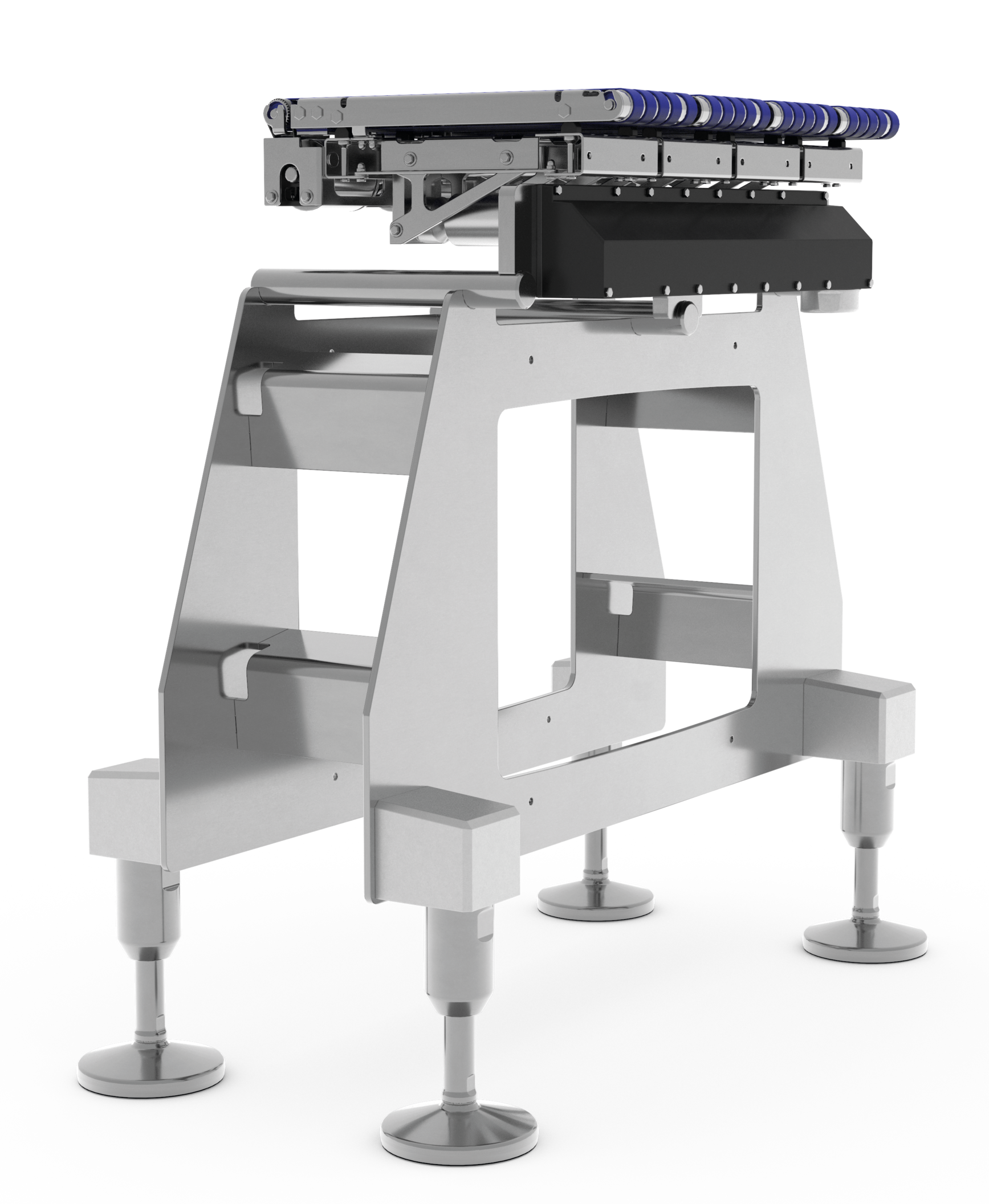

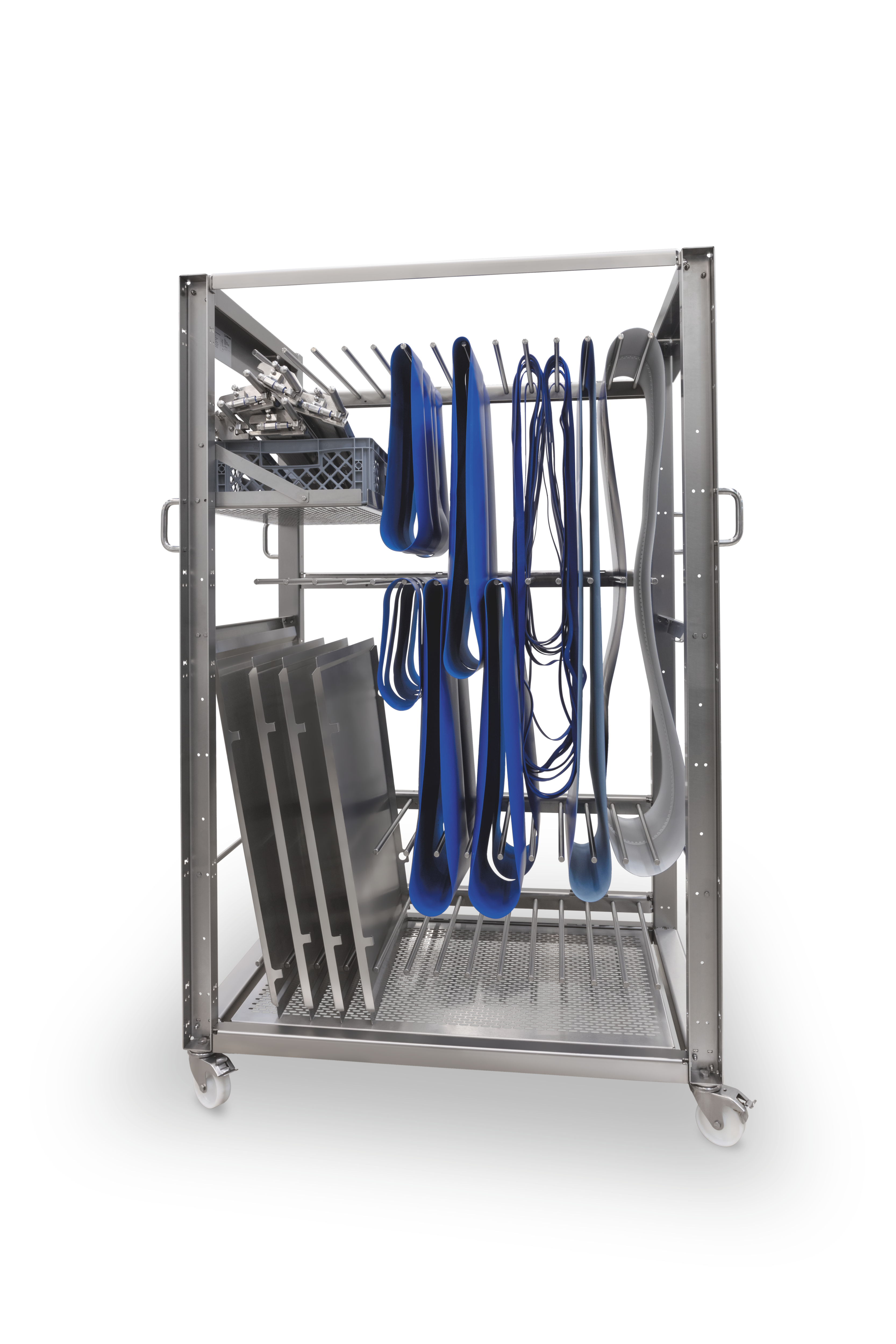

Cleaning and servicing our slicers can be performed simply and efficiently. This enables quick set-up and conversion times, which increases the effective running time of your production.

Our slicers are easy to operate. Thanks to line integration, you can maximize the automation of your processes without increasing your personnel. Line-integrated MULTIVAC slicers, therefore, enable maximum high speeds to be achieved for the highest possible output - even at the highest production volumes.

Optimized throughput and a high level of availability, as well as rapid product changes, contribute significantly to reduced overall costs and the cost-effectiveness of your overall process.

Success stories

Frozen Meat Slice on White Background

Frozen Meat Slice on White Background

MULTIVAC Meat Slicing Conveyor System

MULTIVAC Meat Slicing Conveyor System