常によりよいカットを。

スライサーの未来形: 新SLXジェネレーション。

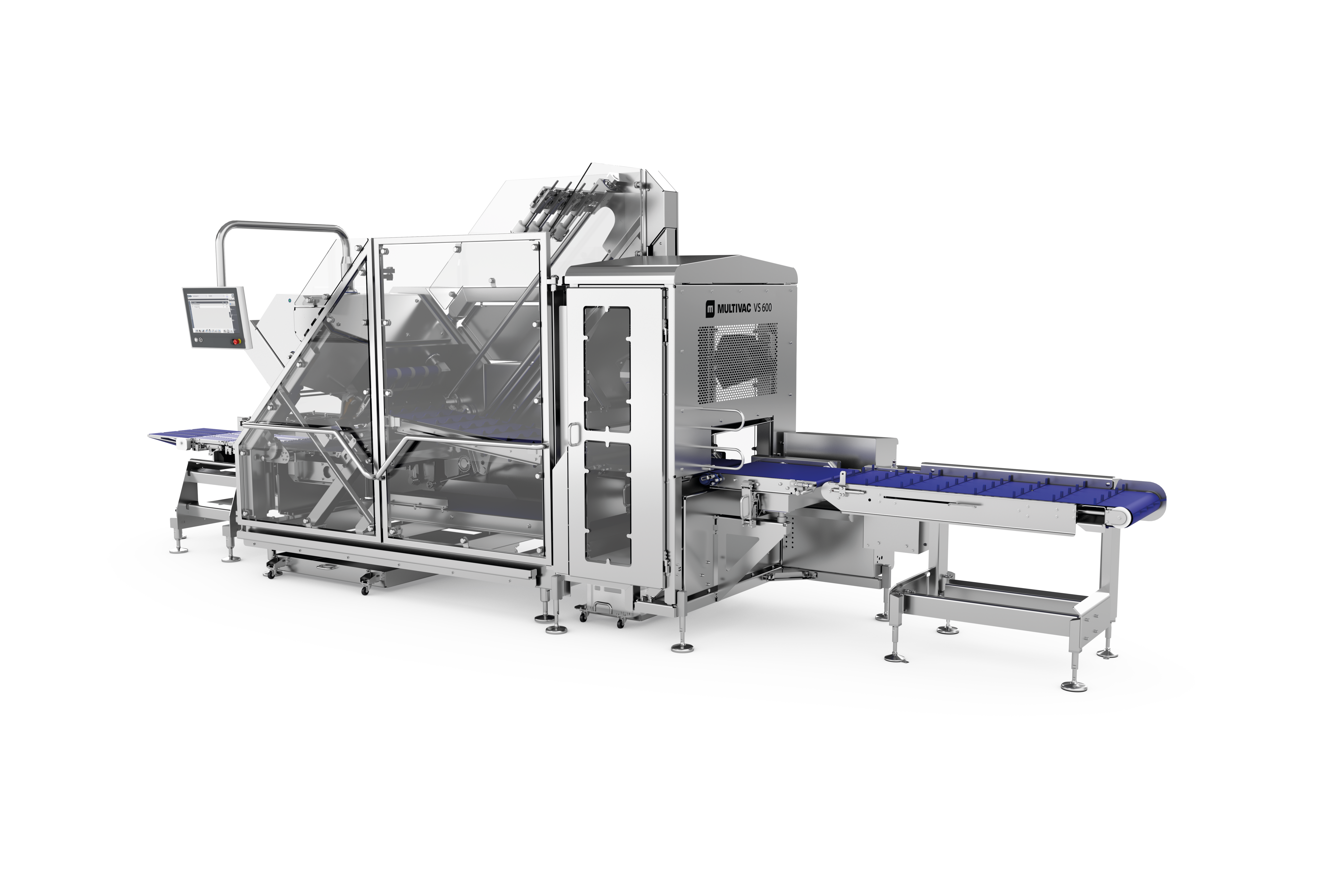

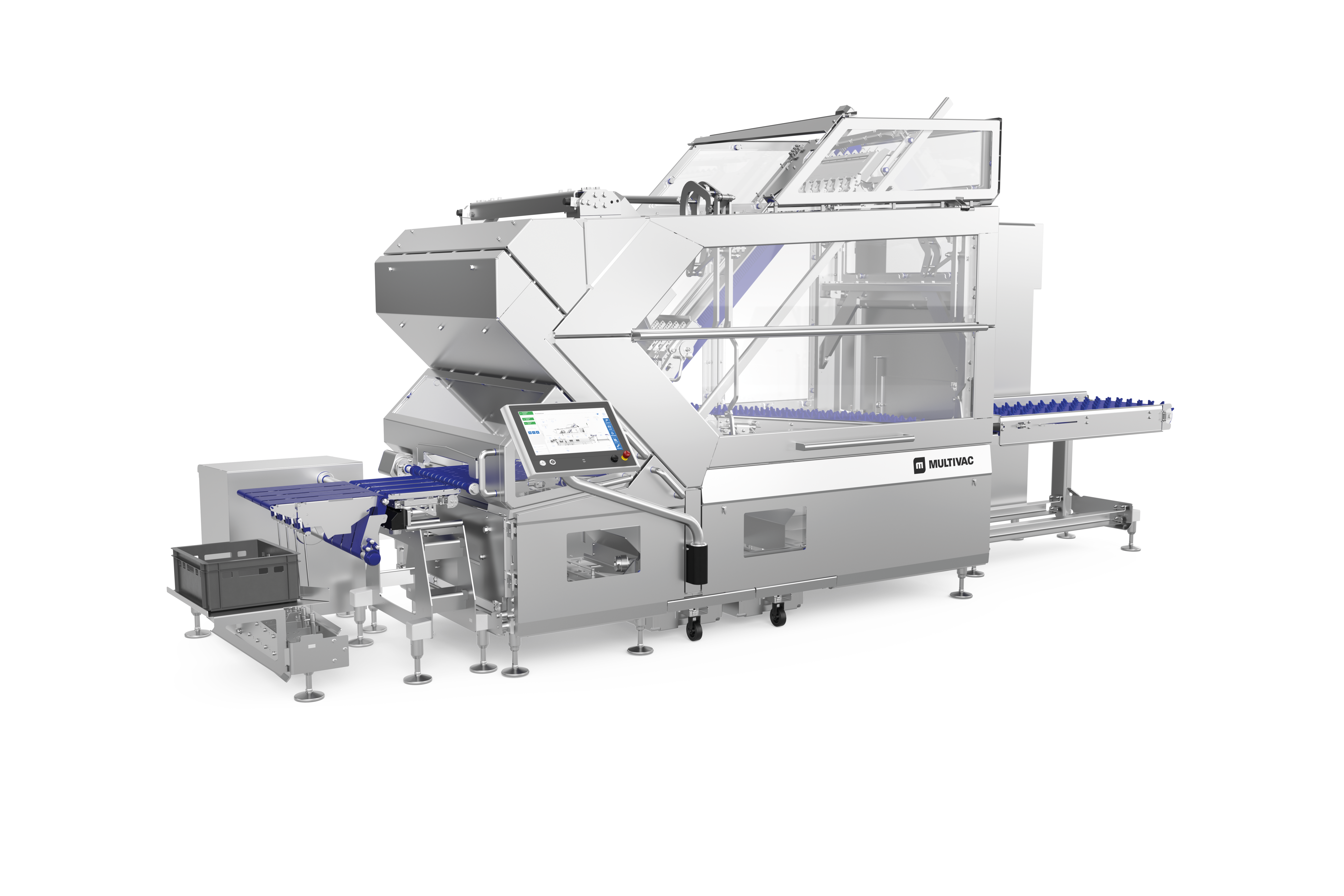

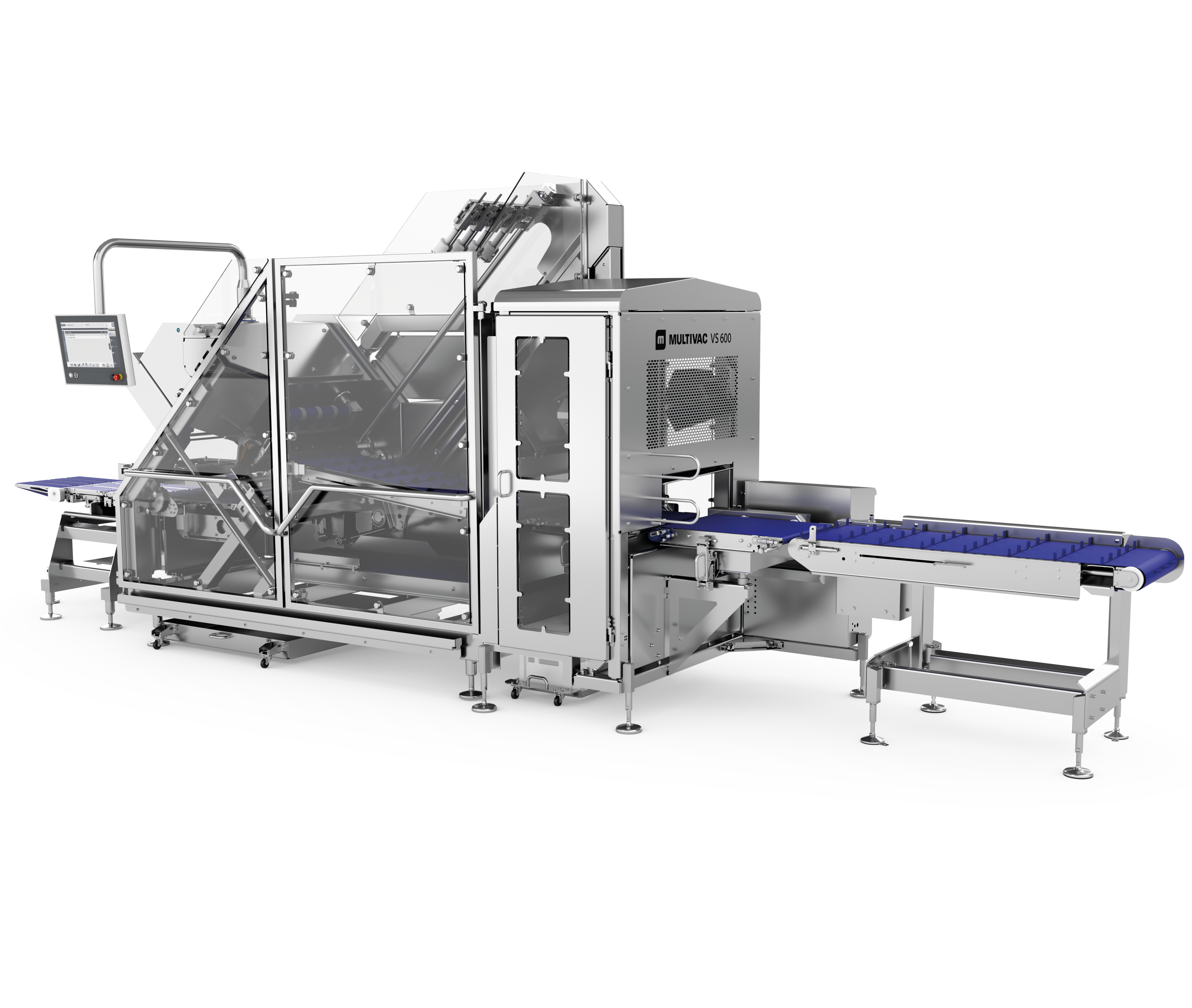

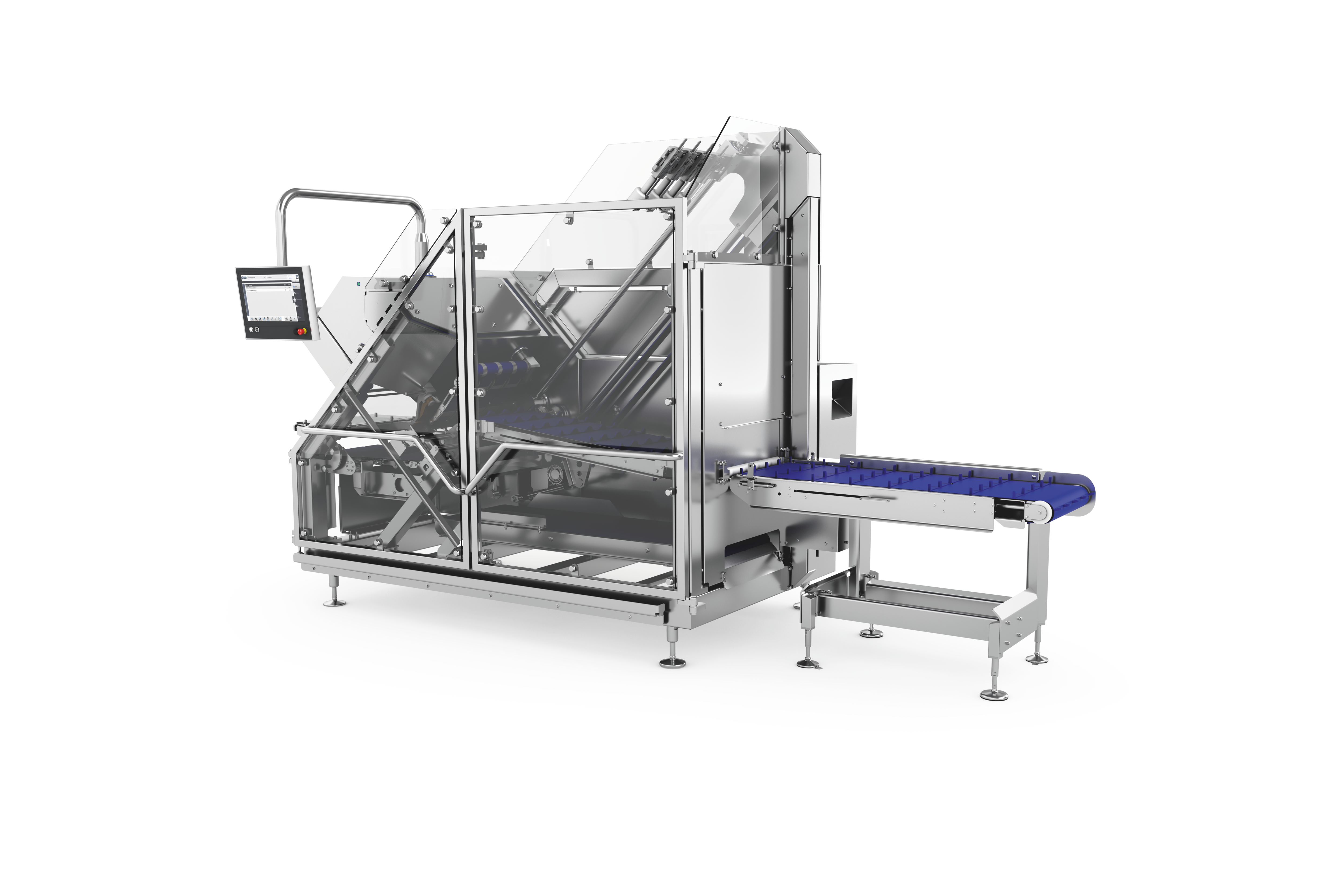

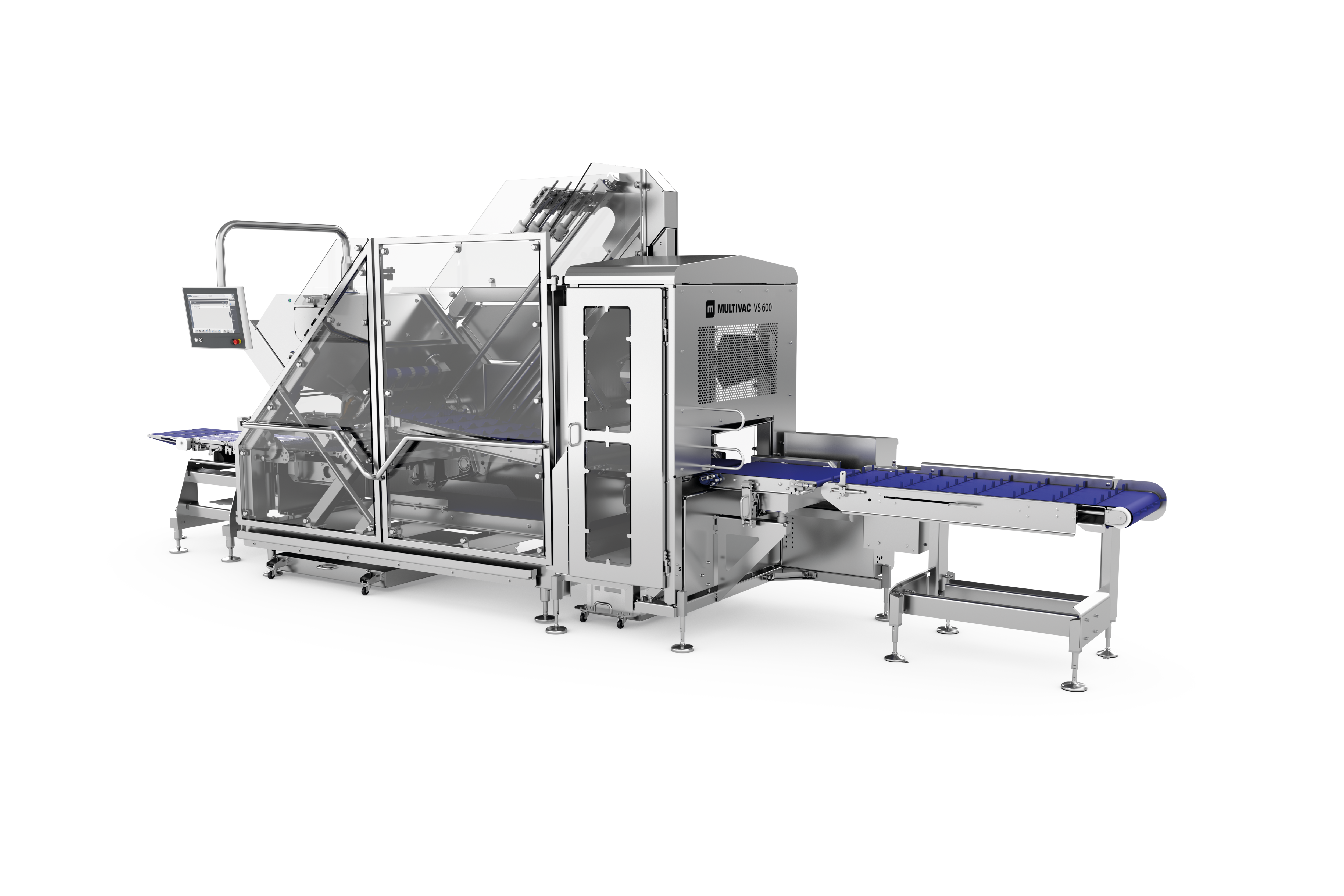

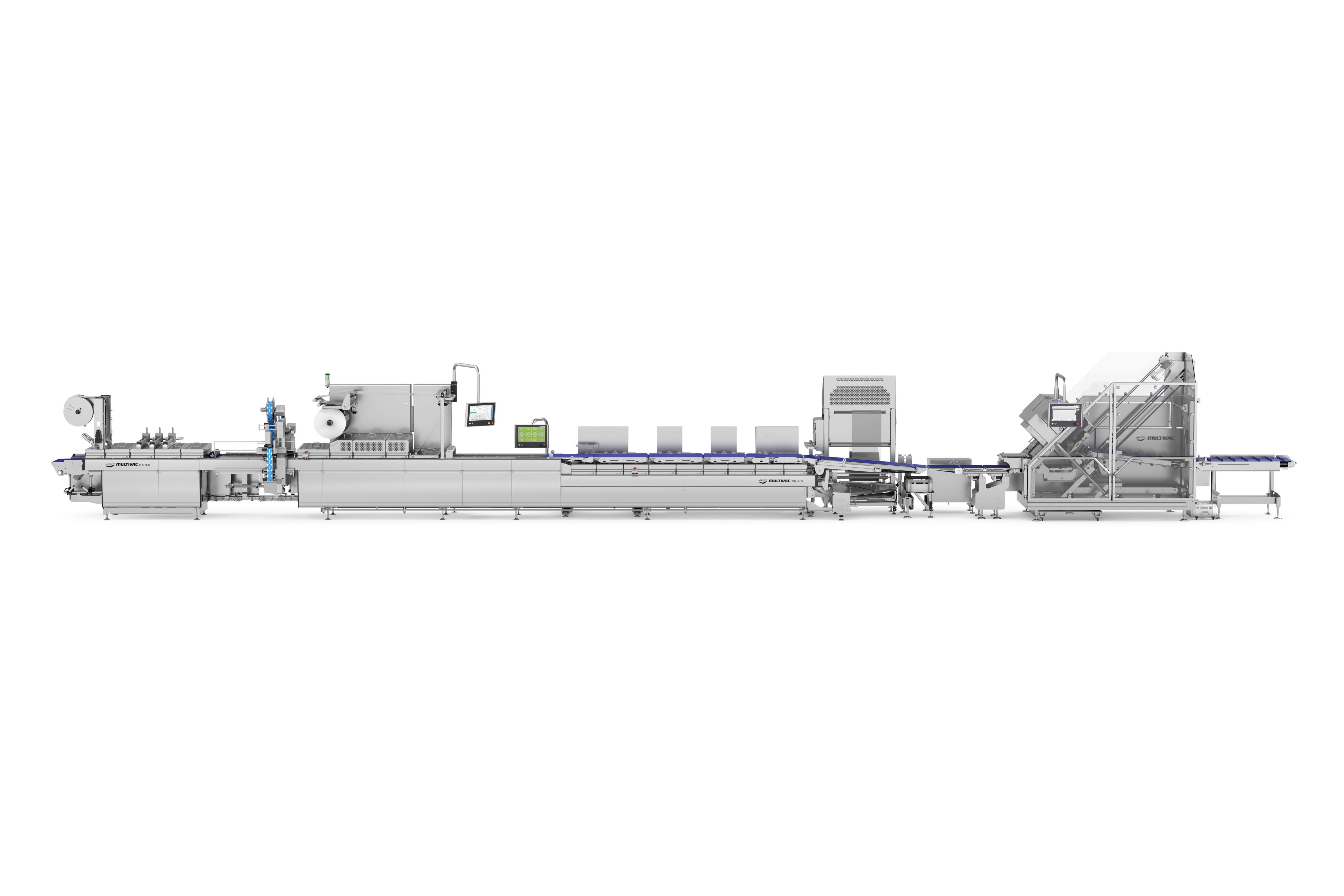

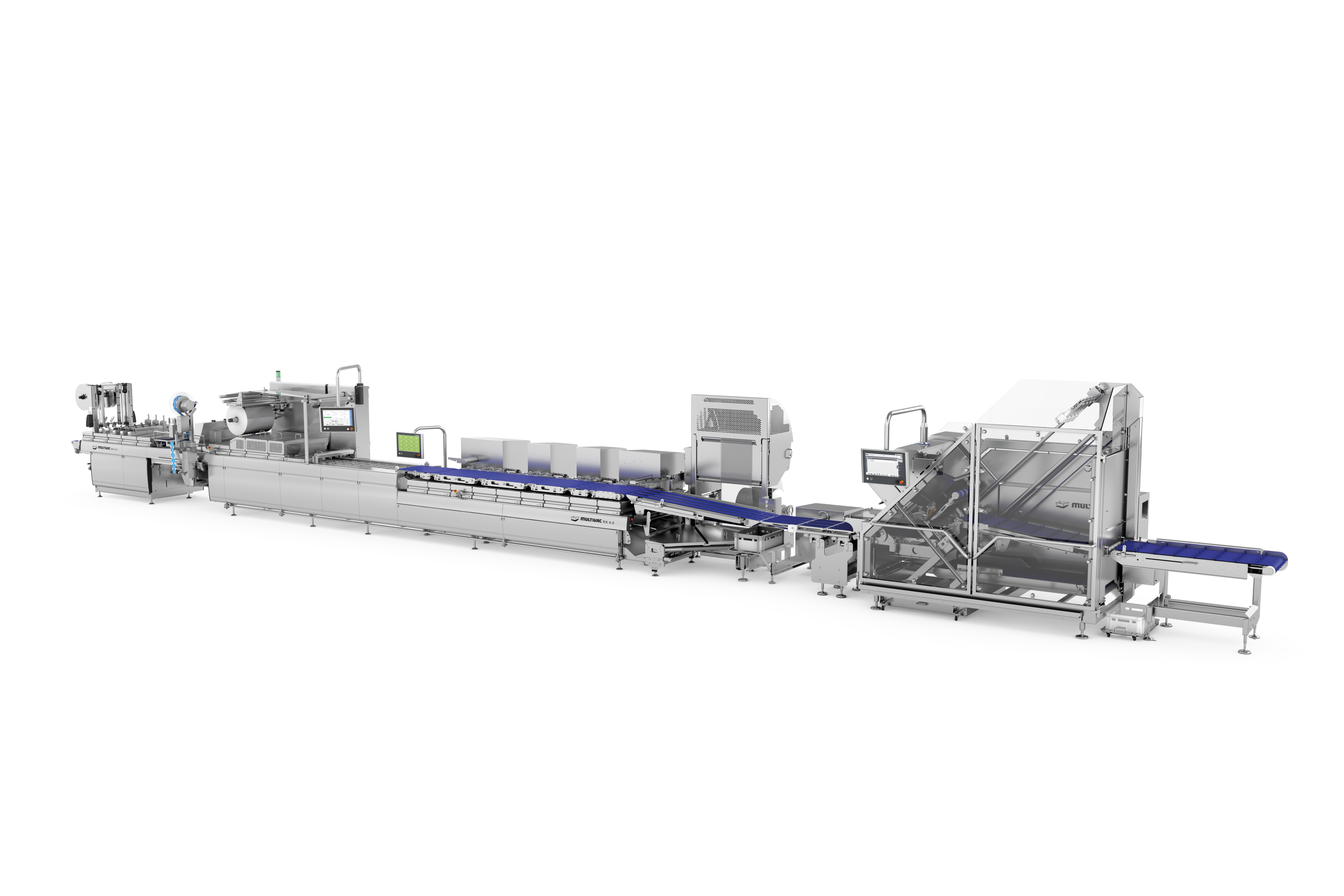

MULTIVAC スライサー装置の新しく、未来を見据えたジェネレーション - 最新技術を使い、内蔵された処理と包装ソリューションへの当社の父かったノウハウに基づいています。スライサーをシリーズに分けることでパフォーマンス、柔軟性、フットプリント、機能性の観点で完全なソリューションが可能になります。

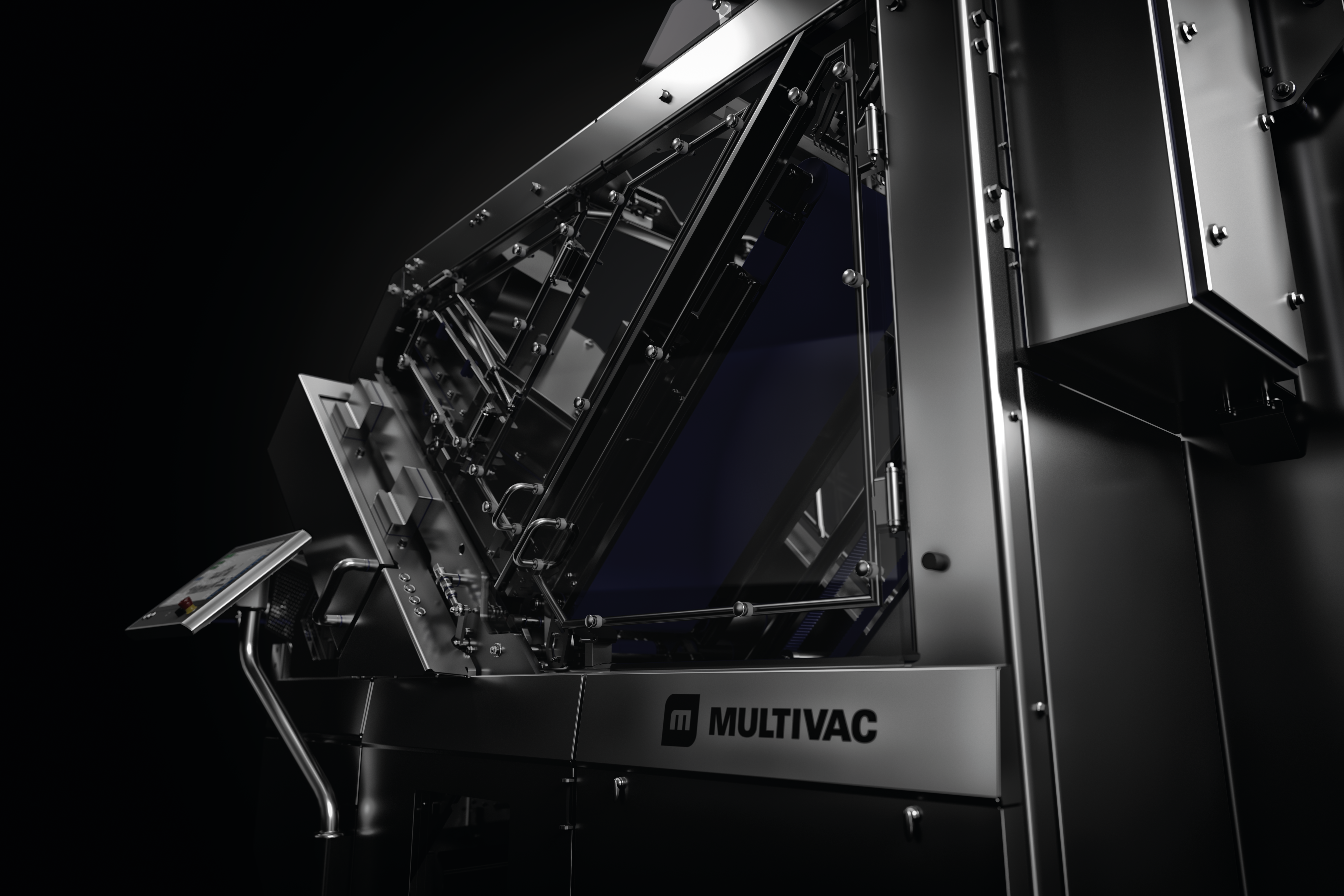

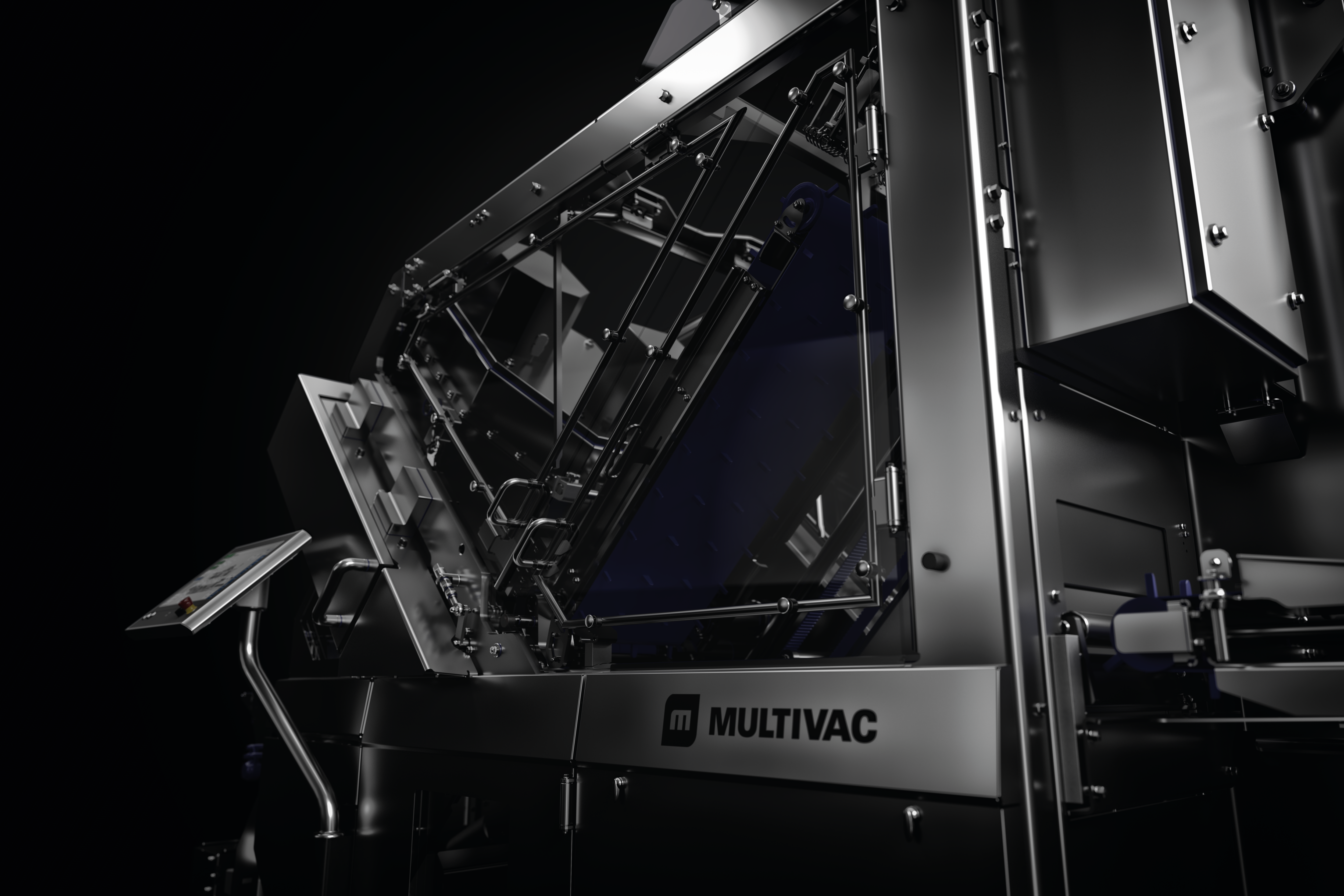

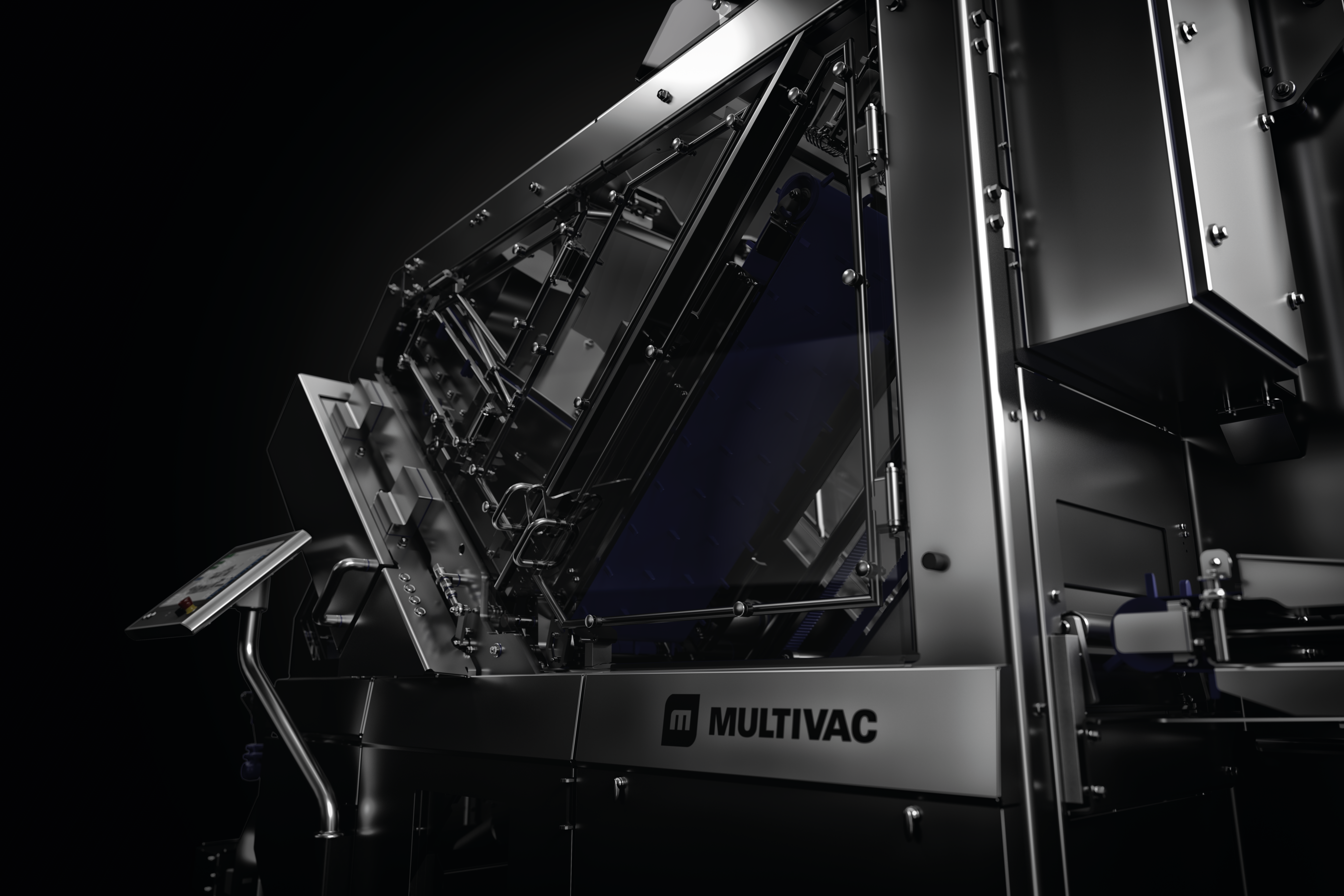

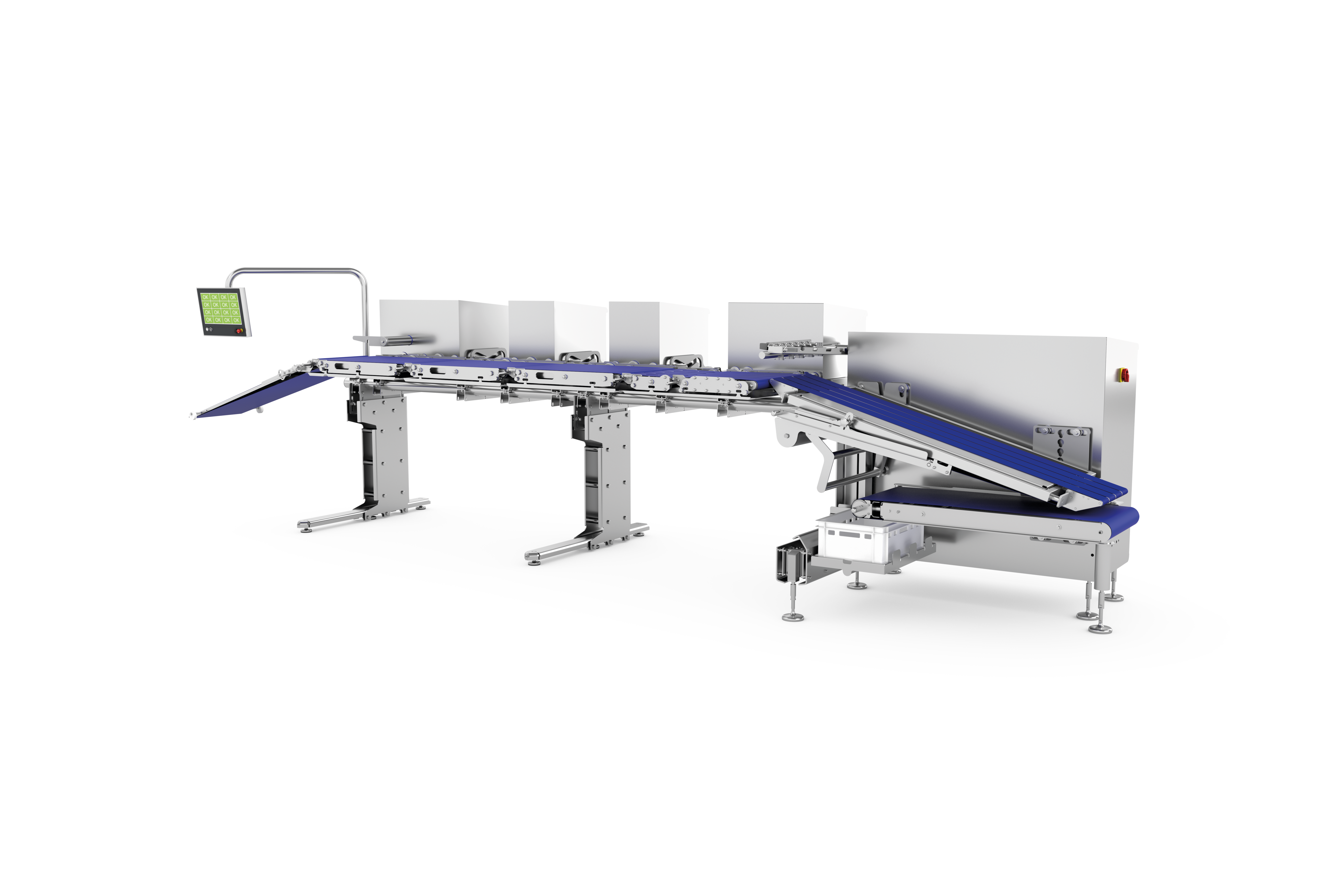

将来を見据えたMULTIVACのお客様の目指すこと: 温かい製品温度の場合でも卓越した切断品質をもち、問題のないスライスと個別化を実行でき、簡単、直感的操作を可能とするHMI3を持つ最新IPC制御。監視、制御、実作業時間での製品工程の簡略化をもたらすプロセス最適化のためのMULTIVACスマートサービス。

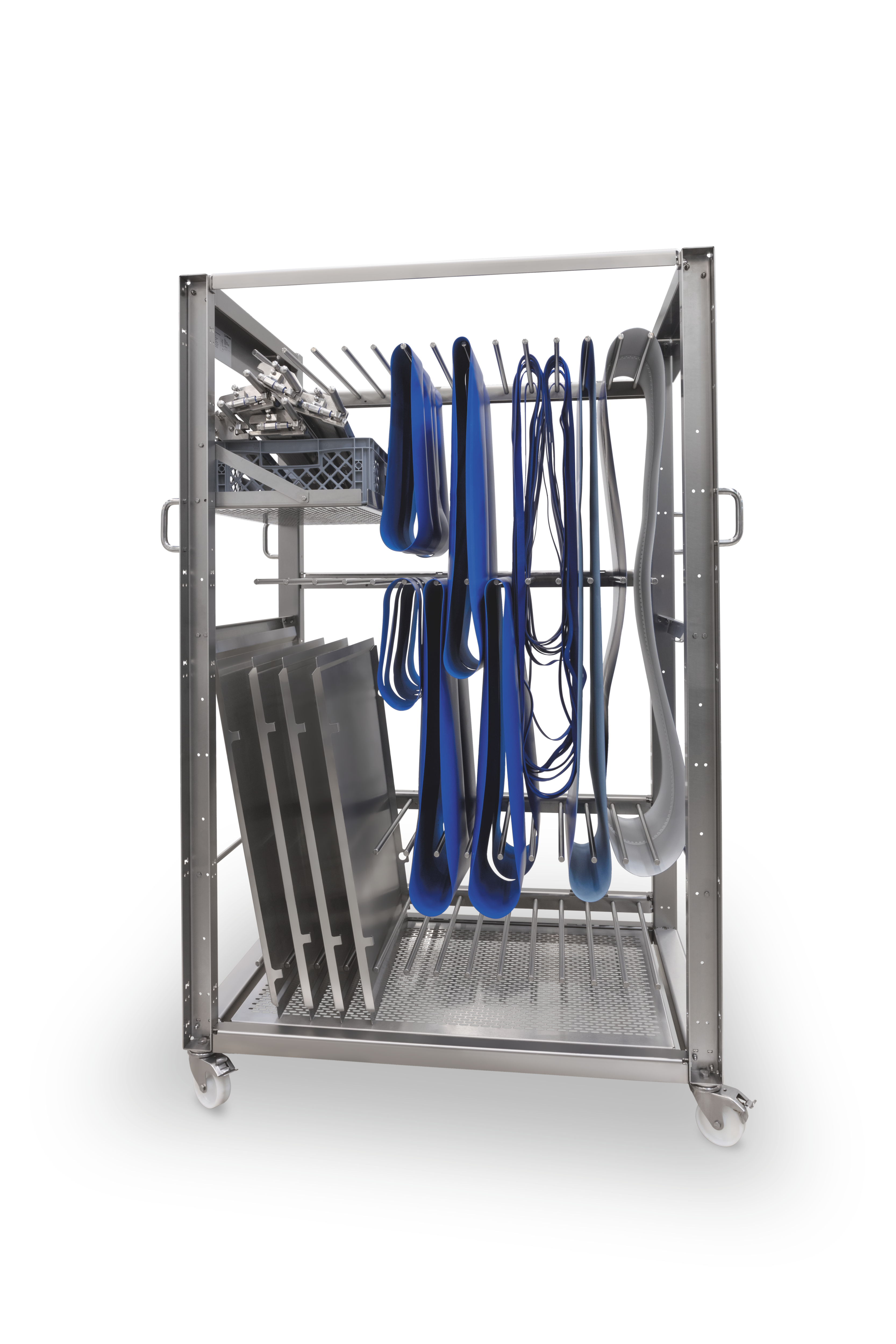

短設置時間、迅速に交換可能、容易なメンテナンスと清掃のための優れたアクセス性が高い可用性を保証します。機械はスタンドアロンとしてもMULTIVAC Line Control (MLC)に内蔵されても完全自動切断及び包装機ラインの一部として利用されることが可能です。特に効率的な機械と装置稼働を安全に行うために理想的です。

- Teaser 1

- Teaser 2

- Teaser 3

- Teaser 4

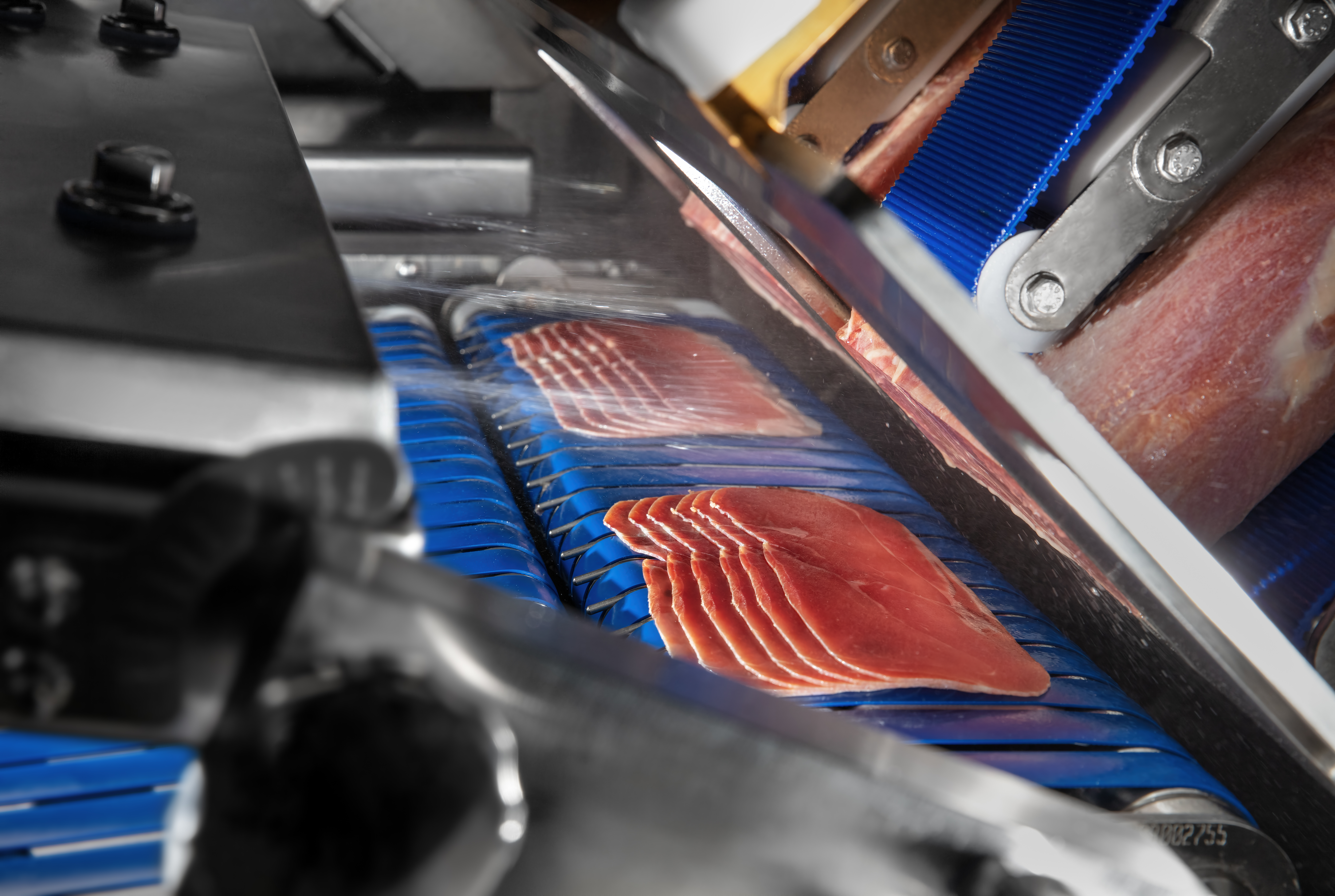

最高のスライス結果のための高い精度

MULTIVAC スライサーは、製品やフォーマットを迅速に変更できる、信頼性の高い精度と高いレベルの柔軟性を備えています。

一貫性のある難しい製品でも、複雑な製品でも、スライスの品質は一定のままです。 当社の高品質スライサーの範囲は、ソーセージや肉製品、ハム、チーズ、および代替タンパク質製品に優れたスライス結果を提供します.

私たちは常にお客様の製品に焦点を当てています。 一緒に、私たちはあなたの製品を魅力的に提示し、最適化された部分であなたの出力を最大化するための適切なソリューションを見つけます.

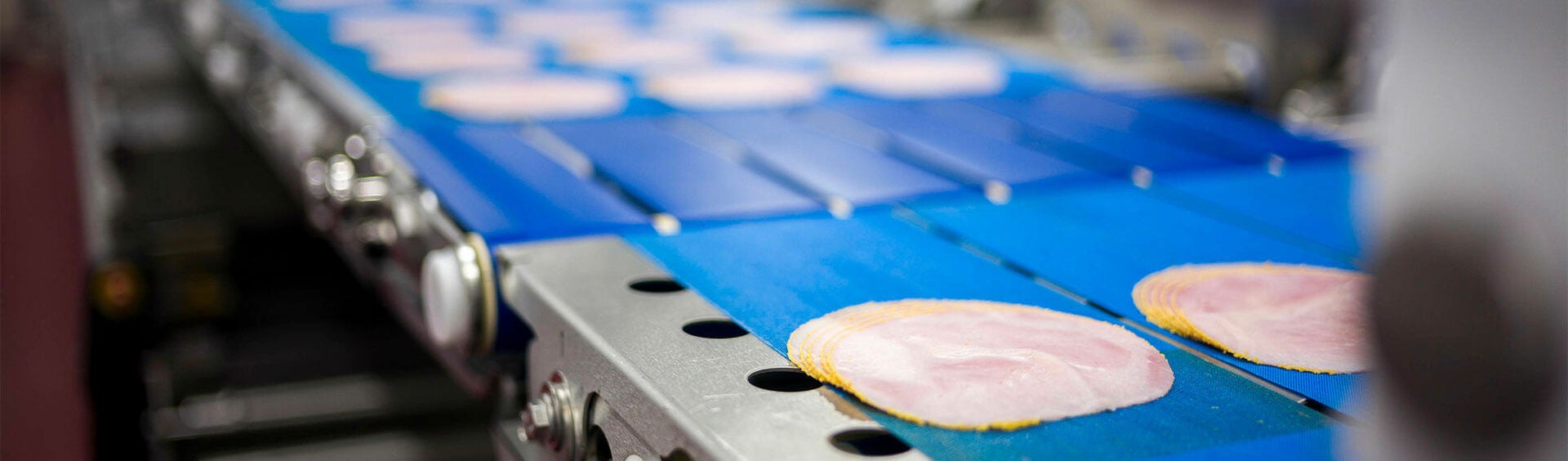

MULTIVAC スライサーは、当社のライン コンセプトに統合できるように完全に設計されています。 シームレスな加工と包装により、製品の品質と味が完全に保護されます。 消費者の賞味期限が長くなり、製品のポジティブな体験が最後まで一定に保たれます。 お客様のご要望にお応えできるよう、喜んでアドバイスさせていただきます。

効率による費用対効果

スライサーの洗浄とメンテナンスを簡単かつ効率的に実行できます。これにより設定と交換時間が迅速になり、生産の効果的な実行時間が短縮されます。

当社のスライサーは操作が簡単です。ライン統合により、スタッフを増員しなくてもプロセスの自動化を最大化できます。そのため、ライン統合されたMULTIVACスライサーは、最大生産量であっても、可能な限り最高出力をえるために高い速度を達成できます。

最適な処理、高い可用性、迅速な製品変更は、全体的なコストの削減とプロセス全体の費用対効果に大きく貢献します。

成功事例

Frozen Meat Slice on White Background

Frozen Meat Slice on White Background

MULTIVAC Meat Slicing Conveyor System

MULTIVAC Meat Slicing Conveyor System