Healthy Salad Bowls with Fresh Ingredients

Healthy Salad Bowls with Fresh Ingredients

優れた印刷品質による最大の魅力

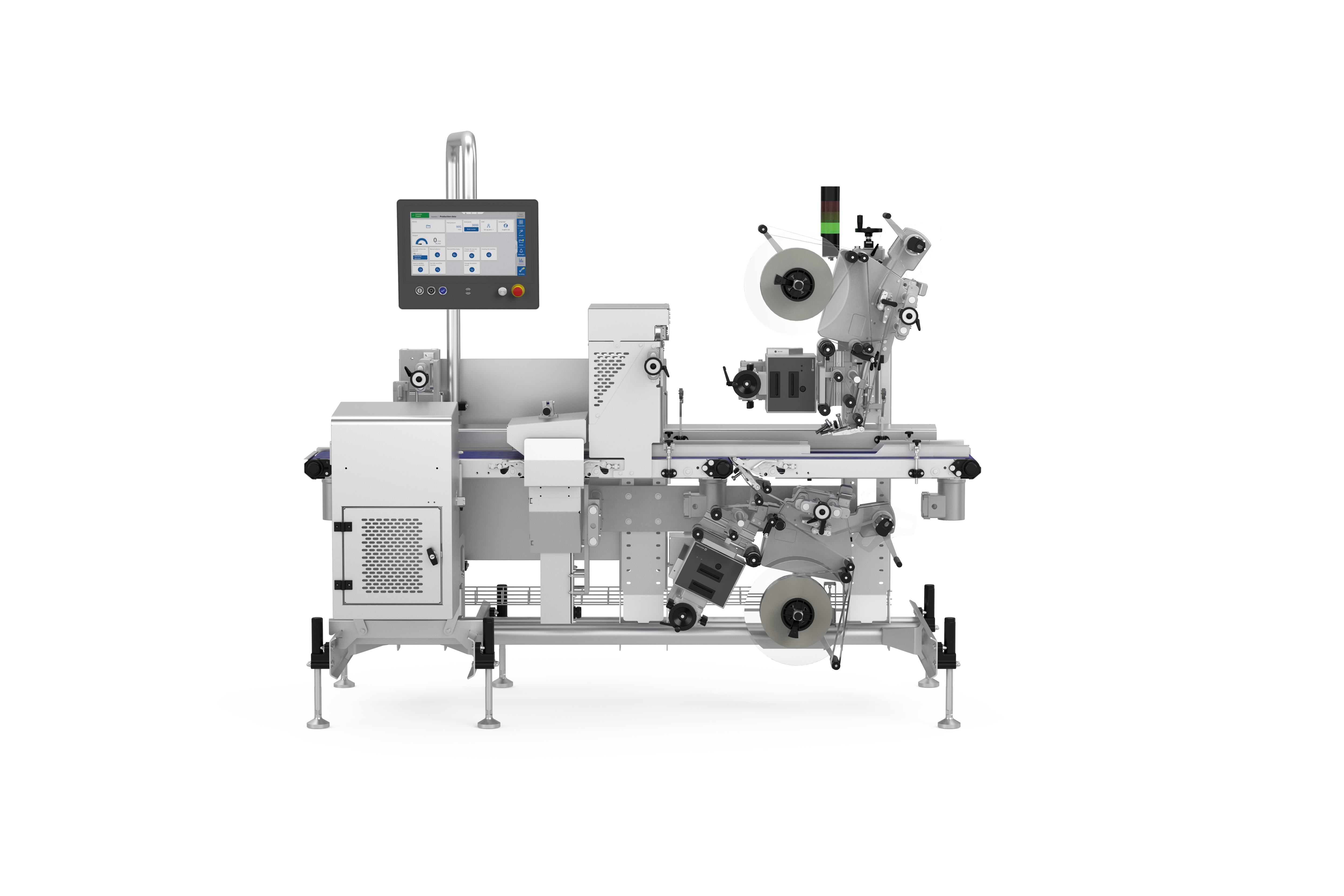

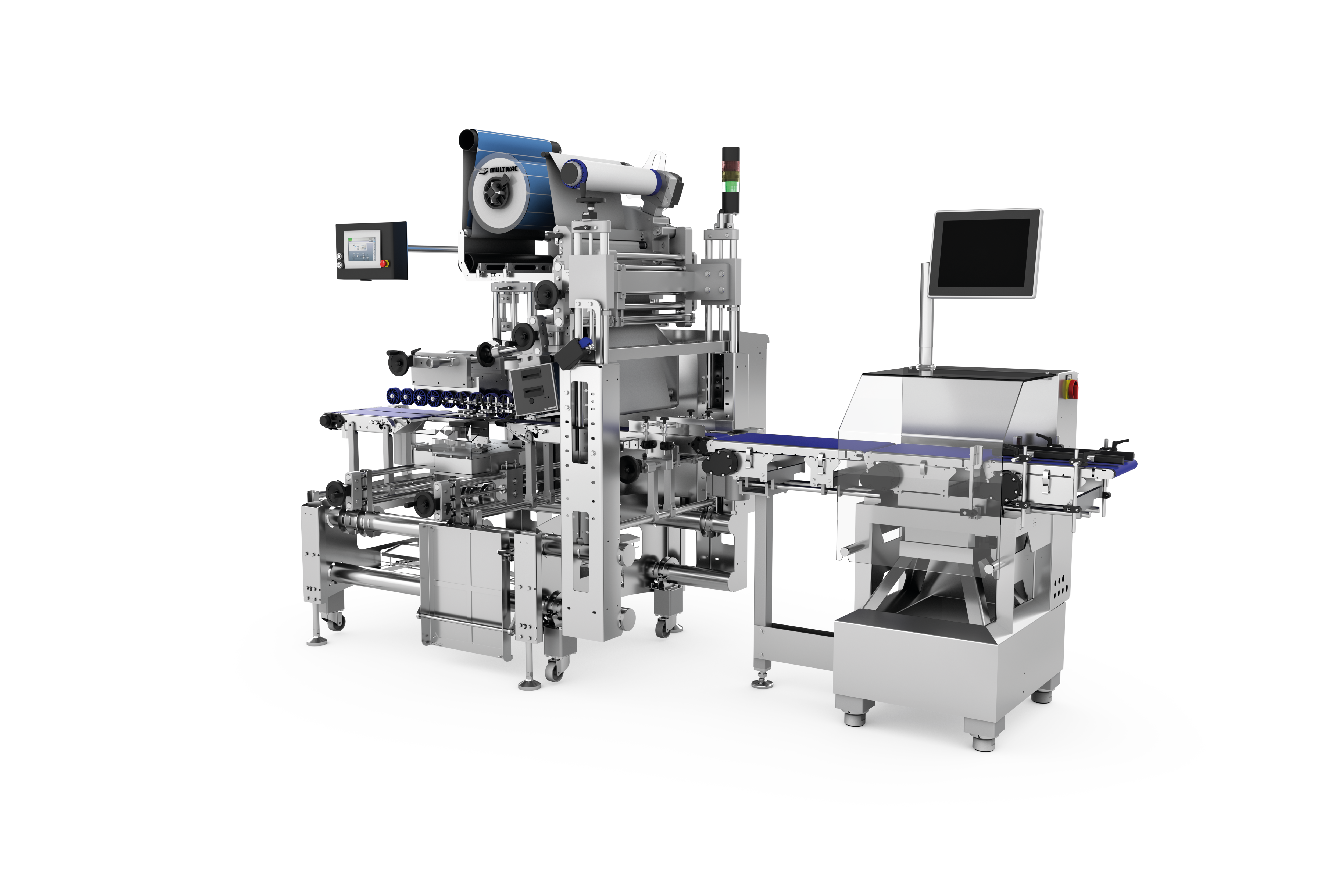

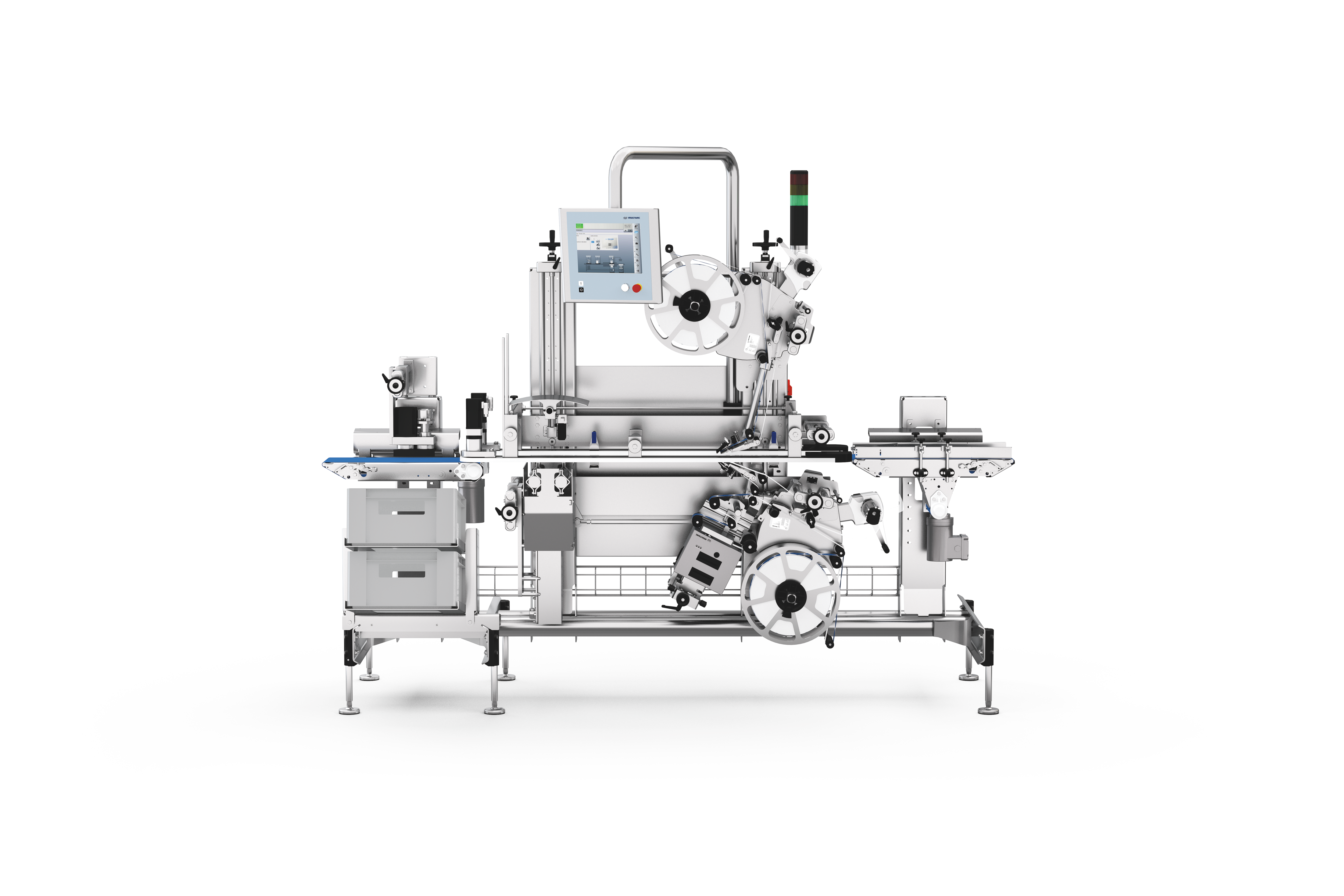

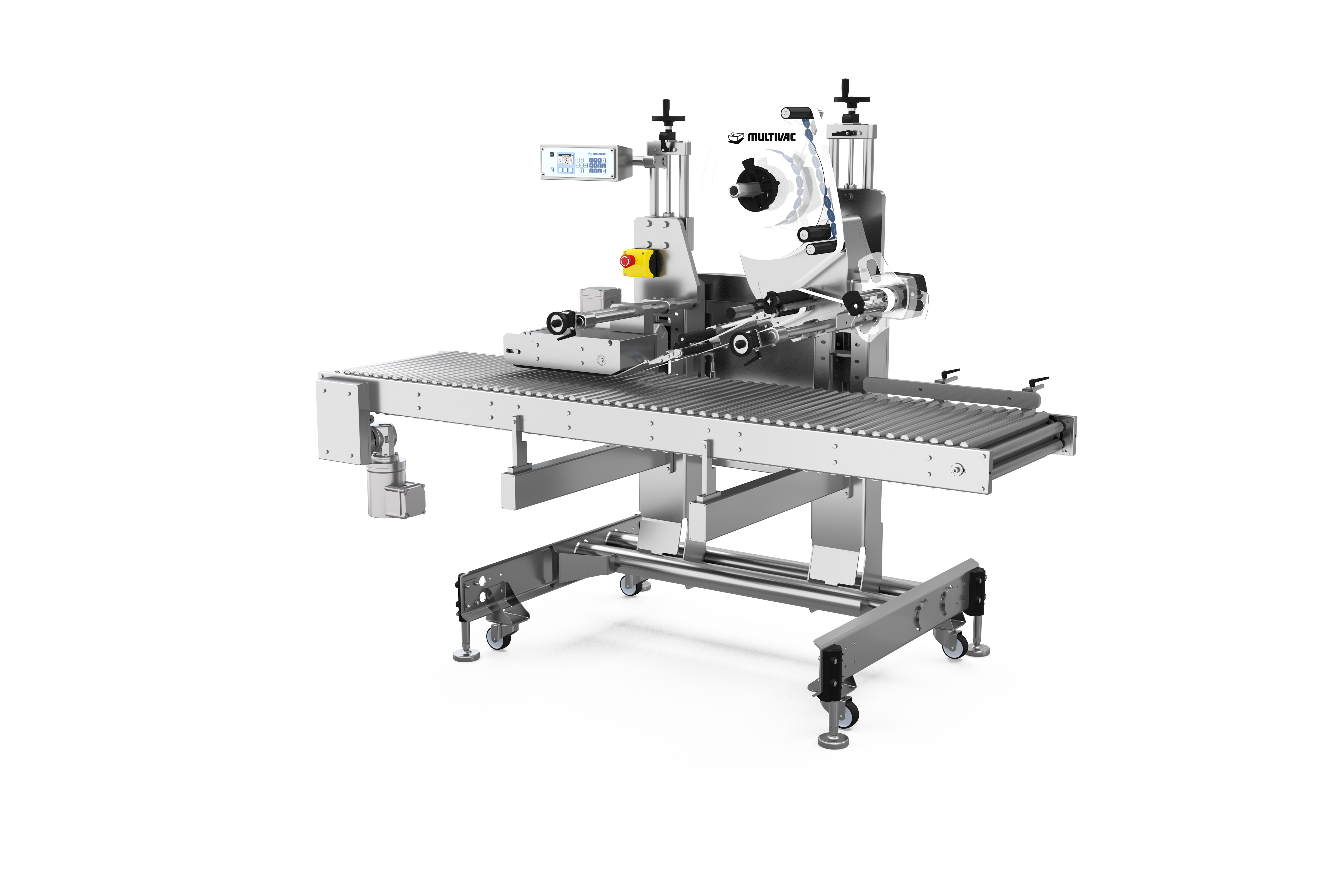

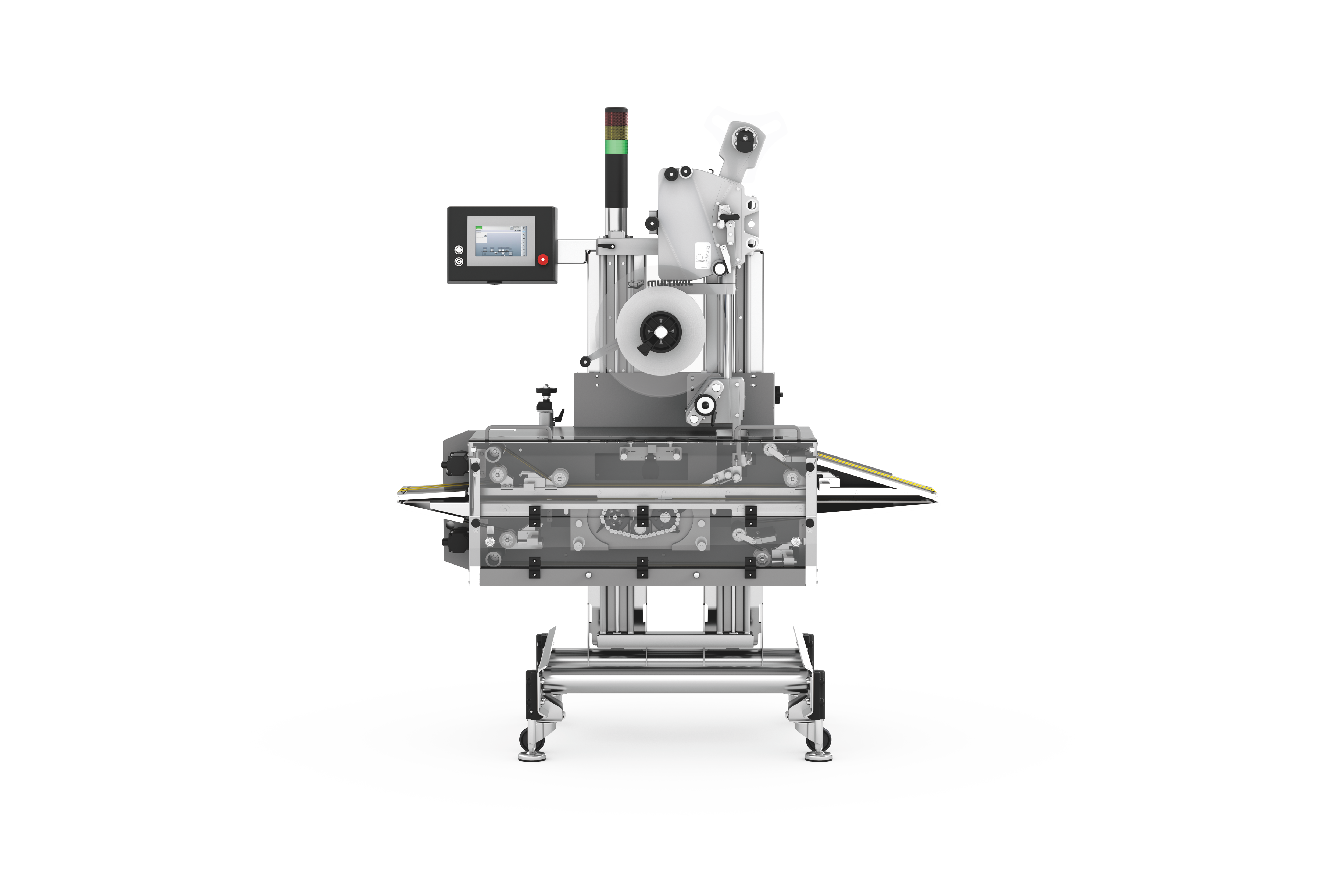

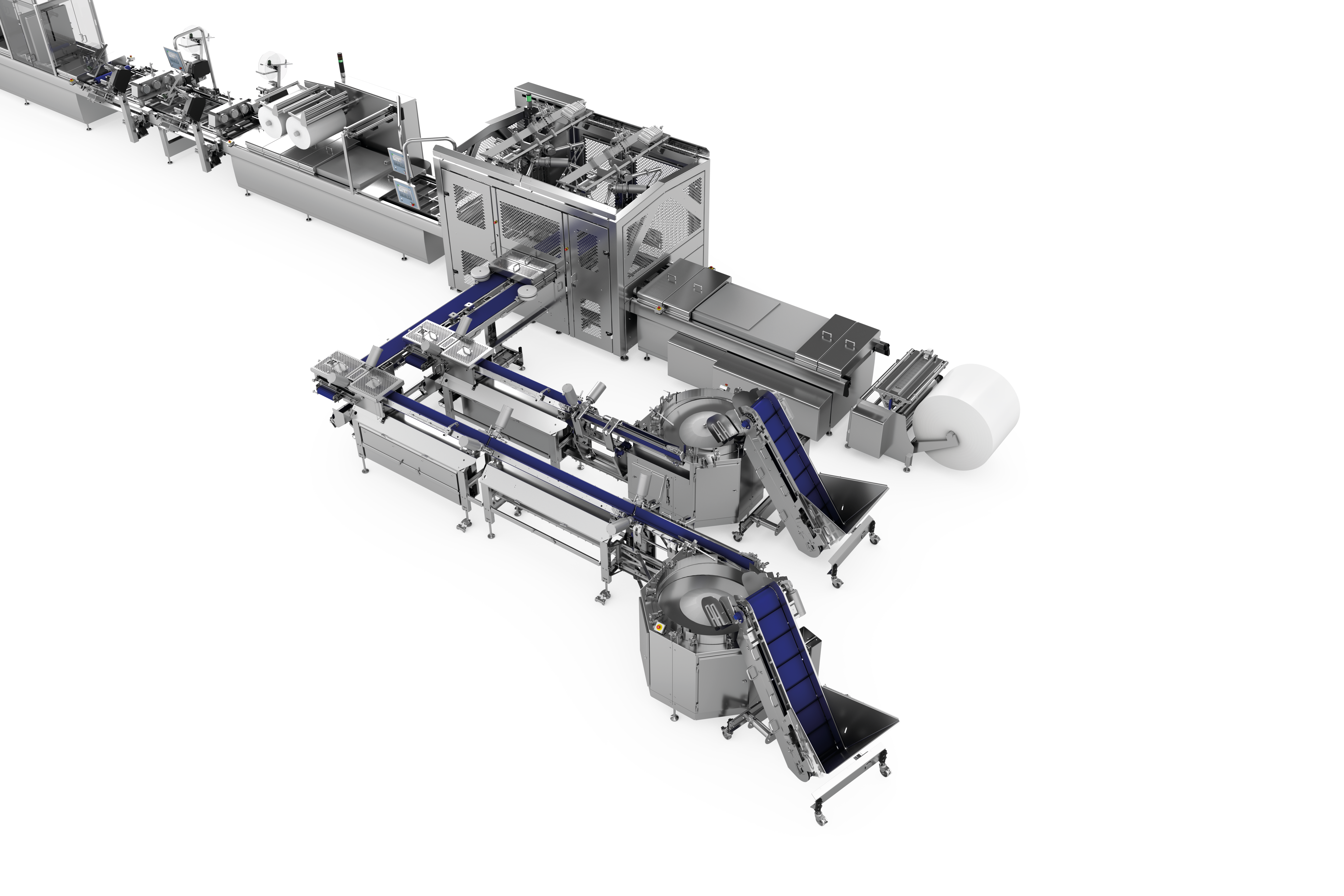

システムのプロセス信頼性を高めることは、最高の品質と高効率の前提条件です。優れた印刷とラベリングの結果が重要です。モジュール化されたMULTIVACコンベアベルトラベラーは、製品のラベリングと印字に関して高い柔軟性を提供します。ラベラーは既存の充填および包装ラインにシームレスに統合でき、自立型ソリューションとして使用することもできます。短い交換時間とパックへの両面印刷は、ノンストップモードでの最大プロセス信頼性を保証します。当社の経験豊富なチームが、お客様の機械のライフサイクル全体を通してサポートし、お客様と共に最適な稼働を保証します。コストのかかる機械のダウンタイムや長時間のダウンタイムもありません - 最大効率で生産を行うことができます!

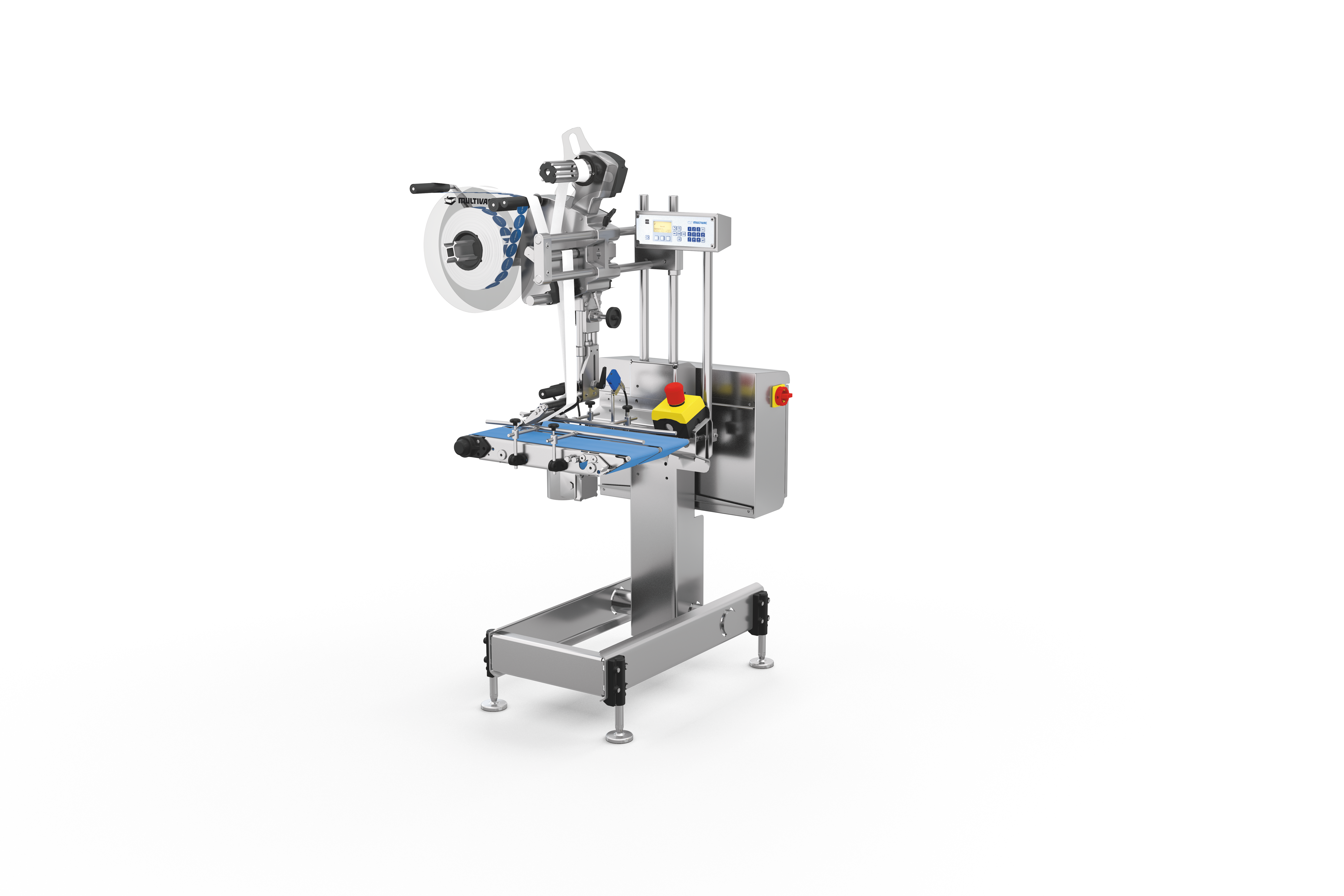

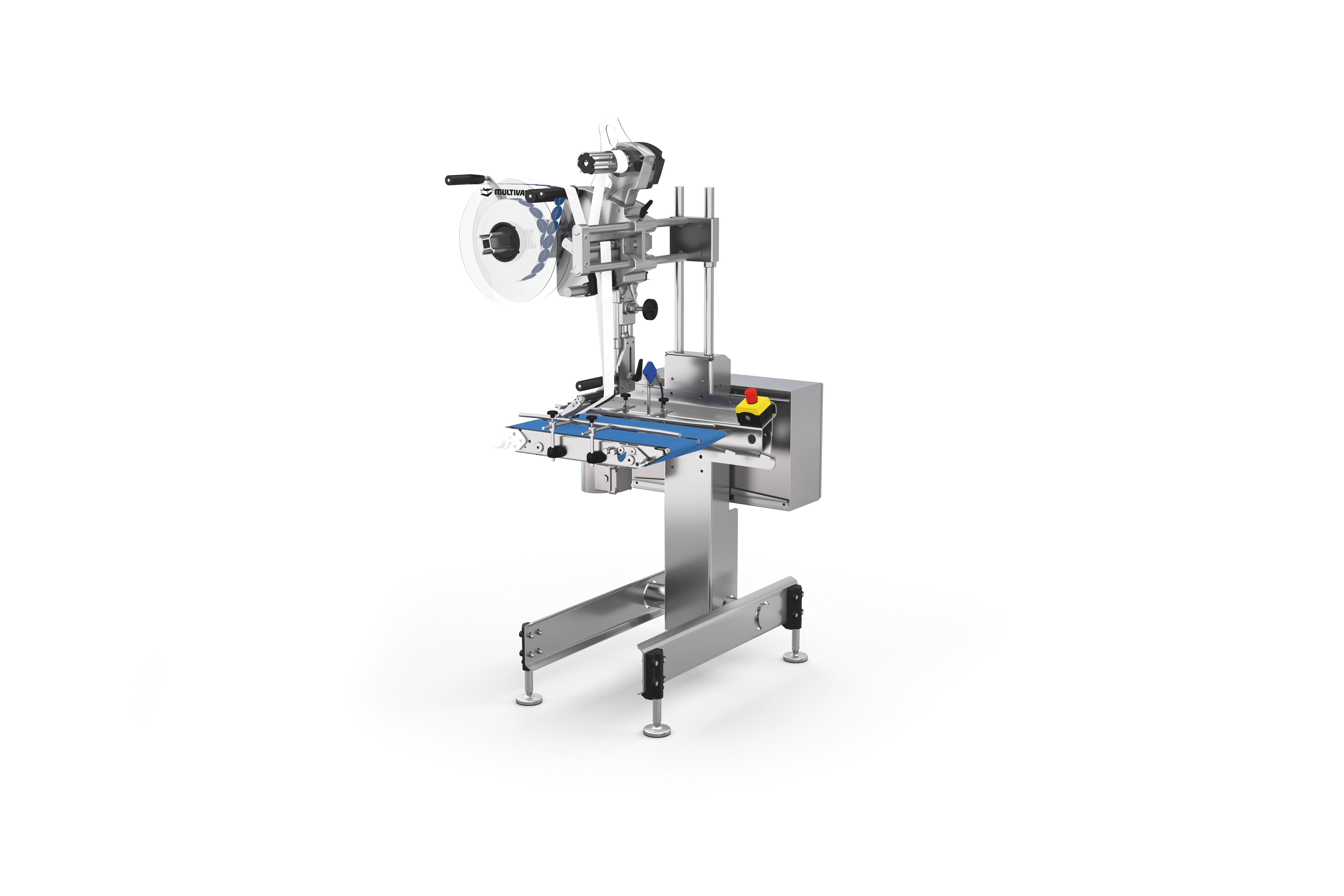

MULTIVAC コンベアベルトラベラー

パックのすべての面に最高品質の印字を

容器、ボトル、折りたたみカートン、ピロー包装、深絞り包装、トレーのどれであっても – MULTIVACのコンベアベルトラベラーは、パッケージのあらゆる面にラベルを貼るソリューションを提供するように設計されています。高い柔軟性と可用性に優れています。前面でも背面でも、下から上からでも、端でも - 印字のニーズに対して優れた品質を期待できます。

成功事例

Healthy Salad Bowls with Fresh Ingredients

Healthy Salad Bowls with Fresh Ingredients

MULTIVAC Food Packaging Machine Honey Peppers

MULTIVAC Food Packaging Machine Honey Peppers

Attractive solutions for full-wrap labelling of packs

MULTIVAC Marking & Inspection has continually expanded its range of conveyor belt labellers in recent years. The spectrum now includes a wide range of solutions for many different labelling requirements and output categories – from the simple BASELINE conveyor belt labellers to 2-track labelling systems with up to ten label dispensers.

MULTIVAC Marking & Inspection has continually expanded its range of conveyor belt labellers in recent years. The spectrum now includes a wide range of solutions for many different labelling requirements and output categories – from the simple BASELINE conveyor belt labellers to 2-track labelling systems with up to ten label dispensers.

Mehr erfahren

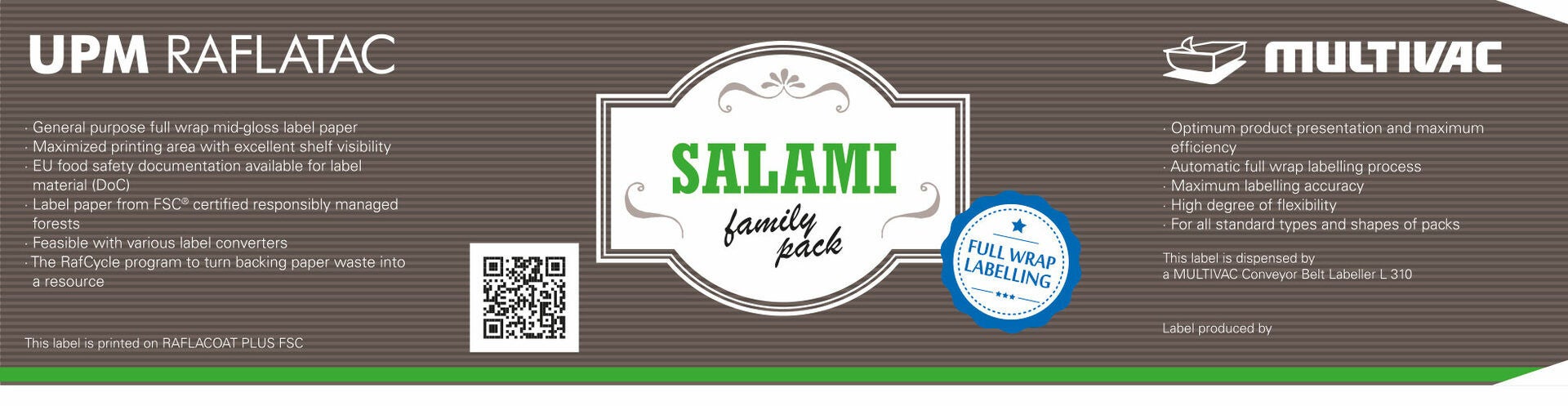

Maximum pack attractiveness with Full Wrap labelling

Full wrap labels offer a broad range of competitive advantages in comparison to other labelling solutions. In addition to their function as an information medium, they are increasingly becoming an important design element of retail packs. This way, they help the brand owners to increase the differentiation of the product at the Point of Sale and to offer further value to the consumer.

Full wrap labels offer a broad range of competitive advantages in comparison to other labelling solutions. In addition to their function as an information medium, they are increasingly becoming an important design element of retail packs. This way, they help the brand owners to increase the differentiation of the product at the Point of Sale and to offer further value to the consumer.

Mehr erfahren

Cheese Platter with Grapes and Crackers

Cheese Platter with Grapes and Crackers

Cheese attractively packed

Vergeer Holland is one of the largest and most innovative cheese processors in the world. The company has grown in recent years into a flourishing business with 550 employees, and today packs around 60 million kilos of cheese per year. The company does not produce cheese, but specializes in maturing, slicing and packaging hard cheese. Its most important customers are retailing companies. When it comes to the packing and labelling of its diverse cheese products, Vergeer Holland relies on solutions from MULTIVAC: a total of 25 packaging machines and over 50 labellers from MULTIVAC are used within the company.

Vergeer Holland is one of the largest and most innovative cheese processors in the world. The company has grown in recent years into a flourishing business with 550 employees, and today packs around 60 million kilos of cheese per year. The company does not produce cheese, but specializes in maturing, slicing and packaging hard cheese. Its most important customers are retailing companies. When it comes to the packing and labelling of its diverse cheese products, Vergeer Holland relies on solutions from MULTIVAC: a total of 25 packaging machines and over 50 labellers from MULTIVAC are used within the company.

Mehr erfahren

Fresh Vegetables and Fruits Display

Fresh Vegetables and Fruits Display

Koninklijke Vezet places its trust in labelling solutions from MULTIVAC

Fresh food products, together with quality, convenience, and sustainability, are of increasing importance in the everyday lives of consumers. Koninklijke Vezet has developed into a fruit and vegetable specialist, which meets all these requirements. Companies which want to survive in the growing but very challenging fresh food market must also guarantee fast deliveries and the right packaging. Labelling is also an important part of the packaging procedure: labels not only have an effect on the appearance of the packs, they also contain important information for consumer protection.

Fresh food products, together with quality, convenience, and sustainability, are of increasing importance in the everyday lives of consumers. Koninklijke Vezet has developed into a fruit and vegetable specialist, which meets all these requirements. Companies which want to survive in the growing but very challenging fresh food market must also guarantee fast deliveries and the right packaging. Labelling is also an important part of the packaging procedure: labels not only have an effect on the appearance of the packs, they also contain important information for consumer protection.

Mehr erfahren

MultiFresh™ packs with full-wrap labelling increase the attractiveness at the point of sale

With its deep, clear and cold fjords, Norway is a paradise for salmon and salmon farms alike. Best conditions therefore for Seafood Farmers of Norway AS, which was founded in 1986, and its parent company the HOFSETH Group, which processes the freshly caught fish and exports most of it abroad. In order to increase the attractiveness of the fish products at the point of sale, the company in Valderøy recently invested in a thermoforming packaging machine for producing high-quality vacuum skin packs and in a labelling solution for the D labelling of the packs.

With its deep, clear and cold fjords, Norway is a paradise for salmon and salmon farms alike. Best conditions therefore for Seafood Farmers of Norway AS, which was founded in 1986, and its parent company the HOFSETH Group, which processes the freshly caught fish and exports most of it abroad. In order to increase the attractiveness of the fish products at the point of sale, the company in Valderøy recently invested in a thermoforming packaging machine for producing high-quality vacuum skin packs and in a labelling solution for the D labelling of the packs.

Mehr erfahren

Sterile Medical Connectors by MULTIVAC

Sterile Medical Connectors by MULTIVAC

Valve sets packed efficiently and reliably

Science and technological progress, combined with inspiration and

determination - this is the basis of Boston Scientific's success.

Science and technological progress, combined with inspiration and

determination - this is the basis of Boston Scientific's success.

Mehr erfahren

MULTIVAC Packaging Machine in Action

MULTIVAC Packaging Machine in Action

Successful collaboration

In the summer of 2020 Zandbergen World's Finest Meat successfully put two MULTIVAC lines into service in its new factory (The New Plant) in Zoeterwoude in the Netherlands, where Beyond Meat products are manufactured. The lines are complete with handling solutions as well as a labelling and marking system

In the summer of 2020 Zandbergen World's Finest Meat successfully put two MULTIVAC lines into service in its new factory (The New Plant) in Zoeterwoude in the Netherlands, where Beyond Meat products are manufactured. The lines are complete with handling solutions as well as a labelling and marking system

Mehr erfahren

MULTIVAC Packaging Machine with Food Tray

MULTIVAC Packaging Machine with Food Tray

Sushi Mania - A bit of the Far East in Switzerland

Maximum efficiency, cost-effectiveness and pack appeal - with a big plus in terms of sustainability.

Maximum efficiency, cost-effectiveness and pack appeal - with a big plus in terms of sustainability.

Mehr erfahren

Less food wastage thanks to sustainable packaging and labelling concepts for fruit and vegetables

MULTIVAC adjusted to this trend at an early stage: Its solutions not only meet the sustainability requirements of customers, they also protect the packaged product perfectly, as well as reducing food wastage and appealing to retailers and consumers alike with their attractive design.

MULTIVAC adjusted to this trend at an early stage: Its solutions not only meet the sustainability requirements of customers, they also protect the packaged product perfectly, as well as reducing food wastage and appealing to retailers and consumers alike with their attractive design.

Mehr erfahren