Data Visibility: The New Currency of Manufacturing

For decades, manufacturing success was measured by output alone — units per hour, uptime percentages, and labor efficiency. Today, those metrics still matter, but they no longer tell the full story. The most competitive manufacturers aren’t just producing more — they’re seeing more.

Data visibility has become the new currency of manufacturing.

In modern production environments, the difference between reacting to problems and preventing them often comes down to one thing: real-time insight. Without visibility into what’s happening on the line — and why — inefficiencies remain hidden, small disruptions snowball into downtime, and performance improvements stall.

From "We didn't know" to "We saw it coming"

Many production losses don’t come from catastrophic failures. They come from what manufacturers often call micro-stops — short, recurring interruptions that seem insignificant on their own but quietly add up to hours of lost production each shift.

Without live production data, these issues are easy to miss:

- Slight variations in machine speed

- Gradual increases in reject packs

- Frequent recipe changes that introduce quality inconsistencies

- Components wearing faster than expected

By the time these problems are visible to operators or maintenance teams, they’ve already impacted throughput, quality, or equipment health.

Smart Services changes this dynamic by making inefficiencies visible as they happen — not after the fact.

Turning raw data into actionable insight

Modern manufacturing equipment generates enormous amounts of data. The challenge isn’t access to data — it’s turning that data into insight teams can actually use.

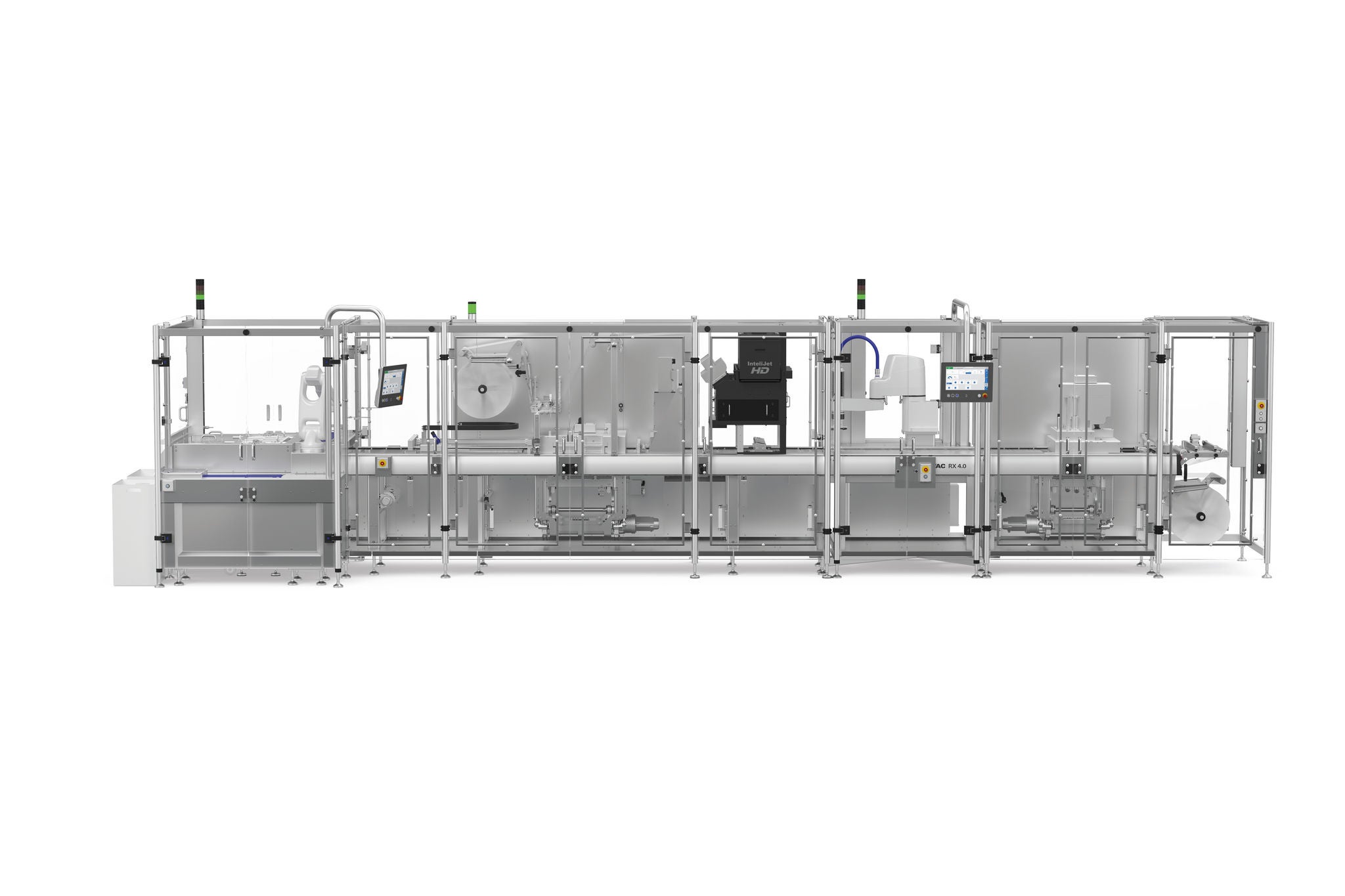

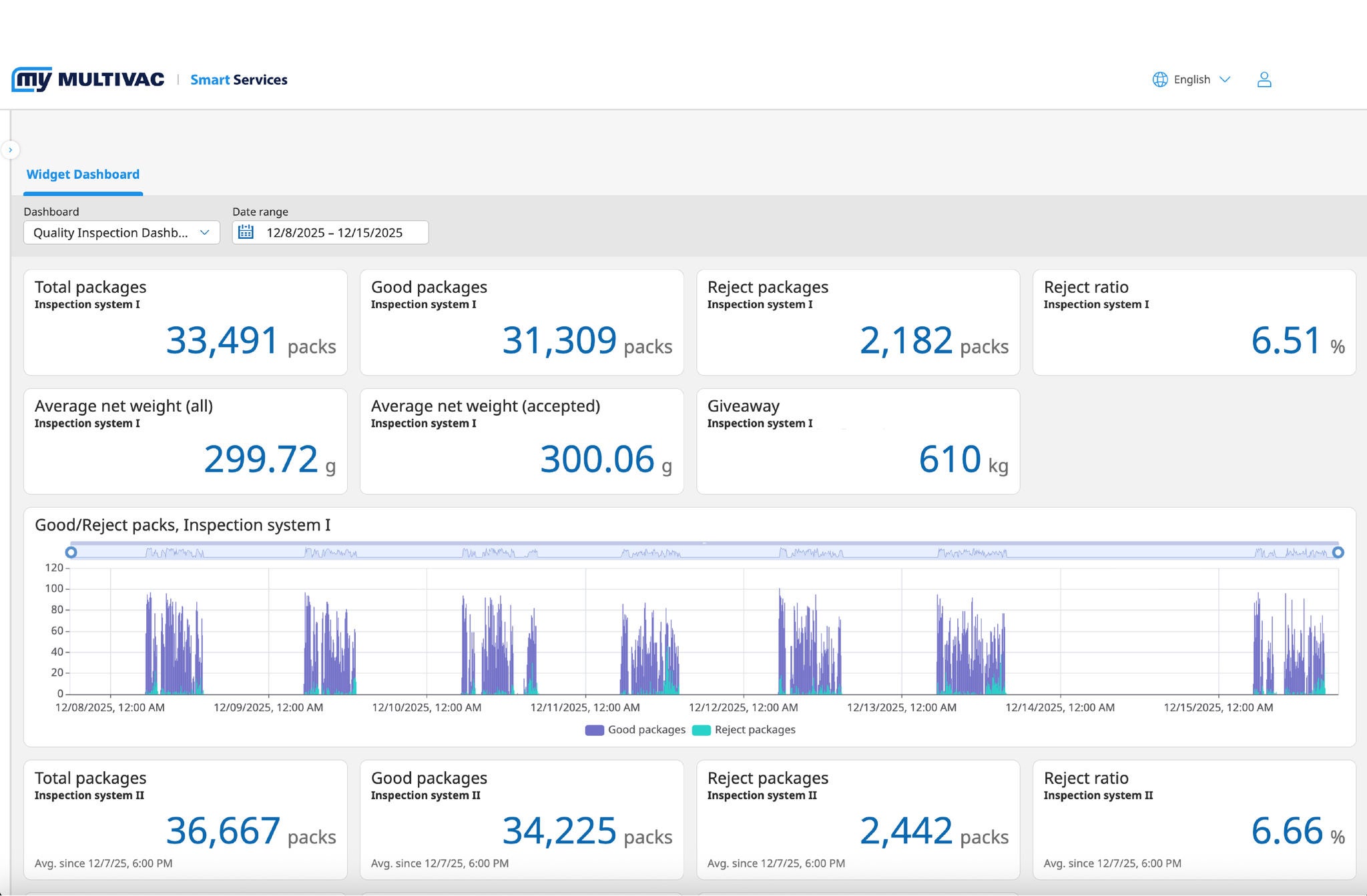

Smart Services aggregates real-time production data directly from MULTIVAC Group equipment and translates it into clear, role-specific insights:

- Operators see performance trends, quality deviations, and process stability

- Maintenance teams identify early warning signs of wear or misalignment

- Managers gain a clear view of OEE drivers, downtime causes, and improvement opportunities

Instead of relying on manual logs, assumptions, or end-of-shift reports, teams can respond to issues as they emerge — or prevent them entirely.

Visibility enables predictive action

True data visibility doesn’t just explain what happened. It enables manufacturers to anticipate what’s coming next.

When production data is continuously monitored and analyzed, patterns begin to emerge:

- A component that consistently degrades after a specific number of cycles

- A packaging parameter that drifts before quality failures occur

- A recurring stop tied to a specific product or shift

These insights allow teams to move from reactive maintenance to predictive action — scheduling interventions before failures occur, optimizing settings proactively, and stabilizing production without disruption.

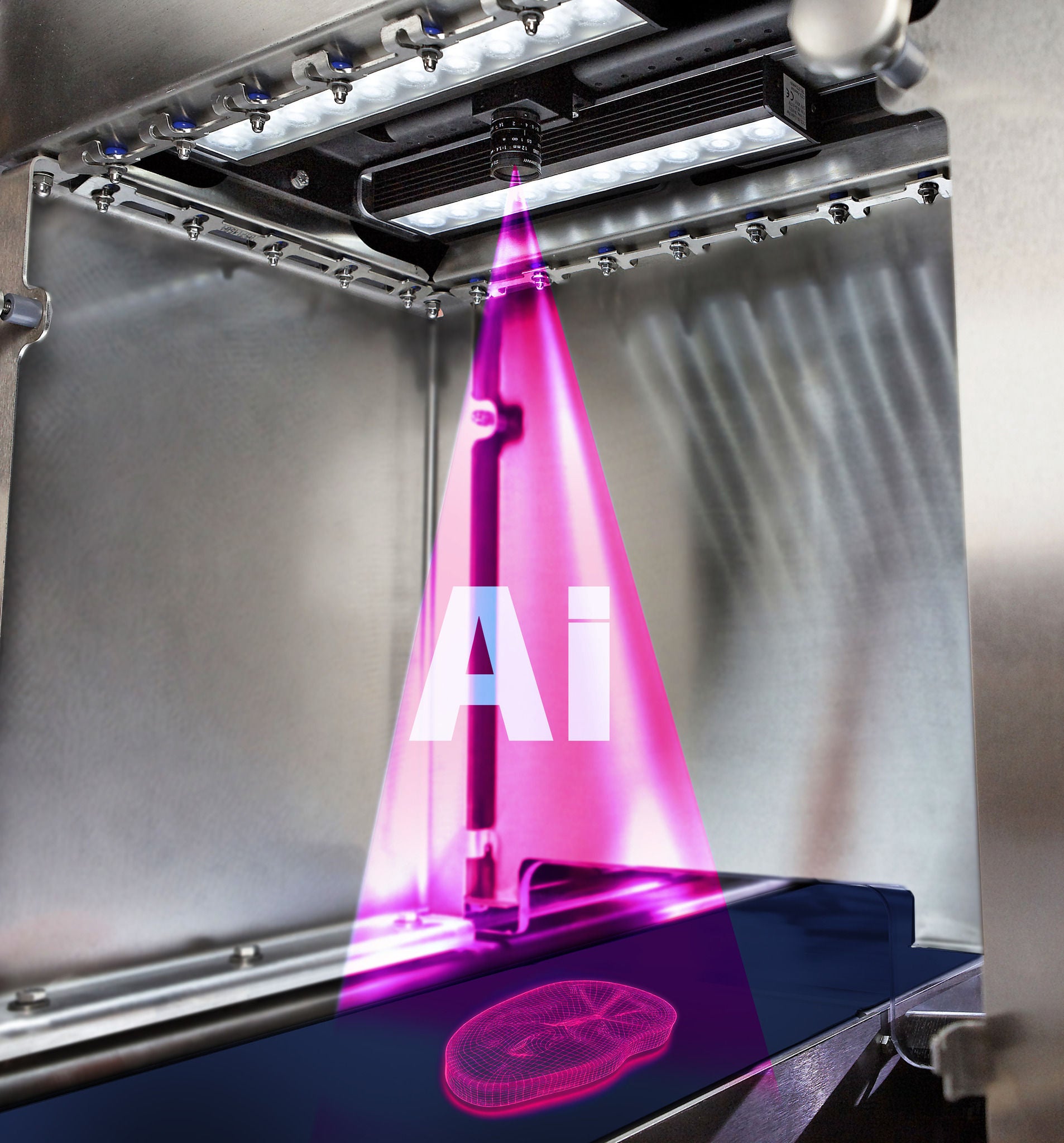

This shift is foundational to Intelligent Manufacturing. AI-enabled systems can only deliver value when they are fed consistent, high-quality data — and that starts with visibility at the machine level.

Why data visibility is a competitive advantage

Manufacturers who invest in data visibility gain more than operational improvements. They gain confidence:

- Confidence in production decisions

- Confidence in maintenance planning

- Confidence in continuous improvement efforts

And increasingly, they gain a strategic edge. As customer expectations rise, labor challenges persist, and margins tighten, the ability to see and act in real time becomes essential — not optional.

Intelligent Manufacturing isn’t about adding complexity. It’s about removing uncertainty.

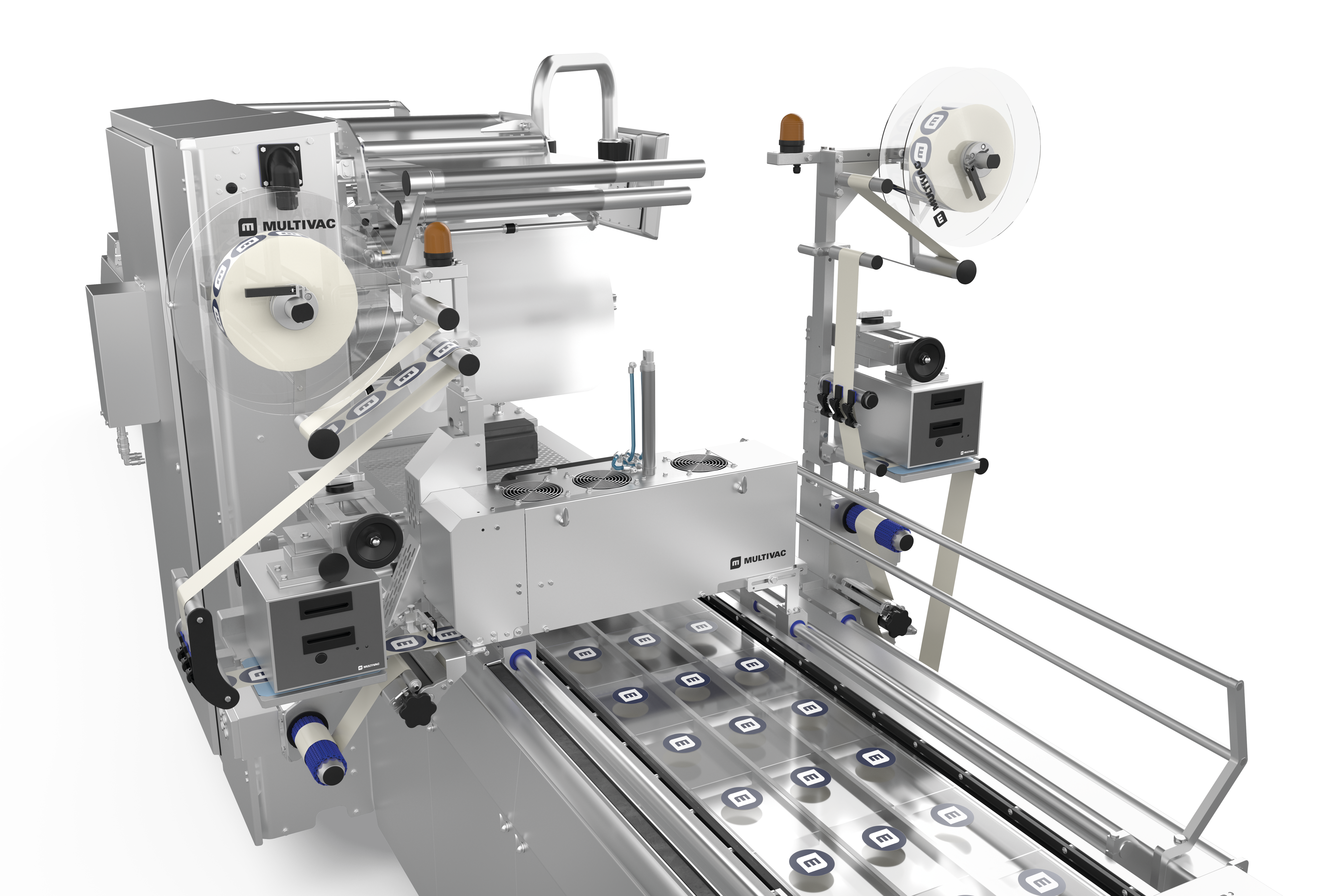

With Smart Services, data visibility becomes a powerful tool — transforming equipment from isolated assets into intelligent contributors to performance, availability, and quality. See how real-time data visibility turns production insight into predictive action — and why it’s the foundation of Intelligent Support. Contact your trusted Customer Support Representative today at 1-800-800-8552.

Latest news

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

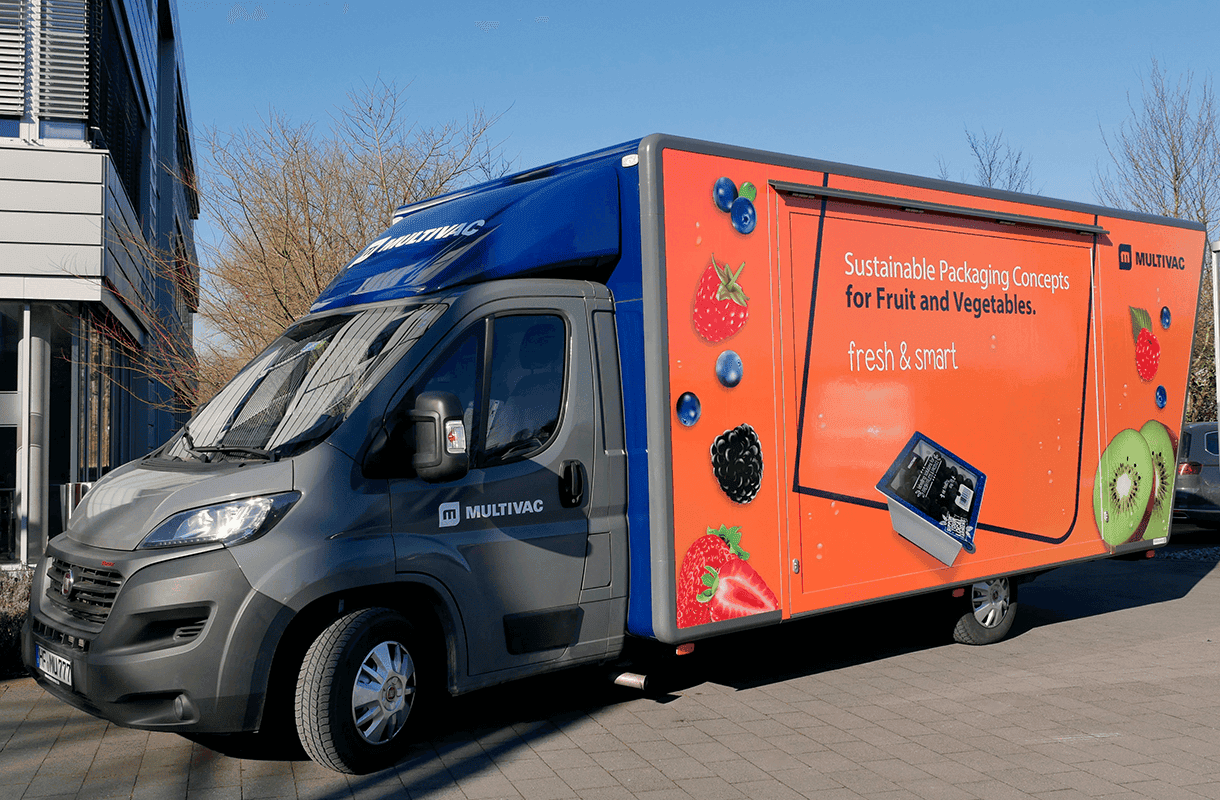

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

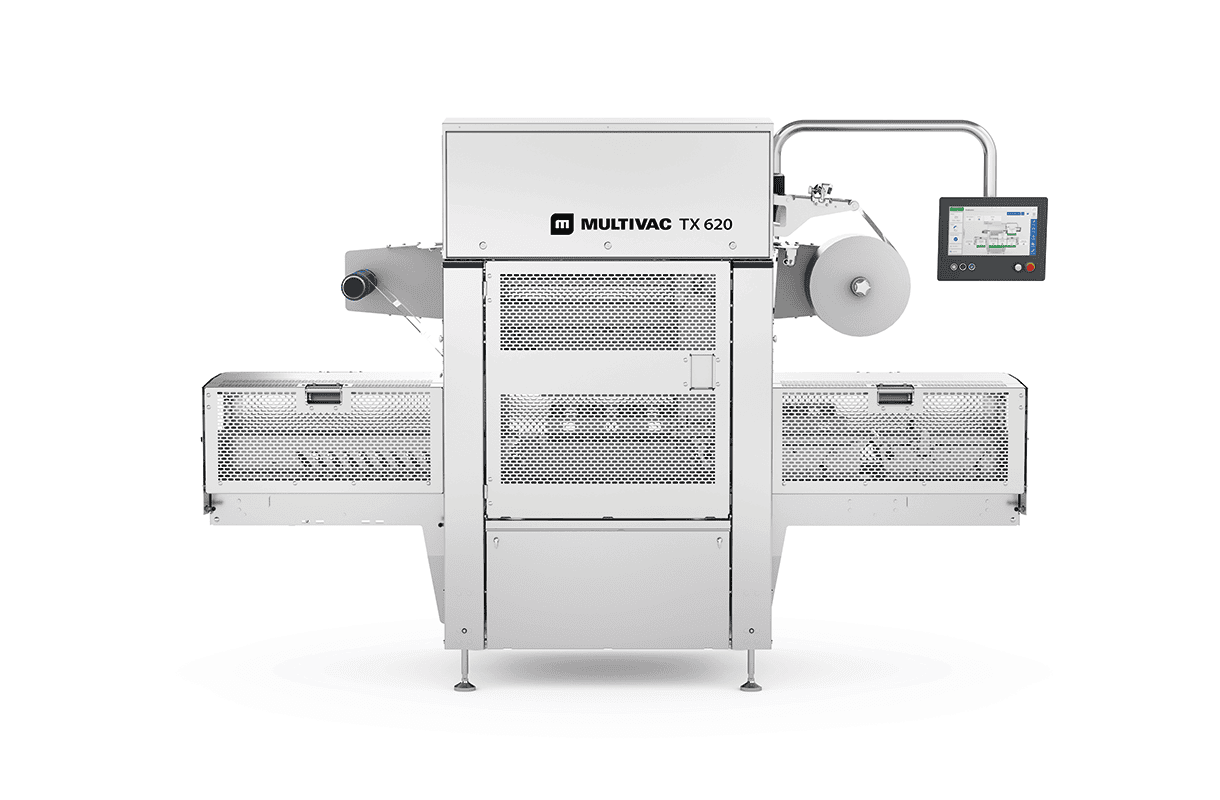

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

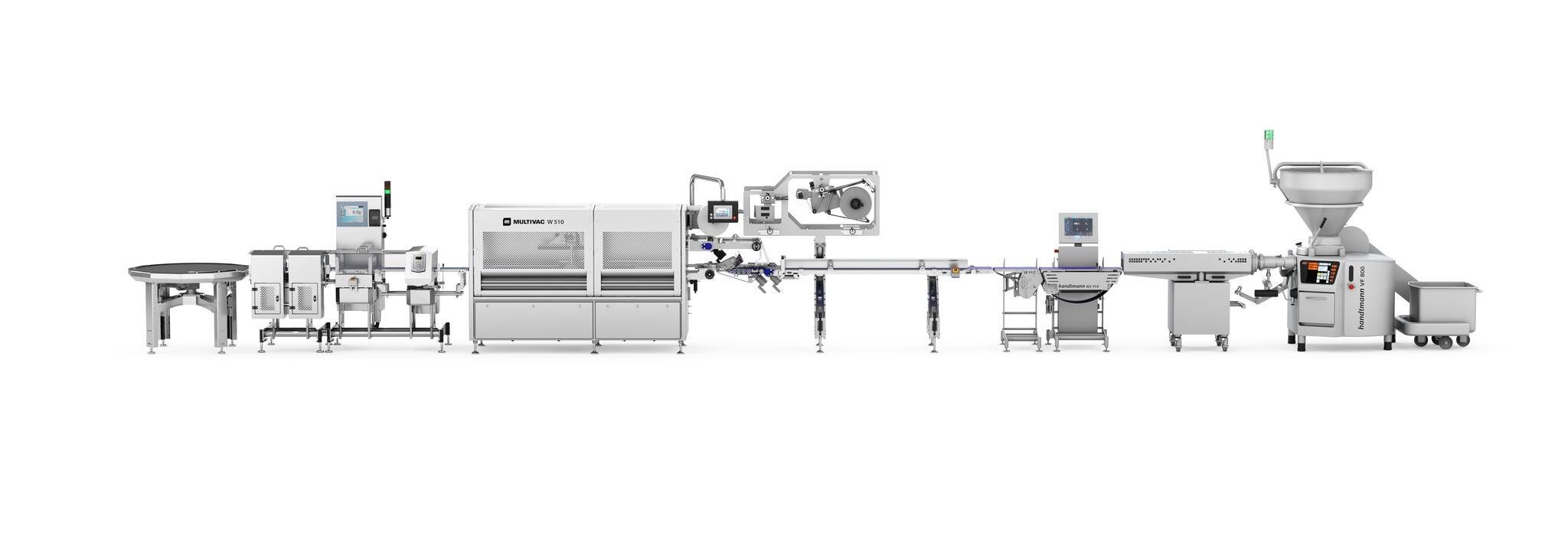

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

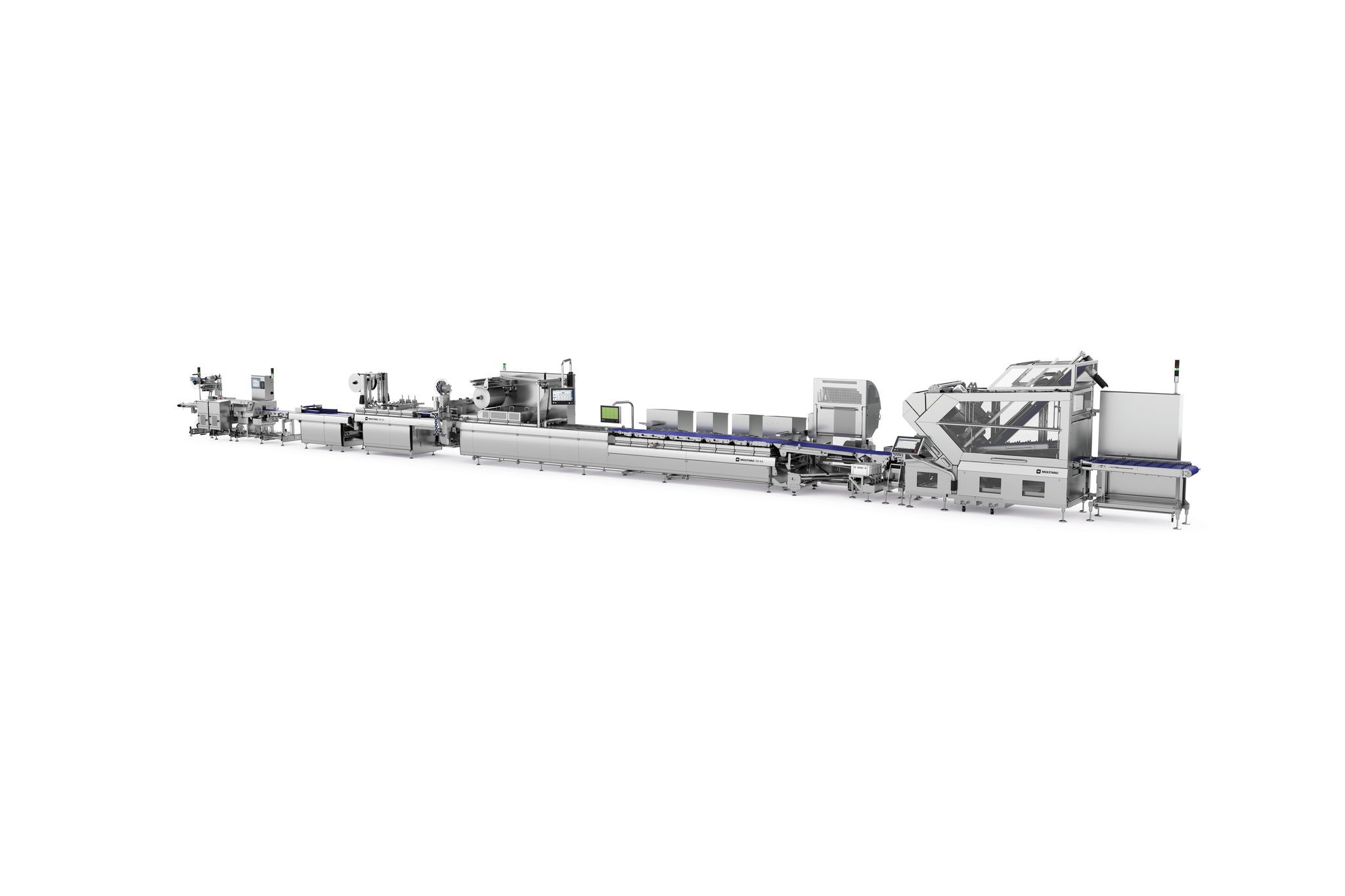

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com