MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

Digital Native Since 2017

MULTIVAC Leads the Future of Smart Manufacturing

Whether you call it Smart Manufacturing, IoT, or Industry 5.0, the goal is the same: production lines that don’t just automate — they anticipate, adapt, and support sustainability. At MULTIVAC, we’ve been digital native since 2017. From real-time cost-per-pound visibility to predictive Service Intelligence that prevents downtime, we built digital into our machines and support from day one — not as retrofits, but as core design principles.

The global conversation in manufacturing is shifting fast. Industry experts warn about the risks of moving production data into the cloud — cybersecurity, remote access, and system readiness. These are valid concerns. But they also highlight why it matters who you trust to lead you into the future.

MULTIVAC has been digital native since 2017. Whether you call it Smart Manufacturing, IoT, or Industry 5.0, the goal is the same: production lines that don’t just automate — they anticipate, adapt, and support sustainability. The difference is we didn’t retrofit our approach. We built intelligence into our machines and customer support from the start.

It began with the X-Line platform, Pack Pilot, and Smart Services, which gave processors real-time visibility they had never had before — from cost-per-pound clarity to predictive maintenance alerts.

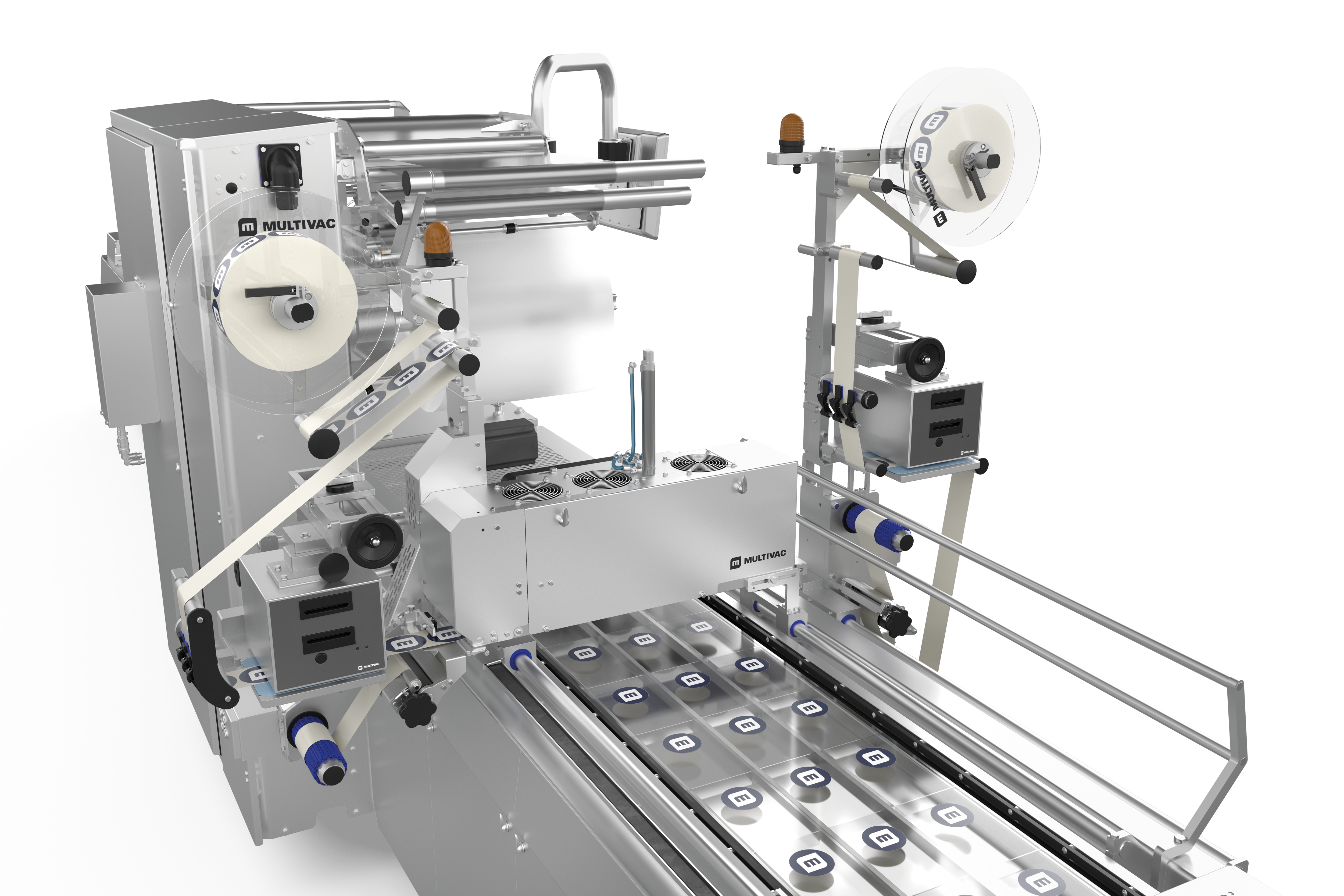

Today, our customers don’t just run machines. They harness a complete ecosystem of digital tools and expert support designed to keep production running stronger, longer, and with fewer surprises:

- Smart Services: The plant-floor visibility layer that turns data into real-time clarity. Processors can recover the hour, not just explain the day.

- myMULTIVAC Portal: A single hub for parts, service, documentation, and data — always on, always connected.

- Spare Parts Subscriptions: Critical components automatically replenished to match machine usage. No more scrambling for last-minute orders — essentials are always in stock.

- Consumables Refill Programs: Just-in-time delivery of films, labels, and materials. By eliminating bulk storage, processors free up space, simplify planning, and keep production running without interruption.

- DirectTECH AR Remote Support: Our experts “see what you see” through augmented reality, resolving issues faster and reducing downtime.

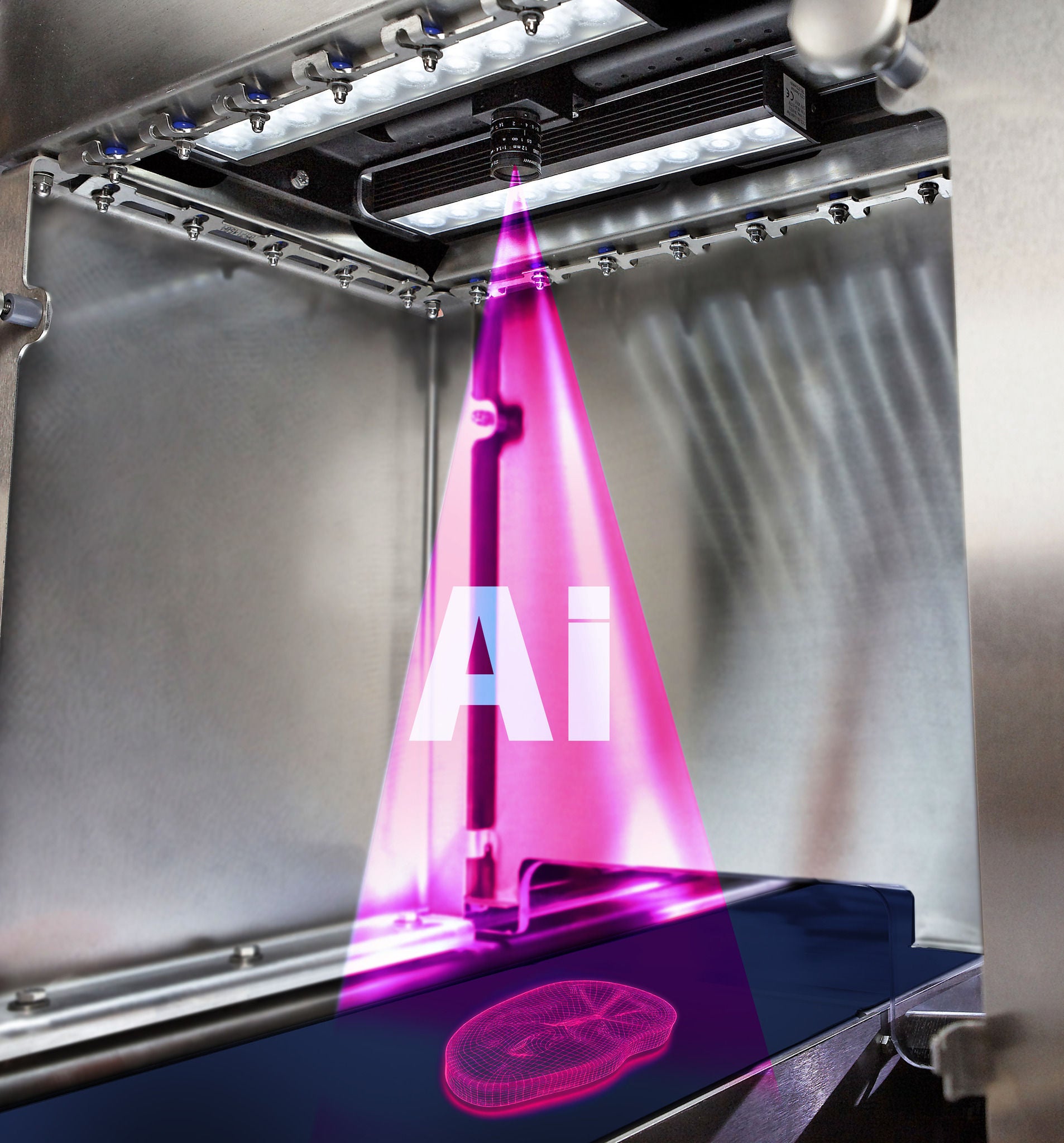

- Service Intelligence Center: Our newest innovation. It continuously monitors RX and TX machines with intelligent rules to detect when performance begins drifting toward a critical state. Instead of waiting for an error, our experts are notified early — and proactively reach out to customers before downtime strikes. Already proven in the field, the Service Intelligence Center has successfully predicted failures, prevented unplanned shutdowns, and saved customers from lost revenue. It’s not reactive support — it’s proactive resilience.

Yes, concerns about data security and digital readiness are real. But MULTIVAC’s digital stack wasn’t bolted on later — it’s been baked in since 2017. We built our ecosystem around visibility, connectivity, and proactive intelligence — not as retrofits, but as core design principles.

We didn’t just connect the line — we connected the future. MULTIVAC is Digital Native.

- Size

- 5 MB

- Format

Latest news

MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

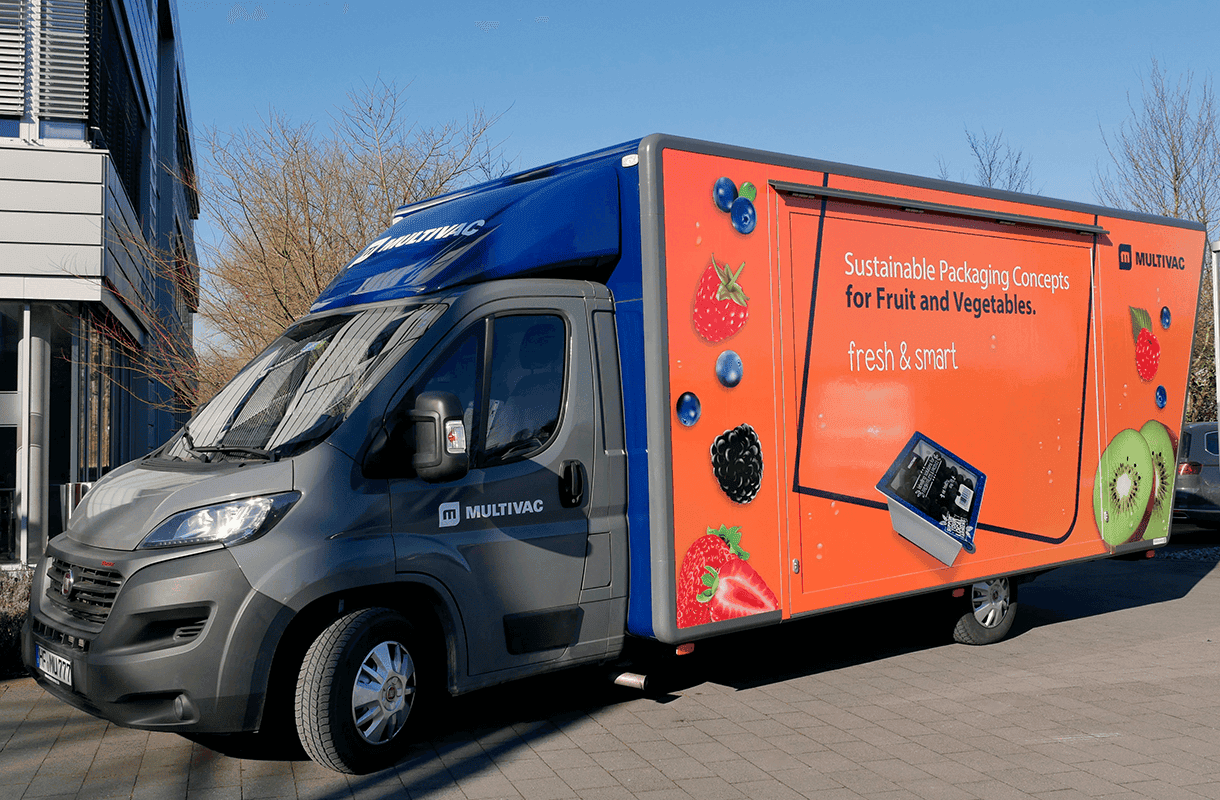

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

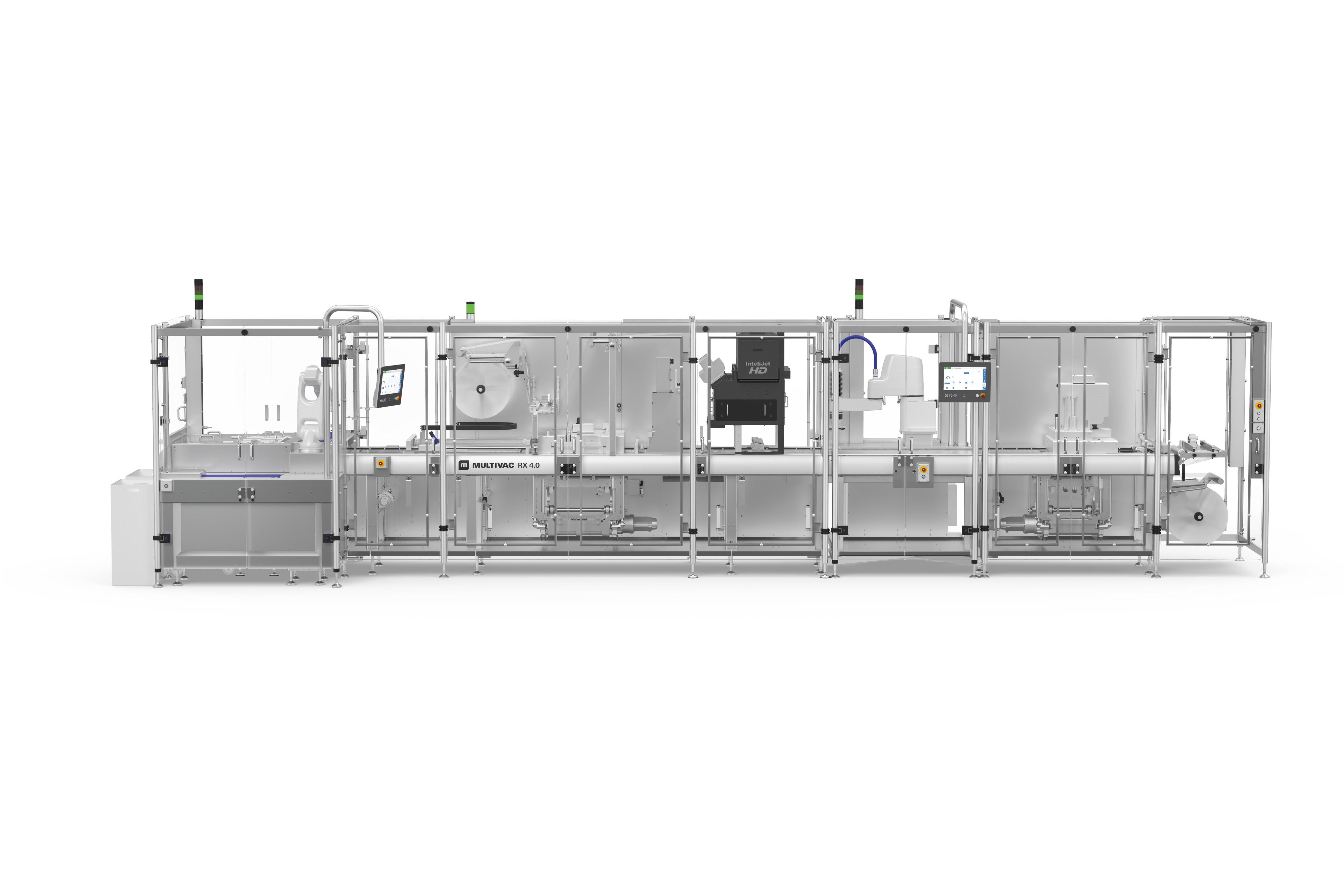

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com