The Hidden Cost of Unstable Utilities in Manufacturing — And How to Combat It

In the fast-paced world of food manufacturing, from processing fresh meat to crafting artisanal baked goods, the reliability of power, water, and compressed air utilities can make or break your operations. For industries like meat, dairy, bakery, and produce, downtime doesn’t just mean delays—it means spoiled products, missed deliveries, and a direct hit to your bottom line.

At MULTIVAC Group, we specialize in manufacturing solutions, but we recognize how critical power, water, and compressed air stability are to your production success. While we don’t control utilities, we have seen firsthand how disruptions impact operations, and we work closely with customers to help mitigate those risks.

Downtime: A Silent Profit Killer

Did you know that downtime costs in manufacturing can range from thousands to tens of thousands of dollars per hour? Exact figures vary by industry, but the reality is clear: power, water, and compressed air instability can lead to lost revenue, wasted product, recovery time, and supply chain disruptions. Even a brief disturbance can result in costly downtime and damaged equipment, creating long-term financial strain.

The worst part? 80% of power quality problems originate within the facility itself—often due to improper installations, inadequate surge protection, or aging infrastructure. Additionally, water and compressed air quality issues such as fluctuating pressure, moisture contamination, and leaks can cause significant damage to equipment and lead to compliance concerns. For dairy processors maintaining temperature control, produce packagers relying on consistent water flow for cleaning systems, or bakeries depending on compressed air for precision mixing and forming, utility instability can be a major operational threat.

Strategies for managing power, water, and compressed air risks

The shift to renewable energy sources like wind and solar has introduced variability to the power grid, creating additional risks for food manufacturers. Similarly, water and compressed air infrastructure challenges, including aging pipelines, inconsistent municipal supply, and air compressor inefficiencies, pose risks to production stability. However, manufacturers can take proactive steps to reduce these risks:

- Proactive Power, Water, and Compressed Air Monitoring: Using high-speed power recorders, water quality sensors, and air pressure monitoring systems to detect and address disturbances before they escalate.

- Proper Surge, Filtration, and Pressure Regulation: Installing surge suppressors and line reactors at key service entrances for power stability, industrial water filtration systems to prevent contamination or scaling, and air dryers and filters to ensure clean, dry compressed air.

- Smart Equipment Design: Ensuring that transformers, impedance ratios, water treatment systems, and air compressor capacity are properly sized to prevent inrush currents, pressure fluctuations, or quality inconsistencies that can damage equipment.

- Evaluate Legacy Systems: Conducting a week-long power, water, and compressed air quality assessment to pinpoint vulnerabilities, such as poor grounding, oversized systems, mineral deposits in water lines, or compressed air leaks, to inform improvements.

- Invest in Conditioning and Backup Systems: Implementing constant voltage power conditioners, uninterruptible power supplies (UPS), backup water reserves, and compressed air storage systems to maintain consistent performance even during disturbances.

By implementing these strategies, food manufacturers can significantly reduce the risk of downtime and equipment failures caused by unstable utilities.

Building a Resilient Operation

Resilient operations are built on preparation, not reaction. Food manufacturers can strengthen their production lines by:

- Performing regular power, water, and compressed air utility assessments to understand unique facility risks.

- Working with trusted third-party experts to implement best practices in surge protection, grounding, water treatment, and compressed air management.

- Equipping teams with the knowledge to identify early warning signs of utility instability.

By taking these steps, manufacturers can reduce costly shutdowns, maintain compliance, and protect product integrity.

Smart Solutions to Keep You Ahead

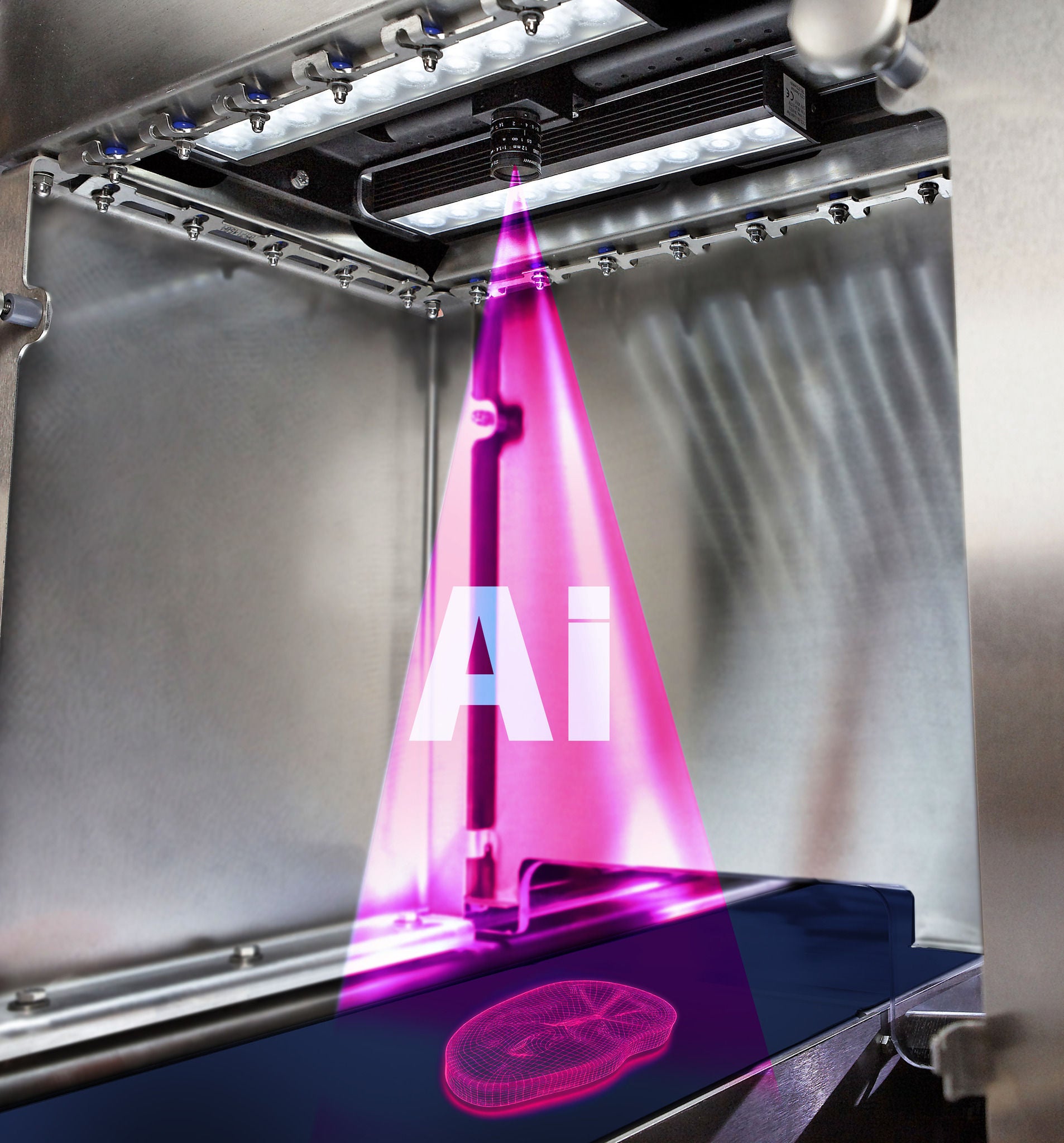

While mitigation strategies form the foundation of a resilient operation, MULTIVAC’s Smart Services provide a tailored approach to take your performance to the next level. Designed with our customers in mind, Smart Services enable you to:

- Monitor Equipment and Utilities in Real-Time: Detect and address power, water, and compressed air quality disturbances before they lead to failures or interruptions.

- Analyze Historical Data: Understand trends in downtime, enabling smarter decisions about equipment maintenance and upgrades.

- Maximize Equipment Performance: Ensure MULTIVAC’s packaging, slicing, and portioning equipment operates at peak efficiency—even in challenging environments.

At MULTIVAC Group, we’re more than a solutions provider—we’re a partner in your success. Contact us today to learn how our Smart Services can help safeguard your operations, protect your bottom line, and keep your products moving from line to shelf without interruption.

Schedule a demo today! Call 1-800-877-5200 to talk to a digital professional.

The Importance of Power Quality

White Paper outlining the importance of power quality and how it effects your manufacturing equipment.

- Size

- 30 MB

- Format

Latest news

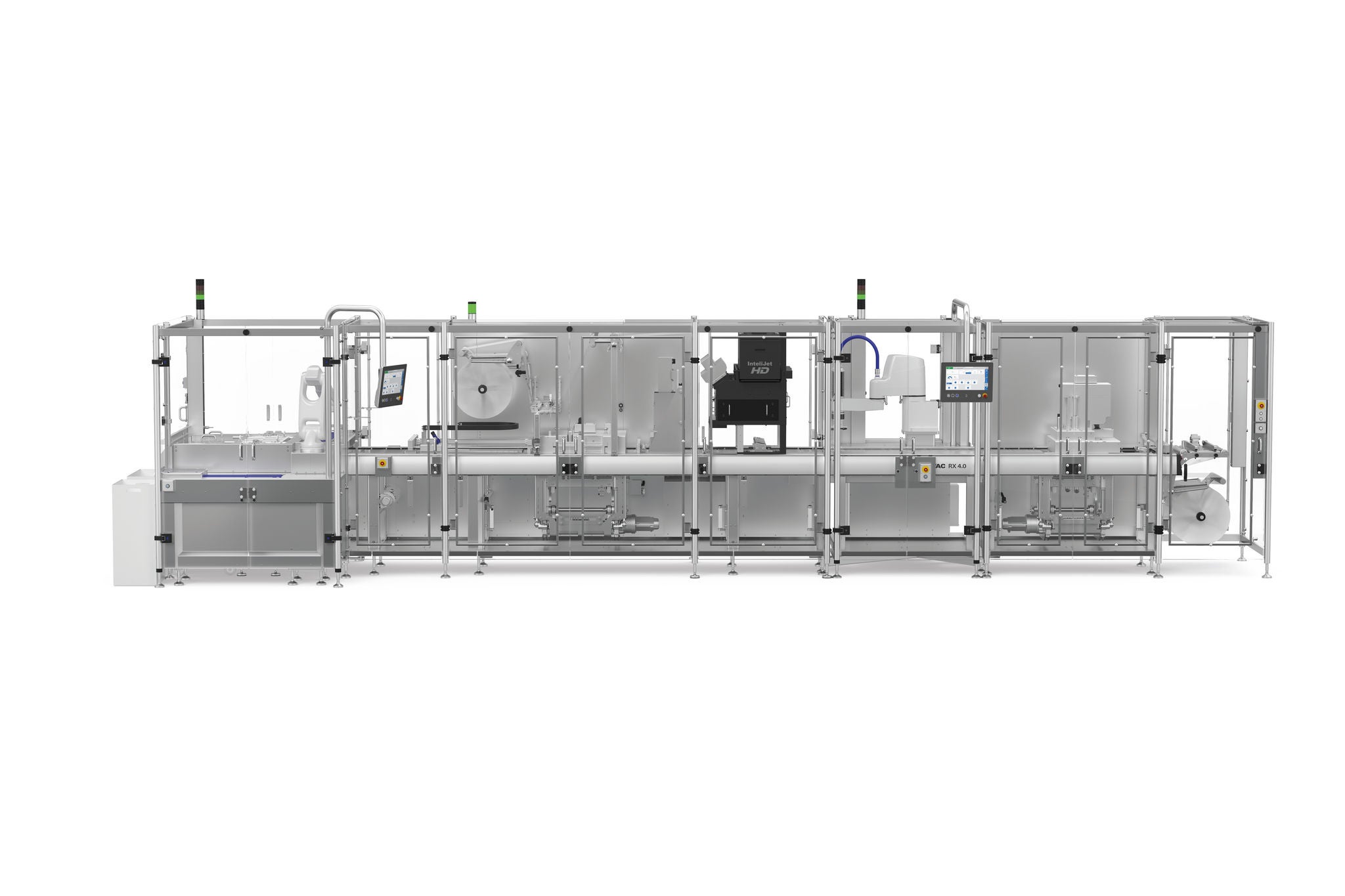

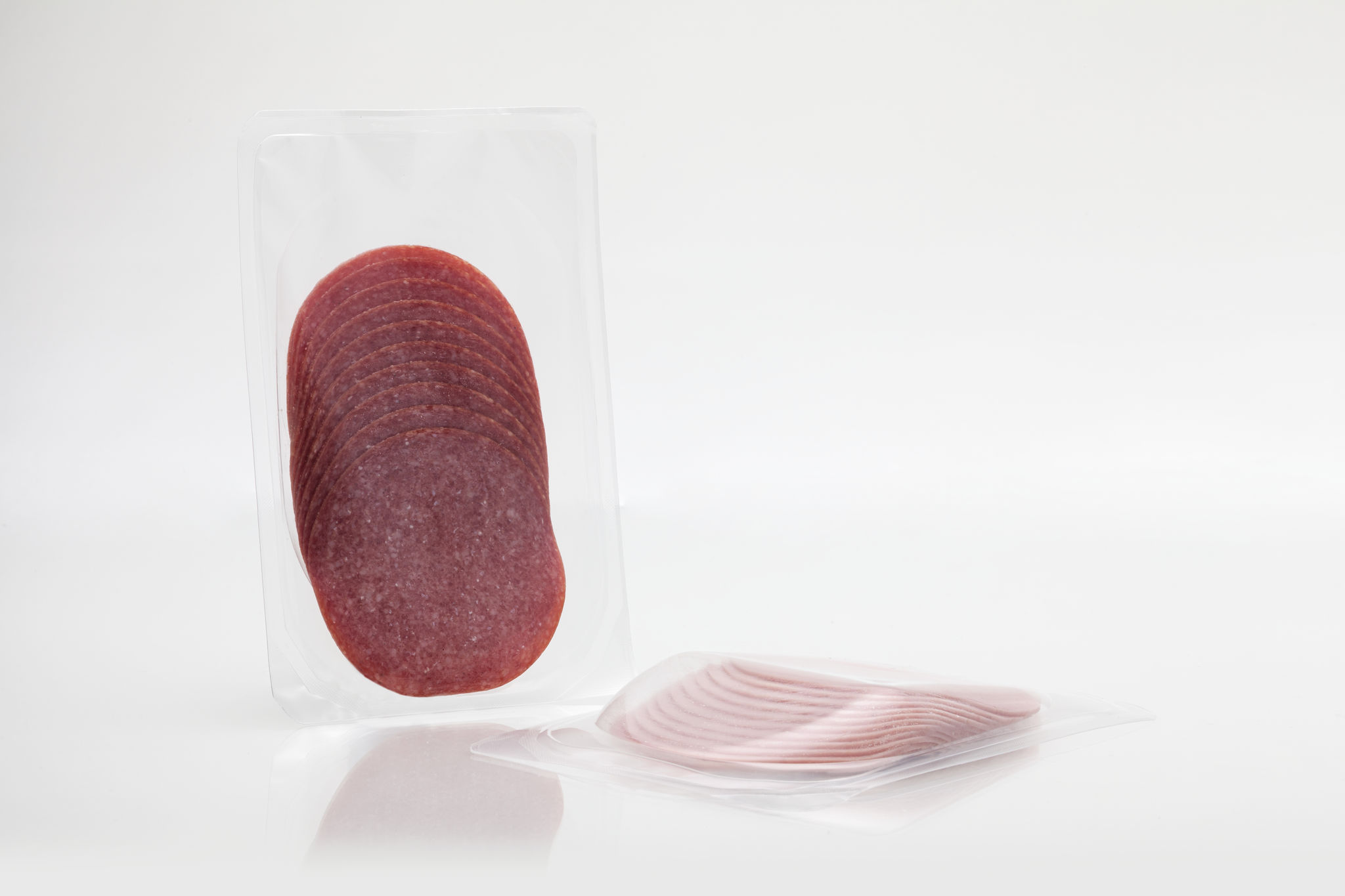

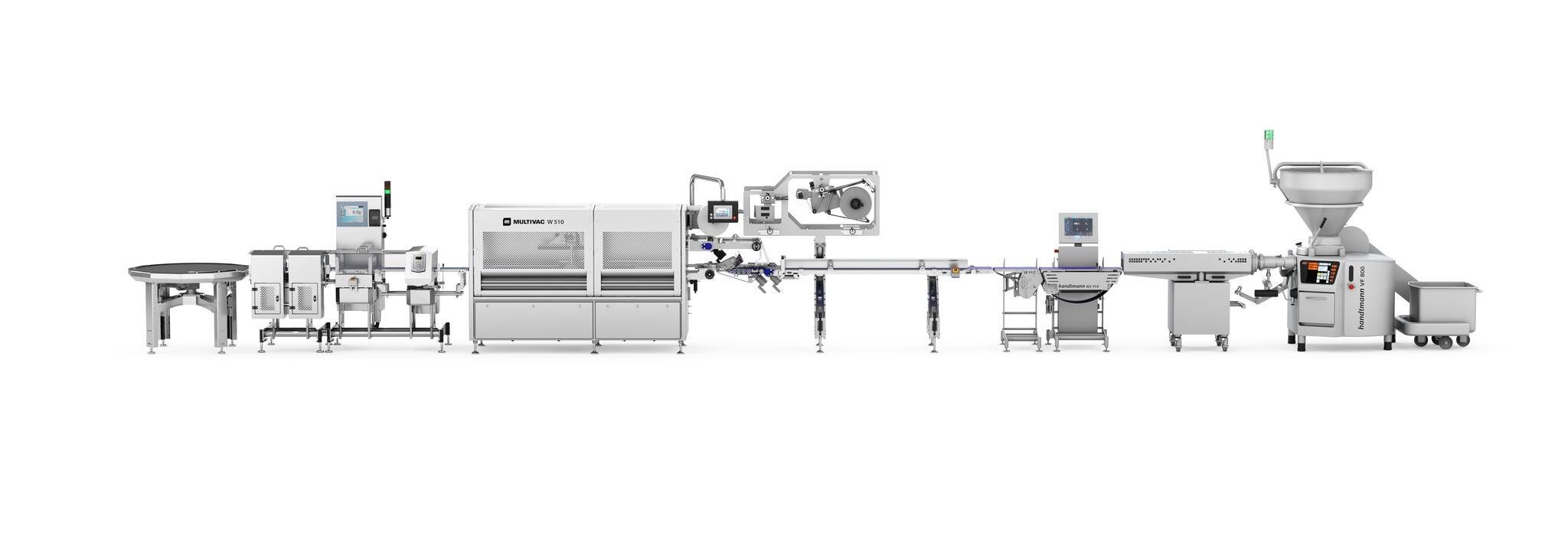

MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

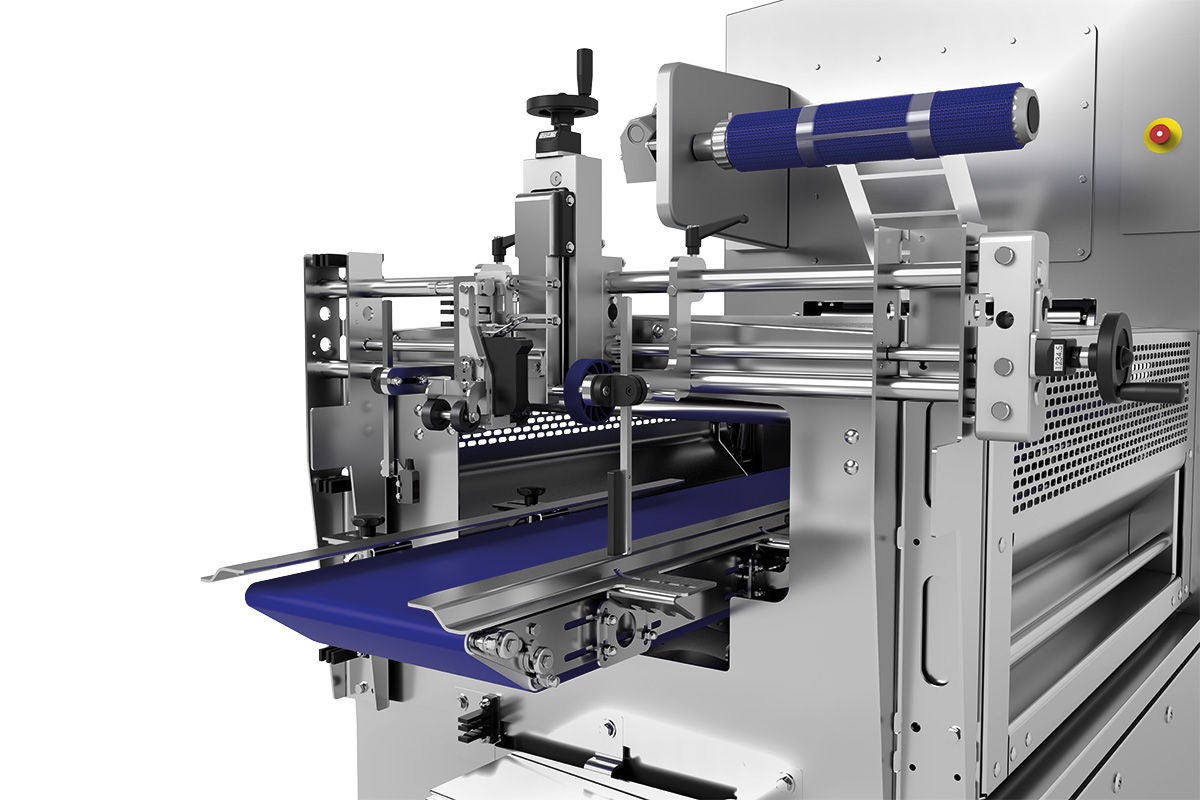

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

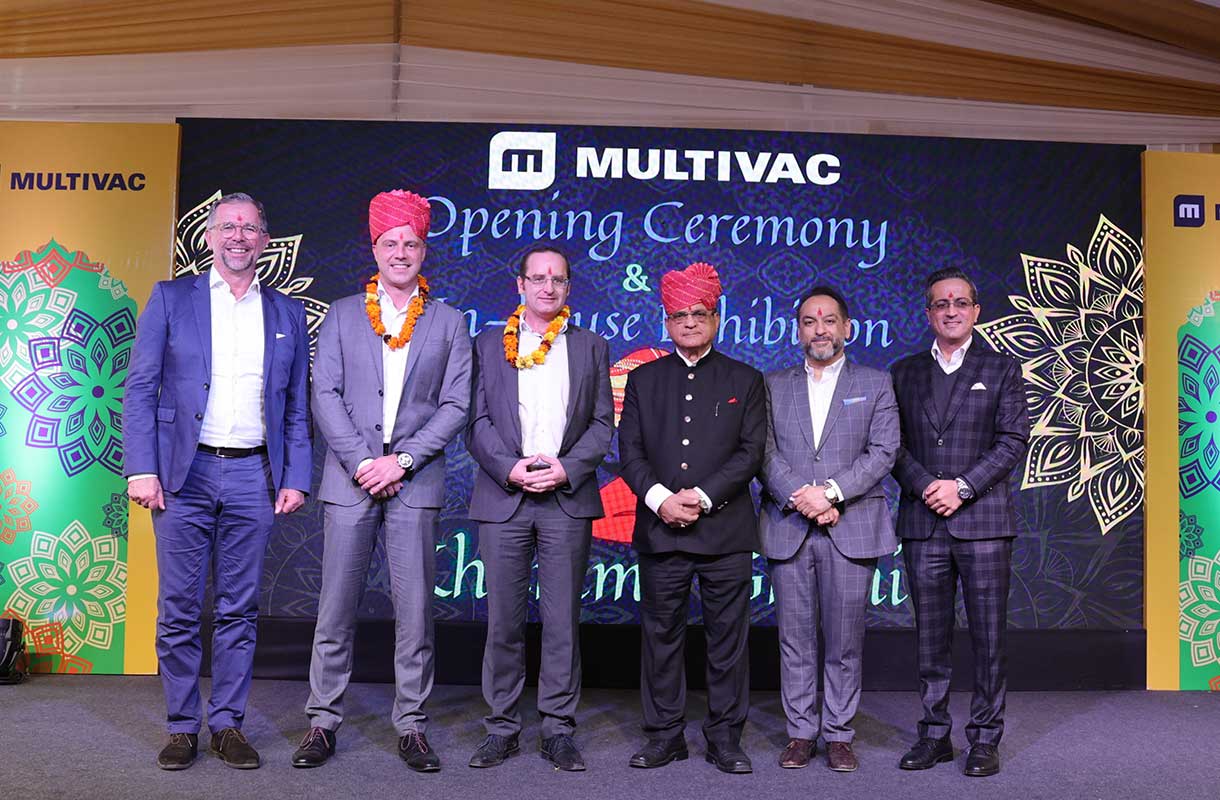

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

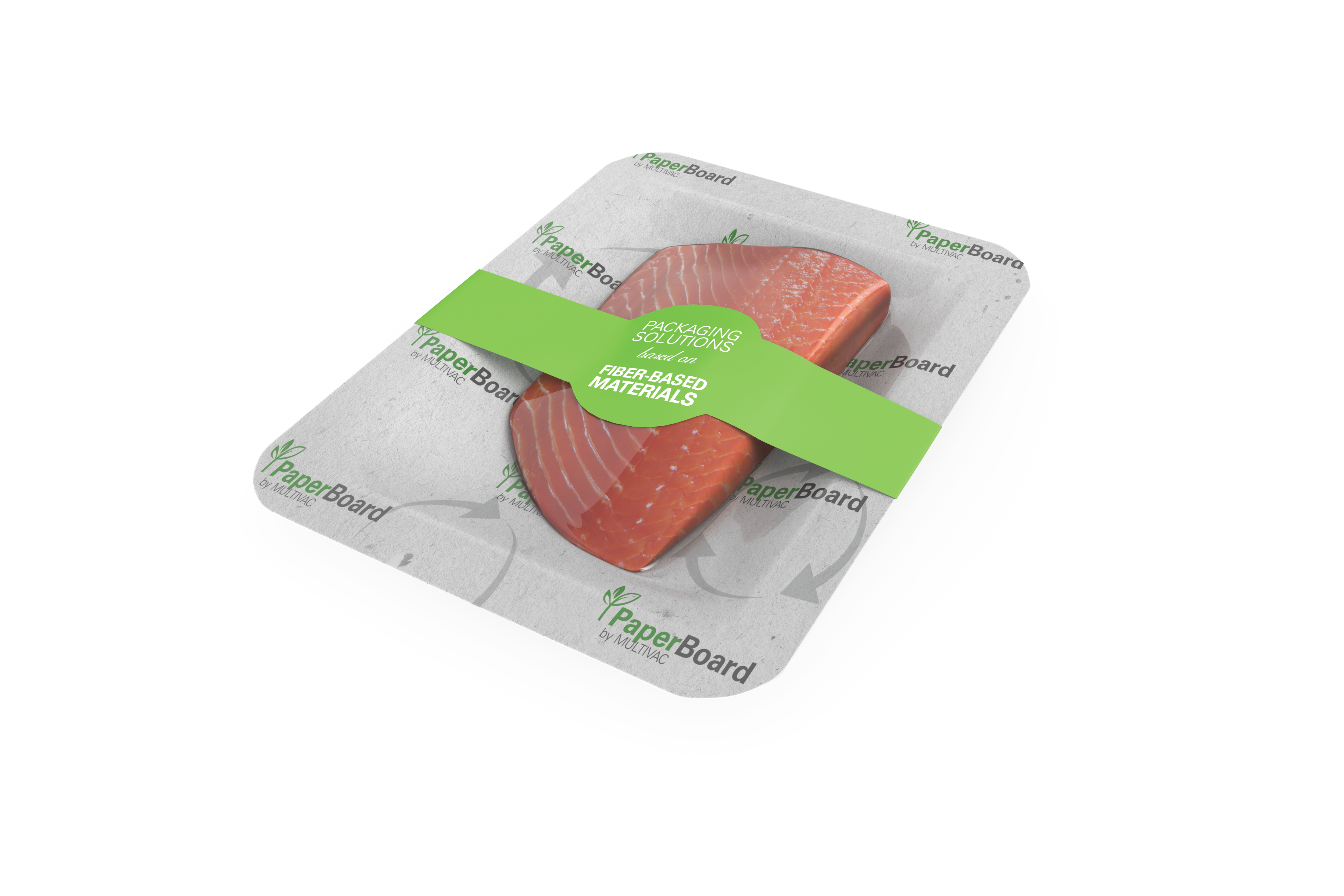

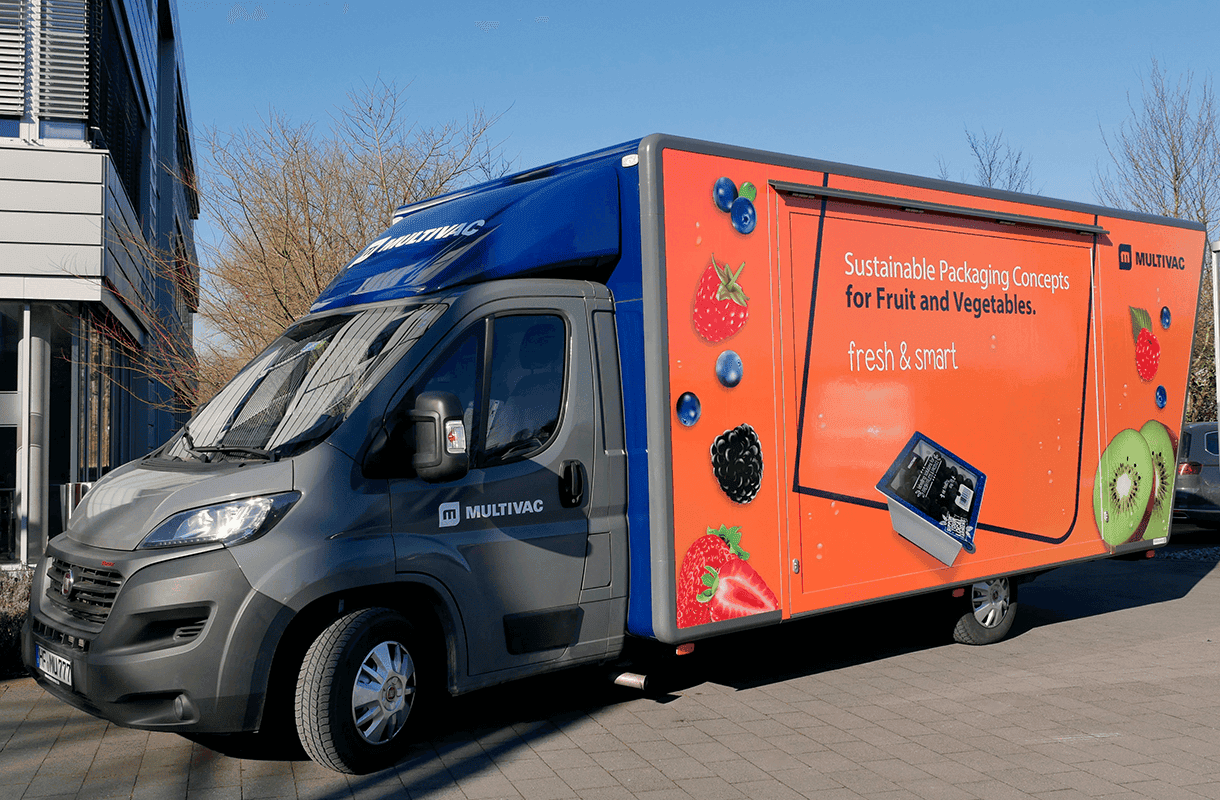

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

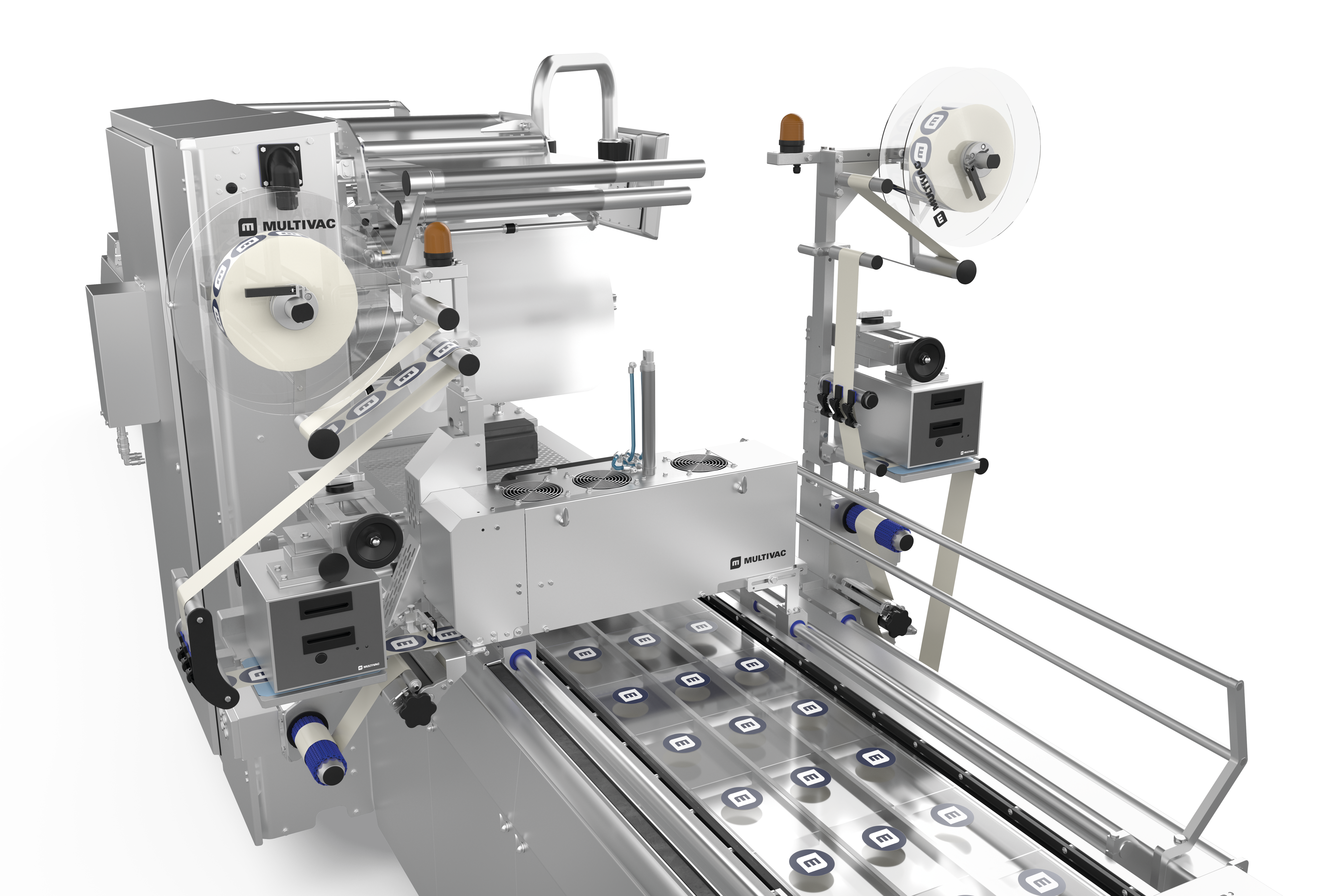

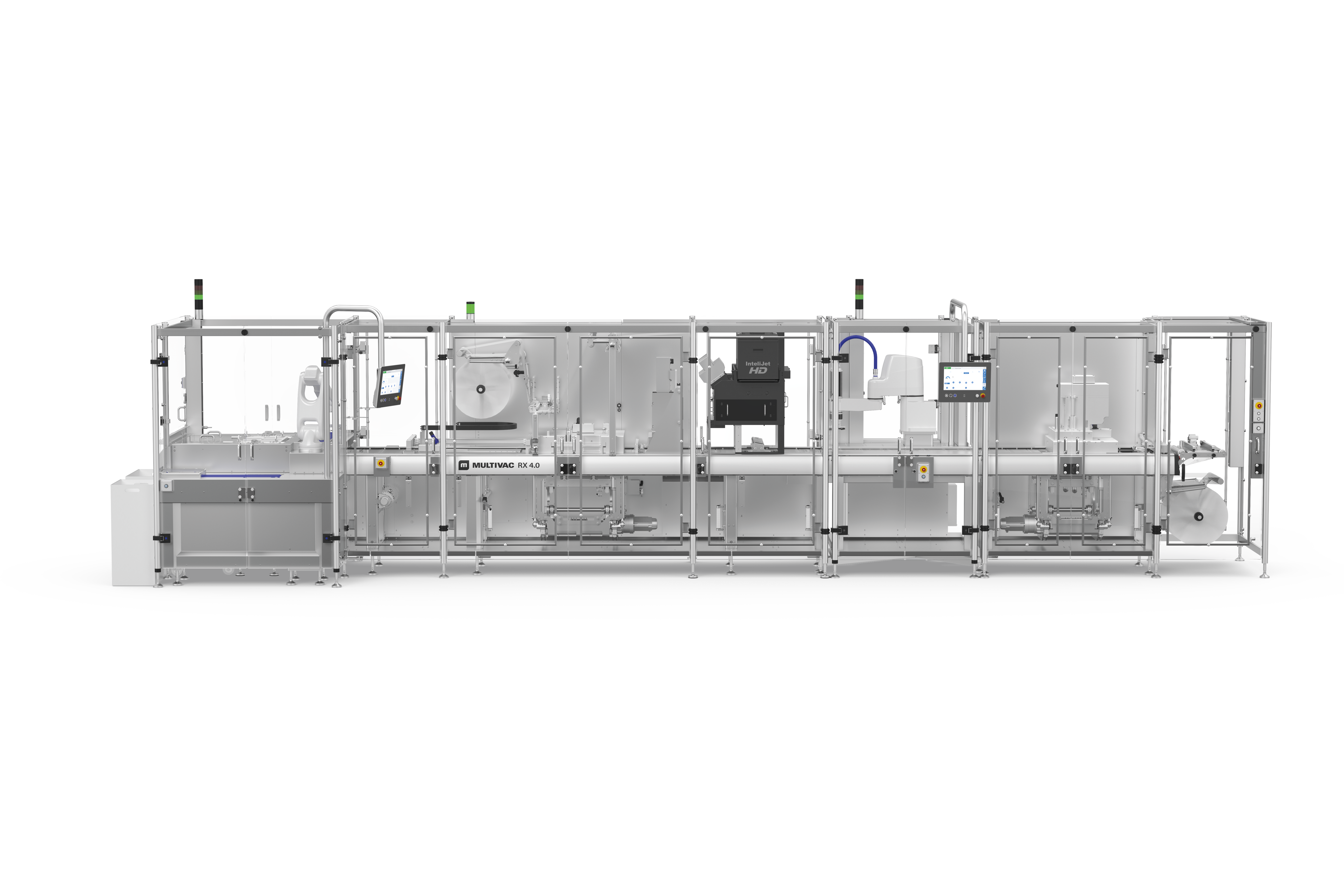

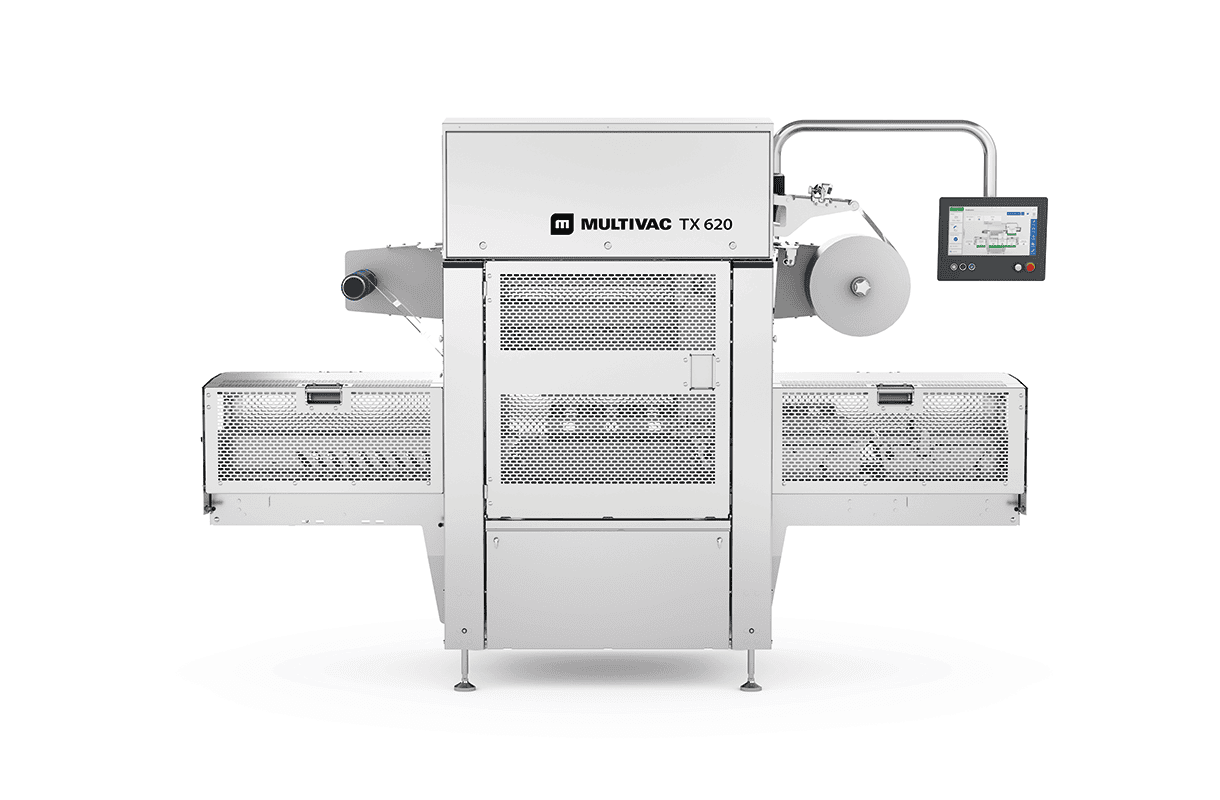

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

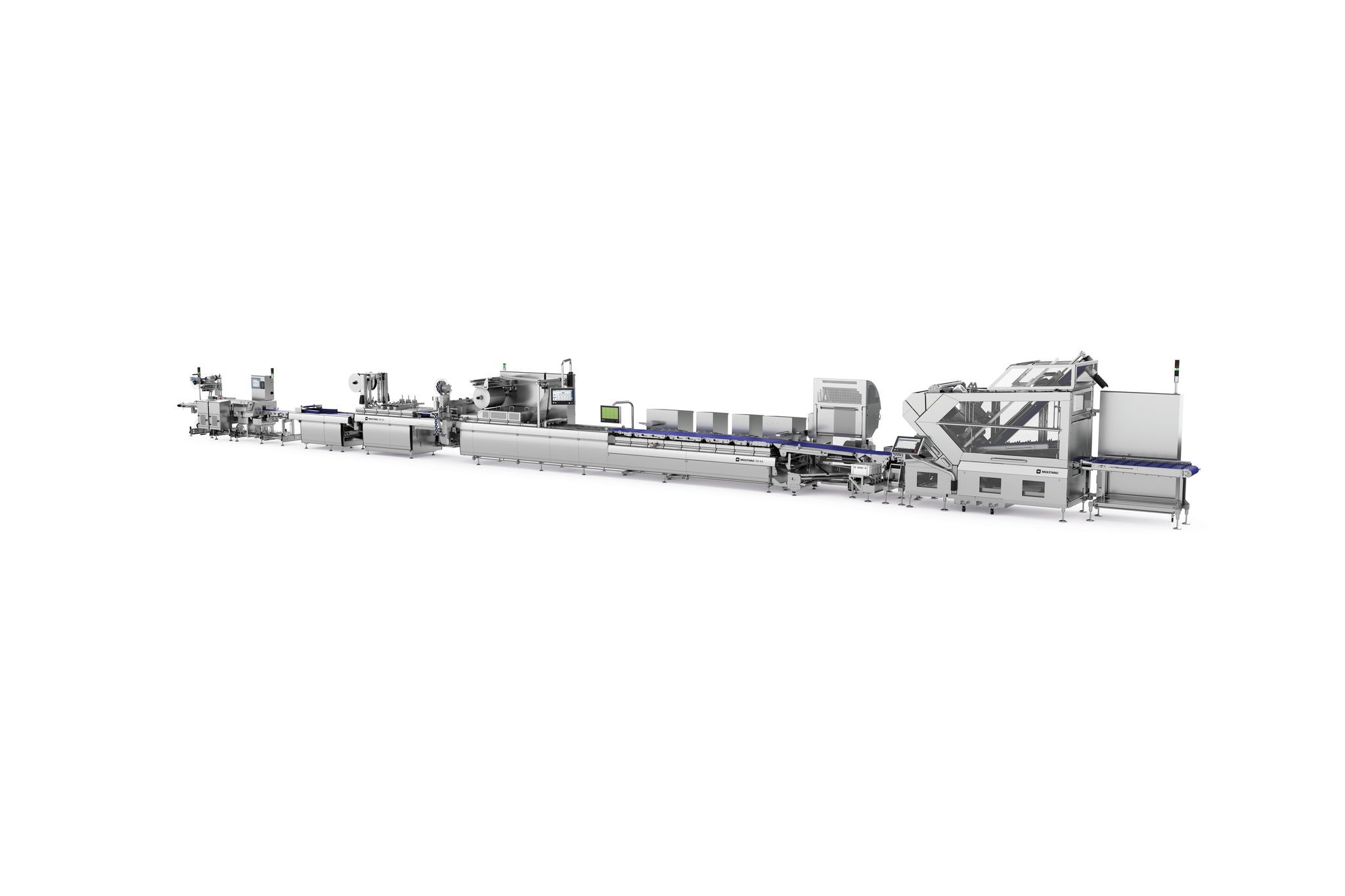

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com