When Innovation Reaches Orbit: How MULTIVAC Supports NASA's Astronauts

Innovation rarely announces the places it will go. Sometimes it shows up in a neighborhood grocery store or a food-processing plant. And sometimes—unexpectedly—it shows up 250 miles above Earth, orbiting at 17,500 miles per hour.

Recently, a visit to NASA’s Johnson Space Center revealed a remarkable connection: MULTIVAC C 200 chamber machines are helping package the meals that astronauts rely on aboard the International Space Station (ISS) and for missions supported by SpaceX. For a company focused on precision, reliability, and the highest standards of food safety, discovering our equipment in one of the most demanding environments imaginable is more than an honor—it’s a testament to what thoughtful engineering can achieve.

A Behind-the-Scenes Look at Space Food Preparation

Astronaut food might seem like a simple detail in the larger story of space exploration, but it is anything but simple. Meals must be nutritionally complete, shelf-stable, lightweight, easy to rehydrate, and safe to consume in zero gravity. As Brian Shamblin, Megan Place, and Bret Moeller learned during their tour, astronauts can also be surprisingly discerning eaters. Meals are evaluated by tasting panels, curated by mission commanders, and sometimes even crafted with input from professional chefs.

It’s a global effort as well. Food for space missions is prepared in facilities across the United States, Russia, France, and Italy—each contributing to the diverse menus that sustain astronauts during long missions. Packaging for these meals must also meet practical communication needs, with labeling provided in both English and Russian.

Precision Sealing for a Zero-Gravity Dining Room

In this complex system, MULTIVAC’s role is both focused and vital. NASA recently purchased two additional C 200 chamber machines, each modified with a specialized seal bar that allows a tube to be inserted so astronauts can rehydrate their meals. The opposite side of the package includes an easy-open feature, ensuring astronauts can access their food without unnecessary tools or complications—especially important in microgravity.

These requirements leave no room for error. A seal must be perfect. Materials must withstand vibration, extreme temperature fluctuations, and long storage times. Every package must protect its contents completely, because there is no backup food locker floating in space.

The fact that NASA relies on MULTIVAC equipment speaks to several hard-earned qualities: reliability, precision sealing technology, engineering consistency, and trust from world-class organizations operating in the harshest environments. Space is the ultimate proving ground—and our equipment is helping meet the challenge.

Walking Through History and Future Missions

Beyond the food lab, the team also had a chance to step into the rich legacy of human spaceflight. They visited the restored Mission Control room preserved as it appeared during Apollo 13—from original coffee cups to the ashtrays that once sat beside consoles monitoring a crisis that the world watched unfold.

They also toured full-scale ISS training modules, where astronauts rehearse missions before ever leaving Earth, and explored the Rocket Room, home to the Saturn V rocket on loan from the Smithsonian. Each stop underscored the extraordinary blend of history, engineering, and human determination that defines NASA’s work.

Latest news

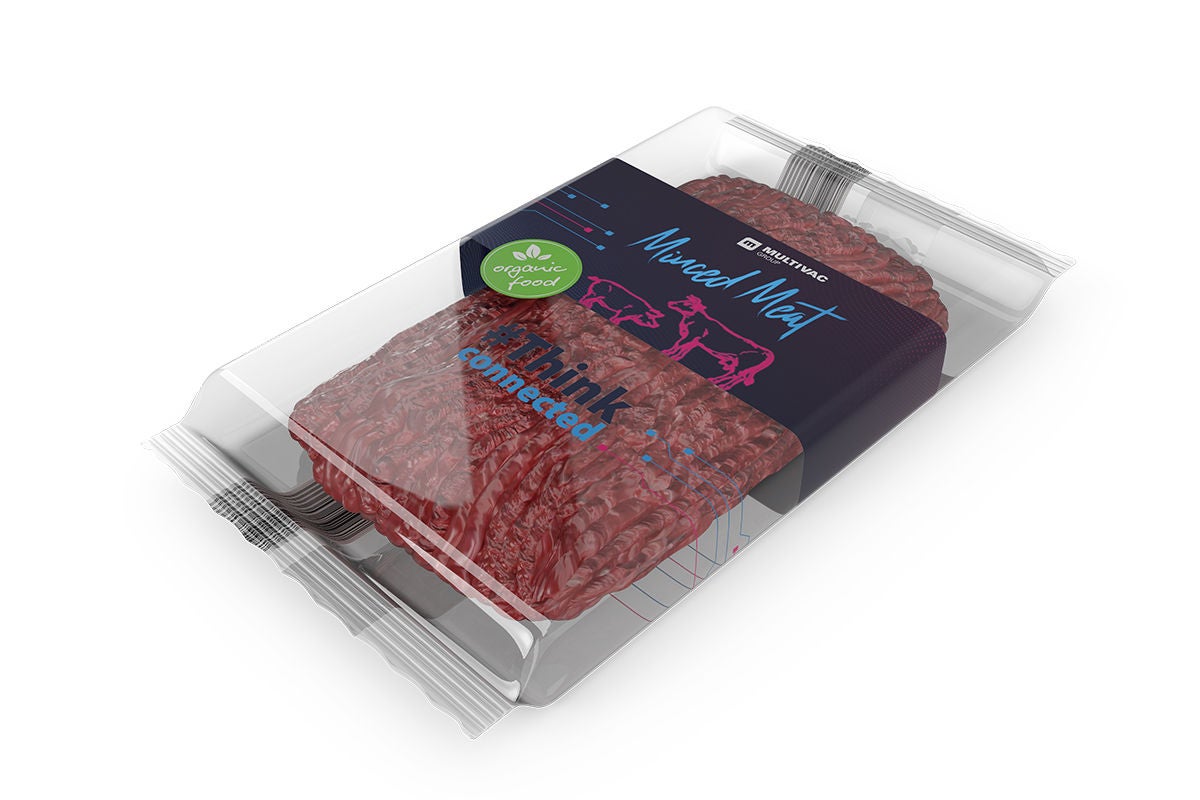

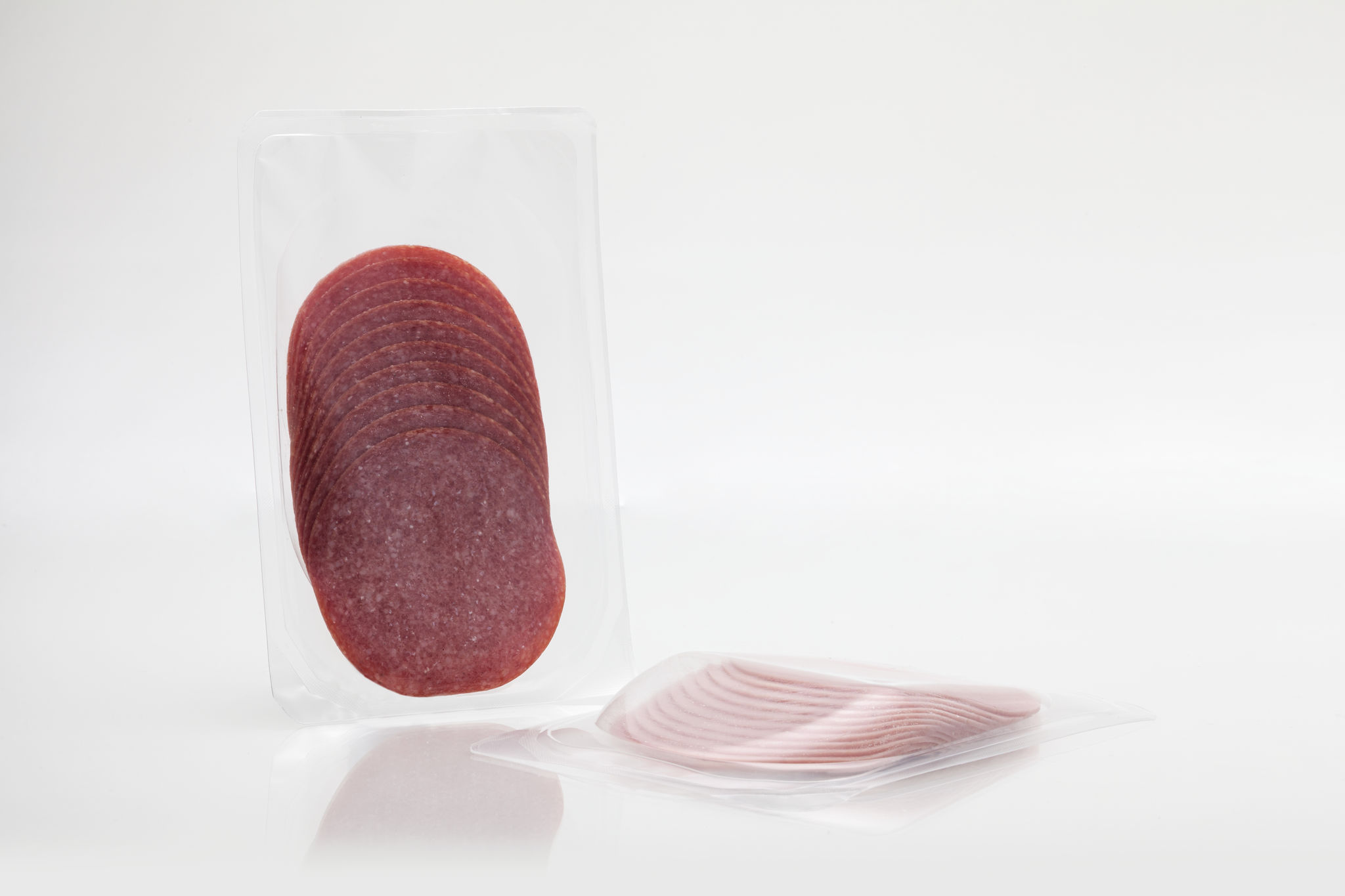

MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

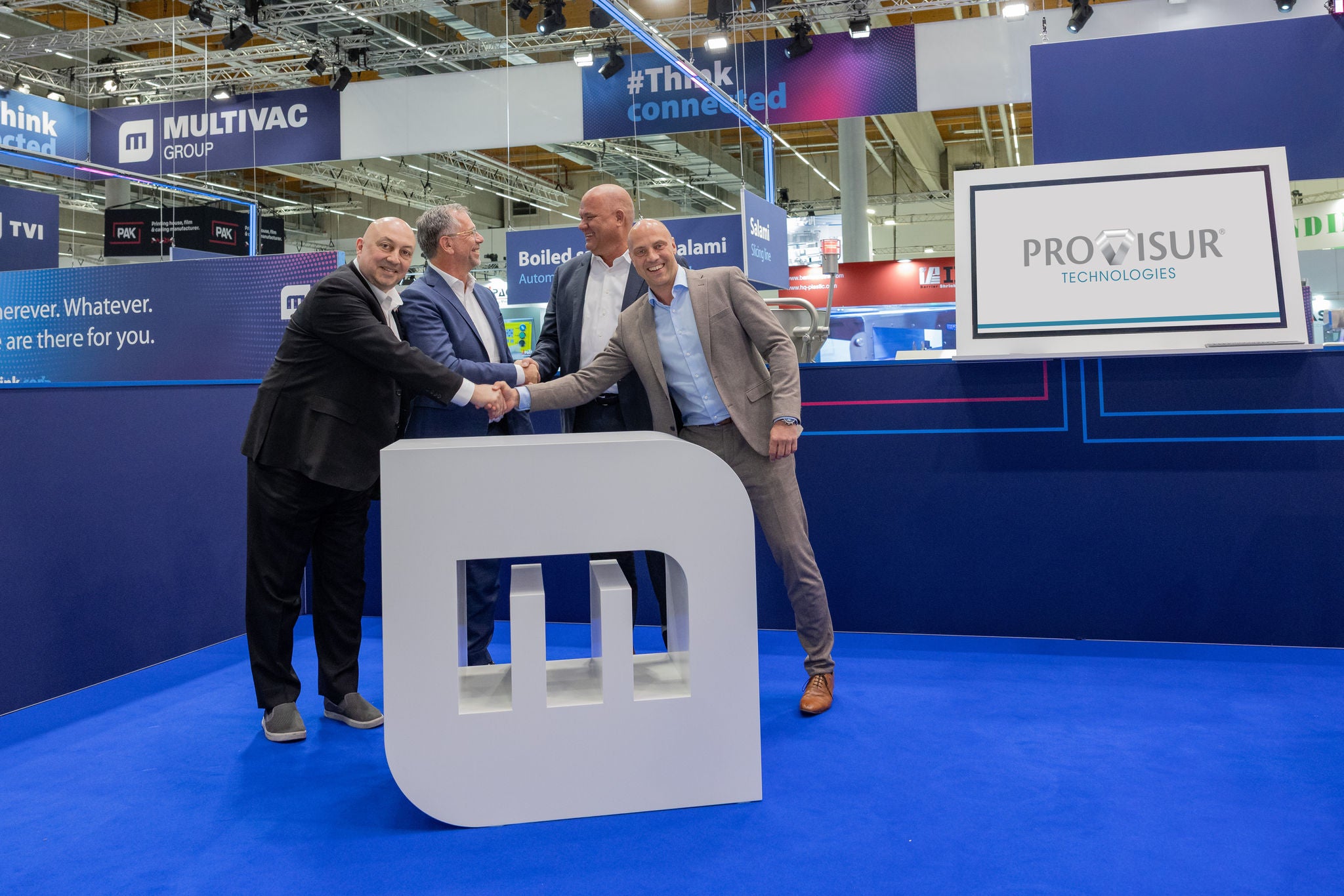

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

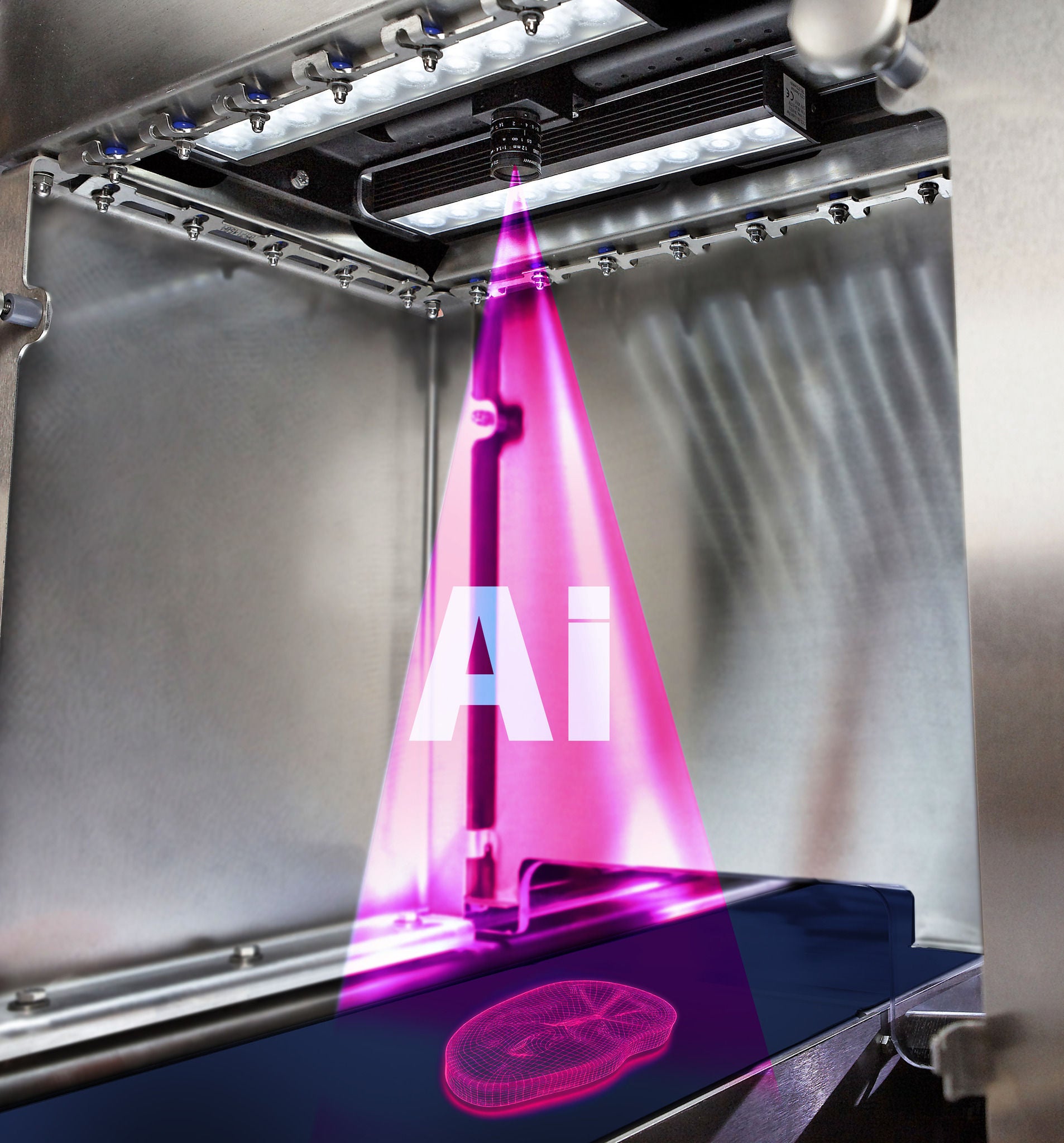

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

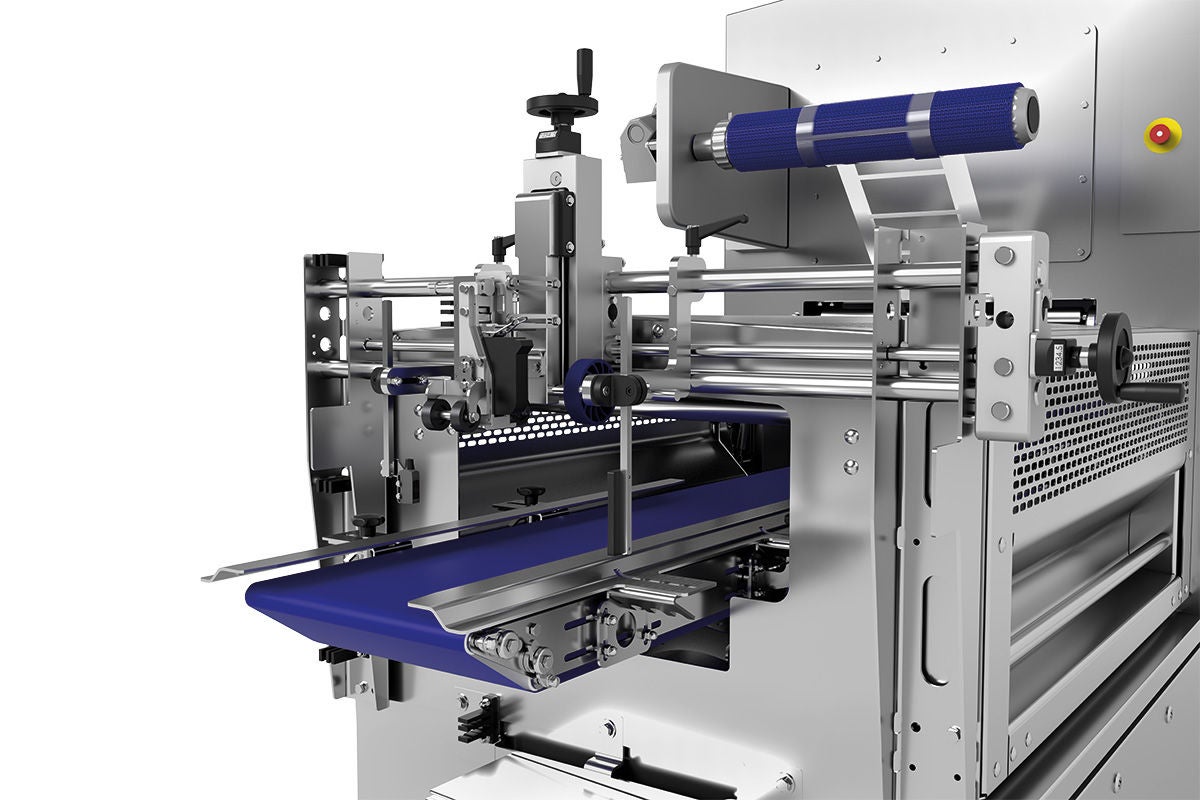

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

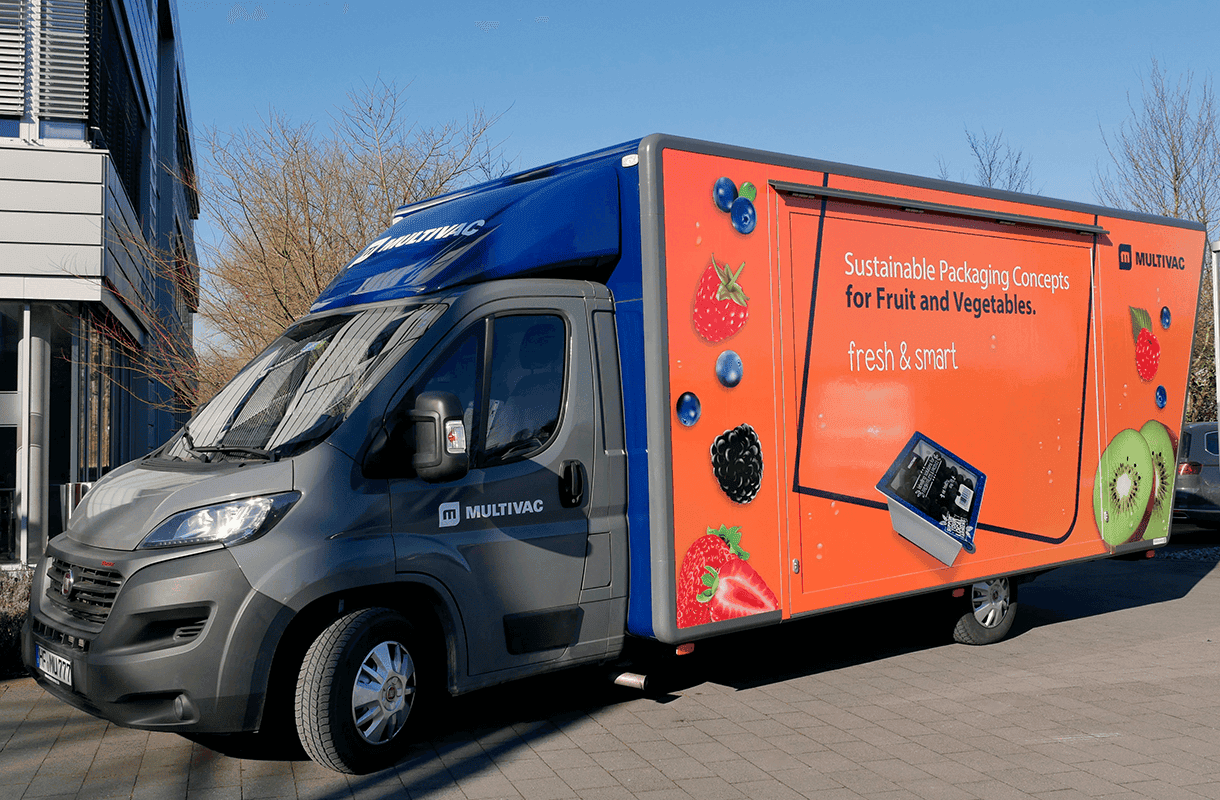

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

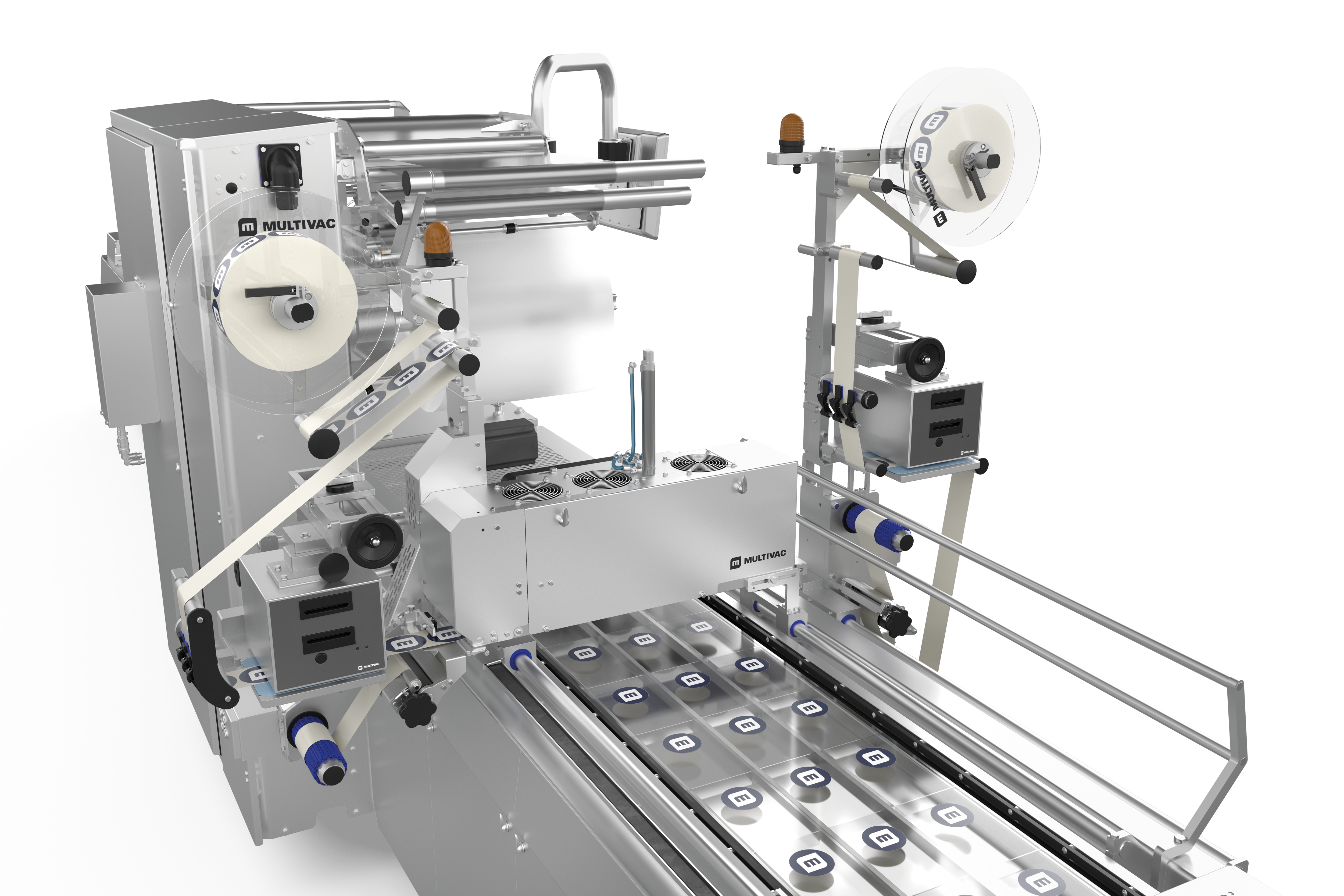

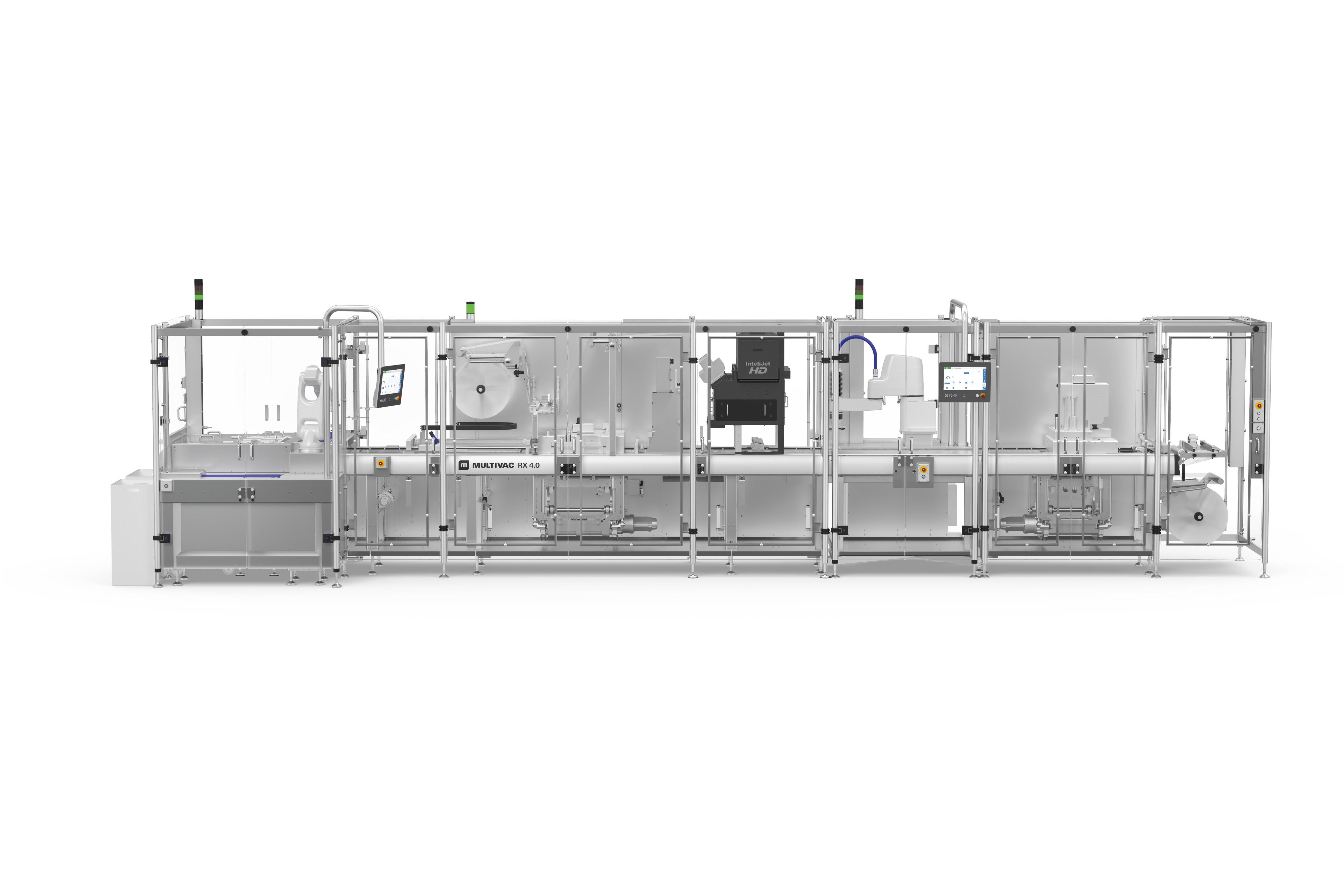

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

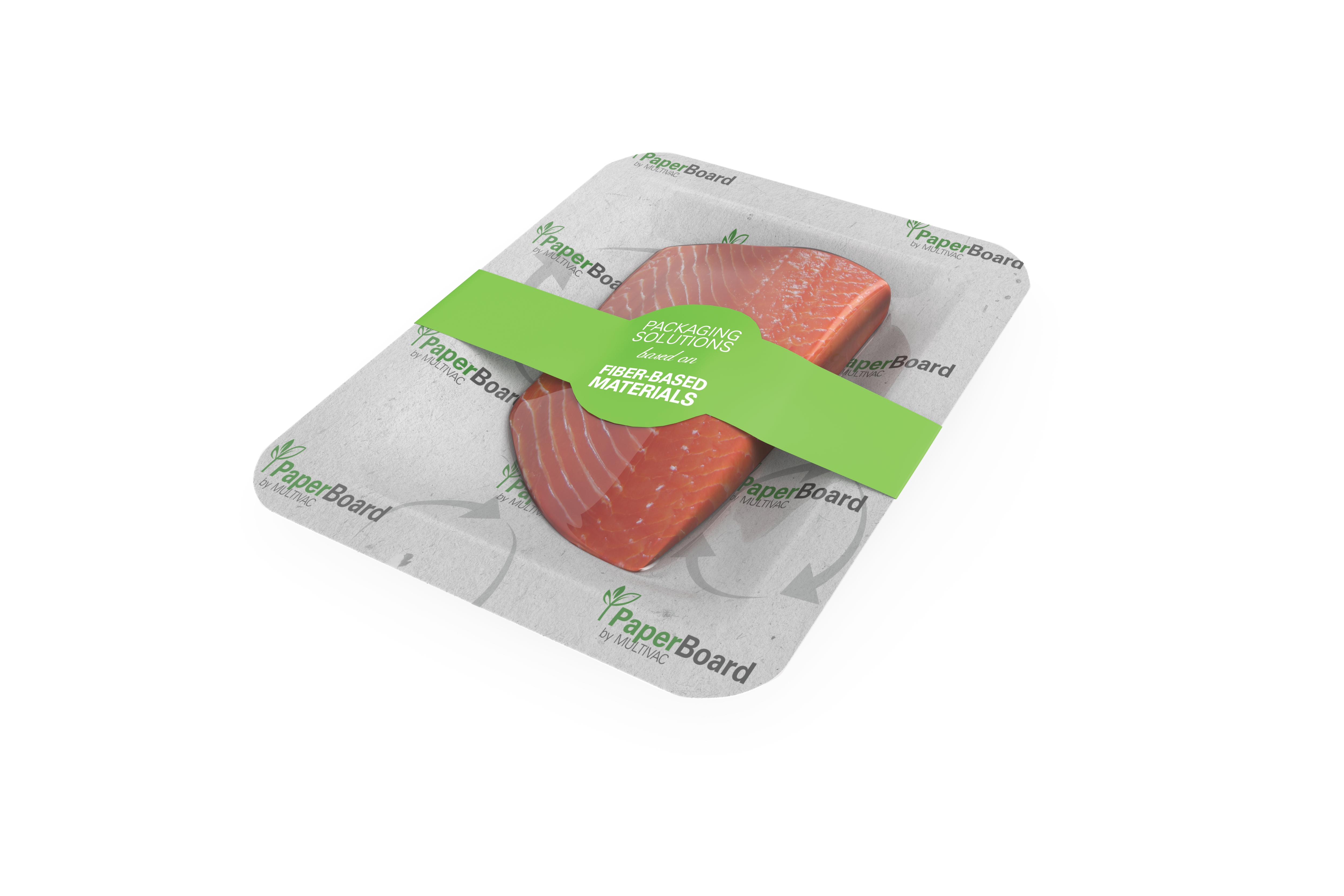

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com