When Support Thinks Ahead

Traditional service models are reactive by design. A machine stops, production is impacted, and support is called in to fix the problem. While fast response will always matter, it’s no longer enough for today’s production environments.

The next evolution of customer support is proactive — and human expertise, supported by data, is at the center of that shift.

The Service Intelligence Center brings together experienced Technical Support Specialists who continuously monitor connected equipment data to identify abnormal patterns and early warning signals — often before issues escalate into downtime.

From signals to insight

Modern equipment generates valuable indicators long before a failure occurs:

- Subtle performance deviations

- Inconsistent cycle times

- Repeating alarms or alerts

- Gradual increases in component stress

Individually, these signals can be difficult to detect on a busy production floor. When monitored over time and reviewed by experienced engineers, however, they reveal patterns that point to developing issues. The Service Intelligence Center combines live equipment data with historical performance knowledge to flag when machines are operating outside expected parameters — even if production is still running.

Proactive support in action

When abnormal trends are identified, the Service Intelligence Center proactively reaches out to customers with recommended actions to help prevent escalation.

These actions may include:

- Suggested inspections or adjustments

- Planned maintenance recommendations

- Replacement of components showing early signs of wear

- Process optimization guidance to stabilize performance

By intervening early, customers can schedule work on their terms, reduce emergency service calls, and avoid unplanned downtime.

Expertise, enhanced by intelligence

Data analysis tools and historical comparisons help support teams prioritize issues and focus on what matters most. Instead of starting from scratch, support specialists can reference similar scenarios, known failure modes, and proven corrective actions.

This approach doesn’t replace human expertise — it strengthens it. Technical Support Specialists spend less time diagnosing symptoms and more time helping customers maintain stable, efficient production.

Redefining the support experience

When support thinks ahead, the relationship changes.

Support becomes:

- Proactive instead of reactive

- Predictive through pattern recognition and expert review

- Focused on prevention, not just repair

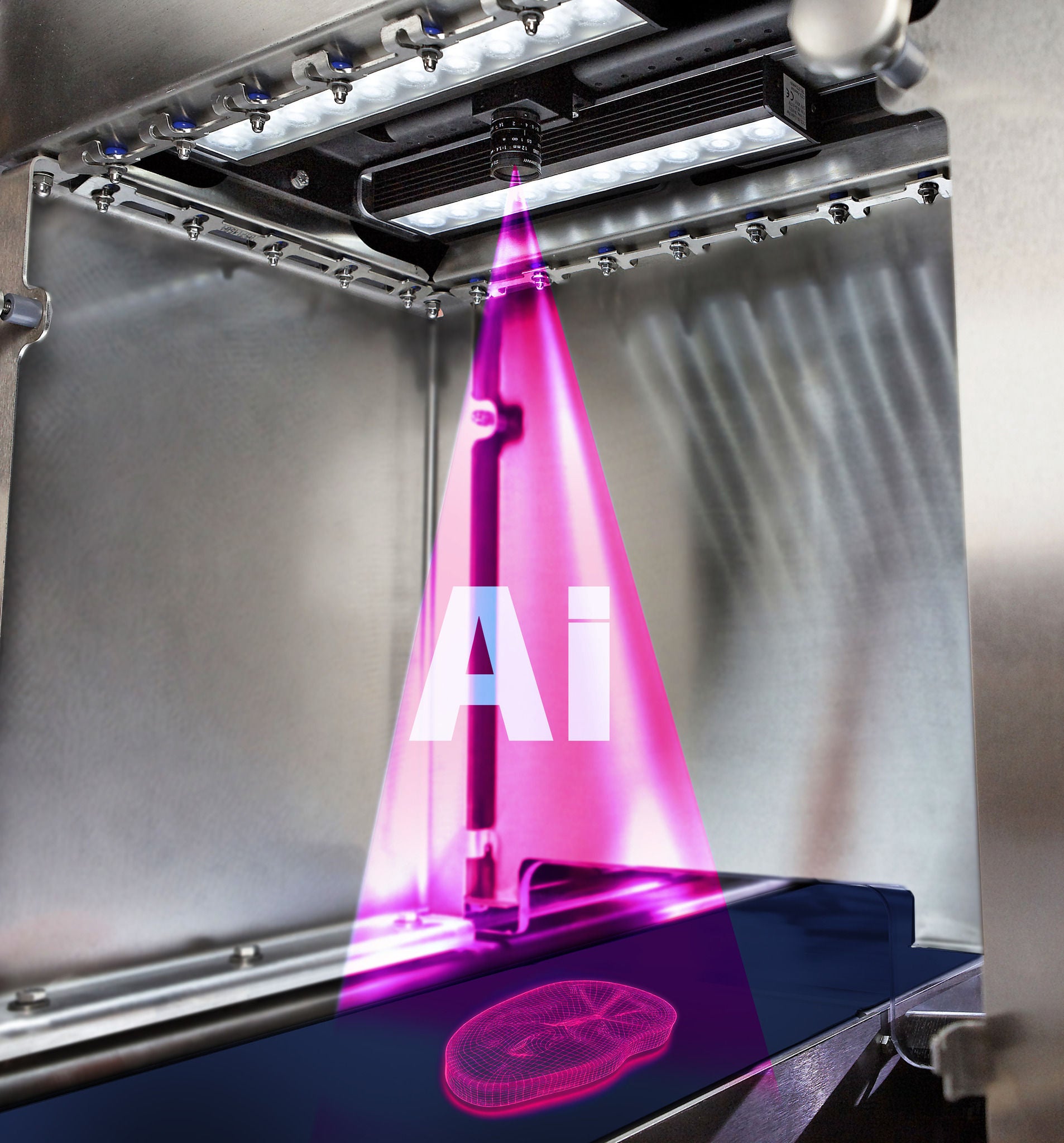

The Service Intelligence Center represents Intelligent Support in practice — combining human expertise, data visibility, and early intervention to help customers avoid downtime before it happens. See how predictive insights and AI-assisted diagnostics are transforming customer support from reactive to proactive. Contact your trusted Customer Support Representative today at 1-800-800-8552.

Latest news

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

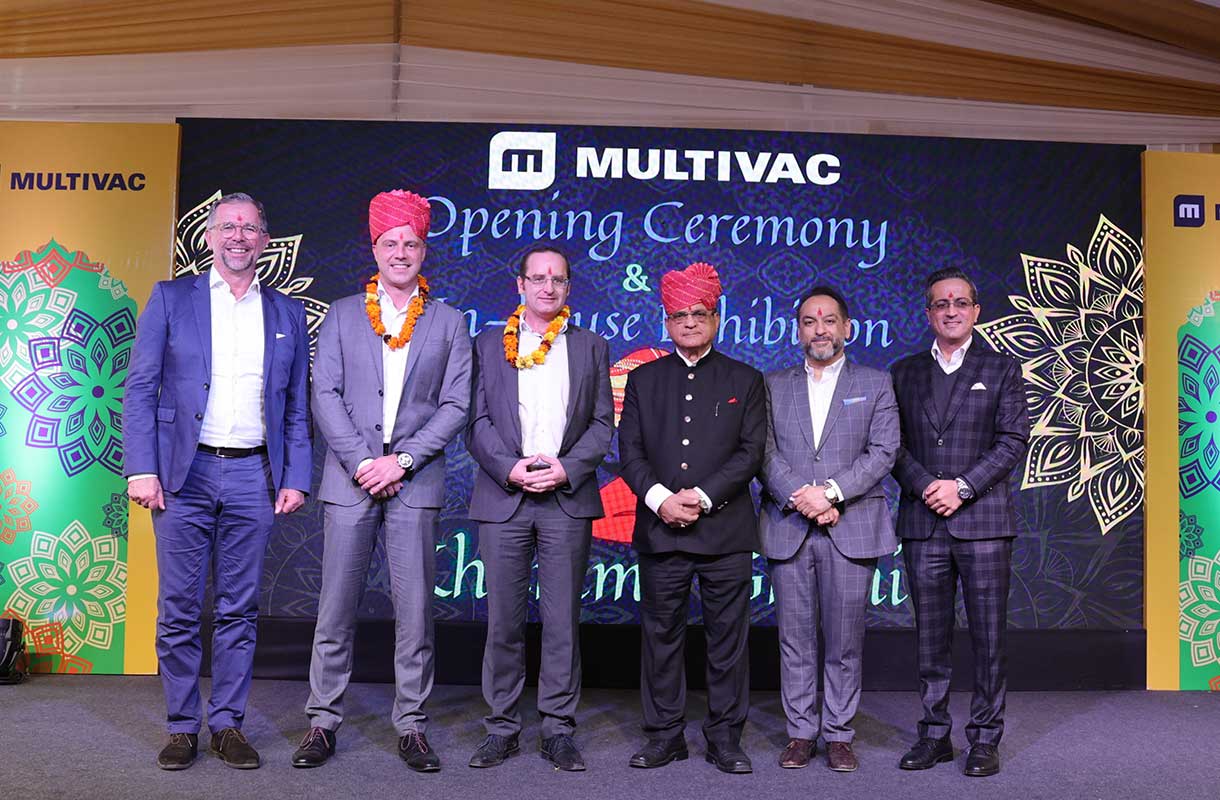

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

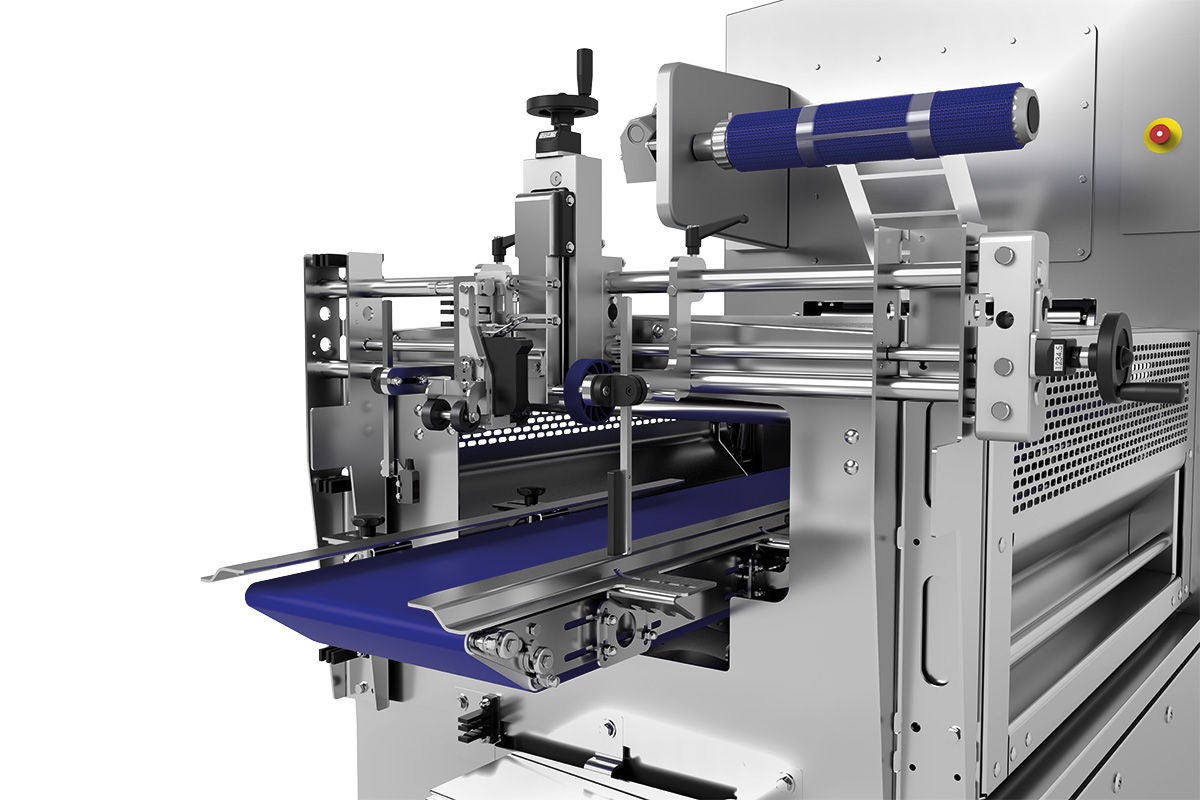

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

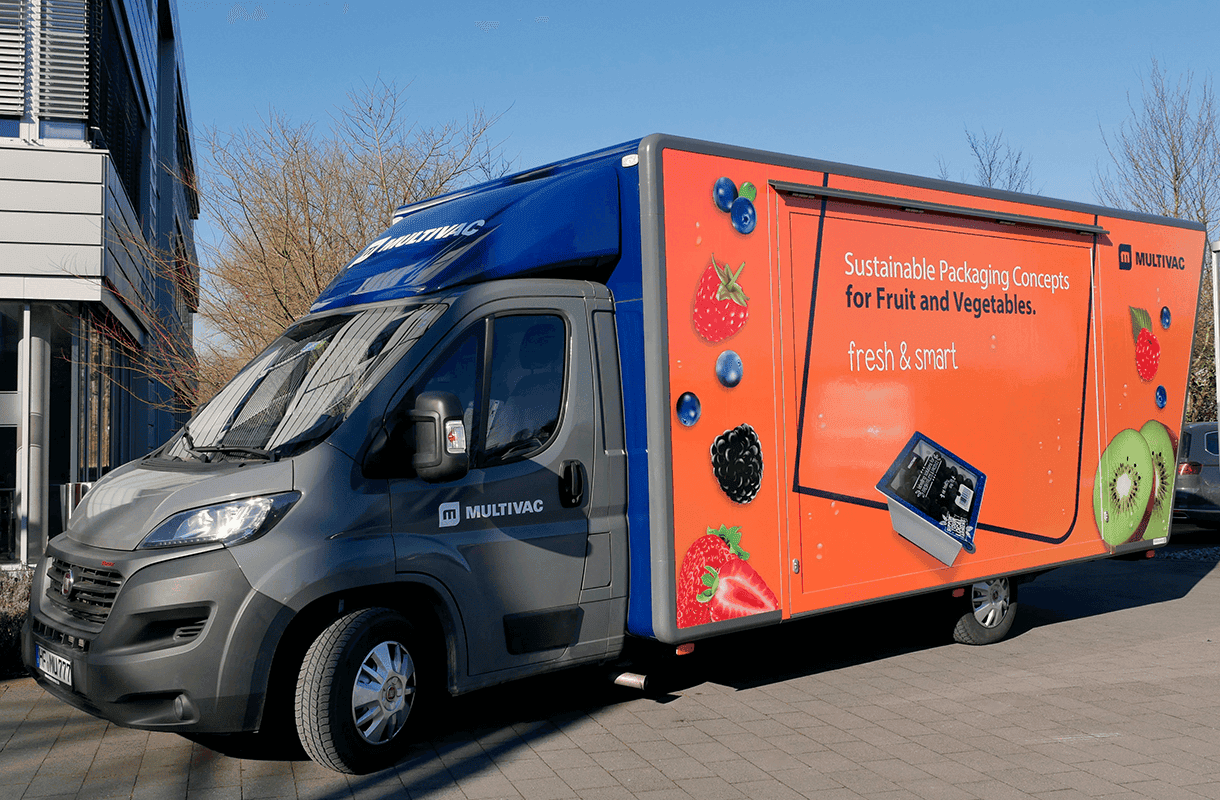

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

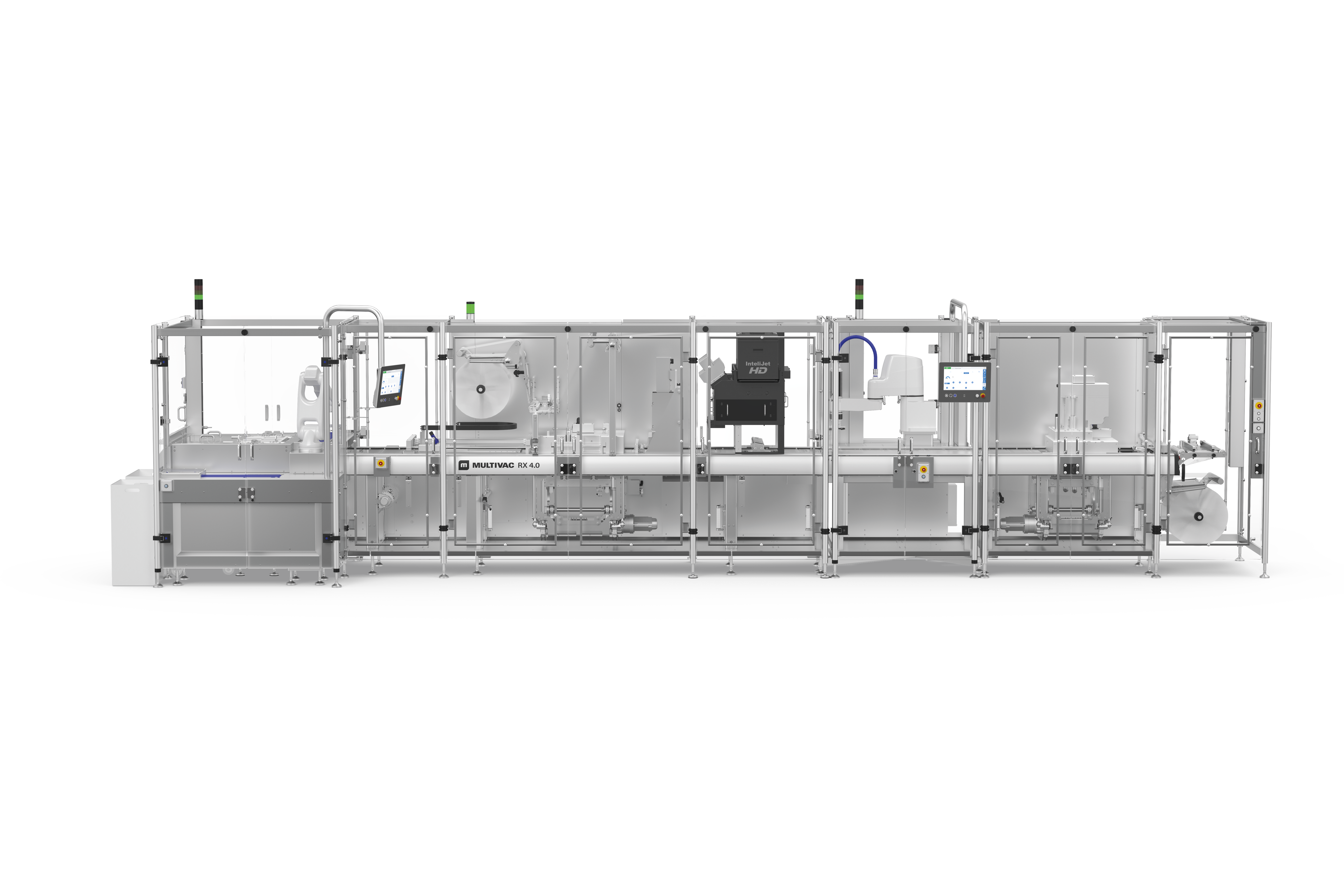

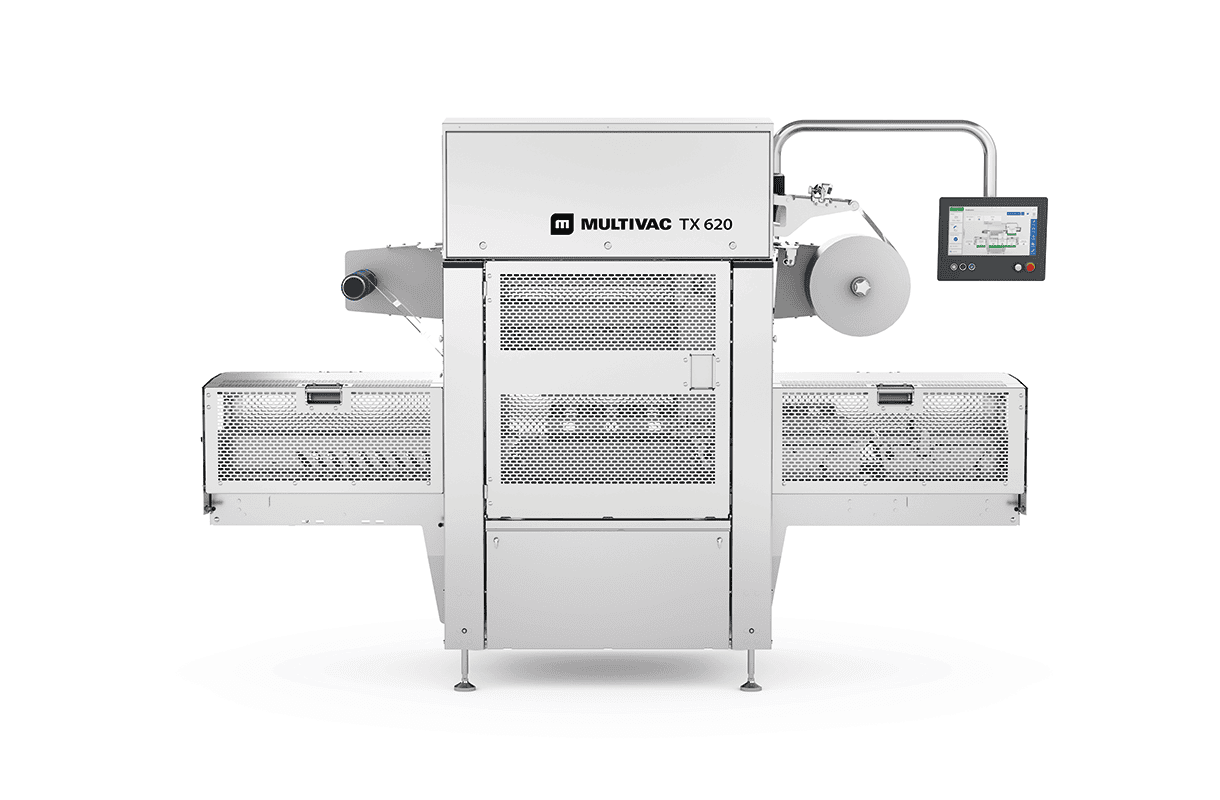

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

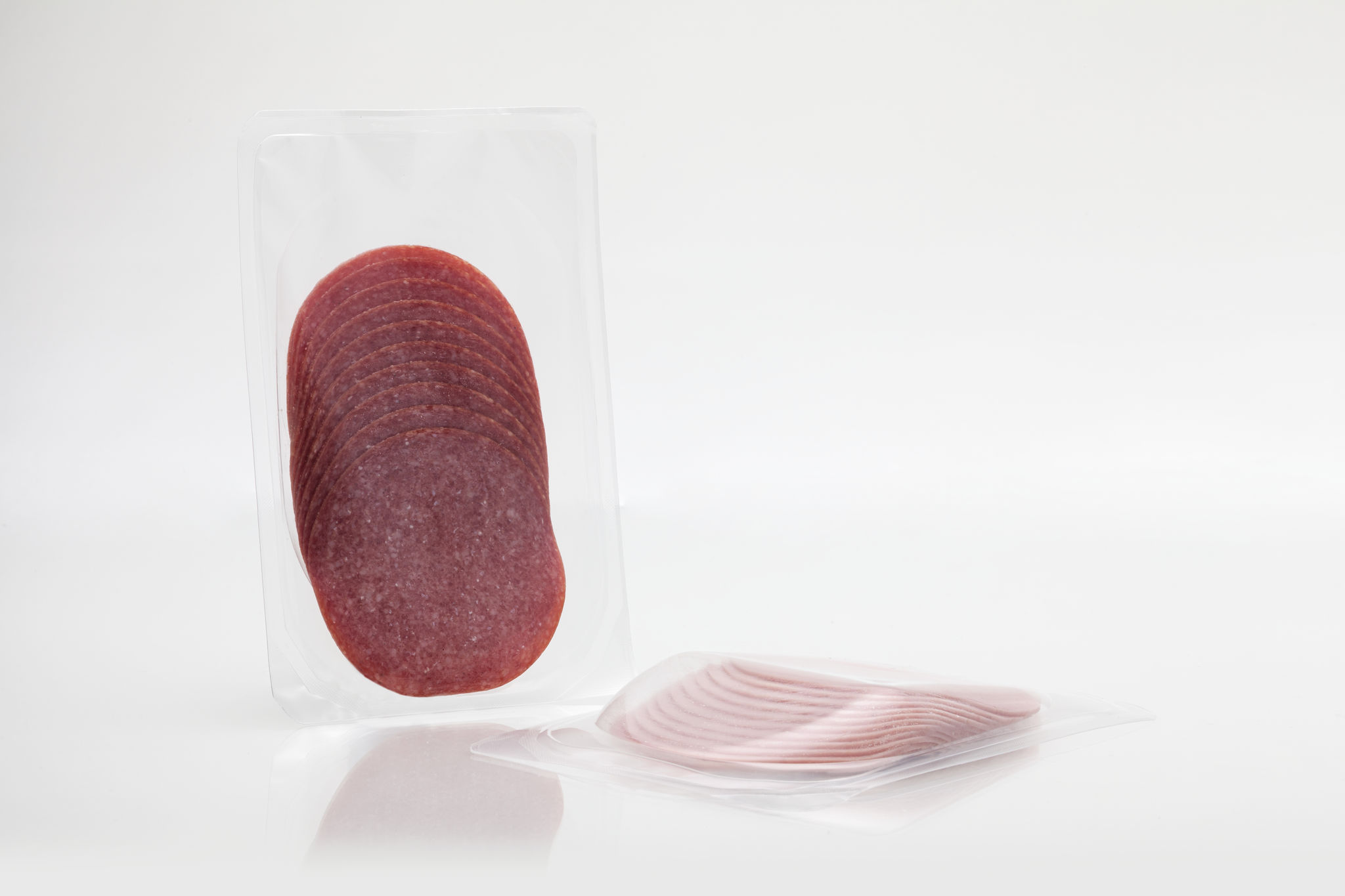

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

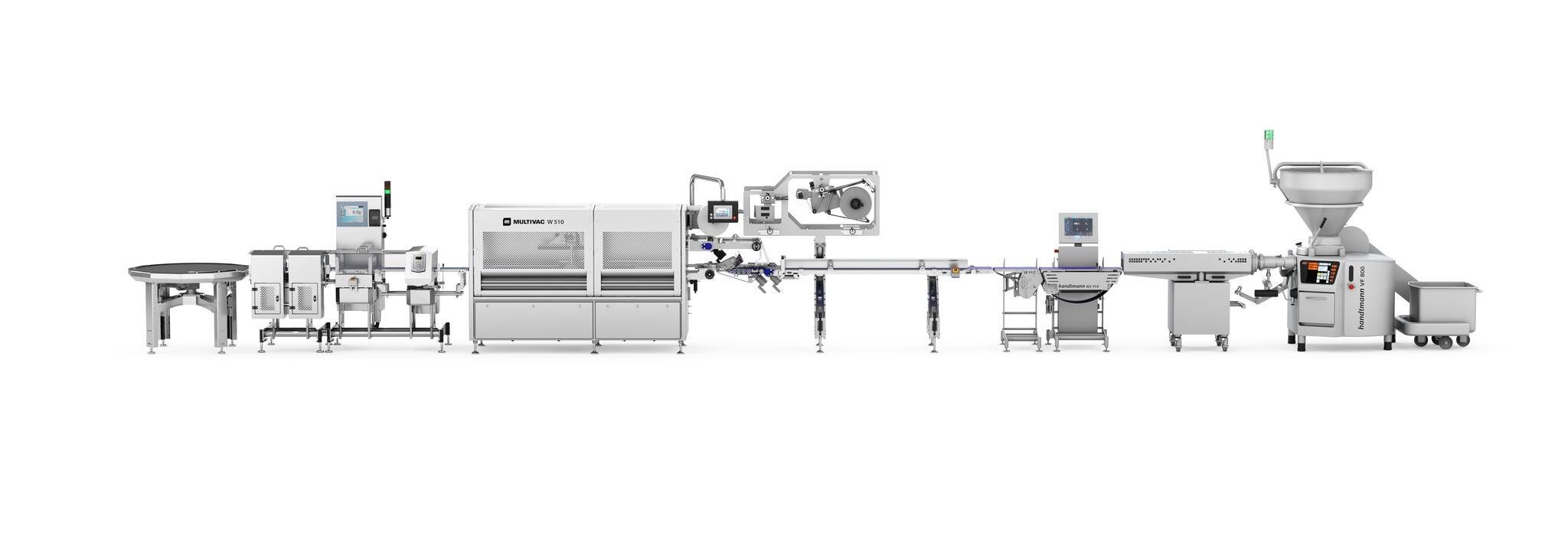

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

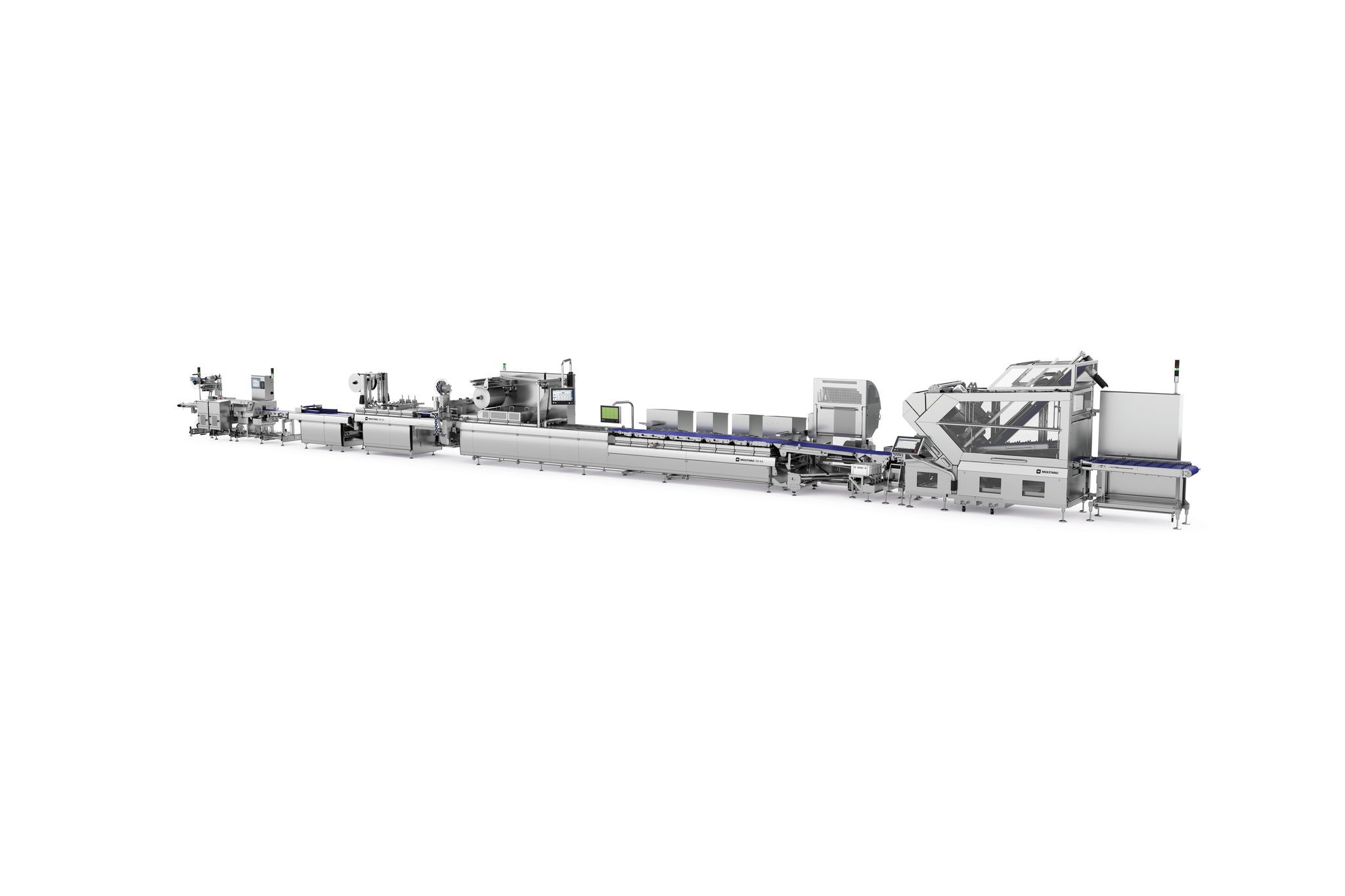

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com