Potato Harvesting Machine by MULTIVAC

Potato Harvesting Machine by MULTIVAC

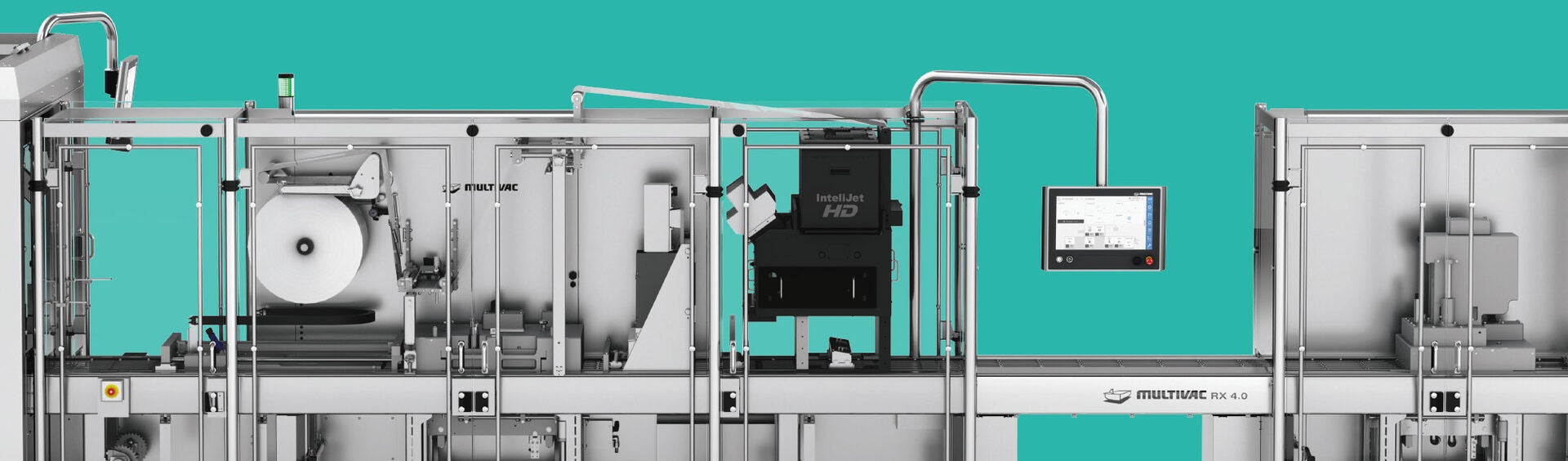

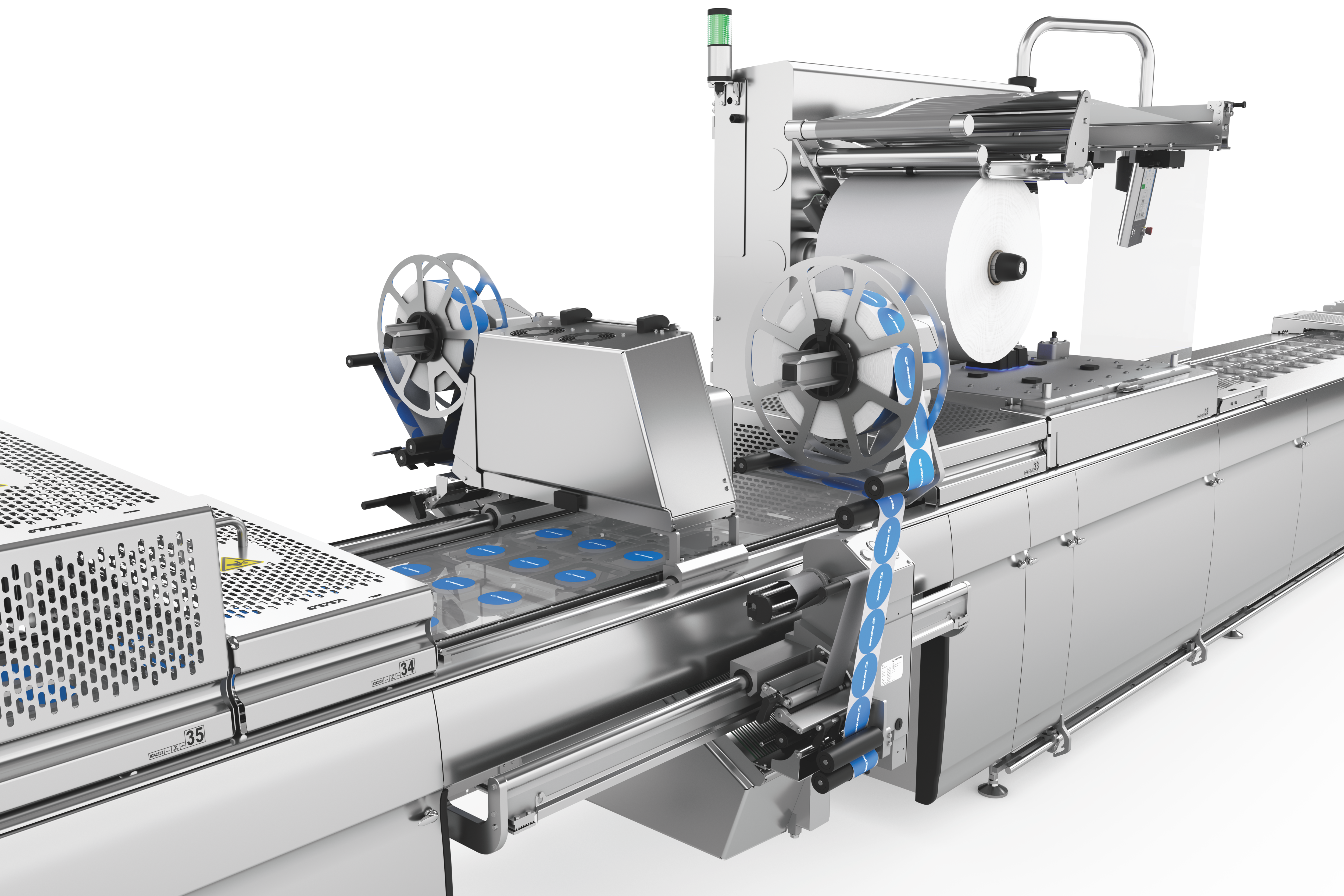

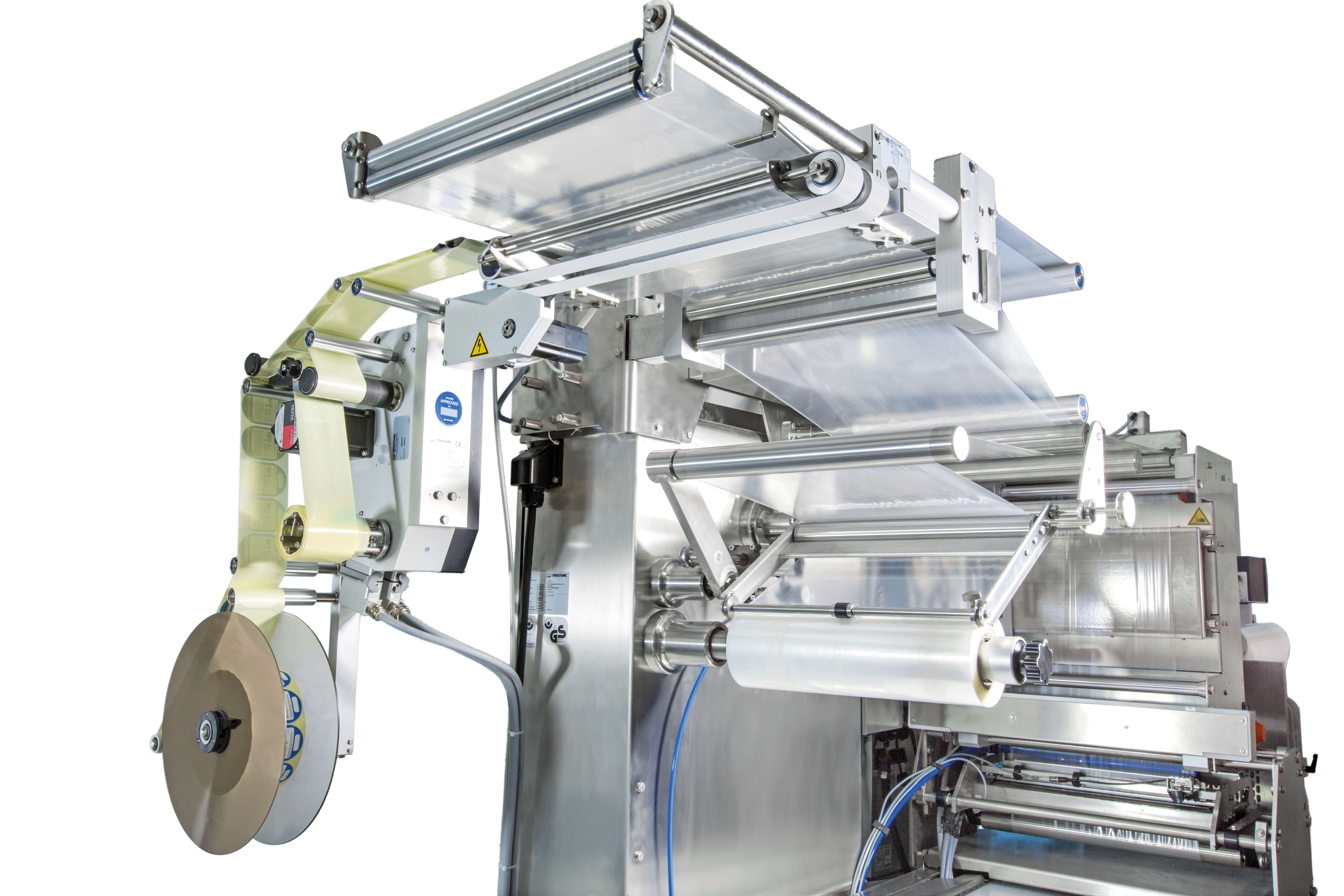

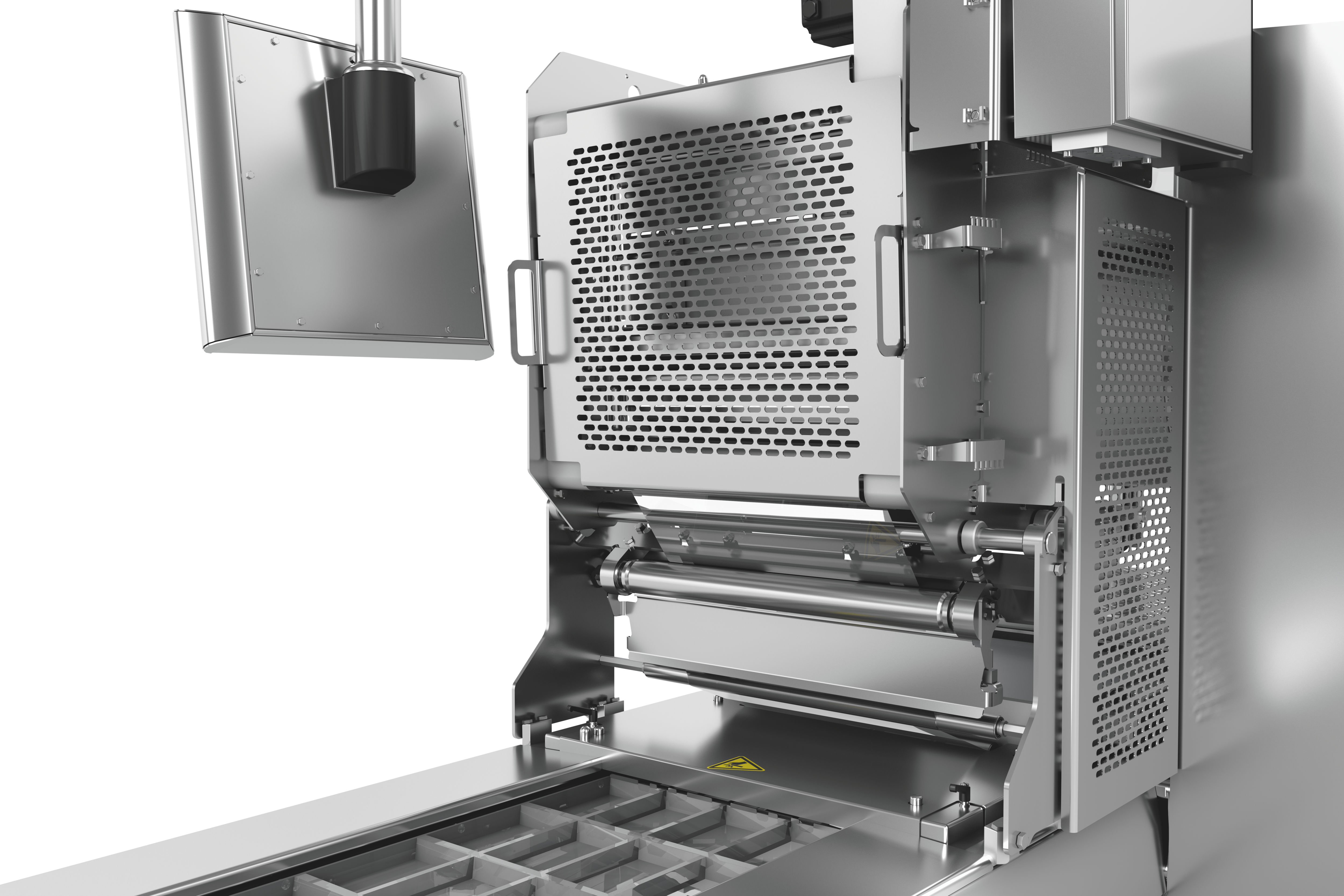

Flexibility and reliability in the labelling and marking of thermoformed packs

For the marking of thermoformed packs, we offer you two customizable, flexible and fully integratable labelling solutions with cross web labelers and direct web printers. The labelling machines and direct web printers are controlled centrally via the HMI (Human Machine Interface). We will gladly advise you on the selection of formats and materials.

Efficiency and cost-effectiveness

Market demands are continuously growing. Companies have to keep up with developments and market expectations to maintain their position in the future. Economically viable investment decisions need to be future-proof. This also includes the labelling of thermoformed packs. Lengthy conversion times, for example, have a negative influence on equipment efficiency. Furthermore, if individual line components don't work as a single, cohesive unit, the entire process will suffer.

Success stories

Potato Harvesting Machine by MULTIVAC

Potato Harvesting Machine by MULTIVAC