MULTIVAC's new production factory in Japan: an important building block in the expansion strategy

06/09/2022

MULTIVAC Japan is expanding capacity significantly

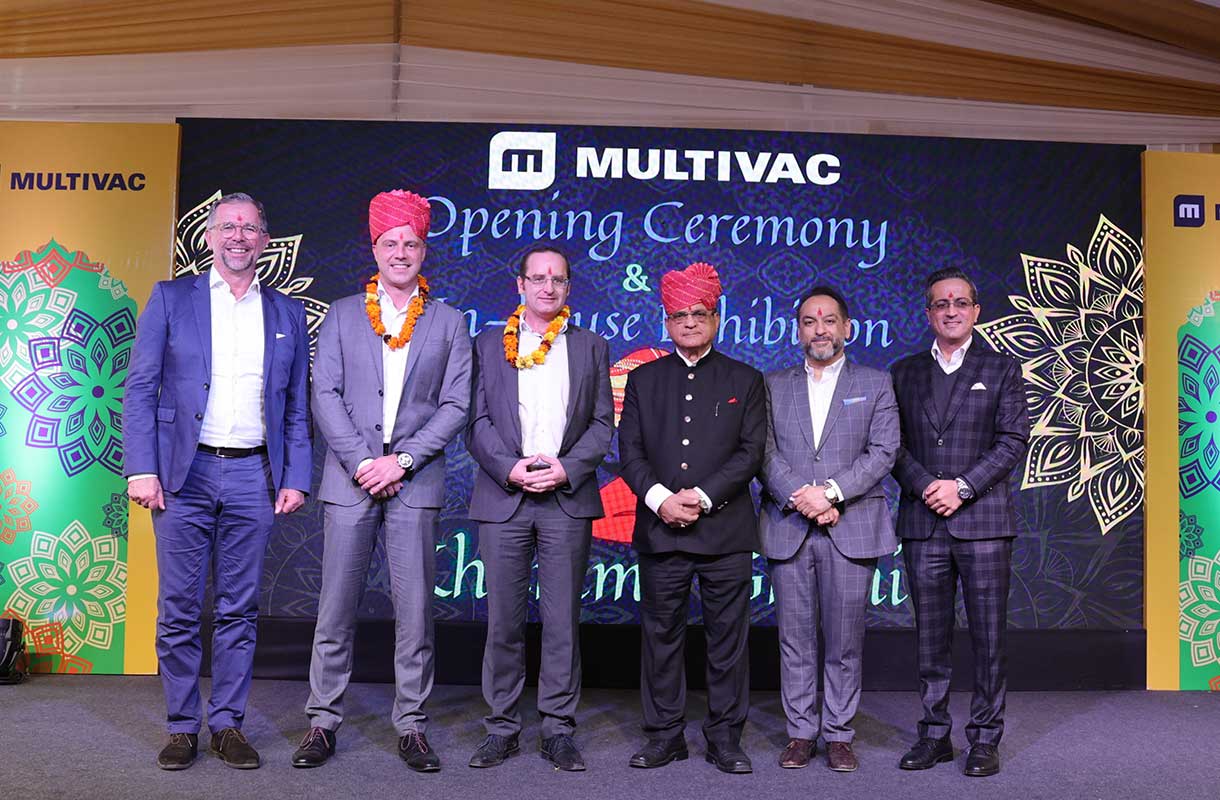

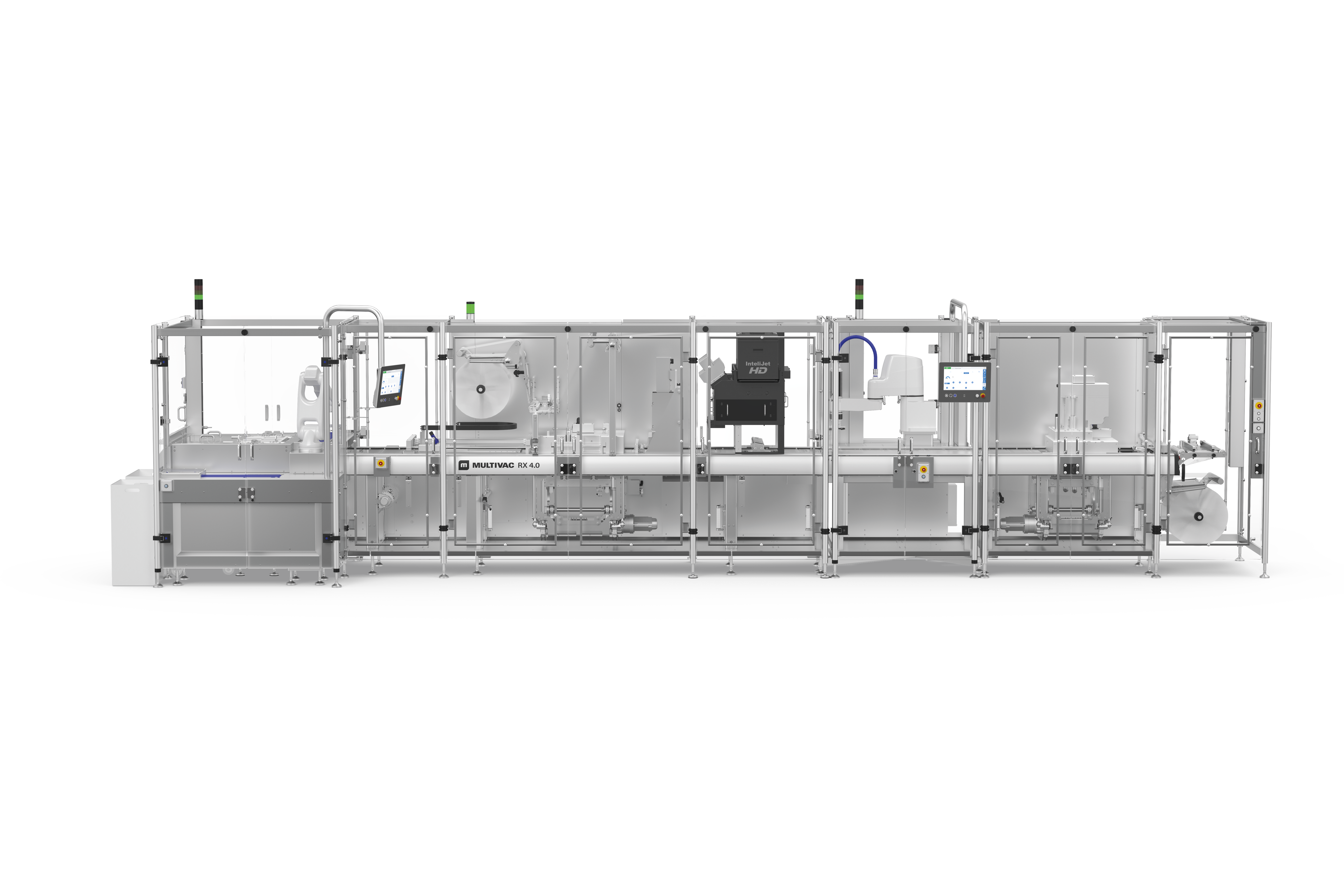

Wolfertschwenden, 06. September 2022 – A two-storey building complex with around 5,100 m² of production space on a total area of 14,400 m² - MULTIVAC is laying down a marker in Japan. The new production factory in Tsukuba, which despite the corona pandemic was opened in July 2022 as planned in the presence of MULTIVAC's joint Group Presidents, Christian Traumann and Guido Spix, is already running at full speed. In addition to the assembly hall, spare parts warehouse and attractive showroom, the heart of the investment of around 20 million euros is the state-of-the-art Test Center, which has five times the capacity of its predecessor.

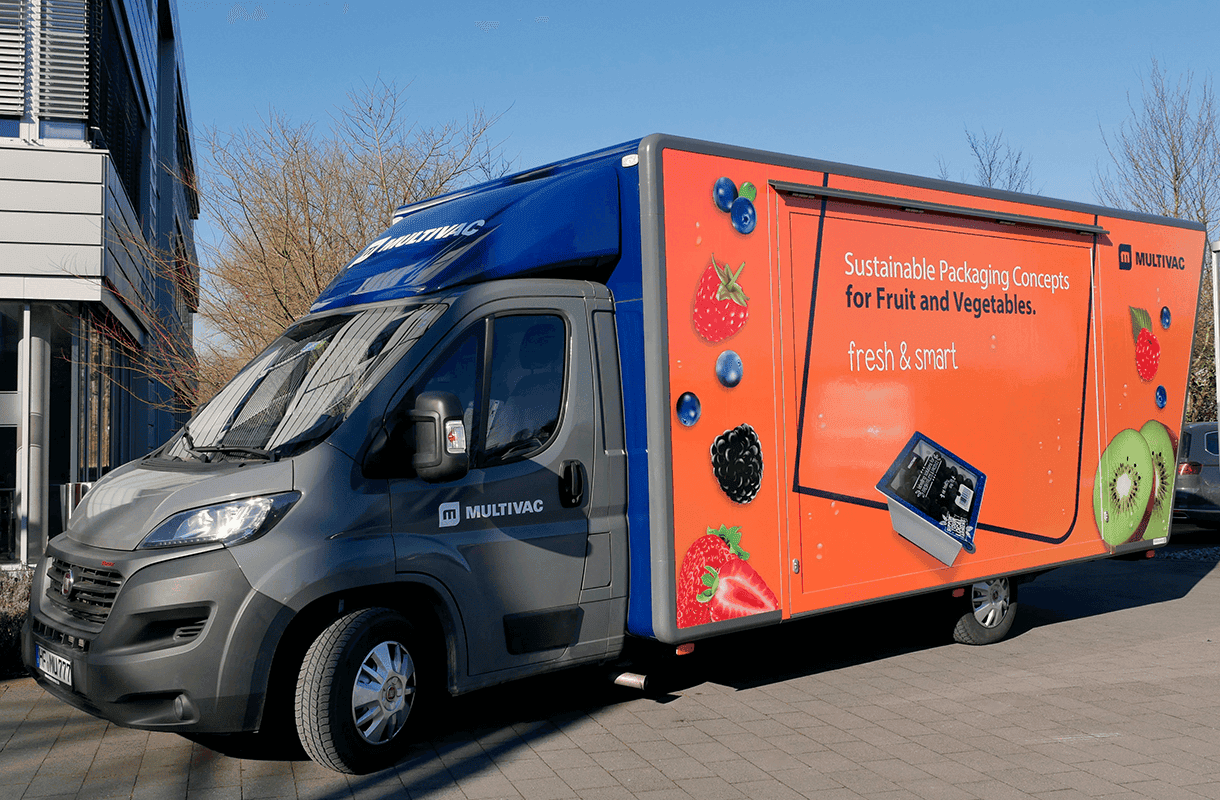

Located 60 kilometres north east of Tokyo - the brand new and highly modern production site of MULTIVAC Japan. The transport links are excellent: Just five minutes away from the main highway, and only two kilometres from the important Midorino railway station, which is served by the Tsukuba Express. An essential aspect, since the new factory is intended not just to offer extensive production areas, but also to optimise logistics and be the Training & Test Center for customers as well as a showroom.

The new site brings together two areas of production, which up to now had been separate: whereas die production had been carried out in the nearby city of Toda, assembly had been concentrated in Abiko. “In order to be able to better serve the important Japanese market, as well as fully exploit the growth potential in the area of system integration, it was necessary to have a completely new concept. Despite continuous improvement in manufacturing processes, we had reached the limits of our capacity,” explains Guido Spix.

The multifunctional building: Added value in all aspects

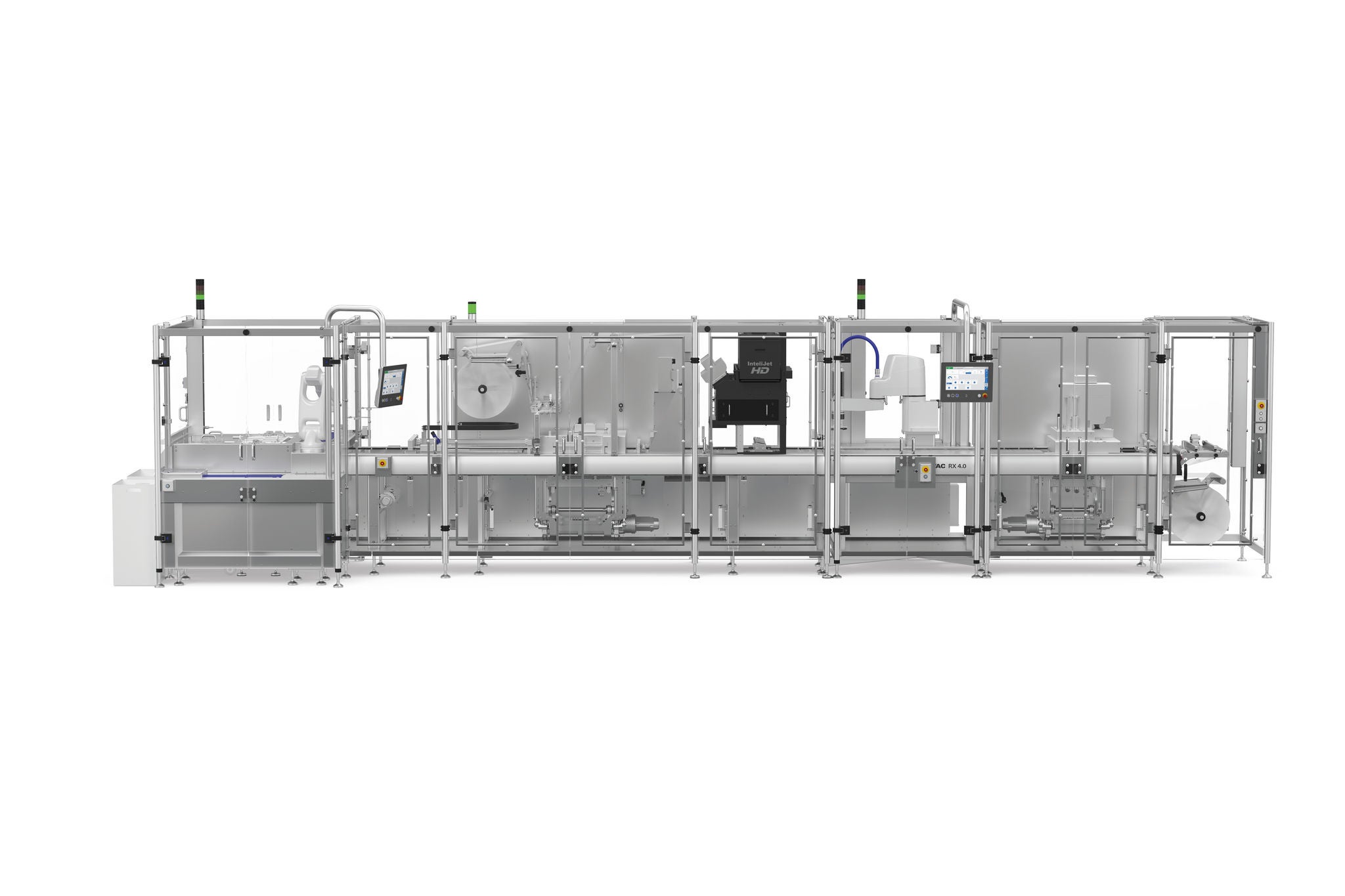

In addition to the manufacturing and assembly areas for packaging machines and line modules, the multifunctional building, which is the size of two football pitches, also has an Application & Training Center for all types of packaging and processing, as well as an Application Center for bakery technology, the so-called World of Bakery in Japan. The upper floor accommodates a small-parts warehouse, as well as a canteen and offices for the around 100 staff, and there are also meeting and training rooms.

“The whole complex offers us sufficient space for production, administration and logistics - and we also have the opportunity to train the staff of our Japanese service network to the current state of machine technology. And above all, here we can give our customers advice on every aspect of system integration, as well as demonstrate our innovative solutions to them in our showrooms,” says Kenichiro Onuma, Managing Director of MULTIVAC Japan, expressing his delight.

State-of-the-art Test Center

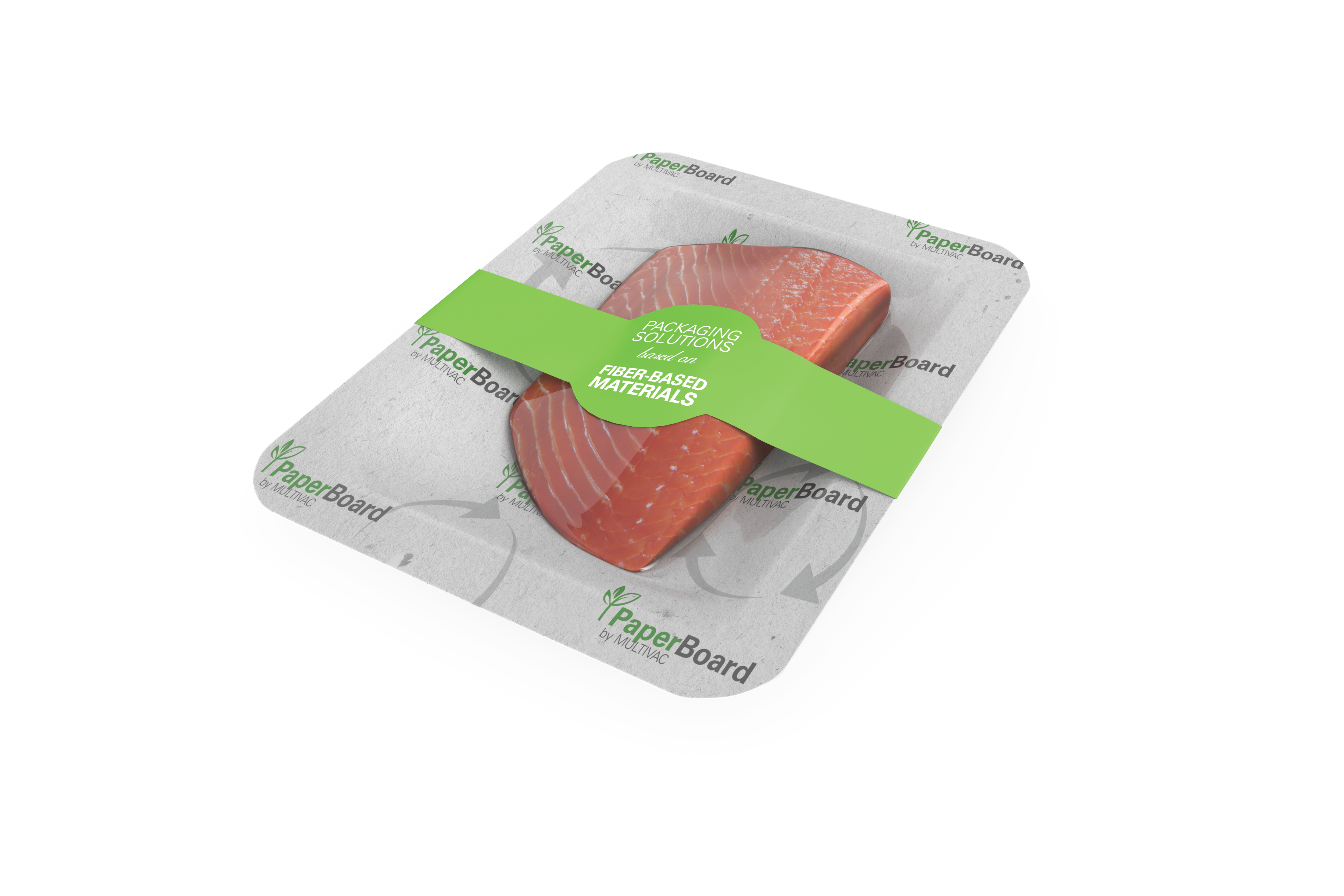

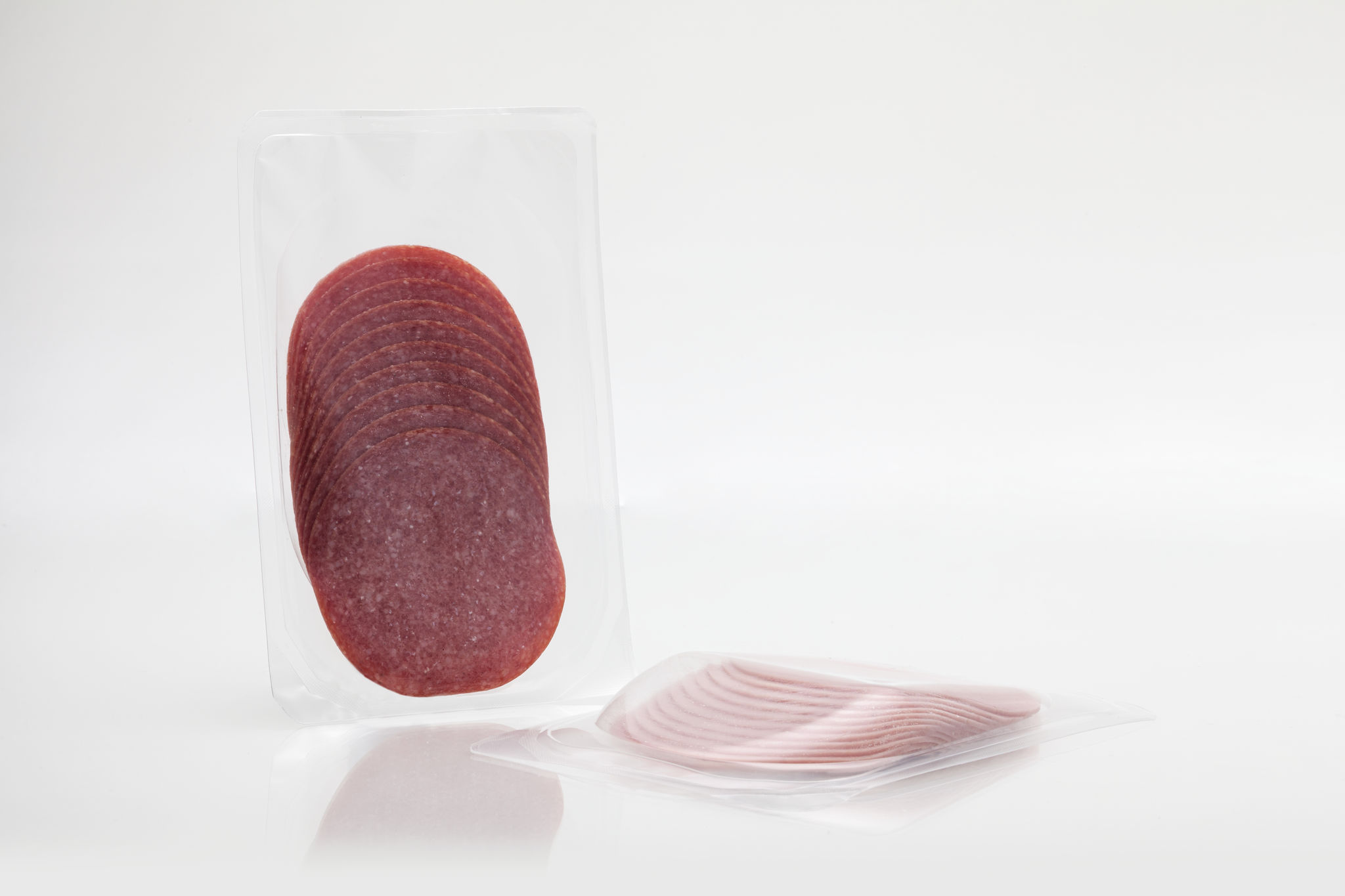

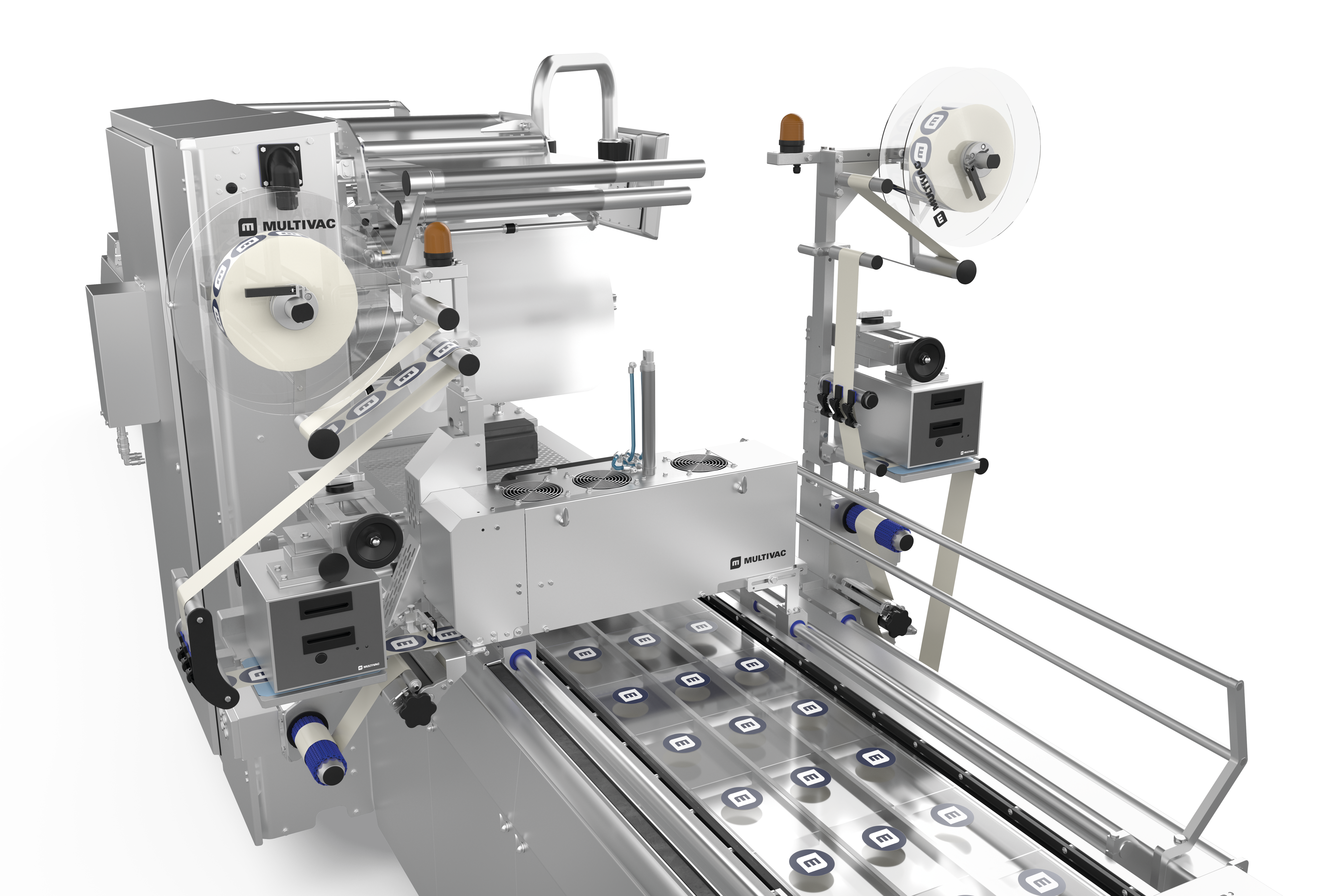

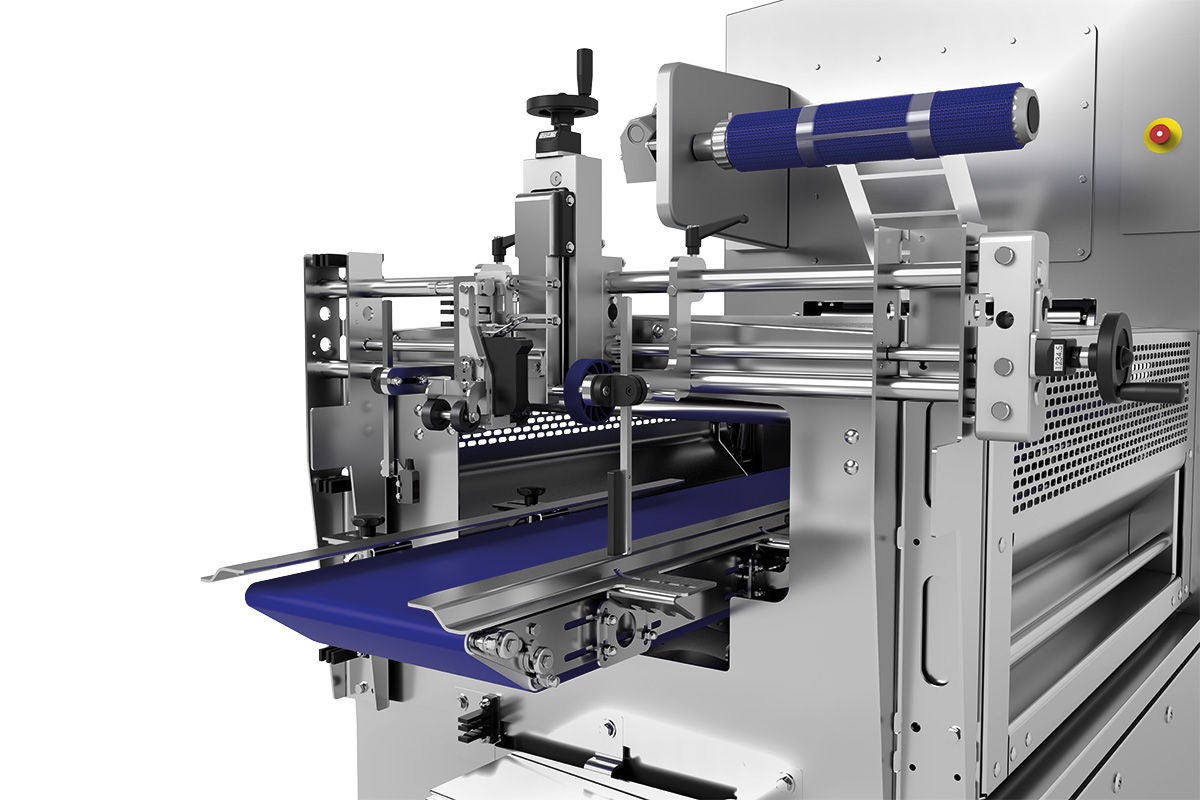

An important factor is the significantly expanded Test Center. “We Japanese place great value on healthy and high-quality food, which we have traditionally preferred to buy fresh and unpackaged. But during the corona pandemic the behaviour of consumers changed dramatically. They started to demand secure and hygienic packaging concepts, particularly for fish, vegetables, meat, bakery products and convenience foods, which offer consumers the best possible protection for the product, and which enable the food to be easily cooked at home. This can for example be achieved particularly well with MAP solutions, the Modified Atmosphere Packaging applications provided by MULTIVAC. Here the natural atmosphere in the pack is replaced with a gas mixture, which is matched to the product in order to maintain its form, colour and freshness, and therefore also to extend the shelf life of the product. This is important, because there is a much greater negative impact on the environment from food, which must be destroyed if it no longer has the shelf life and taste or nutritional properties. As a result of this, there has been a significant rise in demand for MULTIVAC packaging machines, given the comprehensive advice and support we are able to provide,” says the Chairman of MULTIVAC Japan, Tetsushi Hata.

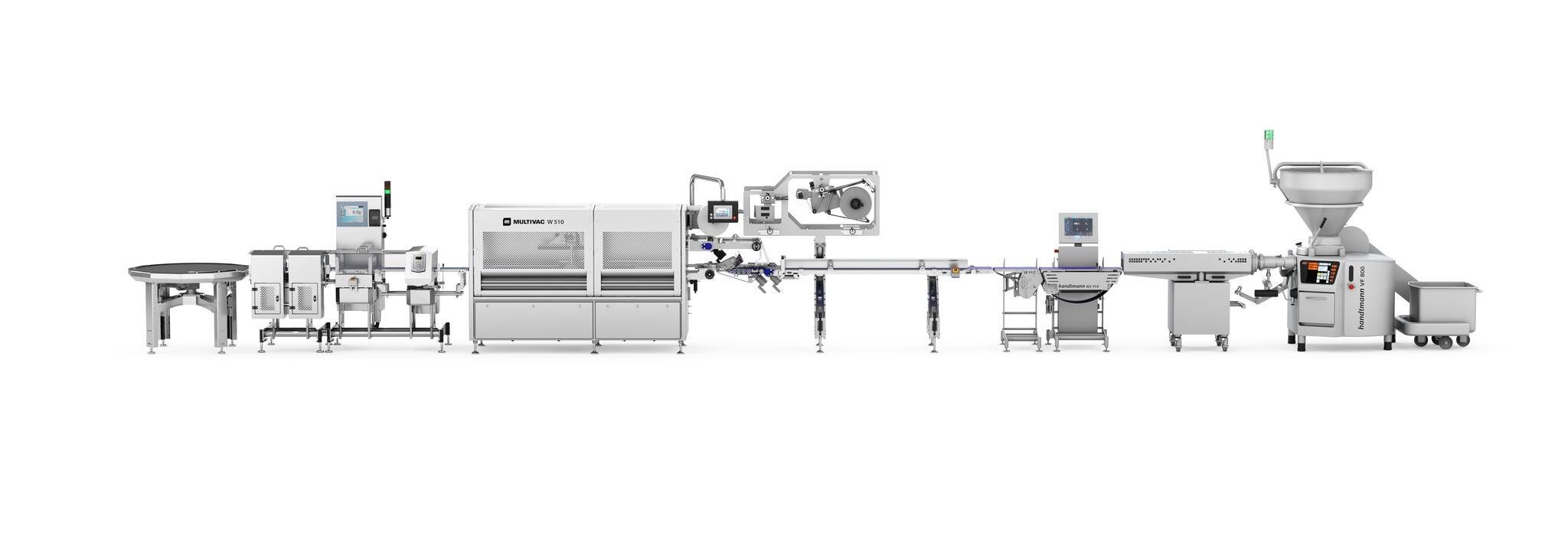

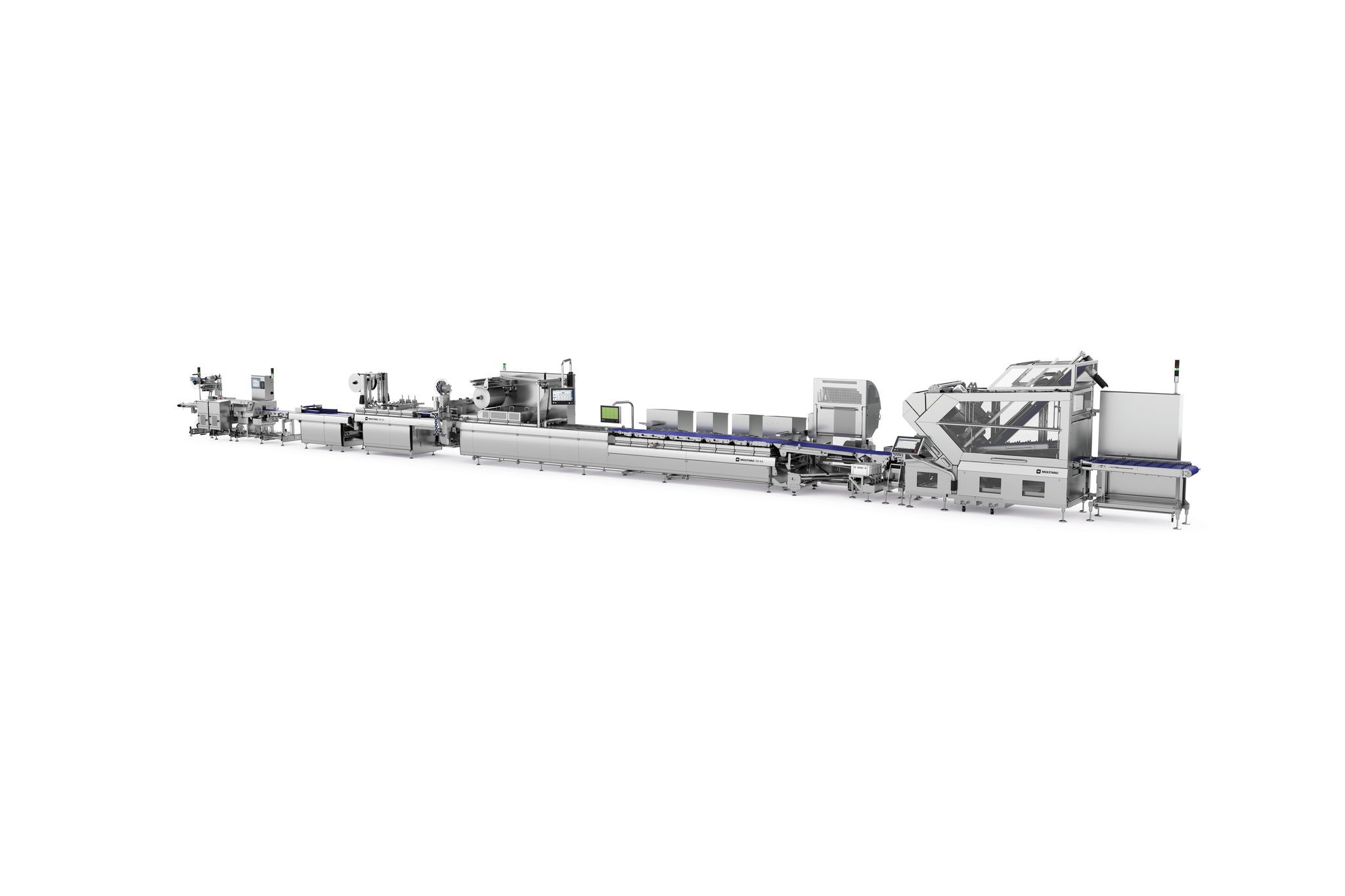

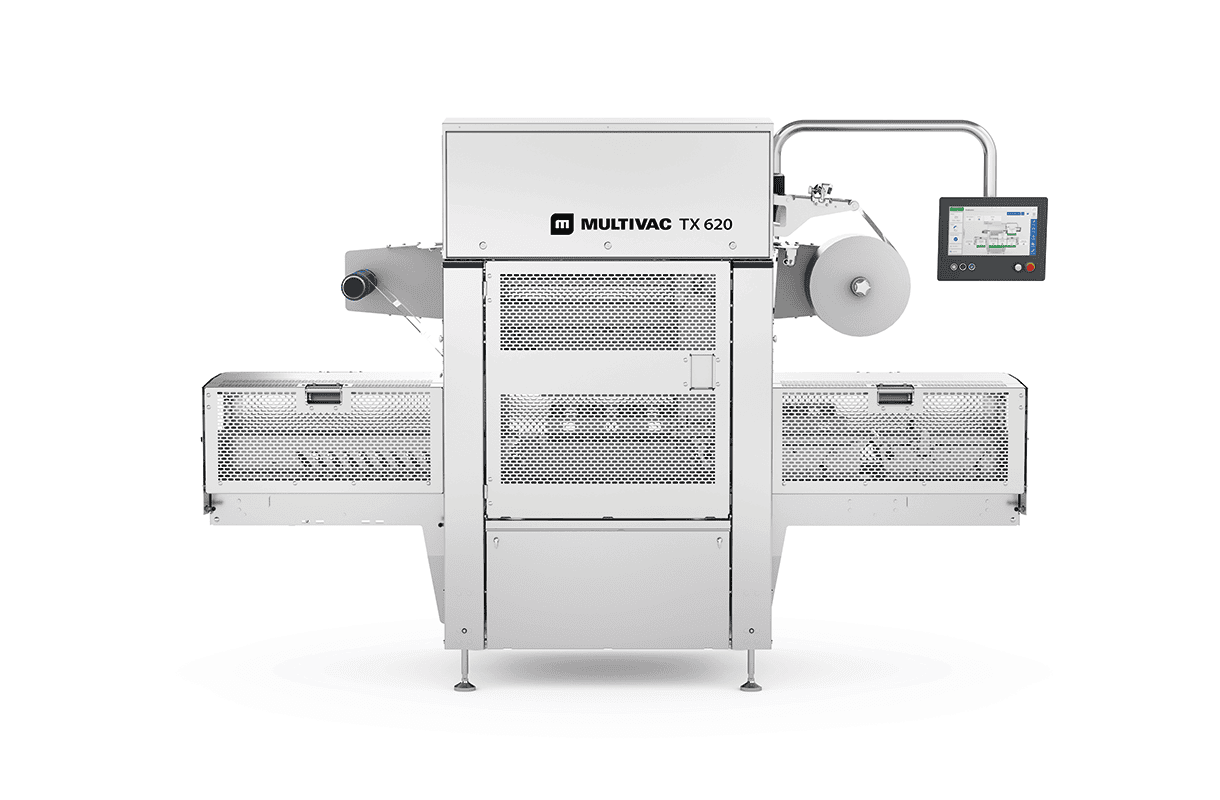

In addition to the latest thermoforming packaging machines, traysealers and slicers from MULTIVAC, the Test Center also includes bakery equipment from FRITSCH and portioning machines from TVI, which are all available for test purposes and sample production. The temperature range for processing and packaging customers' products can be matched to the production environment at the customer, so that tests can be carried out under real conditions - whether on single machines or complete lines.

Latest News

2327146963

2327146963

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com