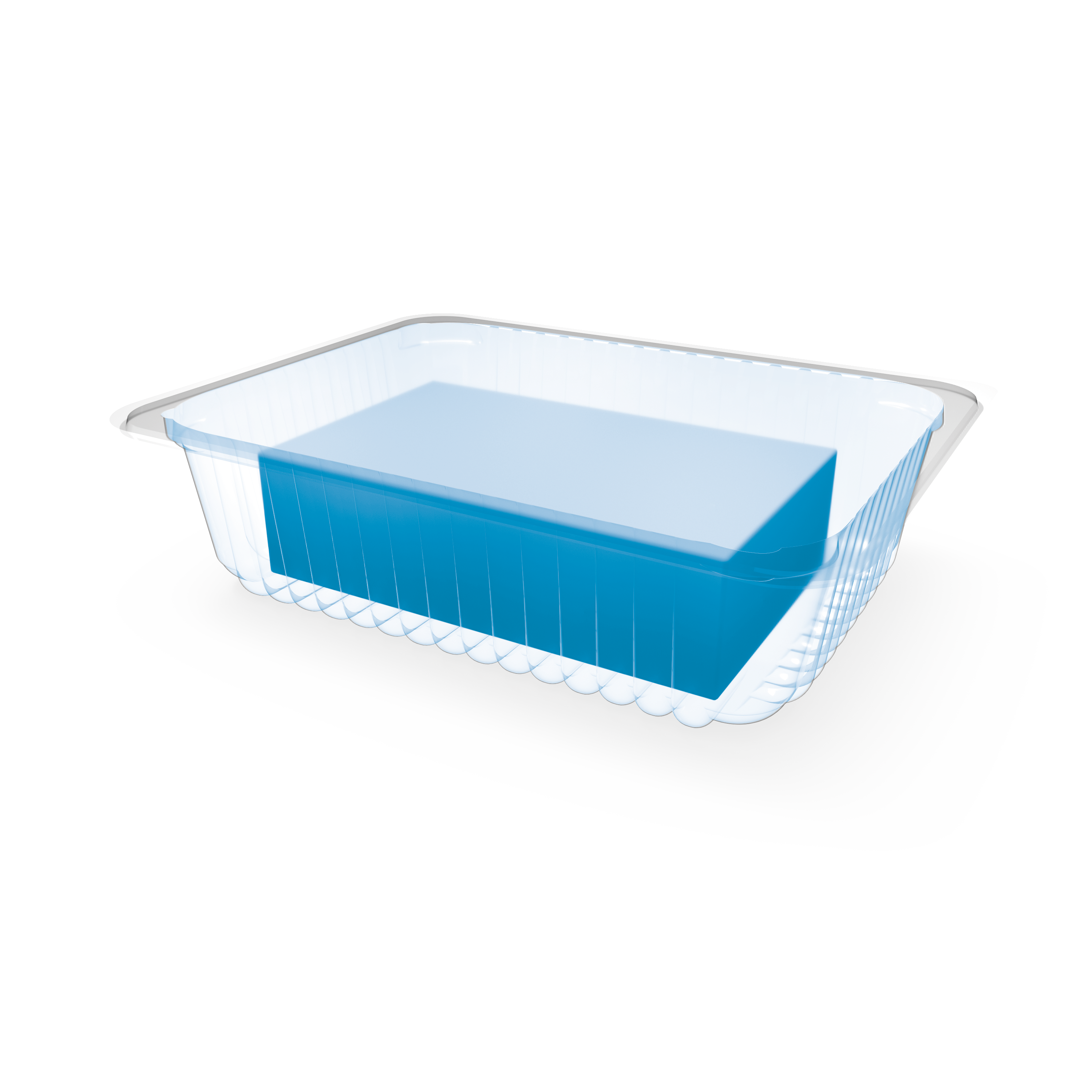

MAP ensures the right atmosphere

Your product needs its own "feel-good" environment to maintain its color, shape, and freshness. Therefore, the natural atmosphere is replaced with a modified atmosphere ideally matched to your product - without additional chemicals. This modified atmosphere generally consists of carbon dioxide, nitrogen, and oxygen.

We focus on high-quality packaging that guarantees gas-tightness to maintain this atmosphere—preventing the protective atmosphere from escaping and oxygen, moisture, or unwanted flavors from penetrating the package. Our laminated films are also optimized for sealability to ensure reliable sealing during transport and at POS.

Modified atmosphere packs

Modified atmosphere packs

The many benefits of MAP

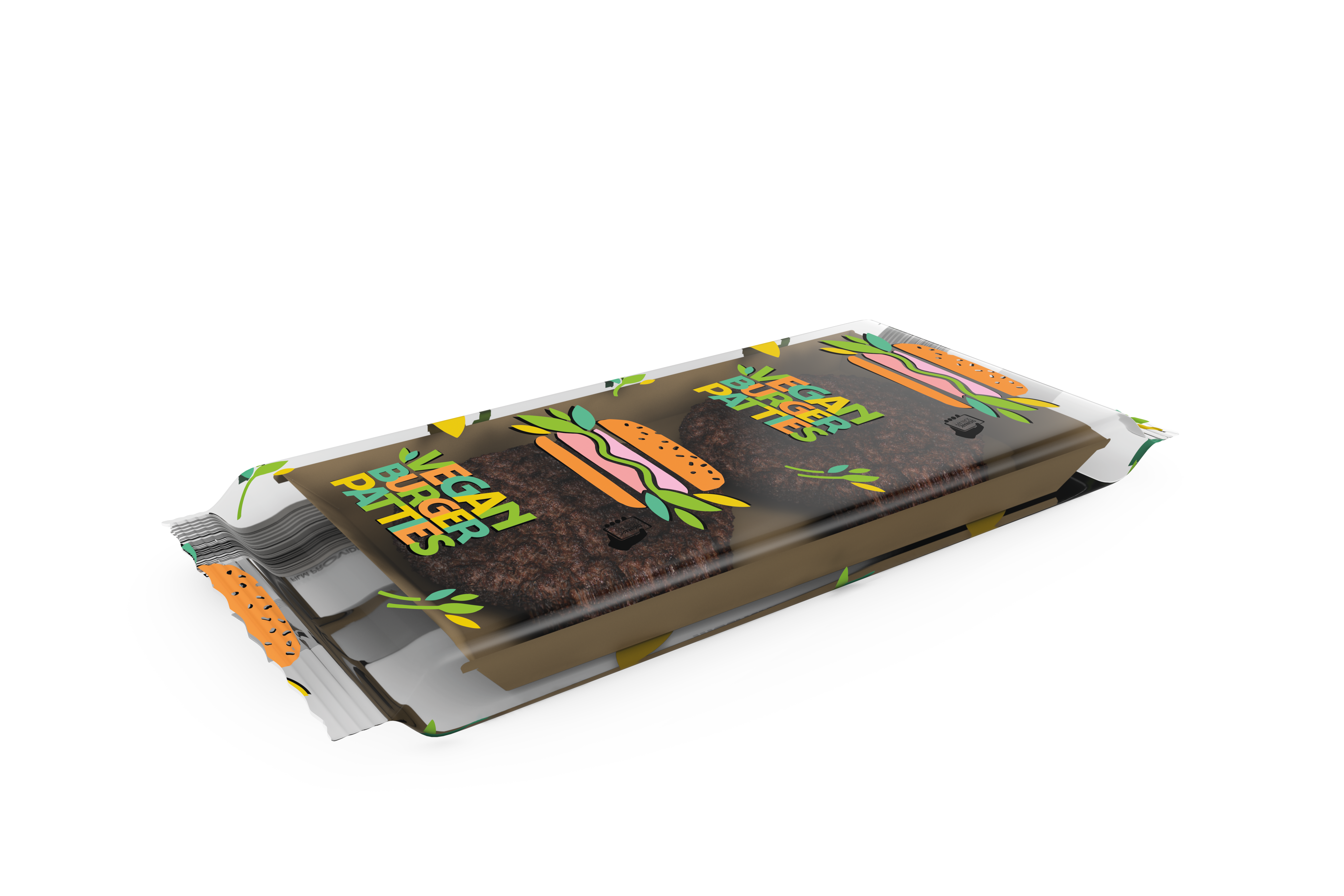

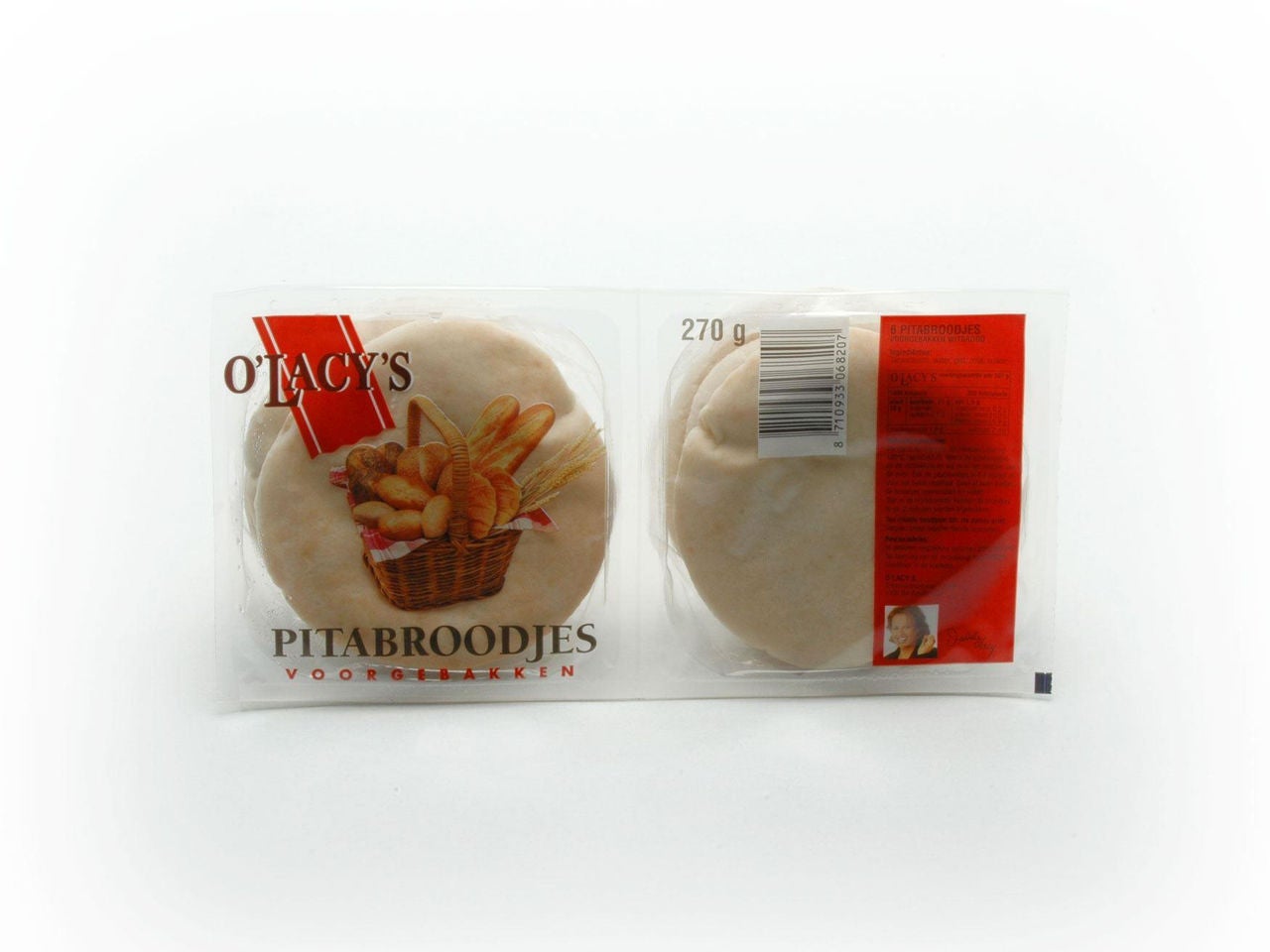

Fresh foods and products containing protein, bread, and other baked goods will benefit from packaging with a modified atmosphere (MAP). Additionally, products from the medical sector, bio-products, and other technical products will benefit from the protective properties of MAP packs.

Do you have special requirements in terms of shelf life and product safety? Discover the many advantages of MULTIVAC's MAP packaging:

- Extended shelf life and product safety, maintaining the best-before date and reducing food waste

- Improved handling and transport protection of the product

- No other chemicals or additives

- Attractive presentation at POS thanks to high-quality visual appearance, texture, and product information

- Avoiding corrosion in the case of industrial or consumer products

- Protection of sensitive medical products

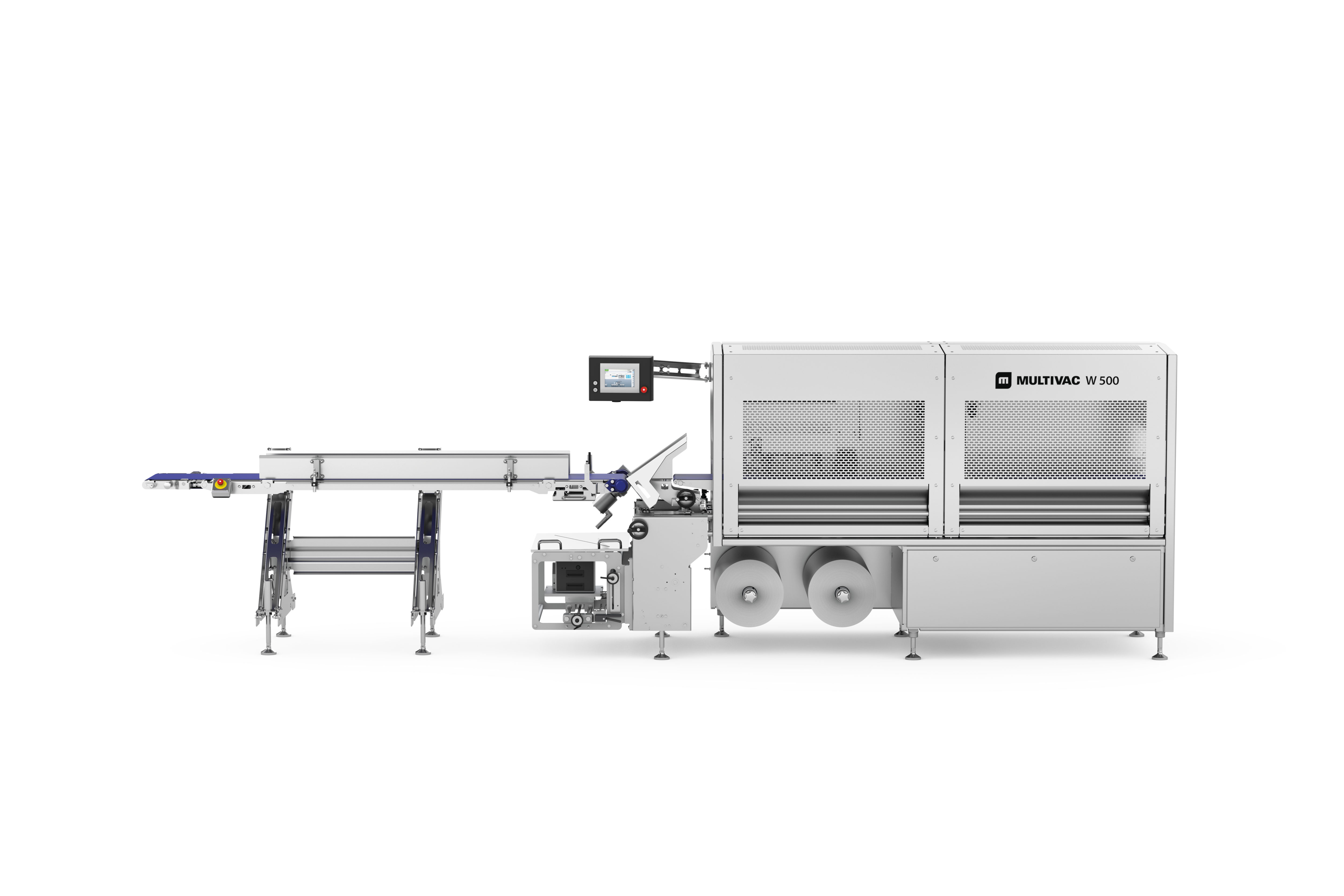

Thermoforming packaging machines, traysealers, flowpackers, and chamber machines from MULTIVAC can be used to produce MAP packs.

Suitable for these sectors

Suitable machines and films

Suitable machines

MULTIVAC Packaging Machine Close-Up View

MULTIVAC Packaging Machine Close-Up View

MULTIVAC T710 Packaging Machine Front View

MULTIVAC T710 Packaging Machine Front View

MULTIVAC Packaging Machine VS500

MULTIVAC Packaging Machine VS500

EMAP atmosphere maintains the balance

It is microperforations, which use EMAP technology to exchange the atmosphere between the pack and the environment - and this enables an ideal equilibrium atmosphere to be generated. Without using preservatives, you can extend the shelf life of your products and improve safety.

Get to know the EMAP advantages

Fresh fruit and vegetables are best kept in their ambient atmosphere. EMAP packs are the right choice. For ensuring the equilibrium atmosphere within the pack, the FreshSAFE technology offers the most reliable solution. This system is integrated with a perforator in the packaging line of thermoforming packaging machines. The film is perforated during the packaging process. This means that you can process your standard film and do not store perforated film. This saves costs and increases your flexibility. You can also of course use directly perforated film on the packaging.

In addition, you benefit from other advantages:

Extended shelf life for packaged products without using preservatives

A reduction in food wastage

Improved handling protection and stackable packs for more efficient transport and reduction of the carbon footprint

Attractive presentation at the point of sale

A wide variety of packaging

MULTIVAC Packaging for Juicy Cut Meat Products

MULTIVAC Packaging for Juicy Cut Meat Products

MULTIVAC Packaging Baklava Pastry Sheets Display

MULTIVAC Packaging Baklava Pastry Sheets Display

MULTIVAC Packaging Chiquita Fresh Cut Fruit Tray

MULTIVAC Packaging Chiquita Fresh Cut Fruit Tray

MULTIVAC Packaging for Meaty Bone Chew-lotta Dog Treats

MULTIVAC Packaging for Meaty Bone Chew-lotta Dog Treats

MULTIVAC Packaging Valio Mustaleima Cheese Pack

MULTIVAC Packaging Valio Mustaleima Cheese Pack

MULTIVAC Packaging Fresh Bread Rolls Display

MULTIVAC Packaging Fresh Bread Rolls Display

MULTIVAC Packaging Fresh Whole Chicken Display

MULTIVAC Packaging Fresh Whole Chicken Display

MULTIVAC Packaging Fresh Cut Melon Display

MULTIVAC Packaging Fresh Cut Melon Display

MULTIVAC Packaging for Menzies Demi Baguettes

MULTIVAC Packaging for Menzies Demi Baguettes

MULTIVAC Packaging Fresh Sliced Salami Display

MULTIVAC Packaging Fresh Sliced Salami Display

MULTIVAC Packaging Atria Kalkkuna Filee Turkey

MULTIVAC Packaging Atria Kalkkuna Filee Turkey

MULTIVAC Packaging Cheddar Style Wedge Display

MULTIVAC Packaging Cheddar Style Wedge Display

MULTIVAC Packaging Sliced Ham Vacuum Sealed

MULTIVAC Packaging Sliced Ham Vacuum Sealed

MULTIVAC Packaging Fresh Swiss Veal Slices

MULTIVAC Packaging Fresh Swiss Veal Slices

MULTIVAC Packaging Bärchen-Wurst Sausage Delight

MULTIVAC Packaging Bärchen-Wurst Sausage Delight

MULTIVAC Packaging Malongo Espresso Coffee Pods

MULTIVAC Packaging Malongo Espresso Coffee Pods

MULTIVAC Packaging CurryMax Sausage Product Display

MULTIVAC Packaging CurryMax Sausage Product Display

MULTIVAC Packaging Pita Bread 270g

MULTIVAC Packaging Pita Bread 270g

MULTIVAC Packaging Zwiebel-Mettwurst Wellness Product

MULTIVAC Packaging Zwiebel-Mettwurst Wellness Product

MULTIVAC Packaging BiFi Poultry Snack Sticks 4-Pack

MULTIVAC Packaging BiFi Poultry Snack Sticks 4-Pack