TVI wins the “Fleischer-Handwerk Award 2022”

16/05/2022

And the winner is… TVI!

Bruckmühl (Germany), May 15, 2022 – Quality, innovative strength, and above all, a passion for meat – this is what TVI is all about, portioning at its best. The latest product development from the Bruckmühl-based specialists has just been honored with a coveted award. This year, the Fleischer-Handwerk Award 2022 (Butcher’s Trade Award 2022) in the category of processing machines is going to TVI. The winner: the universal GMS 400 portioning machine. The worldwide unique, attractively priced entry-level model represents a milestone in terms of cost-effectiveness and resource efficiency. It also enables small and medium-sized producers to automatically portion fresh meat with maximum flexibility, portioning quality and yield. The award ceremony took place on May 15 at the IFFA in Frankfurt.

The award from the two renowned industry magazines – Fleischer-Handwerk and Fleischerei-Technik – is being presented for the eighth time. A distinguished jury honors practice-oriented developments, technologies and services in meat and sausage processing that stand out with the sustainable benefits they deliver for the processing company and the product quality.

This year, TVI is among the fortunate winners. With its innovative GMS 400, the specialist in the field of weight-accurate food portioning enables high-tech and affordable portioning with 3D forming for medium-sized companies – for the very first time. Significant savings potential, maximum flexibility, quality and efficiency, and especially a resource-saving process: “Better Portioning” – in the best TVI tradition.

Highest portioning quality

Portioning is a decisive factor behind the cost-effective production of fresh meat. Not only costs are incurred here, but product quality and resource efficiency are especially decisive. TVI’s high-performance compact model ideally meets all these requirements: It can process virtually any type of meat and perform a wide variety of portioning tasks. From pork tenderloin to beef topside, from roast cuts to carpaccio – the GMS 400 gives any starting product a uniform shape and ensures visually appealing portions. “Our latest multitalented machine is the first in the world in this price and performance category to enable flexible shaping and weight-accurate portioning in a single process step,” affirms Alois Allgaier, Managing Director of TVI Entwicklung und Produktion GmbH.

Maximum flexibility

... is the ultimate requirement, especially for medium-sized companies. And the universal portioner from TVI is ideally equipped to meet today’s challenges. Because its three-dimensional shaping options adapt to any raw product and bring even the most varied cross-sections and consistencies into uniformly perfect shape. Thick or thin, large or small, bone-in or non-bone-in, smoked or cooked – the GMS 400 cuts almost anything in slice thicknesses ranging from two to 50 mm. A wide variety of products can be handled with just a few sets of dies – in the blink of an eye and without tools.

Highest yield

Operational profitability is determined primarily by how efficiently the valuable meat resource is handled. By optimizing the shaping and dividing of the meat pieces, the GMS 400 can increase yield to a maximum. If desired, it is even possible to portion the meat entirely without residues. If the portions are intended for an equalized, fixed-weight pack, the give-away can also be reduced to a minimum.

Simple operation

The TVI portioner also sets standards in terms of ease of operation. It can be operated effortlessly and intuitively with a minimum of manpower. The pieces of meat are inserted into a drawer from the side – much more ergonomically than when the machine is loaded from above. The process begins as soon as the drawer is inserted into the machine. In a first step, the product is perfectly shaped and measured in three dimensions. In the next step, it is portioned – free of residue and with minimal cut-off. The feed and stop plate determine the slice thickness in accordance with the target weight. The portions are then discharged via a conveyor belt at an ergonomic height and fed to the downstream process.

The GMS 400 is also line-compatible with other TVI modules and communicates with any TVI auxiliary equipment, such as the checkweigher.

With a real sustainability advantage

Thanks to the outstanding portioning technology, the valuable raw product is used optimally and processed without unnecessary residue. Neither compressed air nor cooling water are required to operate the GMS 400. And with regular maintenance, customers can count on a long service life for the machine. TVI therefore supports medium-sized companies in terms of sustainability and makes an important contribution to an improved CO2 footprint.

Return on investment

The GMS 400 is a solution that targets medium-sized meat processing companies. While the optimum raw material yield quickly provides them with enormous savings potential, they can remain flexible and produce more quickly, more efficiently in terms of personnel, more consistently, and always in outstanding quality. This means that the investment decision pays off within a very short time. In beef processing, for example, the return on investment – depending on production volume – is less than one year.

Awards ceremony

The awards ceremony took place at the Frankfurt exhibition center on May 15 at 2 p.m. on the stage of the IFFA Factory in Hall 11.1. Alois Allgaier, Managing Director of TVI Entwicklung und Produktion GmbH, accepted the coveted industry award on behalf of the entire TVI team.

Latest News

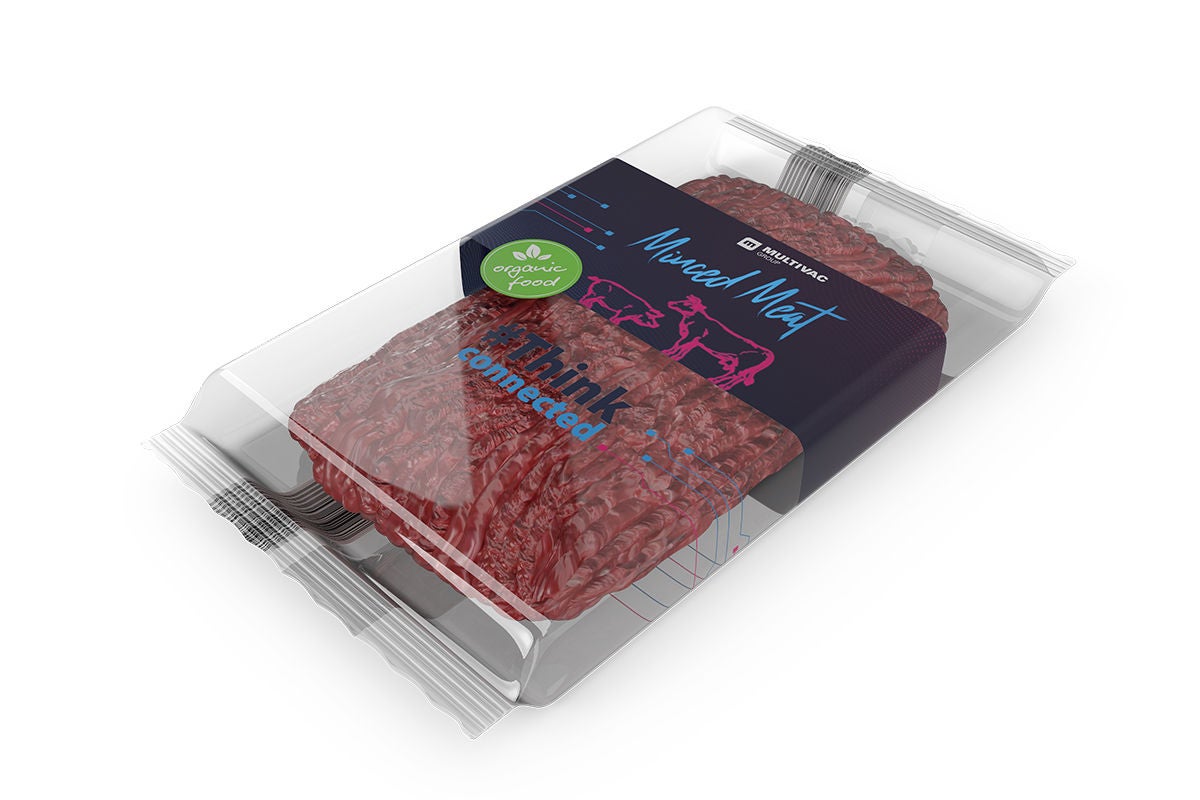

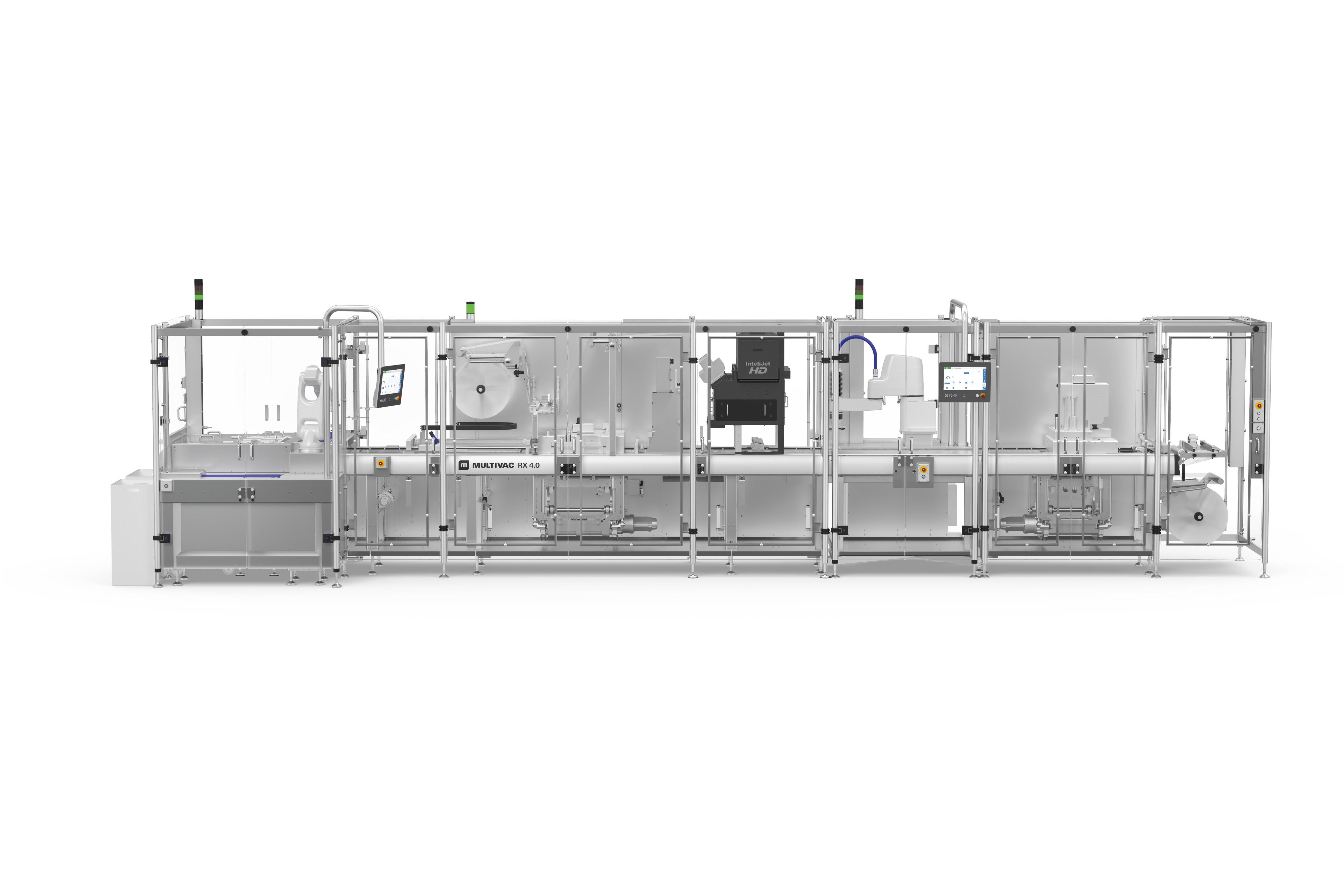

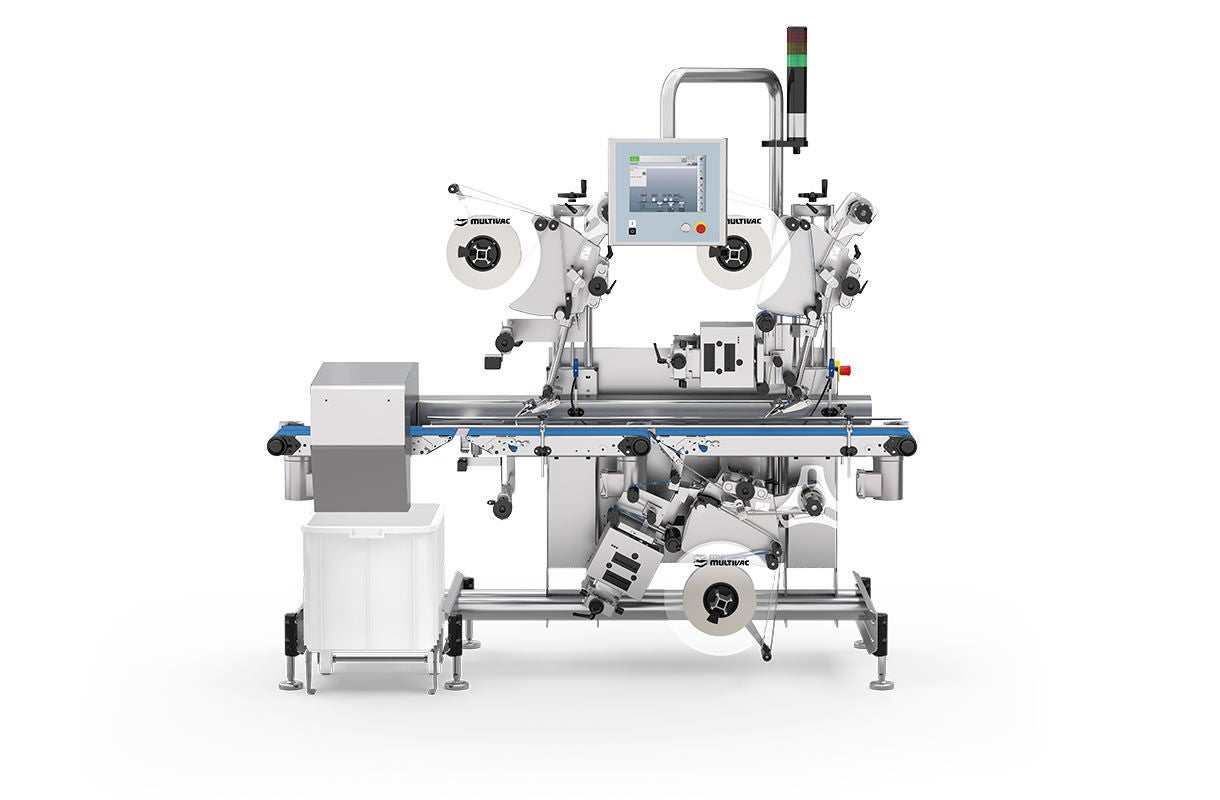

MUMI_Produktabbildung.indd

MUMI_Produktabbildung.indd

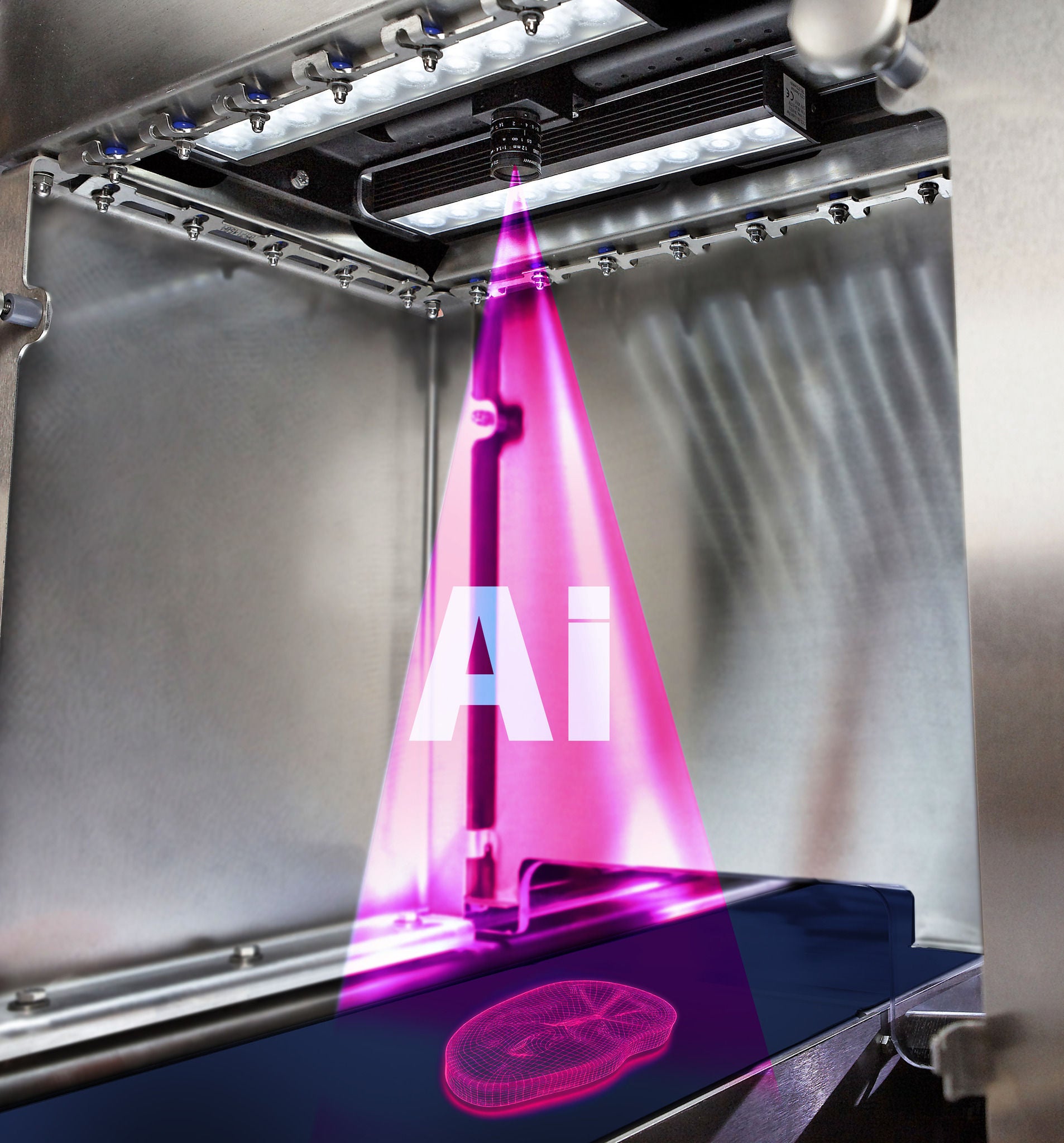

2327146963

2327146963

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

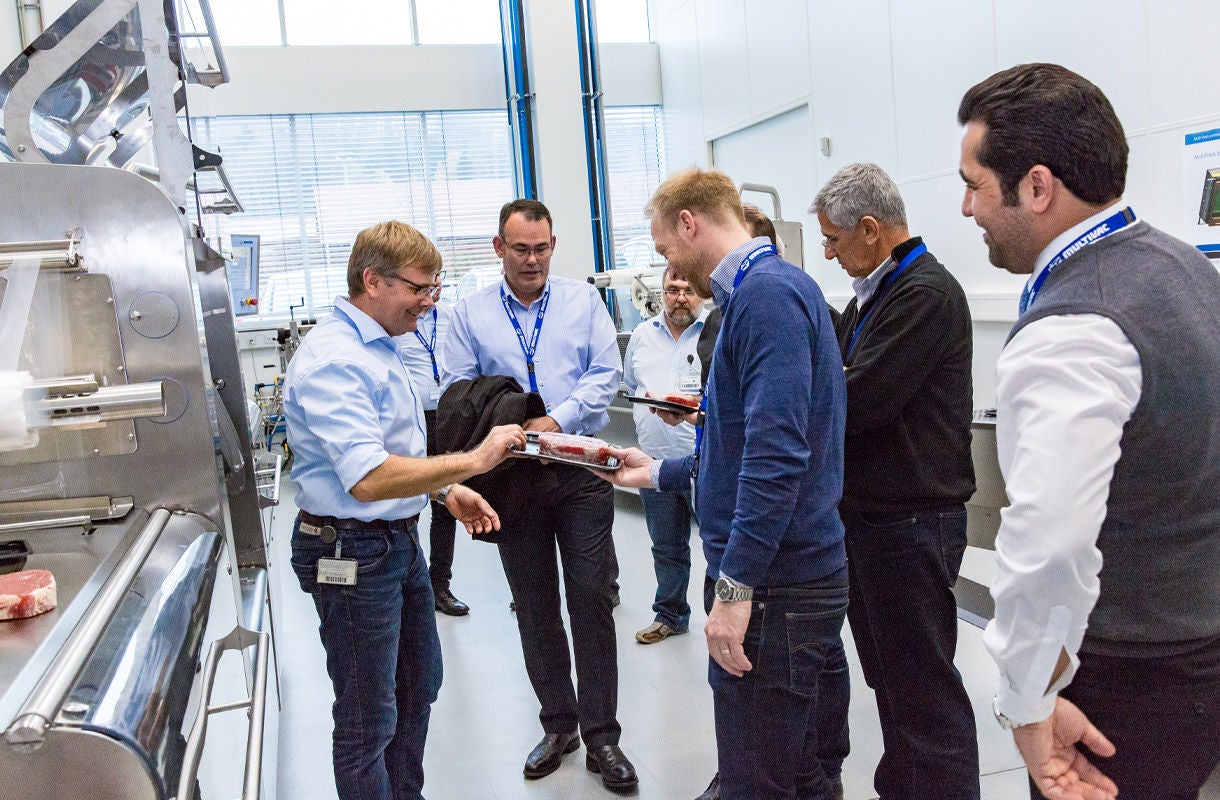

Business Team Meeting Group Photo

Business Team Meeting Group Photo

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

Conference Presentation with Audience

Conference Presentation with Audience

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

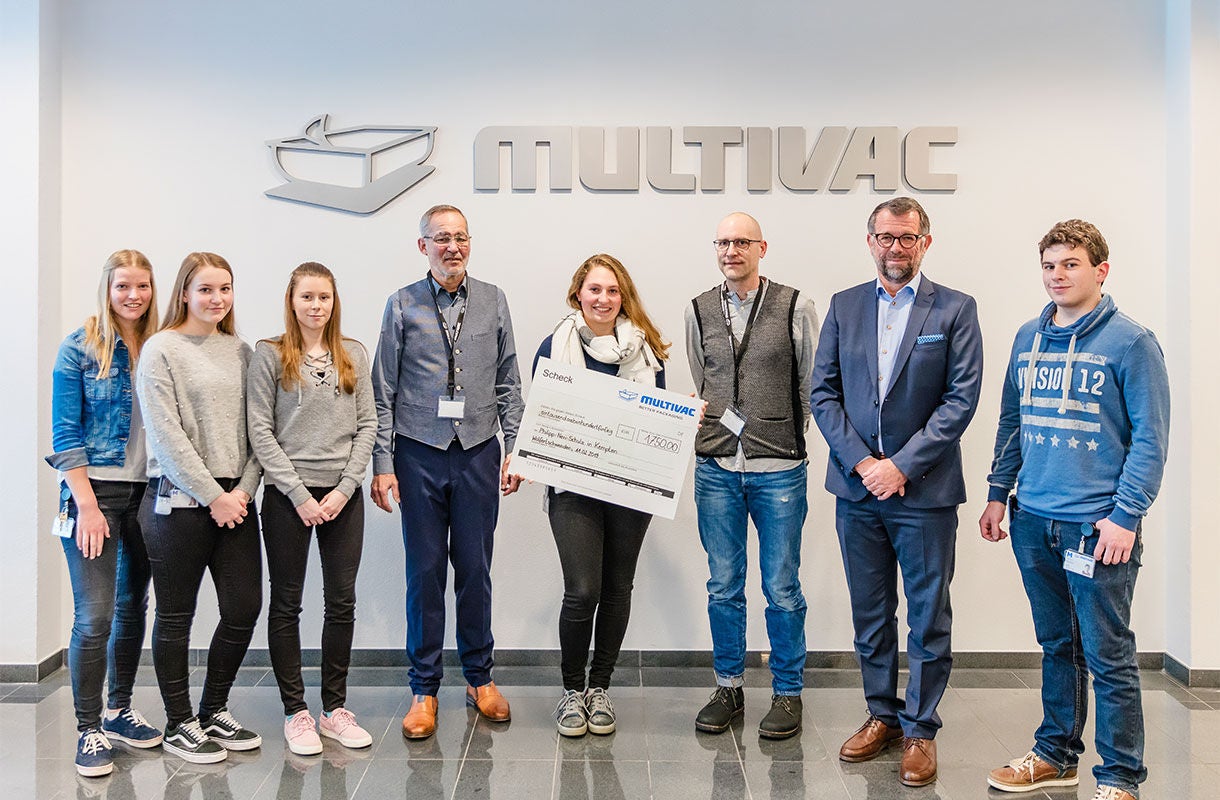

Group Holding Donation Checks Event

Group Holding Donation Checks Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

Modern Conference Room with Presentation Screen

Modern Conference Room with Presentation Screen

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

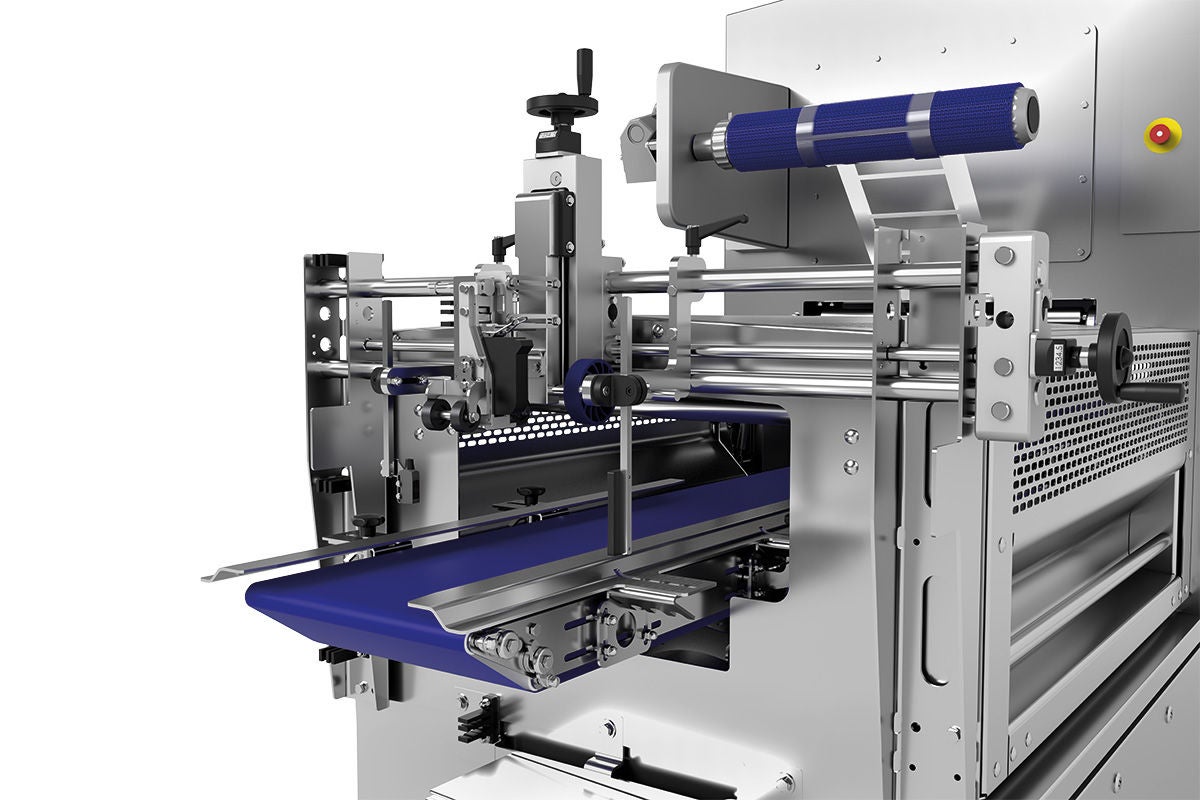

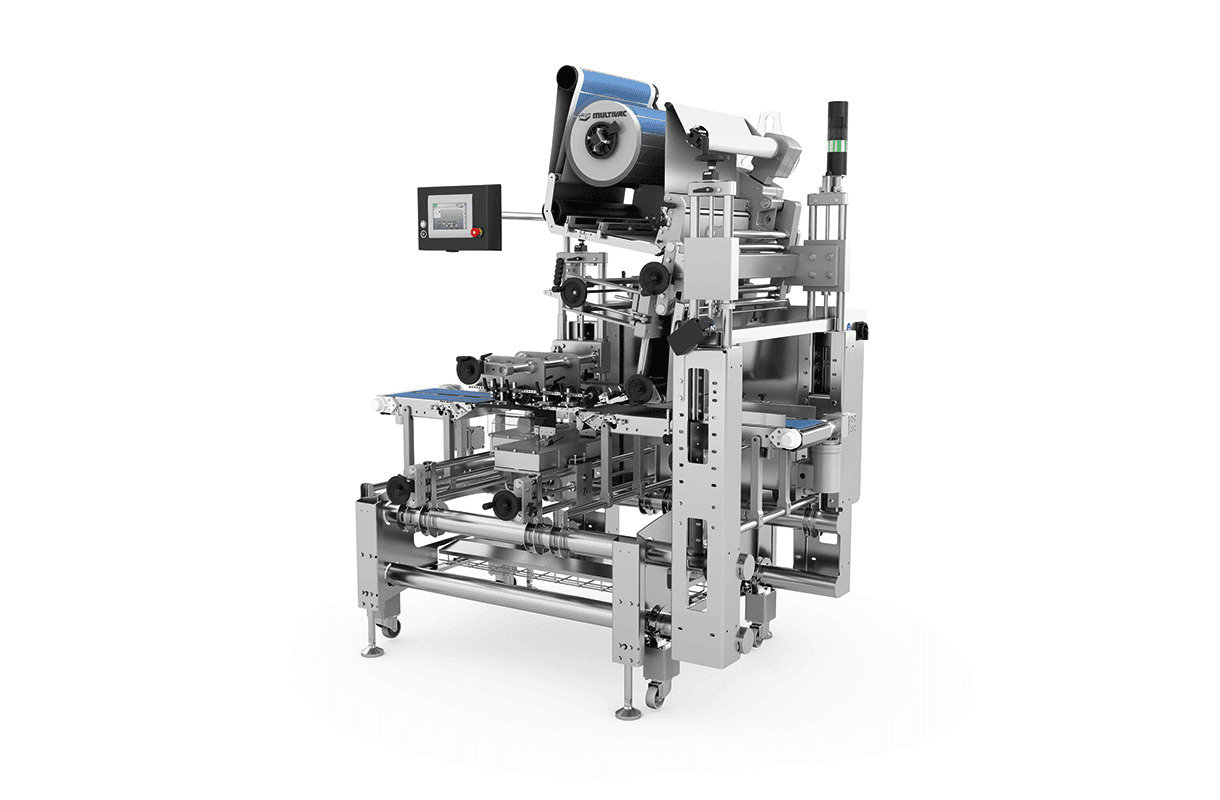

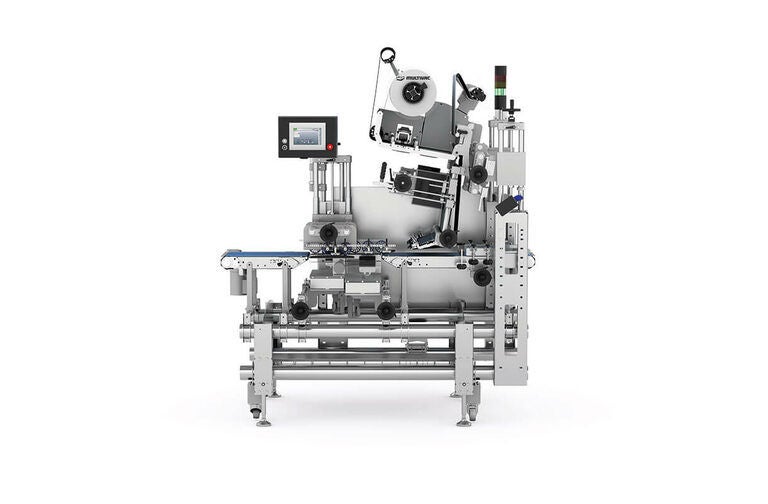

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC PDF

MULTIVAC PDF

MULTIVAC PDF

MULTIVAC PDF

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

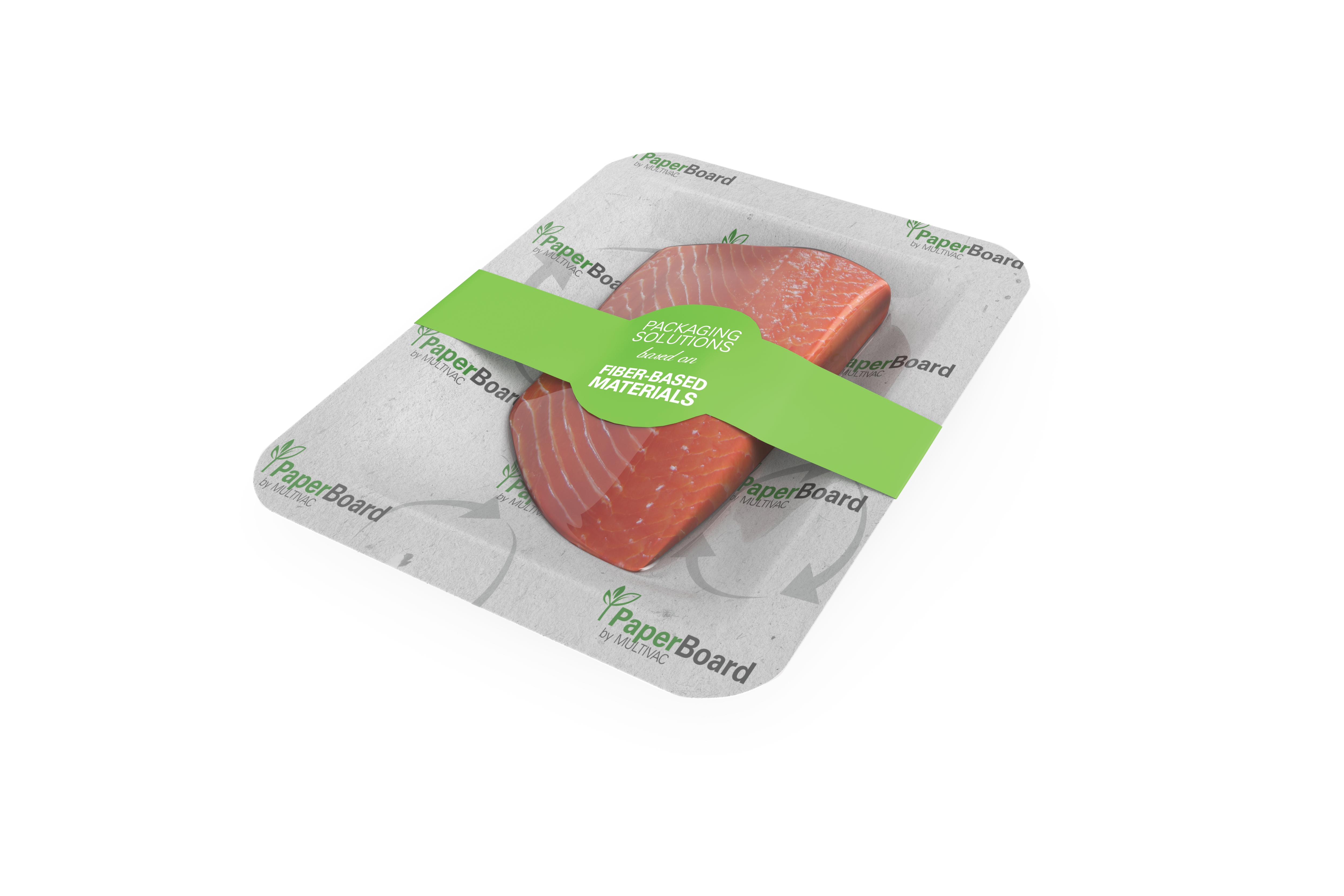

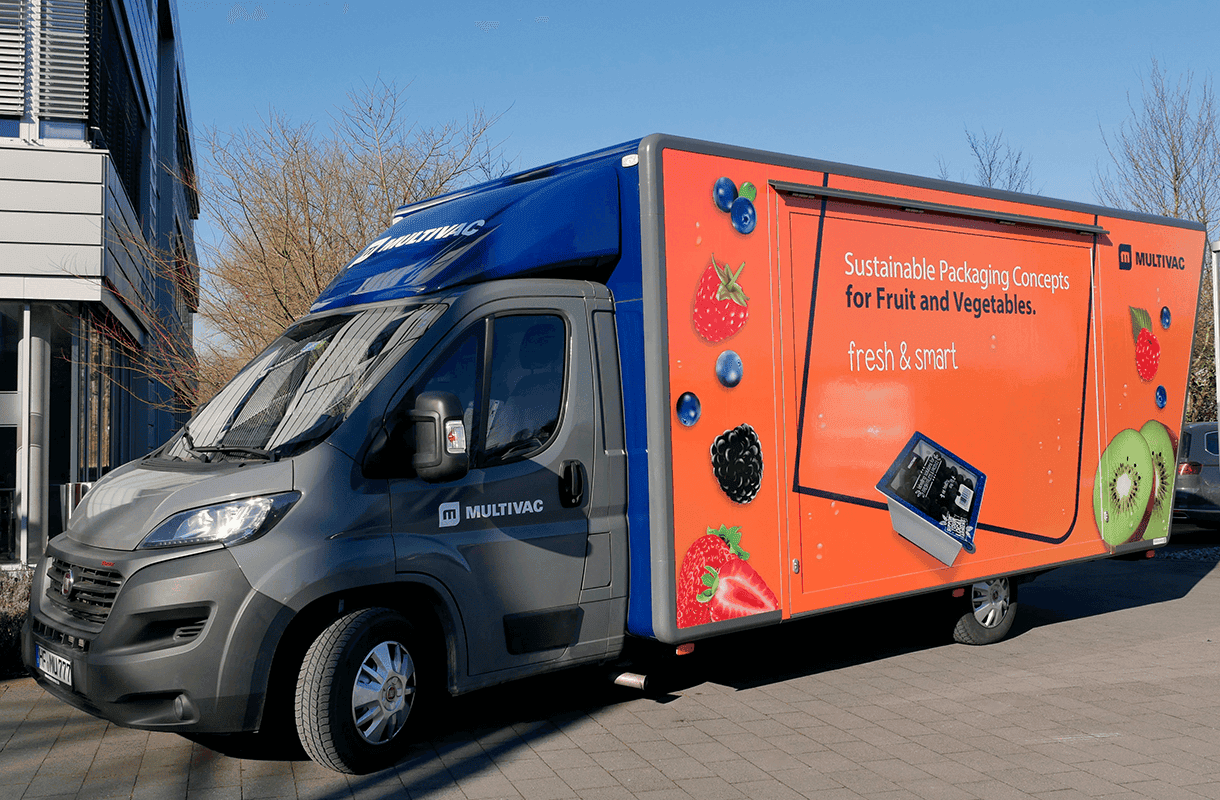

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

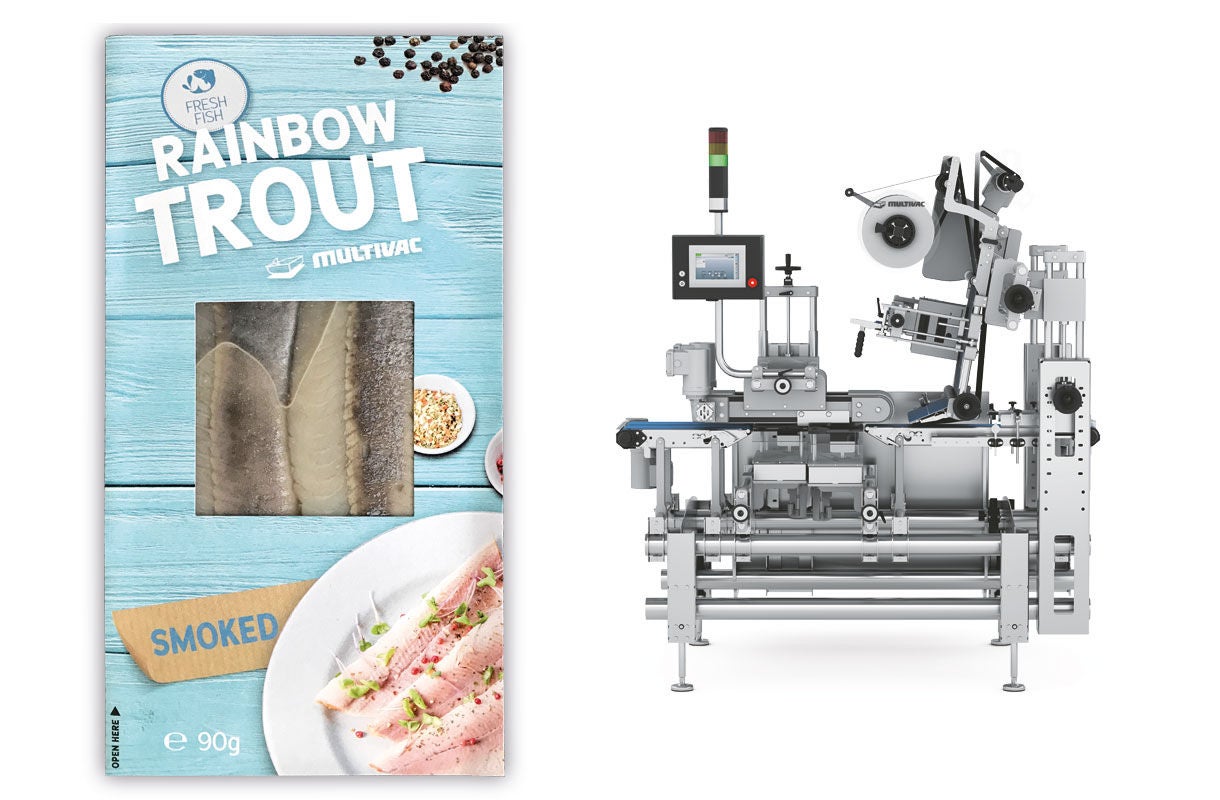

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Group Photo with Certificates on Wooden Stage

Group Photo with Certificates on Wooden Stage

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

Community Tree Planting Event Outdoors

Community Tree Planting Event Outdoors

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

Group Photo in Modern Office Setting

Group Photo in Modern Office Setting

MULTIVAC PDF

MULTIVAC PDF

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Forest Group Hiking Adventure

Forest Group Hiking Adventure

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Team Group Photo

MULTIVAC Team Group Photo

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Child Conducting Leaf Experiment with Pipette

Child Conducting Leaf Experiment with Pipette

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Charity Event with Red Cross Donation

MULTIVAC Charity Event with Red Cross Donation

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Award Ceremony Group Photo on Stage

Award Ceremony Group Photo on Stage

Business Presentation with MULTIVAC Executives

Business Presentation with MULTIVAC Executives

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Machine for Efficient Food Processing

MULTIVAC Packaging Machine for Efficient Food Processing

Business Presentation with MULTIVAC Equipment

Business Presentation with MULTIVAC Equipment

MULTIVAC Packaging Machine at Trade Show

MULTIVAC Packaging Machine at Trade Show

MULTIVAC Packaging Machine with Conveyor System

MULTIVAC Packaging Machine with Conveyor System

MULTIVAC Certification Ceremony

MULTIVAC Certification Ceremony

MULTIVAC Packaging Machine with Fresh Meat Display

MULTIVAC Packaging Machine with Fresh Meat Display

MULTIVAC T305 Packaging Machine Image

MULTIVAC T305 Packaging Machine Image

MULTIVAC Vacuum Packaging for Fresh Meat Products

MULTIVAC Vacuum Packaging for Fresh Meat Products

MULTIVAC Groundbreaking Ceremony Event

MULTIVAC Groundbreaking Ceremony Event

Groundbreaking Ceremony with Shovels

Groundbreaking Ceremony with Shovels

MULTIVAC Certificate Presentation Event

MULTIVAC Certificate Presentation Event

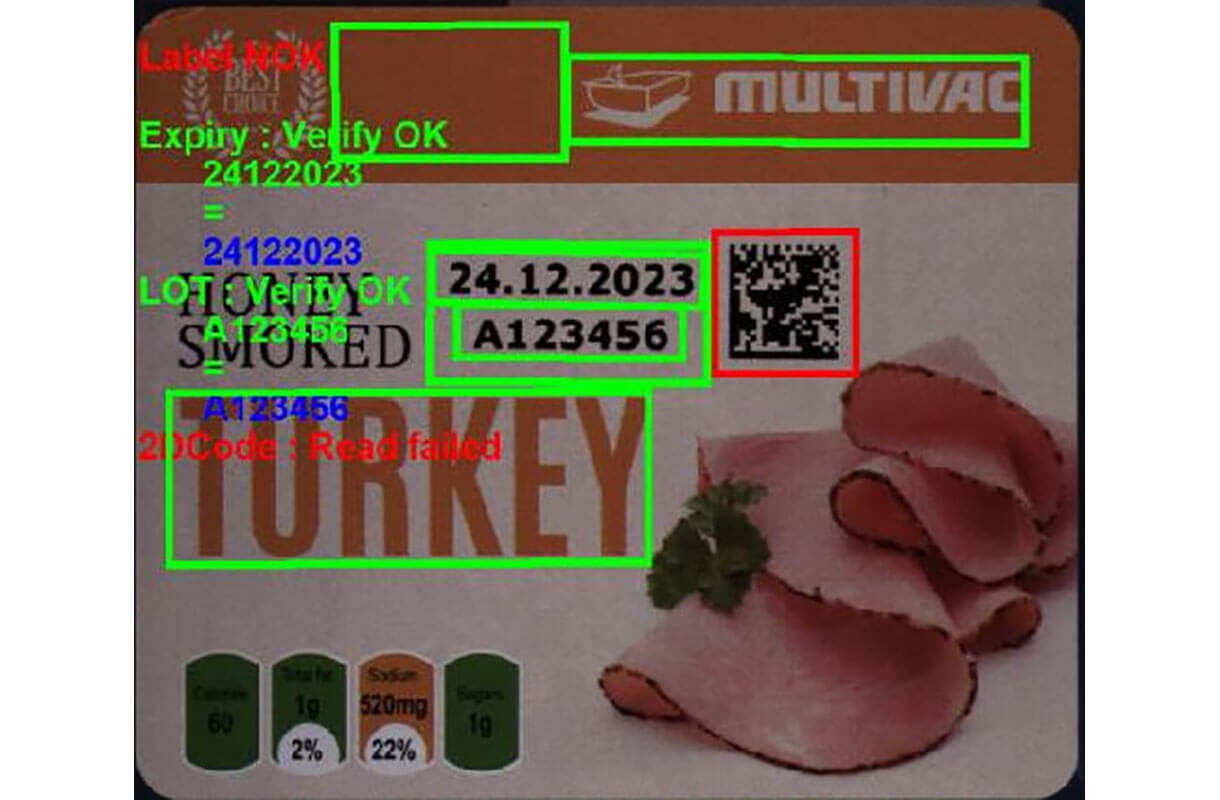

MULTIVAC Packaging Machine Label Verification

MULTIVAC Packaging Machine Label Verification

Business Professionals in Formal Attire

Business Professionals in Formal Attire

MULTIVAC TVI Facility at Sunset Landscape View

MULTIVAC TVI Facility at Sunset Landscape View

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Professional Woman in Business Attire

Professional Woman in Business Attire

MULTIVAC TX 710 Packaging Machine Front View

MULTIVAC TX 710 Packaging Machine Front View

Bayerns Best 50 Award Ceremony Event

Bayerns Best 50 Award Ceremony Event

Medical Packaging Solutions by MULTIVAC

Medical Packaging Solutions by MULTIVAC

MULTIVAC Training Center Team Photo

MULTIVAC Training Center Team Photo

MULTIVAC Food Packaging Machine Demonstration

MULTIVAC Food Packaging Machine Demonstration

Business Conference Panel Discussion Event

Business Conference Panel Discussion Event

MULTIVAC Factory Exterior with German Flag

MULTIVAC Factory Exterior with German Flag

Business Professional in Brown Suit

Business Professional in Brown Suit

MULTIVAC Business Executives Portrait

MULTIVAC Business Executives Portrait

MULTIVAC Meat Packaging Solutions Display

MULTIVAC Meat Packaging Solutions Display

MULTIVAC Packaging Machine Advanced Technology

MULTIVAC Packaging Machine Advanced Technology

MULTIVAC Packaging Machine Front View

MULTIVAC Packaging Machine Front View

MULTIVAC Headquarters Modern Architectural Design

MULTIVAC Headquarters Modern Architectural Design

Recyclable Packaging Solutions by MULTIVAC

Recyclable Packaging Solutions by MULTIVAC

Team Meeting in Modern Office Space

Team Meeting in Modern Office Space

Warehouse Automation with MULTIVAC Packaging Machine

Warehouse Automation with MULTIVAC Packaging Machine

MULTIVAC B425 Packaging Machine Front View

MULTIVAC B425 Packaging Machine Front View

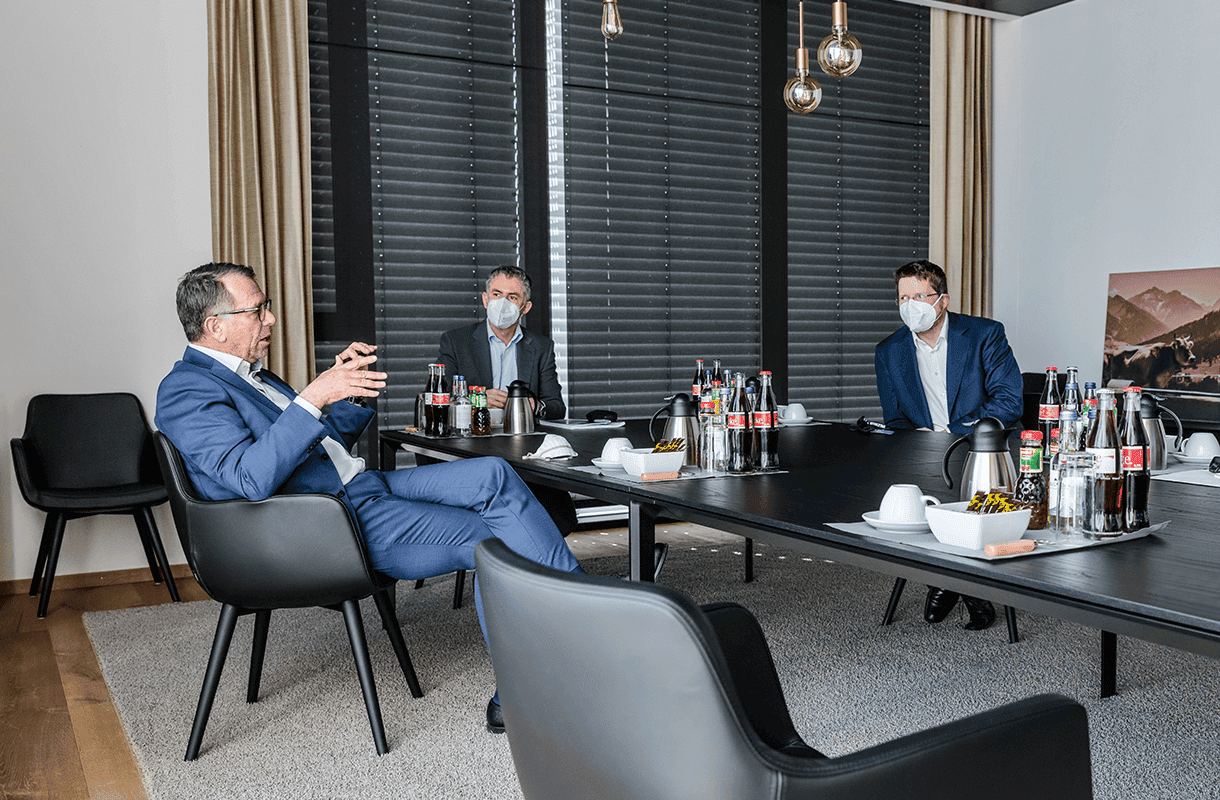

Business Meeting Room with Beverage Setup

Business Meeting Room with Beverage Setup

Office Meeting with Laptops and MULTIVAC Presentation

Office Meeting with Laptops and MULTIVAC Presentation

MULTIVAC Packaging Machine in Factory Setting

MULTIVAC Packaging Machine in Factory Setting

Businessman in Modern Office Corridor

Businessman in Modern Office Corridor

MULTIVAC 60th Anniversary Celebration Event

MULTIVAC 60th Anniversary Celebration Event

Award Ceremony Event at Modern Venue

Award Ceremony Event at Modern Venue

MULTIVAC Executive Portrait in Business Attire

MULTIVAC Executive Portrait in Business Attire

Cheese Slices with Tomato and Parsley on Wooden Board

Cheese Slices with Tomato and Parsley on Wooden Board

MULTIVAC Packaging Machine Celebrating 60 Years

MULTIVAC Packaging Machine Celebrating 60 Years

Smart Packaging Solutions Discussion

Smart Packaging Solutions Discussion

Business Professional in Modern Office Corridor

Business Professional in Modern Office Corridor

Business Professional in Suit and Tie

Business Professional in Suit and Tie

MULTIVAC Packaging Machine with Touchscreen Interface

MULTIVAC Packaging Machine with Touchscreen Interface

Germany Service Technician Locations Map

Germany Service Technician Locations Map

Professional Portrait Photography

Professional Portrait Photography

MULTIVAC Packaging Machine in Factory Setting

MULTIVAC Packaging Machine in Factory Setting

Eco-Friendly Packaging Solutions by MULTIVAC

Eco-Friendly Packaging Solutions by MULTIVAC

Business Meeting Award Ceremony Event

Business Meeting Award Ceremony Event

BGHM Team Event Group Photo

BGHM Team Event Group Photo

Shrimp Packaging Tray by MULTIVAC for Freshness

Shrimp Packaging Tray by MULTIVAC for Freshness

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Children Playing Card Games Indoors

Children Playing Card Games Indoors

MULTIVAC Packaging Machine with Printed Labels

MULTIVAC Packaging Machine with Printed Labels

Deutschland Stipendium Event at Hochschule Kempten

Deutschland Stipendium Event at Hochschule Kempten

MULTIVAC Team Achievement Award Ceremony

MULTIVAC Team Achievement Award Ceremony

MULTIVAC Packaging Machine for Medical Devices

MULTIVAC Packaging Machine for Medical Devices

MULTIVAC TX 710 Packaging Machine at Trade Show

MULTIVAC TX 710 Packaging Machine at Trade Show

MULTIVAC Team Group Photo

MULTIVAC Team Group Photo

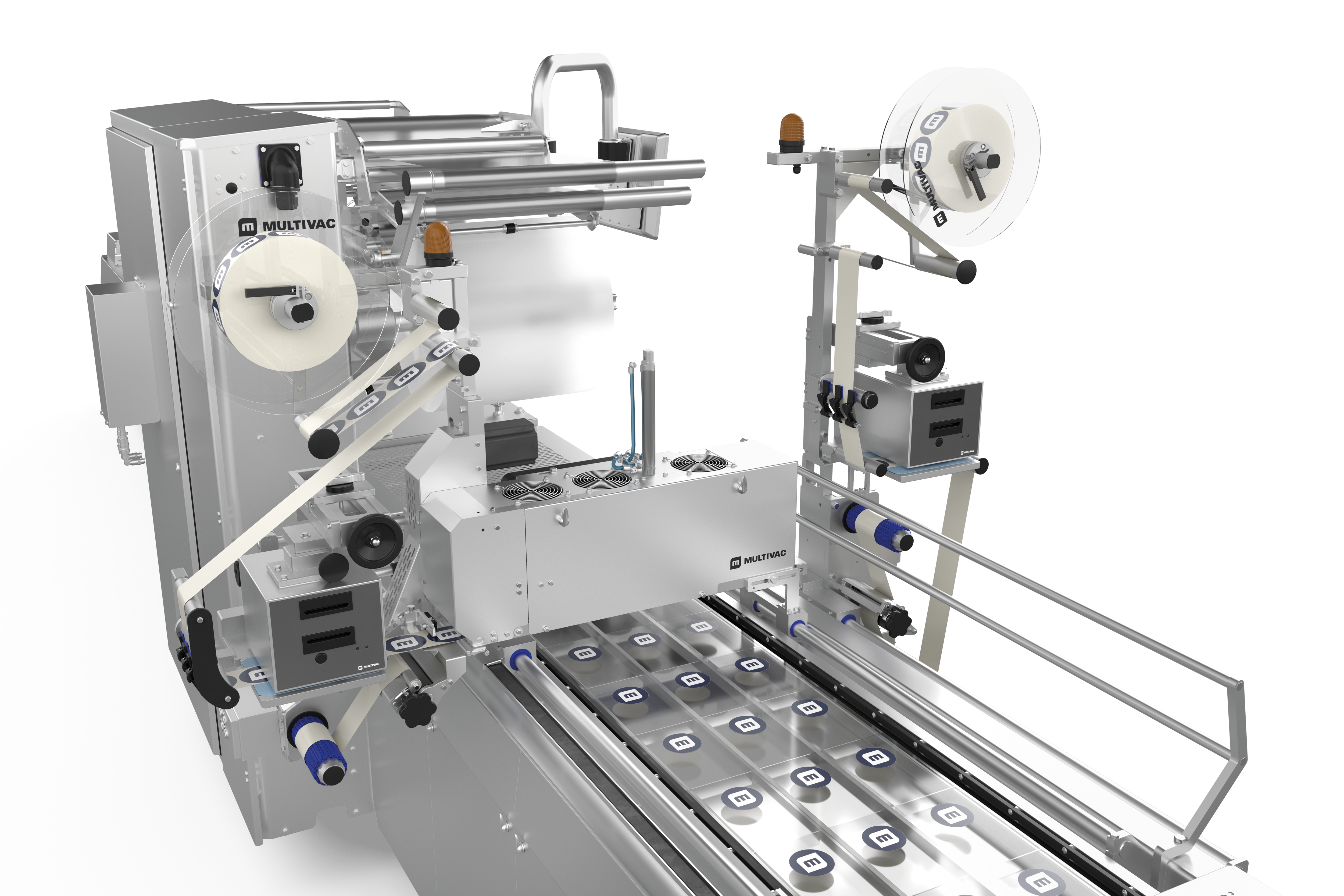

MULTIVAC Packaging Machine with Dual Reel System

MULTIVAC Packaging Machine with Dual Reel System

Group of Children Celebrating Outdoors

Group of Children Celebrating Outdoors

MULTIVAC Packaging Machine in Industrial Setting

MULTIVAC Packaging Machine in Industrial Setting

MULTIVAC Factory Production Line Overview

MULTIVAC Factory Production Line Overview

Group Photo at Competence Center Event

Group Photo at Competence Center Event

MULTIVAC Packaging Machine Front View

MULTIVAC Packaging Machine Front View

Construction Site Groundbreaking Ceremony

Construction Site Groundbreaking Ceremony

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

Group Photo Outside Building Entrance

Group Photo Outside Building Entrance

MULTIVAC Packaging Machine Presentation

MULTIVAC Packaging Machine Presentation

MULTIVAC Meat Packaging Solution Display

MULTIVAC Meat Packaging Solution Display

MULTIVAC TX 710 Packaging Machine Front View

MULTIVAC TX 710 Packaging Machine Front View

Open Industry 4.0 Alliance Logo Design

Open Industry 4.0 Alliance Logo Design

MULTIVAC Meat Packaging Solution Display

MULTIVAC Meat Packaging Solution Display

Fresh Salad Bowl Packaging by MULTIVAC

Fresh Salad Bowl Packaging by MULTIVAC

Vacuum Packaging Machine MULTIVAC Meat Tray

Vacuum Packaging Machine MULTIVAC Meat Tray

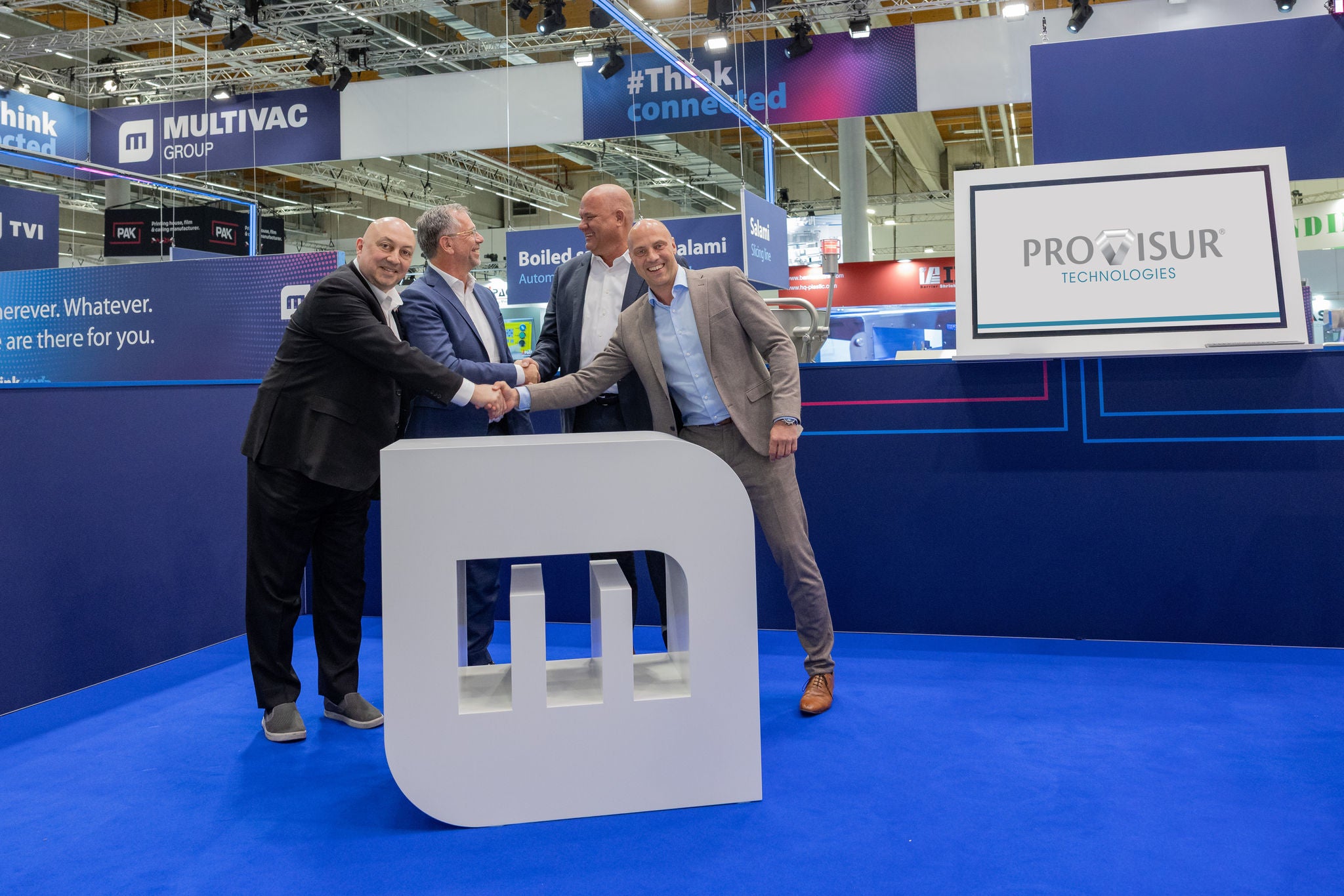

Business Networking Event Global Collaboration

Business Networking Event Global Collaboration

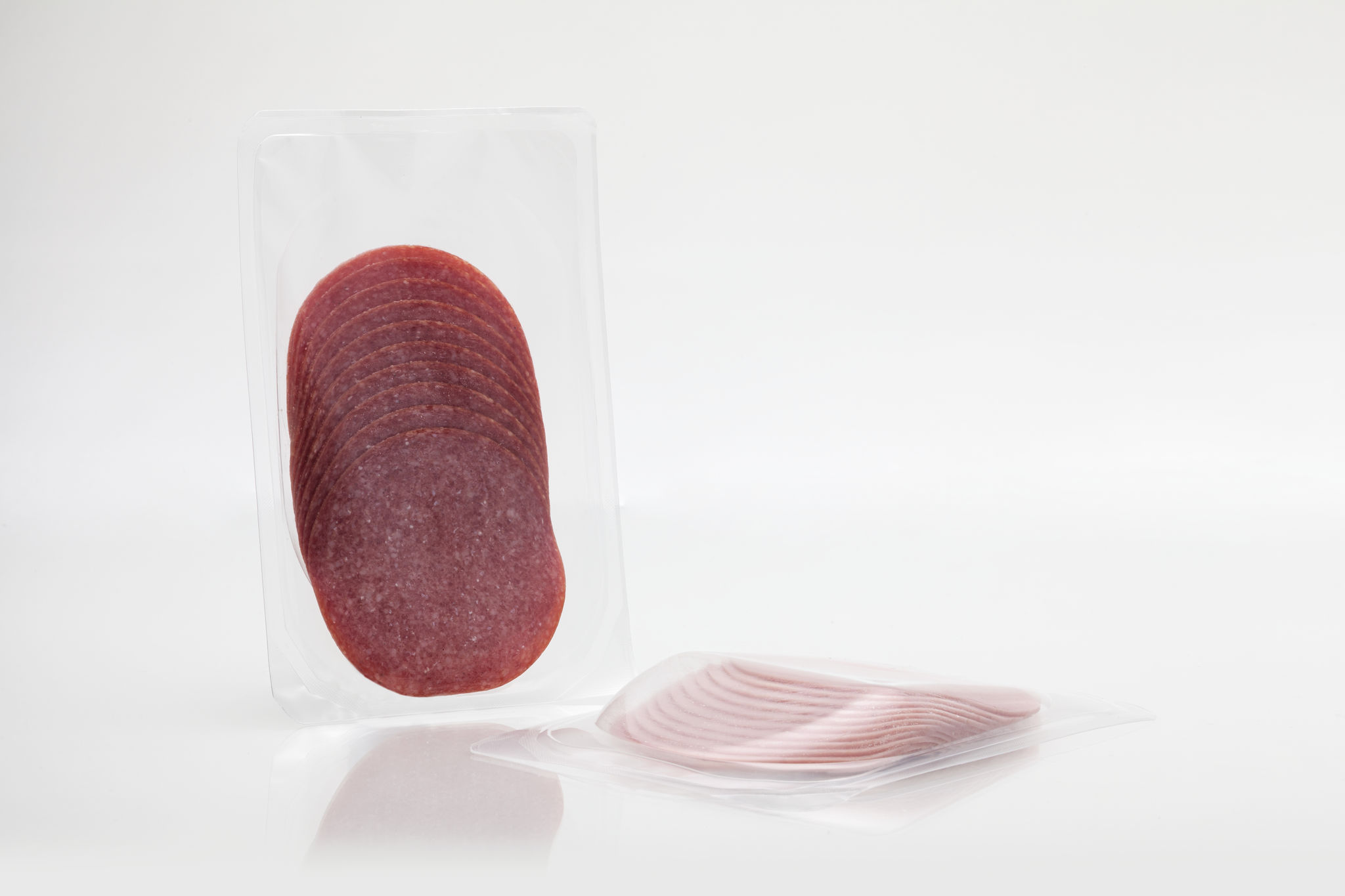

Salami Packaging by MULTIVAC: Freshness Guaranteed

Salami Packaging by MULTIVAC: Freshness Guaranteed

Pharmaceutical Blister Packaging Machine MULTIVAC

Pharmaceutical Blister Packaging Machine MULTIVAC

MULTIVAC Vacuum Sealer Control Panel Close-Up

MULTIVAC Vacuum Sealer Control Panel Close-Up

MULTIVAC Donation Ceremony Group Photo

MULTIVAC Donation Ceremony Group Photo

MULTIVAC Meat Packaging Solution Display

MULTIVAC Meat Packaging Solution Display

MULTIVAC Headquarters Modern Architectural Design

MULTIVAC Headquarters Modern Architectural Design

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com