MULTIVAC at ACHEMA (10 – 14 June 2024 )

22.04.2024

Secure and sustainable packaging solutions for the pharmaceutical industry

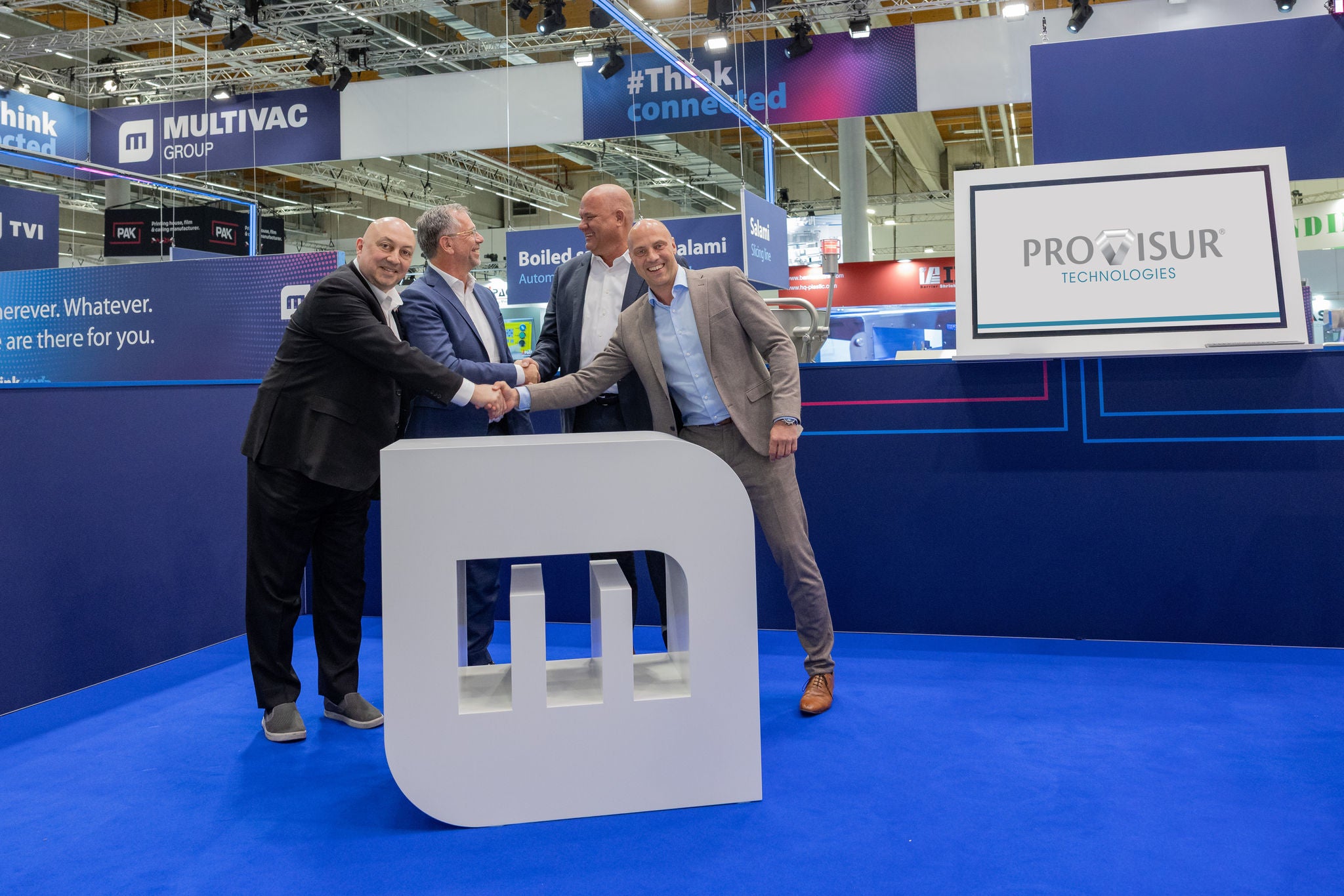

Wolfertschwenden, 22 April 2024 – At ACHEMA 2024 MULTIVAC (Hall 3.1, Stand C 47) will be presenting a range of pioneering and sustainable packaging solutions for the pharmaceutical industry. The focus of the company's presence at the trade fair will be a complete line for producing pharmaceutical combi-packs, as well as a conveyor belt labeller for the flexible and secure labelling of pharmaceutical products. Another focus of MULTIVAC's presence at the trade fair will be the presentation of sustainable packaging concepts.

Sustainable pharmaceutical combi-packs

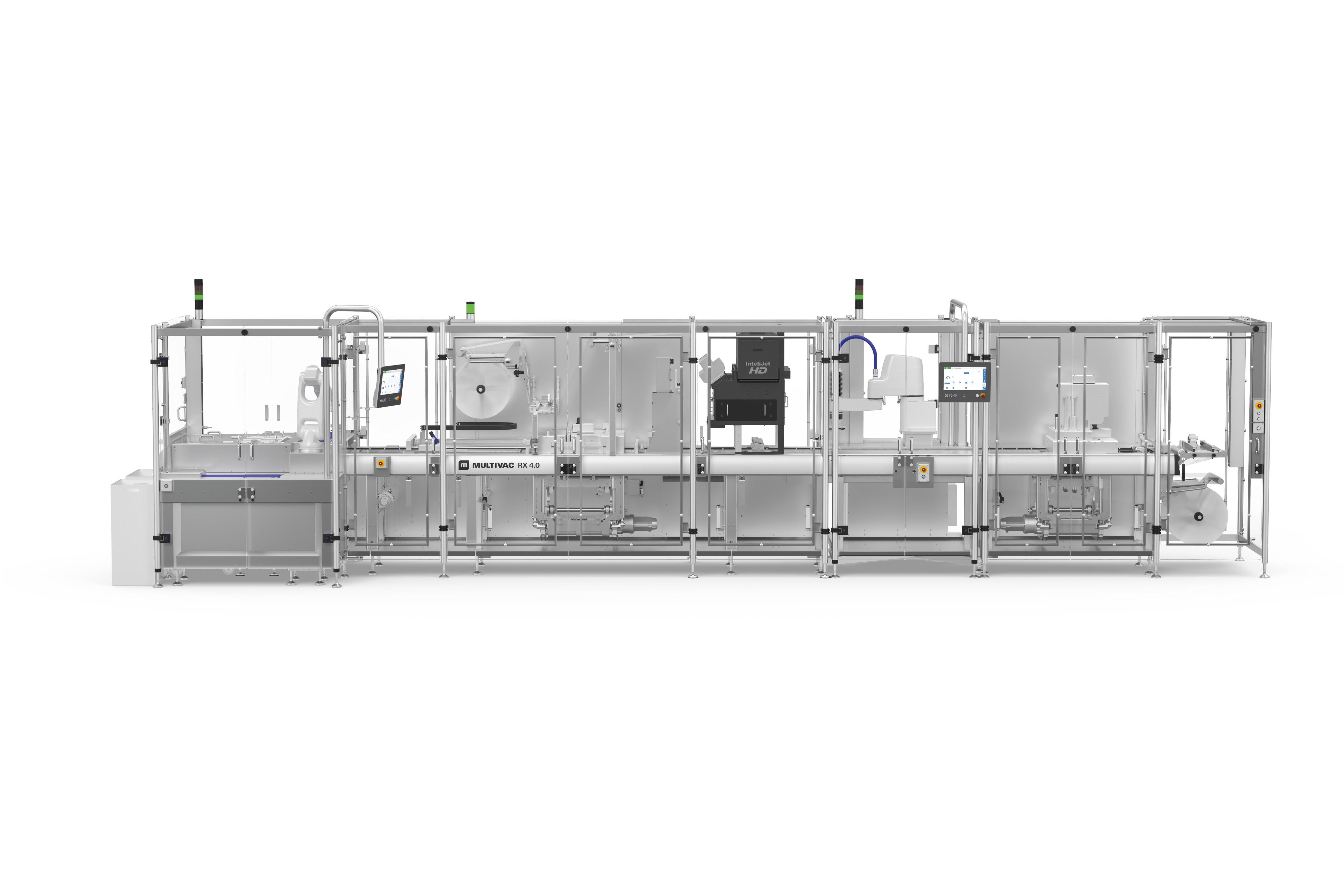

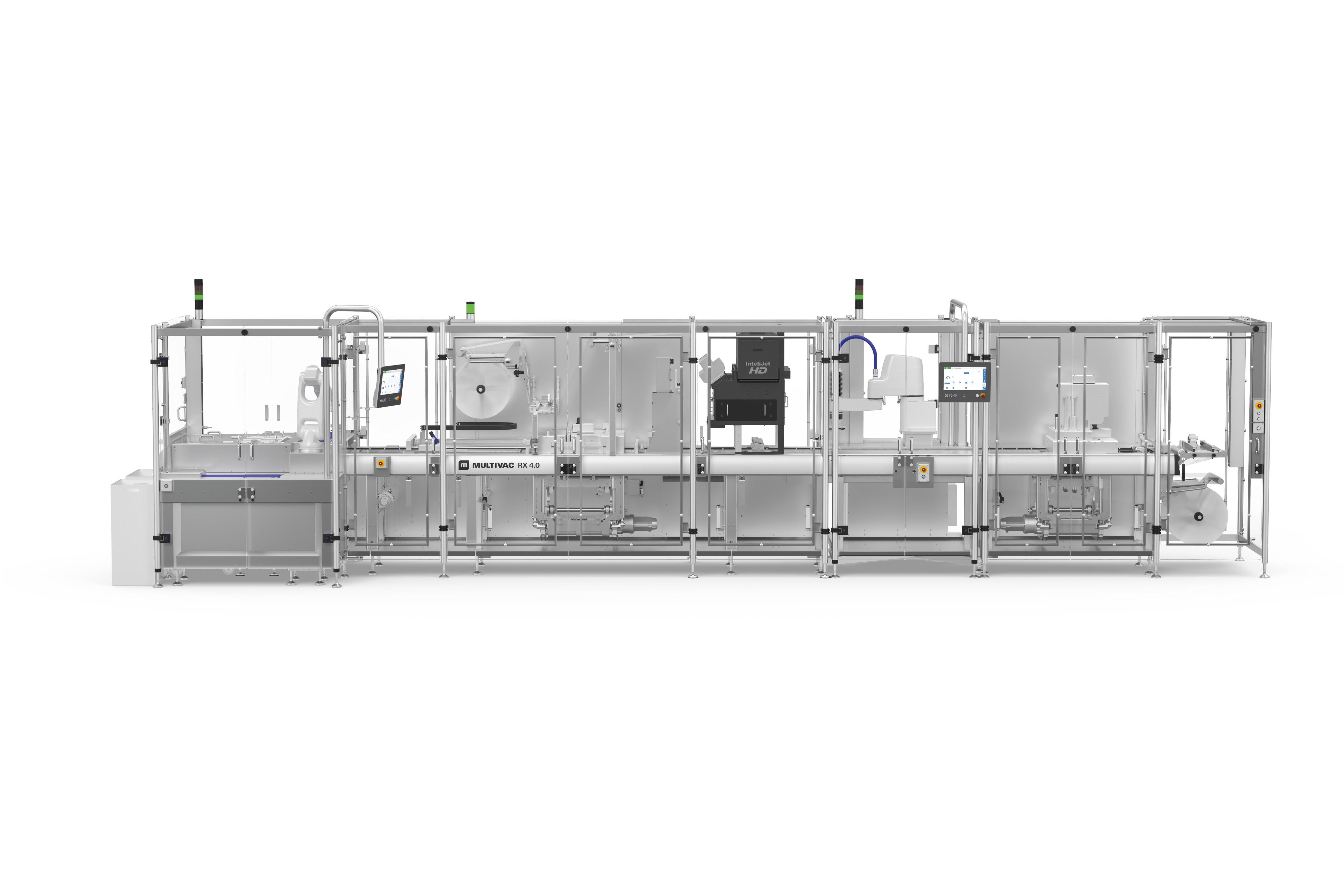

At the trade fair MULTIVAC will be showing a complete line, which produces pharmaceutical combi-packs with a syringe, filter and vial, where the packs are made from sustainable mono film. The heart of this line is the RX 4.0 thermoforming packaging machine in GMP design, which is equipped with a glass safety enclosure for optimum production conditions. An integrated SCARA robot is used for the precise and automated loading of the individual products. Before the upper web is sealed to the lower web, it is printed inline with a multi-colour design by a digital printer. Visual inspection of the print image is then performed by means of a visual inspection system.

Heat-sensitive products are protected during the packaging process by a cooled product shield plate: If the machine comes to a stop, the shield plate is automatically positioned between the hot sealing plate and the product. After the packaging process has been completed, a 6-axis robot separates the packs into good and reject packs, and it places them on various transport conveyors for downstream processing.

Thanks to its comprehensive sensor system and continuous process monitoring, the RX 4.0 thermoforming packaging machine offers a high degree of process precision and reproducibility. The RFID-coded dies with permanent status monitoring ensure that format changes are performed reliably, and that the changed dies are positioned correctly on the machine. The whole line can be controlled conveniently and intuitively by the user-friendly HMI on the packaging machine.

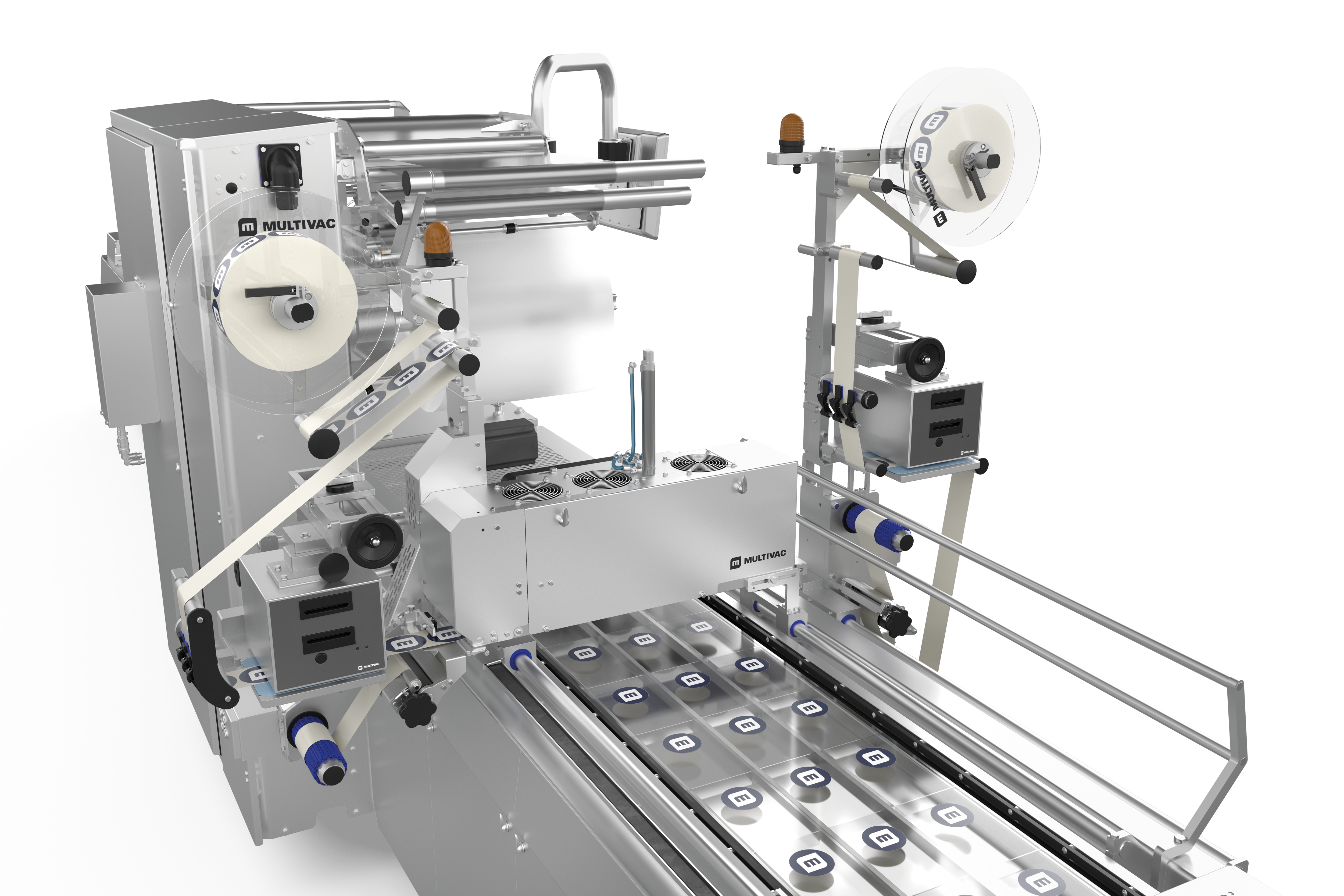

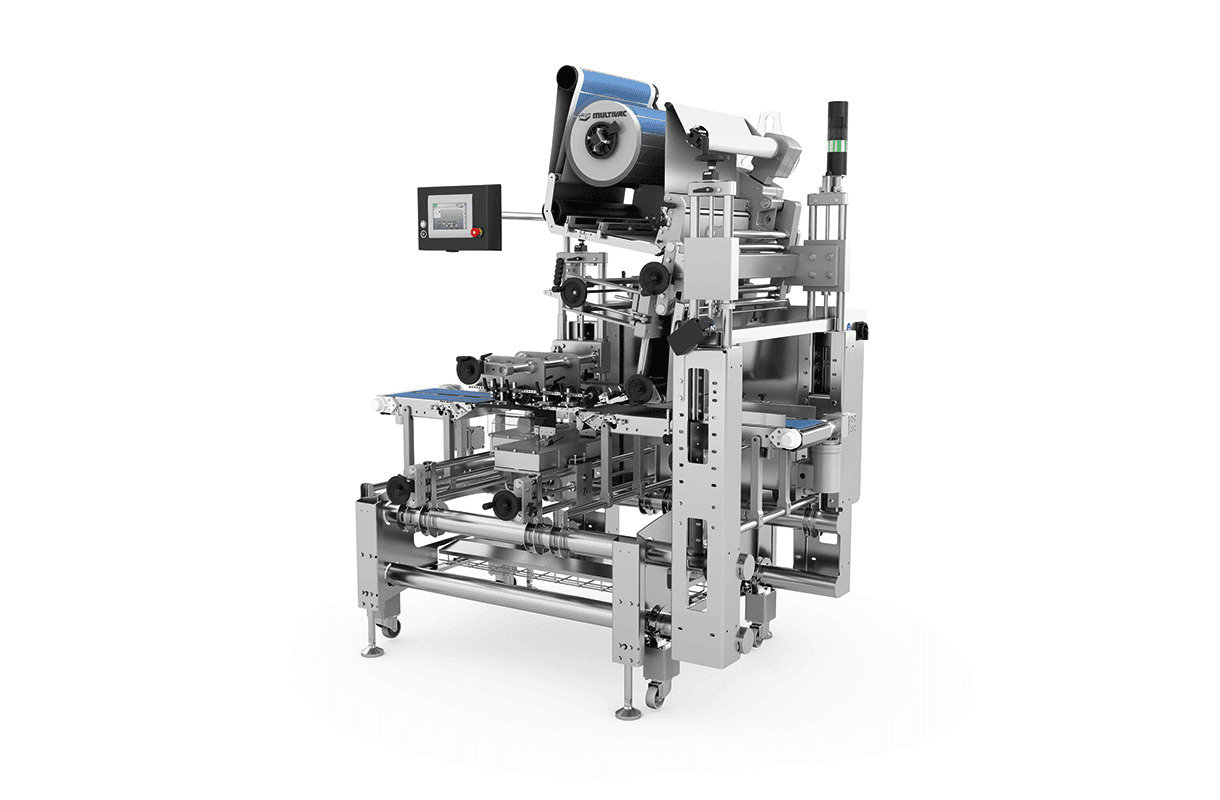

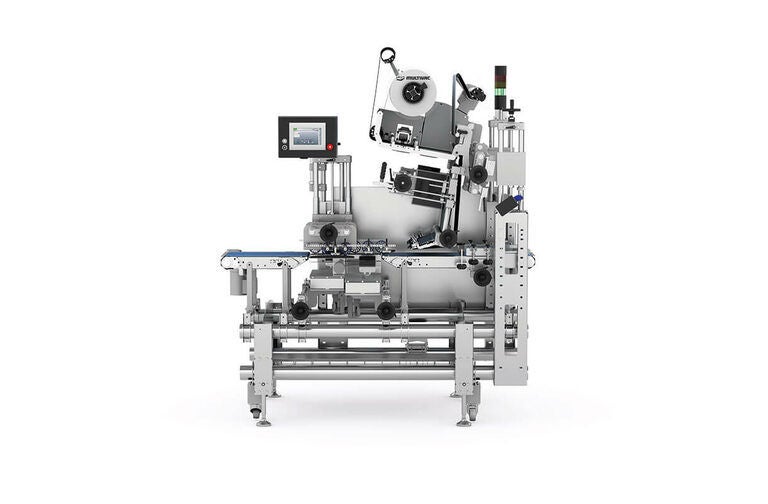

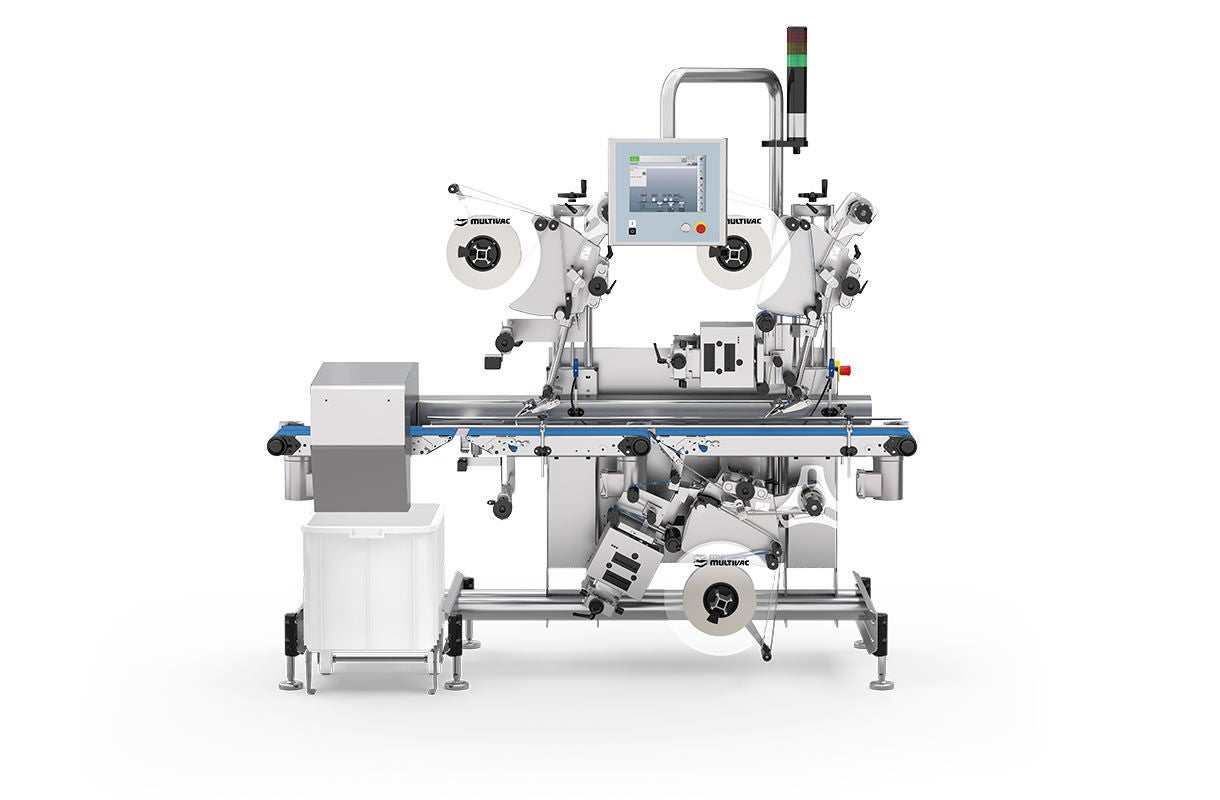

Flexible and secure labelling of pharmaceutical products

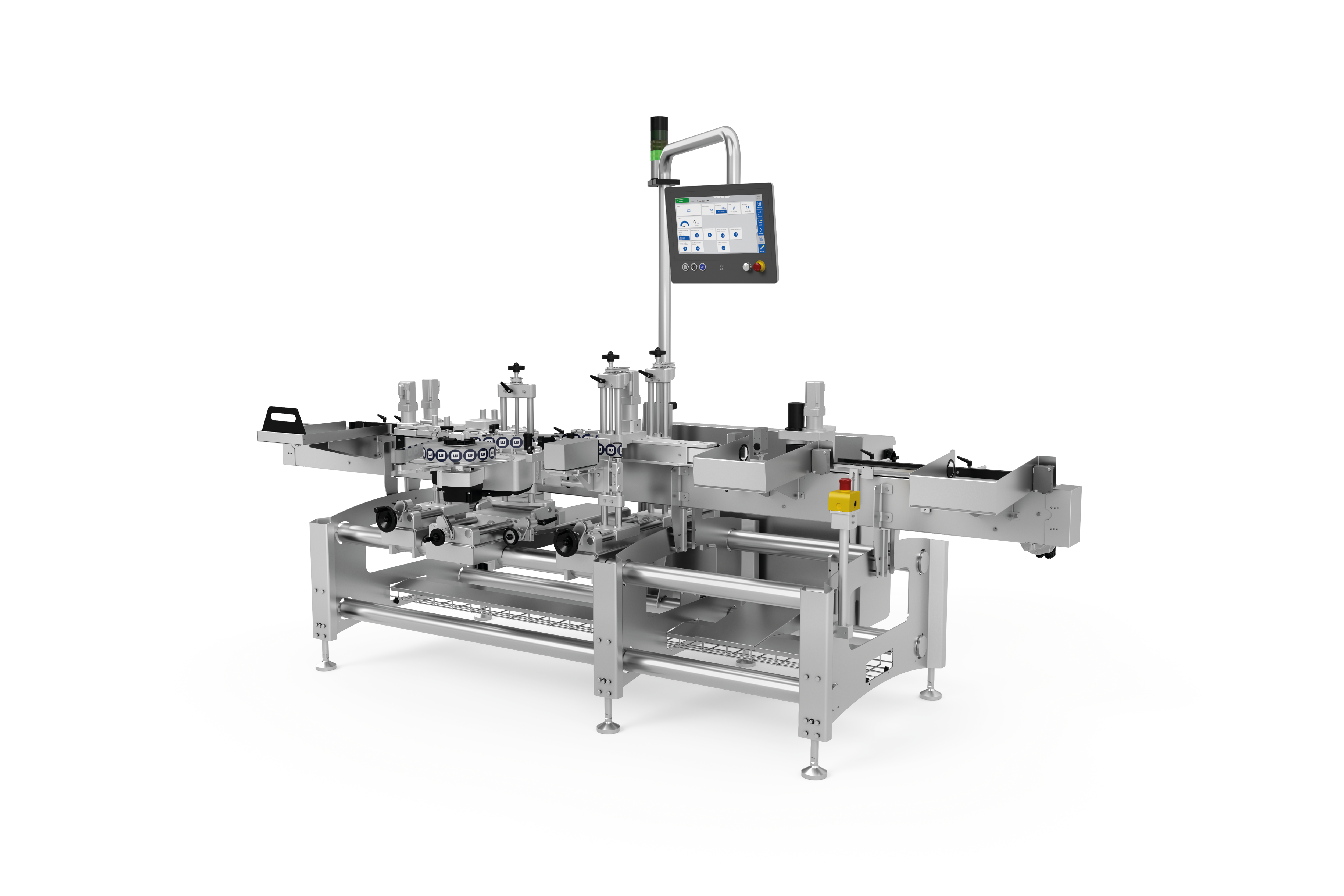

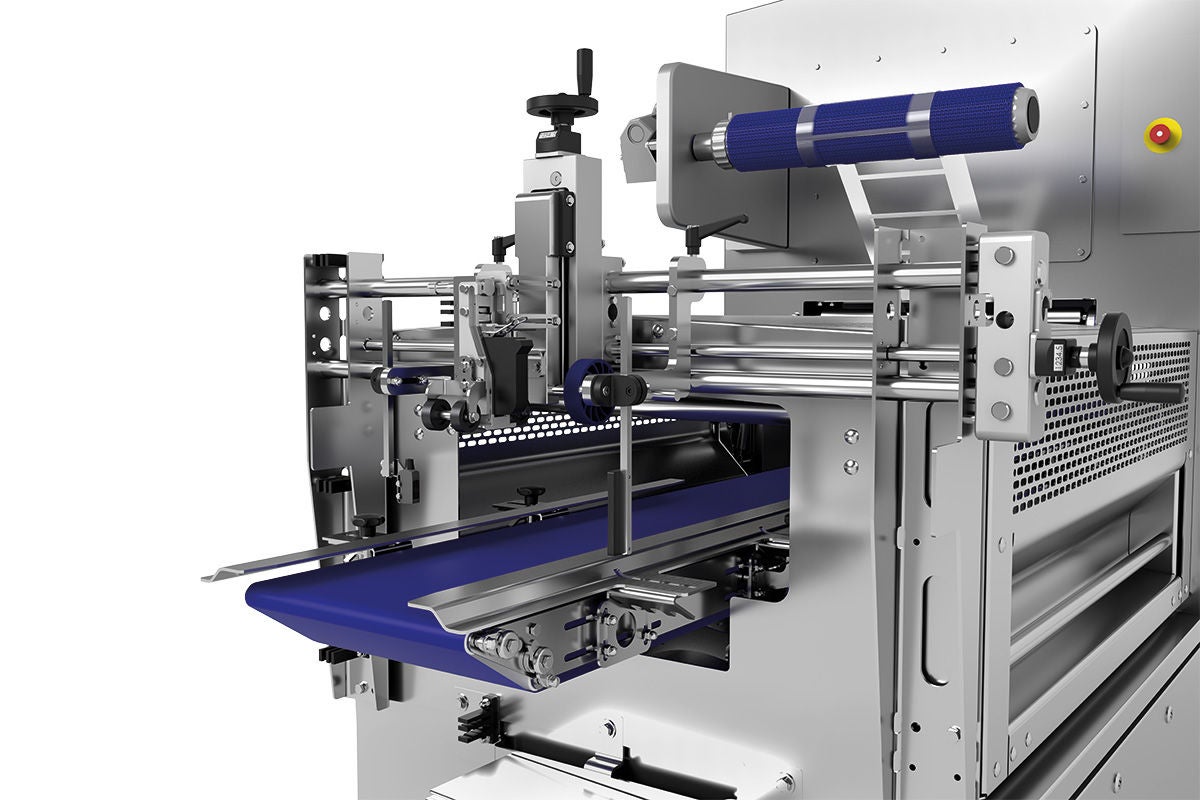

The conveyor belt labellers of the L 320 series offer a high level of flexibility and precision in the labelling of cylindrical products, such as for example vials, medical bottles and jars. Using the "Print, Apply & Verify“ principle, the various stages of printing, label application and verification are integrated in one machine, and they are controlled from one single control terminal. Labels can be applied as wrap-around labels or to the front and back of the product depending on the application. Sealing labels can also be applied. The products are transported on a modular plastic belt, where they can be queued, spaced and aligned very precisely. Thanks to a wide range of options for product handling or label printing and inspection, the modular construction of the labeller allows it to be adapted perfectly to the complex requirements of the pharmaceutical sector. The labeller can also be converted quickly and conveniently to other product formats, and it is therefore very versatile in its use.

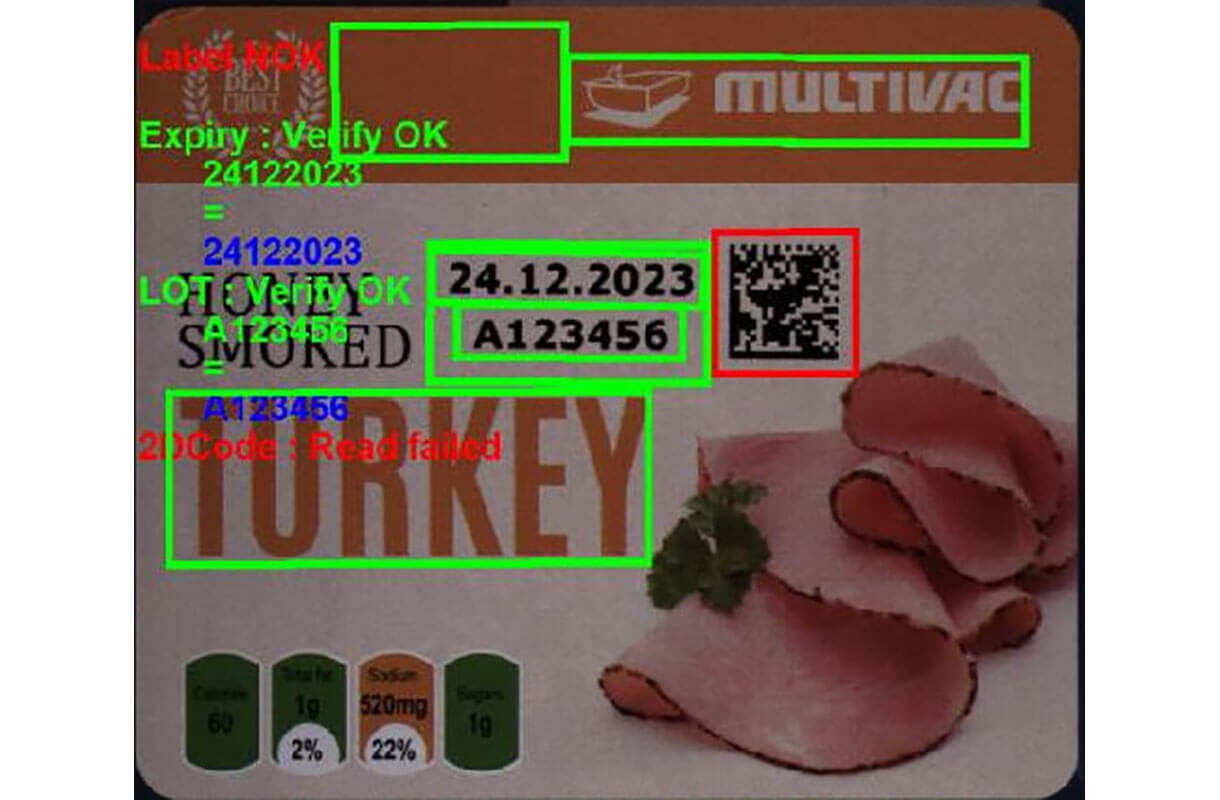

Wide range of solutions for quality control

MULTIVAC also offers a wide range of inspection solutions for inspecting the product, label or print. These include a variety of different components such as cameras, code readers and sensors, which can be integrated seamlessly into the packaging machine or labeller, or alternatively can be used as a stand-alone inspection system. This provides a solution with perfectly matched components and a uniform operating concept, which ensure that efficient and reliable processes are achieved thanks to in-depth integration. At ACHEMA the company will be exhibiting a variety of different solutions for a wide range of inspection tasks, and it offers its customers comprehensive advice on the performance and capabilities of the individual modules.

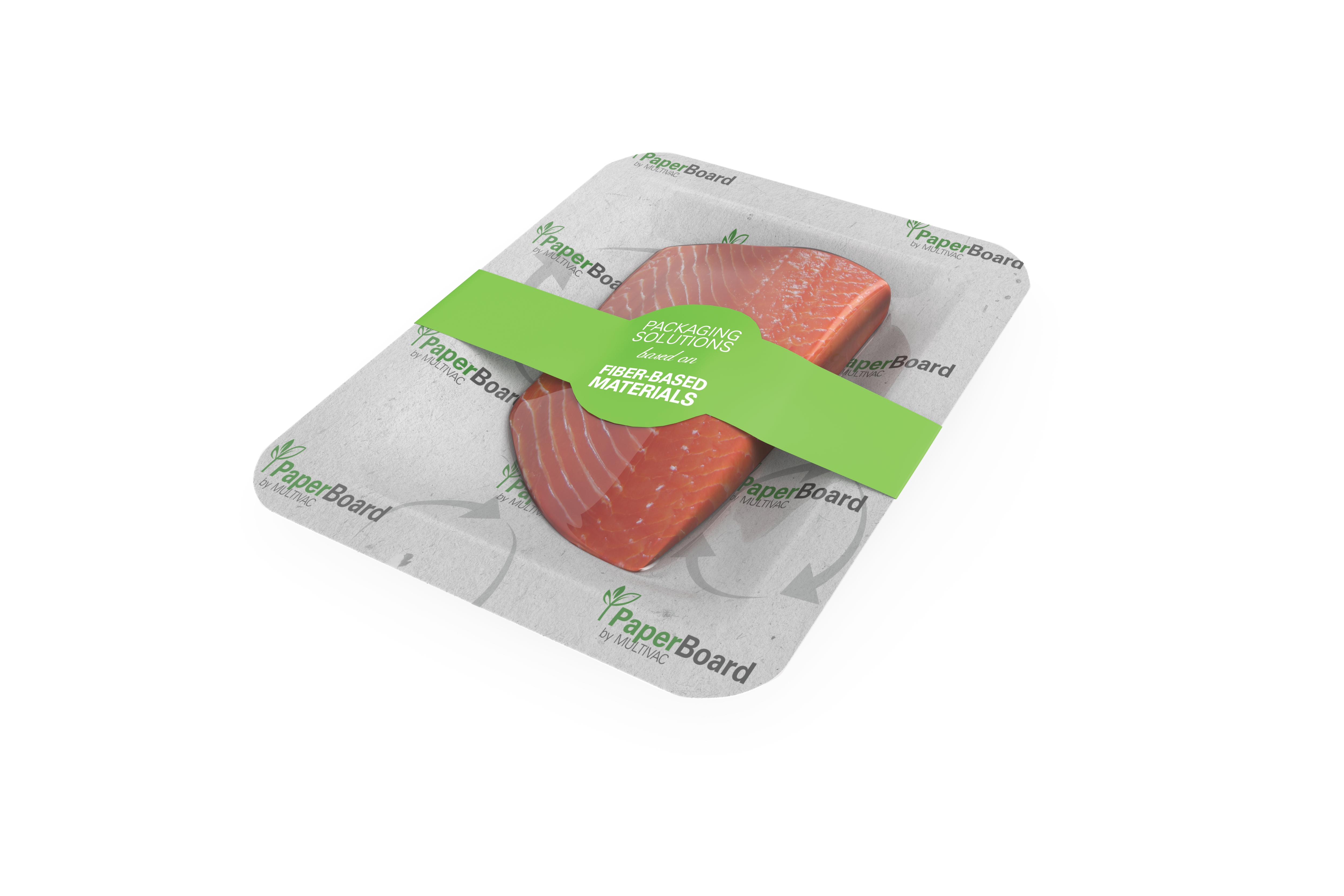

The future of pharmaceutical packaging is green

“Sustainable packaging solutions are becoming increasingly important for the pharmaceutical industry. We are actively committed to environmentally-friendly alternatives, by supporting our customers with packaging concepts, which contribute to saving consumable materials and resources in the packaging process, as well as improving the recyclability of packs,“ says Verena Vetter, Product Manager for Medical & Pharma Solutions at MULTIVAC. “For example, our machines are designed in such a way, that they can run a wide range of packaging materials with ease. These include mono films, which enable the packs to be recycled more easily. Working together with our customers in the Corporate Training & Innovation Center, we can develop tailored packaging solutions and concepts, which offer both process reliability and environmental benefits.“

- 1

- 2

- 3

- 4

- Size

- 99 KB

- Format

- Size

- 50 KB

- Format

- jpeg

Latest News

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Business Team Meeting Group Photo

Business Team Meeting Group Photo

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

Conference Presentation with Audience

Conference Presentation with Audience

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

Group Holding Donation Checks Event

Group Holding Donation Checks Event

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

Modern Conference Room with Presentation Screen

Modern Conference Room with Presentation Screen

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

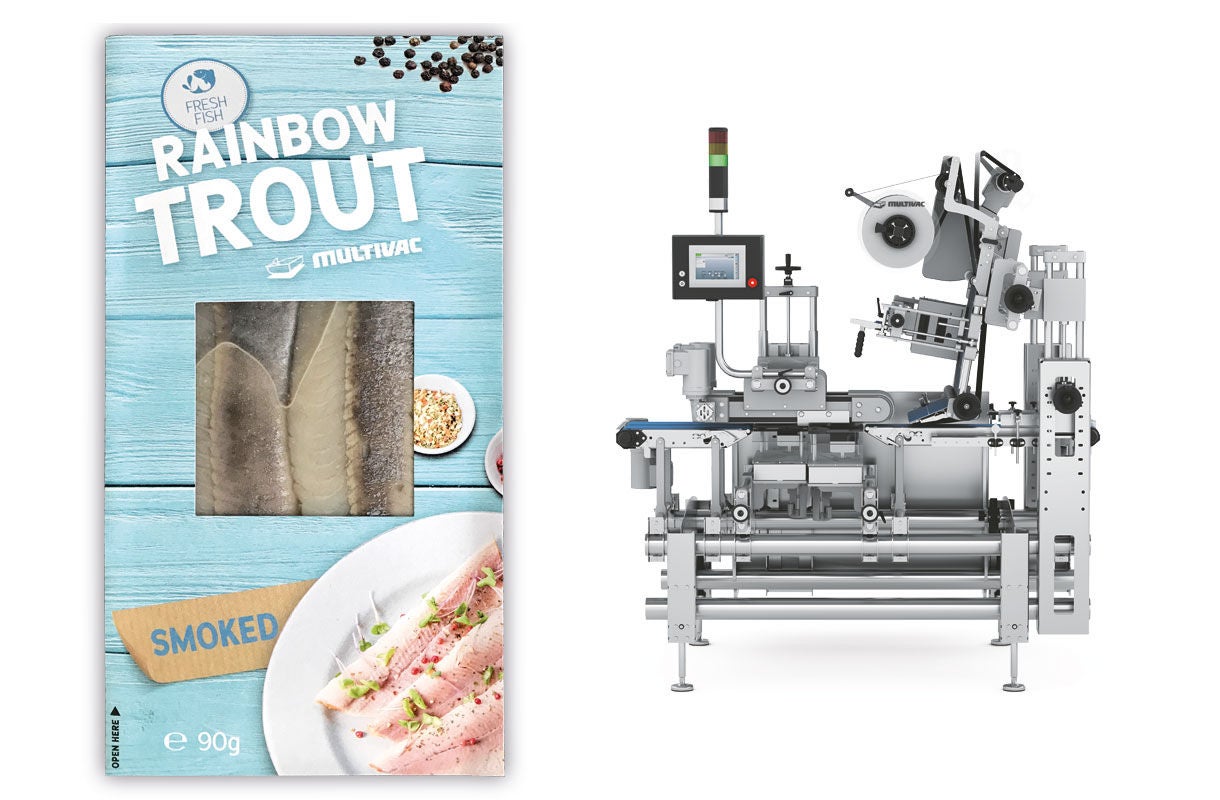

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Group Photo with Certificates on Wooden Stage

Group Photo with Certificates on Wooden Stage

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

Community Tree Planting Event Outdoors

Community Tree Planting Event Outdoors

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

Group Photo in Modern Office Setting

Group Photo in Modern Office Setting

MULTIVAC PDF

MULTIVAC PDF

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Forest Group Hiking Adventure

Forest Group Hiking Adventure

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Team Group Photo

MULTIVAC Team Group Photo

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Child Conducting Leaf Experiment with Pipette

Child Conducting Leaf Experiment with Pipette

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Charity Event with Red Cross Donation

MULTIVAC Charity Event with Red Cross Donation

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Award Ceremony Group Photo on Stage

Award Ceremony Group Photo on Stage

Business Presentation with MULTIVAC Executives

Business Presentation with MULTIVAC Executives

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

MULTIVAC Packaging Machine for Efficient Food Processing

MULTIVAC Packaging Machine for Efficient Food Processing

Business Presentation with MULTIVAC Equipment

Business Presentation with MULTIVAC Equipment

MULTIVAC Packaging Machine at Trade Show

MULTIVAC Packaging Machine at Trade Show

MULTIVAC Packaging Machine with Conveyor System

MULTIVAC Packaging Machine with Conveyor System

MULTIVAC Certification Ceremony

MULTIVAC Certification Ceremony

MULTIVAC Packaging Machine with Fresh Meat Display

MULTIVAC Packaging Machine with Fresh Meat Display

MULTIVAC T305 Packaging Machine Image

MULTIVAC T305 Packaging Machine Image

MULTIVAC Vacuum Packaging for Fresh Meat Products

MULTIVAC Vacuum Packaging for Fresh Meat Products

MULTIVAC Groundbreaking Ceremony Event

MULTIVAC Groundbreaking Ceremony Event

Groundbreaking Ceremony with Shovels

Groundbreaking Ceremony with Shovels

MULTIVAC Certificate Presentation Event

MULTIVAC Certificate Presentation Event

MULTIVAC Packaging Machine Label Verification

MULTIVAC Packaging Machine Label Verification

Business Professionals in Formal Attire

Business Professionals in Formal Attire

MULTIVAC TVI Facility at Sunset Landscape View

MULTIVAC TVI Facility at Sunset Landscape View

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Professional Woman in Business Attire

Professional Woman in Business Attire

MULTIVAC TX 710 Packaging Machine Front View

MULTIVAC TX 710 Packaging Machine Front View

Bayerns Best 50 Award Ceremony Event

Bayerns Best 50 Award Ceremony Event

Medical Packaging Solutions by MULTIVAC

Medical Packaging Solutions by MULTIVAC

MULTIVAC Training Center Team Photo

MULTIVAC Training Center Team Photo

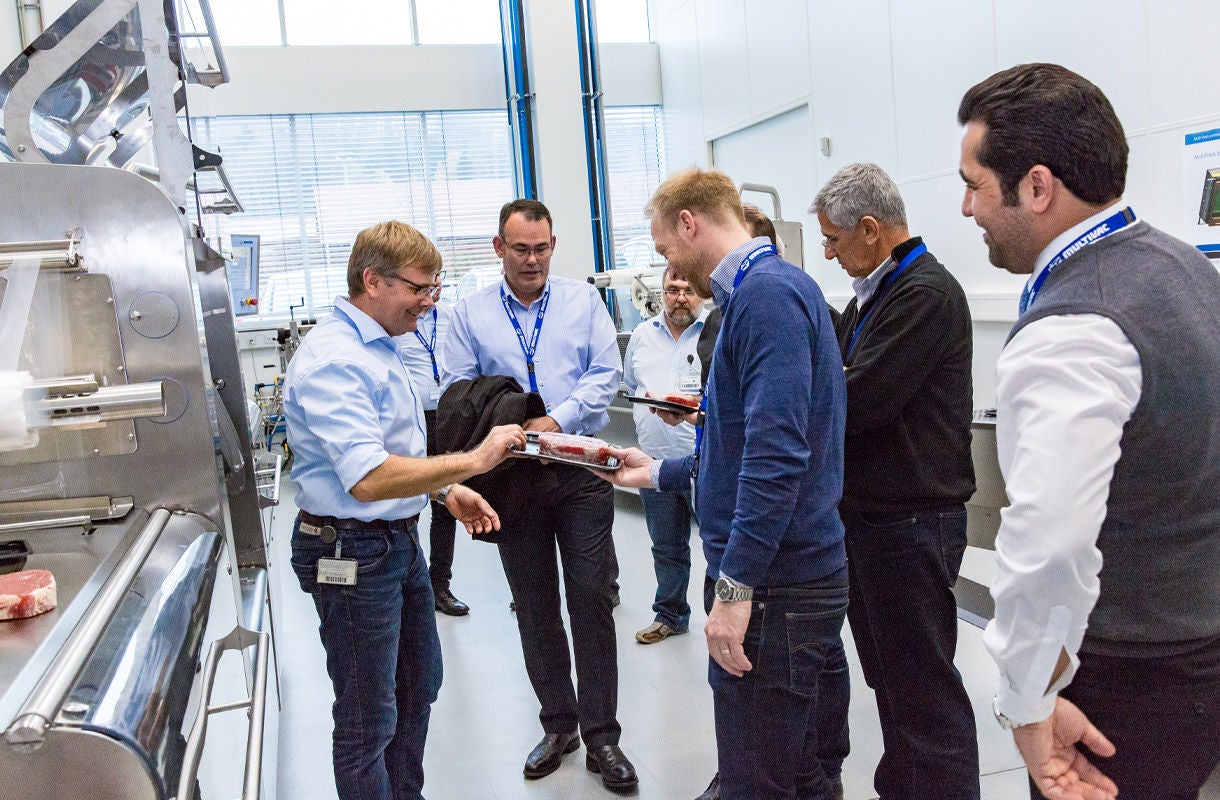

MULTIVAC Food Packaging Machine Demonstration

MULTIVAC Food Packaging Machine Demonstration

Business Conference Panel Discussion Event

Business Conference Panel Discussion Event

MULTIVAC Factory Exterior with German Flag

MULTIVAC Factory Exterior with German Flag

Business Professional in Brown Suit

Business Professional in Brown Suit

MULTIVAC Business Executives Portrait

MULTIVAC Business Executives Portrait

MULTIVAC Meat Packaging Solutions Display

MULTIVAC Meat Packaging Solutions Display

MULTIVAC Packaging Machine Advanced Technology

MULTIVAC Packaging Machine Advanced Technology

MULTIVAC Packaging Machine Front View

MULTIVAC Packaging Machine Front View

MULTIVAC Headquarters Modern Architectural Design

MULTIVAC Headquarters Modern Architectural Design

Recyclable Packaging Solutions by MULTIVAC

Recyclable Packaging Solutions by MULTIVAC

Team Meeting in Modern Office Space

Team Meeting in Modern Office Space

Warehouse Automation with MULTIVAC Packaging Machine

Warehouse Automation with MULTIVAC Packaging Machine

MULTIVAC B425 Packaging Machine Front View

MULTIVAC B425 Packaging Machine Front View

Business Meeting Room with Beverage Setup

Business Meeting Room with Beverage Setup

Office Meeting with Laptops and MULTIVAC Presentation

Office Meeting with Laptops and MULTIVAC Presentation

MULTIVAC Packaging Machine in Factory Setting

MULTIVAC Packaging Machine in Factory Setting

Businessman in Modern Office Corridor

Businessman in Modern Office Corridor

MULTIVAC 60th Anniversary Celebration Event

MULTIVAC 60th Anniversary Celebration Event

Award Ceremony Event at Modern Venue

Award Ceremony Event at Modern Venue

MULTIVAC Executive Portrait in Business Attire

MULTIVAC Executive Portrait in Business Attire

Cheese Slices with Tomato and Parsley on Wooden Board

Cheese Slices with Tomato and Parsley on Wooden Board

MULTIVAC Packaging Machine Celebrating 60 Years

MULTIVAC Packaging Machine Celebrating 60 Years

Smart Packaging Solutions Discussion

Smart Packaging Solutions Discussion

Business Professional in Modern Office Corridor

Business Professional in Modern Office Corridor

Business Professional in Suit and Tie

Business Professional in Suit and Tie

MULTIVAC Packaging Machine with Touchscreen Interface

MULTIVAC Packaging Machine with Touchscreen Interface

Germany Service Technician Locations Map

Germany Service Technician Locations Map

Professional Portrait Photography

Professional Portrait Photography

MULTIVAC Packaging Machine in Factory Setting

MULTIVAC Packaging Machine in Factory Setting

Eco-Friendly Packaging Solutions by MULTIVAC

Eco-Friendly Packaging Solutions by MULTIVAC

Business Meeting Award Ceremony Event

Business Meeting Award Ceremony Event

BGHM Team Event Group Photo

BGHM Team Event Group Photo

Shrimp Packaging Tray by MULTIVAC for Freshness

Shrimp Packaging Tray by MULTIVAC for Freshness

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Children Playing Card Games Indoors

Children Playing Card Games Indoors

MULTIVAC Packaging Machine with Printed Labels

MULTIVAC Packaging Machine with Printed Labels

Deutschland Stipendium Event at Hochschule Kempten

Deutschland Stipendium Event at Hochschule Kempten

MULTIVAC Team Achievement Award Ceremony

MULTIVAC Team Achievement Award Ceremony

MULTIVAC Packaging Machine for Medical Devices

MULTIVAC Packaging Machine for Medical Devices

MULTIVAC TX 710 Packaging Machine at Trade Show

MULTIVAC TX 710 Packaging Machine at Trade Show

MULTIVAC Team Group Photo

MULTIVAC Team Group Photo

MULTIVAC Packaging Machine with Dual Reel System

MULTIVAC Packaging Machine with Dual Reel System

Group of Children Celebrating Outdoors

Group of Children Celebrating Outdoors

MULTIVAC Packaging Machine in Industrial Setting

MULTIVAC Packaging Machine in Industrial Setting

MULTIVAC Factory Production Line Overview

MULTIVAC Factory Production Line Overview

Group Photo at Competence Center Event

Group Photo at Competence Center Event

MULTIVAC Packaging Machine Front View

MULTIVAC Packaging Machine Front View

Construction Site Groundbreaking Ceremony

Construction Site Groundbreaking Ceremony

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

Group Photo Outside Building Entrance

Group Photo Outside Building Entrance

MULTIVAC Packaging Machine Presentation

MULTIVAC Packaging Machine Presentation

MULTIVAC Meat Packaging Solution Display

MULTIVAC Meat Packaging Solution Display

MULTIVAC TX 710 Packaging Machine Front View

MULTIVAC TX 710 Packaging Machine Front View

Open Industry 4.0 Alliance Logo Design

Open Industry 4.0 Alliance Logo Design

MULTIVAC Meat Packaging Solution Display

MULTIVAC Meat Packaging Solution Display

Fresh Salad Bowl Packaging by MULTIVAC

Fresh Salad Bowl Packaging by MULTIVAC

Vacuum Packaging Machine MULTIVAC Meat Tray

Vacuum Packaging Machine MULTIVAC Meat Tray

Business Networking Event Global Collaboration

Business Networking Event Global Collaboration

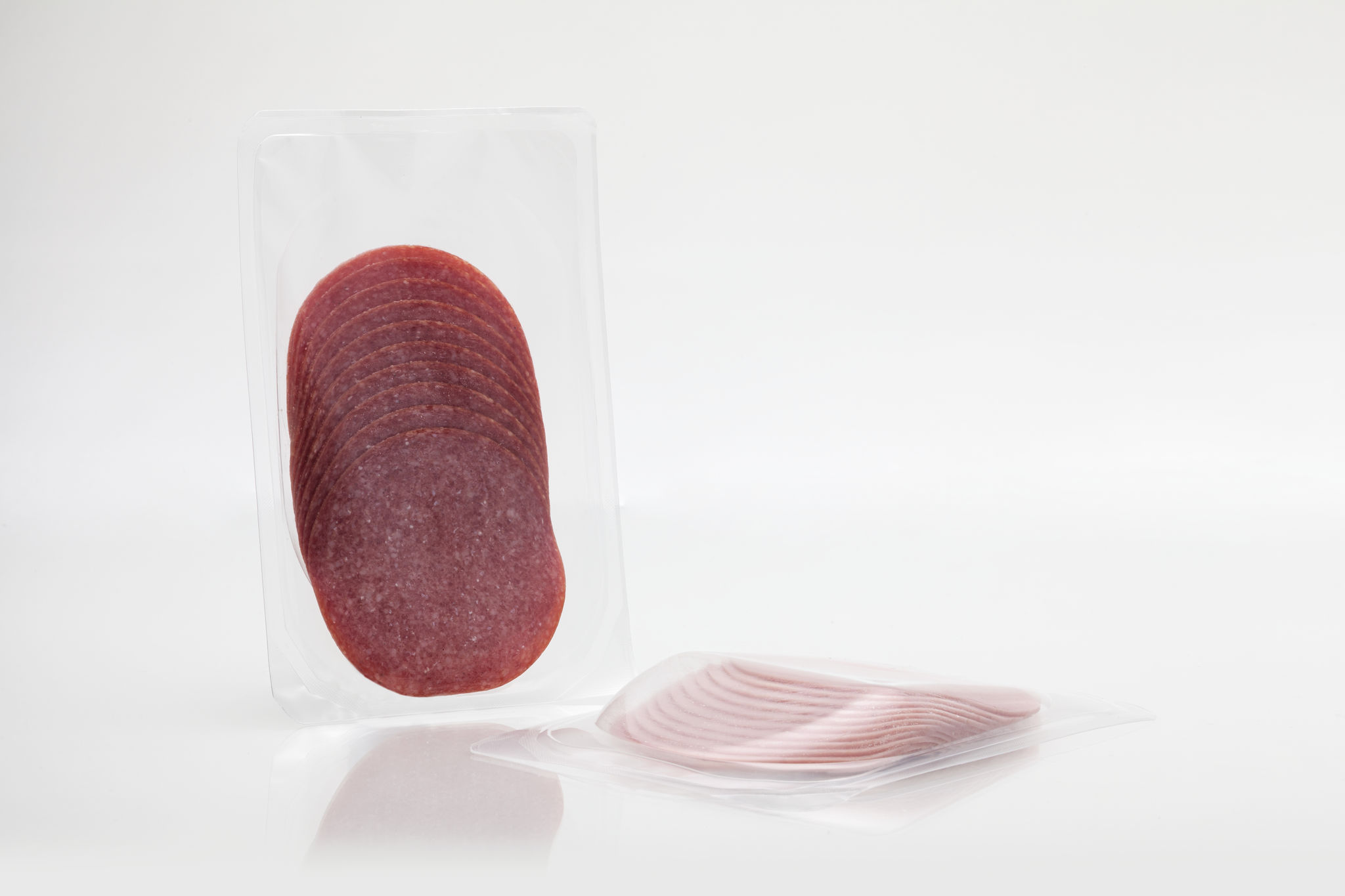

Salami Packaging by MULTIVAC: Freshness Guaranteed

Salami Packaging by MULTIVAC: Freshness Guaranteed

Pharmaceutical Blister Packaging Machine MULTIVAC

Pharmaceutical Blister Packaging Machine MULTIVAC

MULTIVAC Vacuum Sealer Control Panel Close-Up

MULTIVAC Vacuum Sealer Control Panel Close-Up

MULTIVAC Donation Ceremony Group Photo

MULTIVAC Donation Ceremony Group Photo

MULTIVAC Meat Packaging Solution Display

MULTIVAC Meat Packaging Solution Display

MULTIVAC Headquarters Modern Architectural Design

MULTIVAC Headquarters Modern Architectural Design

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com