MULTIVAC wins the German Packaging Award with Cooling@Packing

German Packaging Award 2024 in the packaging machine category and Gold Award

25.09.2024

Wolfertschwenden, 25 September 2024 – Greater freshness and longer shelf life, savings in energy costs and space requirements, as well as increased production capacity. These are the features of the new Cooling@Packing System from MULTIVAC. An innovation for cooling bakery products in a packaging machine, which has now been given the German Packaging Award. The solution was also honoured with a Gold Award, which is presented for outstanding innovations from among all the Packaging Award winners. On the Tuesday of FACHPACK the German Packaging Institute (Deutsche Verpackungsinstitut e. V.) selected the 41 winners of the German Packaging Awards in ten different categories. The award is the biggest prize in Europe for innovation in the packaging sector.

“It is a great honour for us to receive this award for our product innovation Cooling@Packing. A big thank you goes to the entire team for the great cooperation,” said Dr Tobias Richter, group president (CSO) of the MULTIVAC Group. “The solution also reduces energy costs and space requirements – and the recognition by the jury is confirmation of our ongoing commitment to develop groundbreaking new technology, which helps our customers to produce more efficiently and sustainably.“

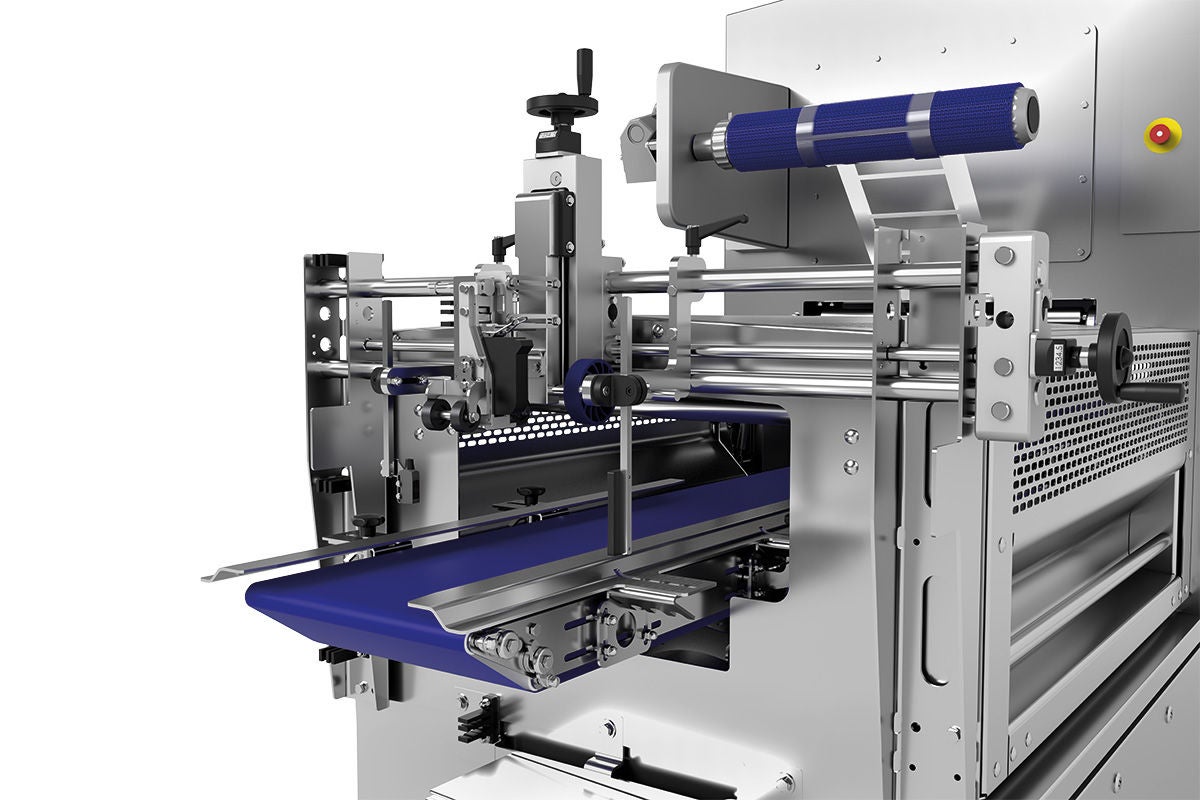

The MULTIVAC Cooling@Packing System is a vacuum application for cooling bakery products, which integrates the cooling process into the thermoforming packaging machine. This enables the bakery products to be packed immediately after baking, so that a longer product shelf life and greater freshness can be achieved.

Bakery products are traditionally cooled by means of cooling spirals at ambient temperature, or alternatively by passing through cooling tunnels. Both procedures require a lot of space in the production area, as well as a high level of investment. There is also the risk of product contamination during slow cooling processes.

The MULTIVAC Cooling@Packing System enables bakery products (e.g. baguettes, breads or biscuits) to be loaded directly from the oven, using loading robots to hygienically place the products into the open packs at the loading station of the thermoforming packaging machine. The bakery products are cooled down within a few seconds from 95°C to approx. 30°C in the packaging machine, using an evacuation process in the chambers. The cooling effect is produced by the vaporisation energy, which is released by the evaporation of the bakery product's own moisture during the evacuation process.

The MULTIVAC Cooling@Packing System not only offers space savings in production areas, but also savings in energy consumption for product cooling. The production capacity can also be increased thanks to shorter baking times, without the product quality suffering. The new solution can be integrated into MULTIVAC thermoforming packaging machines in the high-output range.

Press Release

MULTIVAC wins the German Packaging Award with Cooling@Packing

- Size

- 82 KB

- Format

Latest News

MULTIVAC Packaging Solutions at ACHEMA 2024

MULTIVAC Packaging Solutions at ACHEMA 2024

ANUGA FoodTec Presentation Event Highlights

ANUGA FoodTec Presentation Event Highlights

MULTIVAC Bakery Equipment Storefront Exterior

MULTIVAC Bakery Equipment Storefront Exterior

Pet Food Packaging Solutions by MULTIVAC

Pet Food Packaging Solutions by MULTIVAC

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

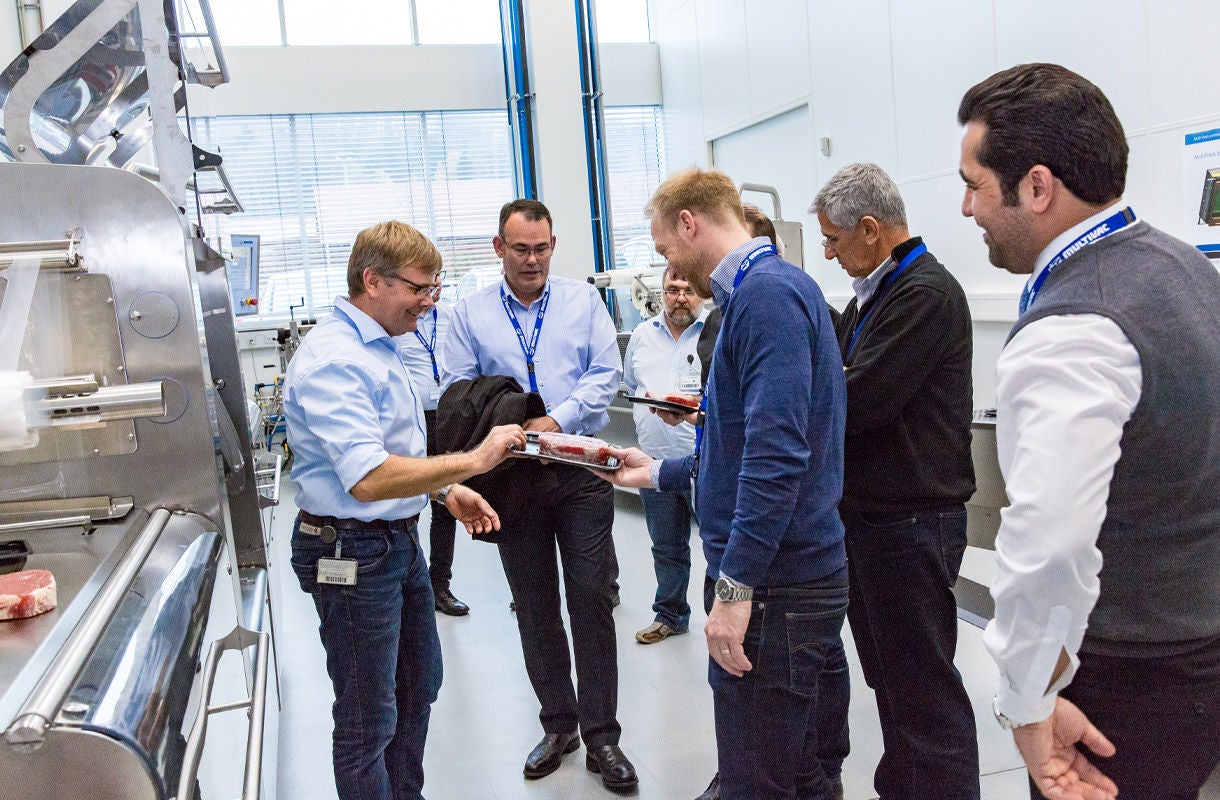

Business Team Meeting Group Photo

Business Team Meeting Group Photo

MULTIVAC Opening Ceremony Event

MULTIVAC Opening Ceremony Event

Conference Presentation with Audience

Conference Presentation with Audience

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

Group Holding Donation Checks Event

Group Holding Donation Checks Event

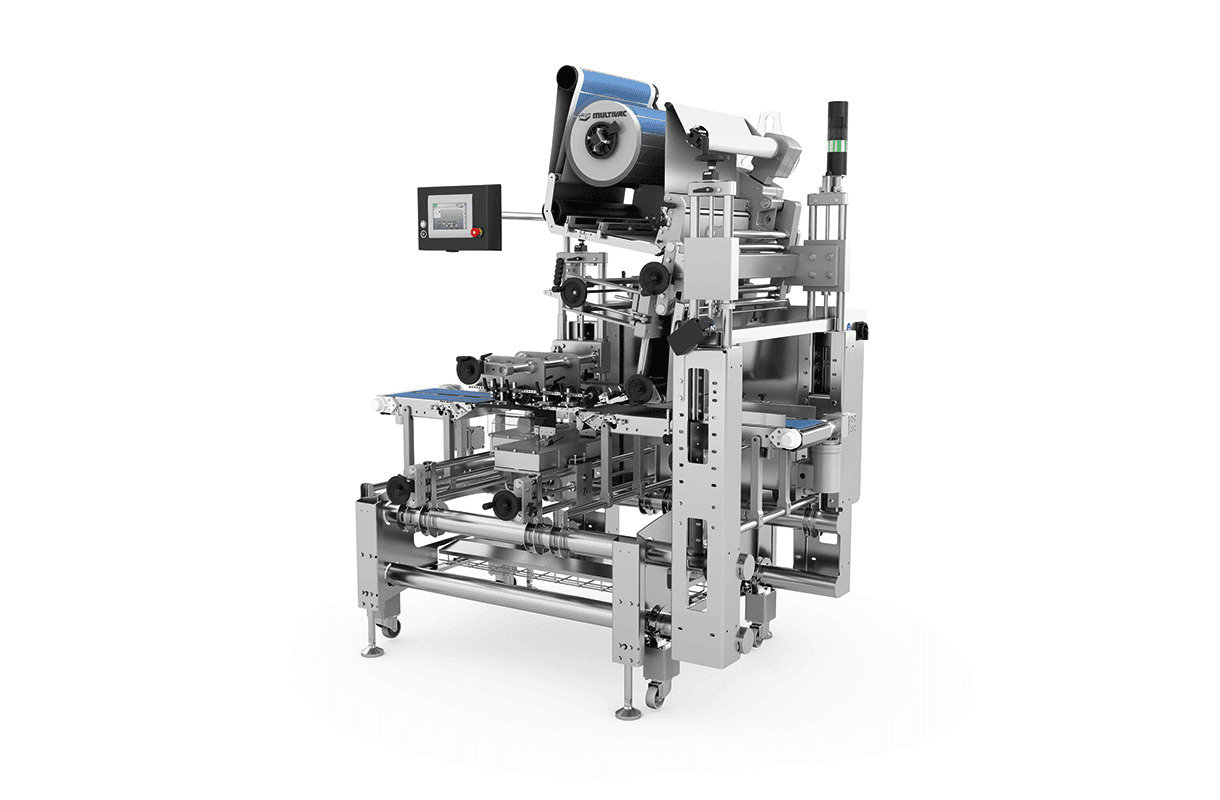

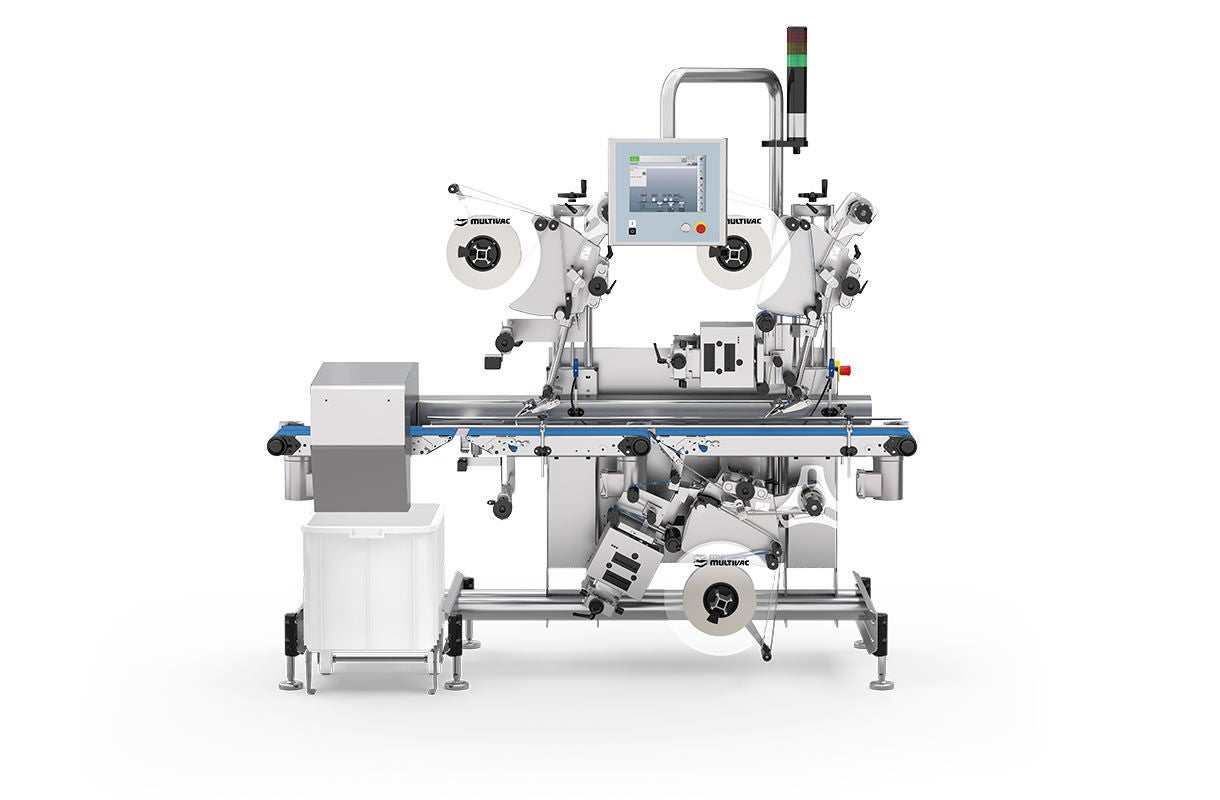

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

MULTIVAC Packaging Machine High-Tech Solution

Modern Conference Room with Presentation Screen

Modern Conference Room with Presentation Screen

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Presentation on Company Figures

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

MULTIVAC Packaging Machine Conveyor System

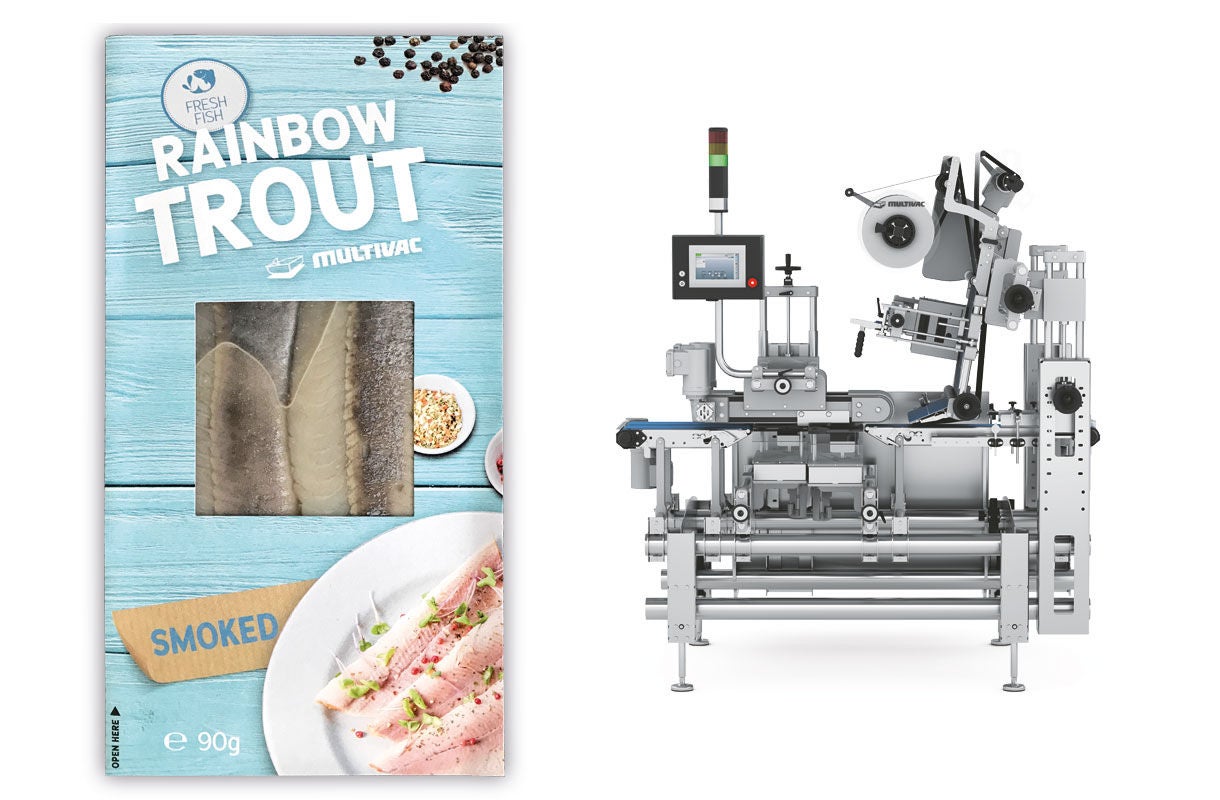

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

MULTIVAC Packaging Machine for Food Processing

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

Award Ceremony Group Photo with Certificates

MULTIVAC Factory Opening Ceremony Event

MULTIVAC Factory Opening Ceremony Event

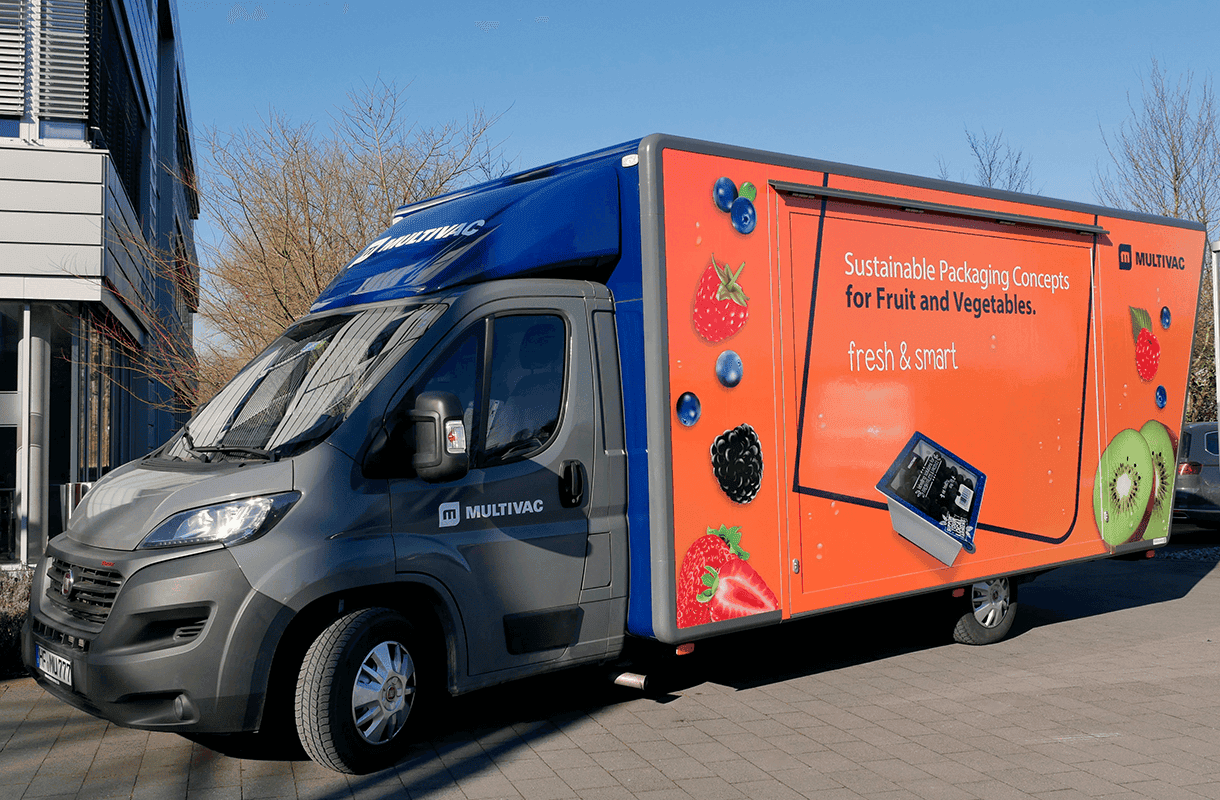

MULTIVAC Sustainable Packaging for Fresh Produce

MULTIVAC Sustainable Packaging for Fresh Produce

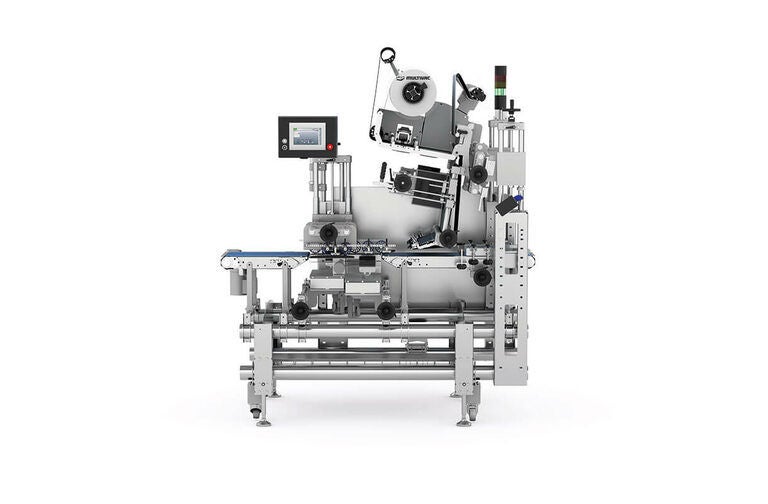

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC TX620 Packaging Machine Front View

MULTIVAC Website Displayed on Tablet Screen

MULTIVAC Website Displayed on Tablet Screen

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Seafood Packaging Solutions by MULTIVAC

Seafood Packaging Solutions by MULTIVAC

Conference Audience in Modern Auditorium

Conference Audience in Modern Auditorium

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

Baking Process with Freshly Kneaded Dough

MULTIVAC Sustainable Packaging Solutions

MULTIVAC Sustainable Packaging Solutions

Group Photo with Certificates on Wooden Stage

Group Photo with Certificates on Wooden Stage

Vegetable Soup Bowl on Wooden Table

Vegetable Soup Bowl on Wooden Table

Community Tree Planting Event Outdoors

Community Tree Planting Event Outdoors

MULTIVAC Future Proteins Conference Banner

MULTIVAC Future Proteins Conference Banner

Group Photo in Modern Office Setting

Group Photo in Modern Office Setting

MULTIVAC PDF

MULTIVAC PDF

MULTIVAC Headquarters Modern Architecture Design

MULTIVAC Headquarters Modern Architecture Design

Business Professional Portrait with Blurred Face

Business Professional Portrait with Blurred Face

Forest Group Hiking Adventure

Forest Group Hiking Adventure

Businessman in Formal Suit Portrait

Businessman in Formal Suit Portrait

Industrial Machinery Setup MULTIVAC Factory Overview

Industrial Machinery Setup MULTIVAC Factory Overview

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Facility Exterior with Palm Tree View

MULTIVAC Team Group Photo

MULTIVAC Team Group Photo

MULTIVAC Food Packaging Machine Display

MULTIVAC Food Packaging Machine Display

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Child Conducting Leaf Experiment with Pipette

Child Conducting Leaf Experiment with Pipette

MULTIVAC Packaging Machine Lineup

MULTIVAC Packaging Machine Lineup

MULTIVAC Charity Event with Red Cross Donation

MULTIVAC Charity Event with Red Cross Donation

MULTIVAC Packaging Machine High-Speed Efficiency

MULTIVAC Packaging Machine High-Speed Efficiency

Community Event in Large Tent Gathering

Community Event in Large Tent Gathering

MULTIVAC Anniversary Celebration Image

MULTIVAC Anniversary Celebration Image

Award Ceremony Group Photo on Stage

Award Ceremony Group Photo on Stage

Business Presentation with MULTIVAC Executives

Business Presentation with MULTIVAC Executives

Fleischer-Handwerk Award Ceremony Event Photo

Fleischer-Handwerk Award Ceremony Event Photo

MULTIVAC Trade Show Presentation

MULTIVAC Trade Show Presentation

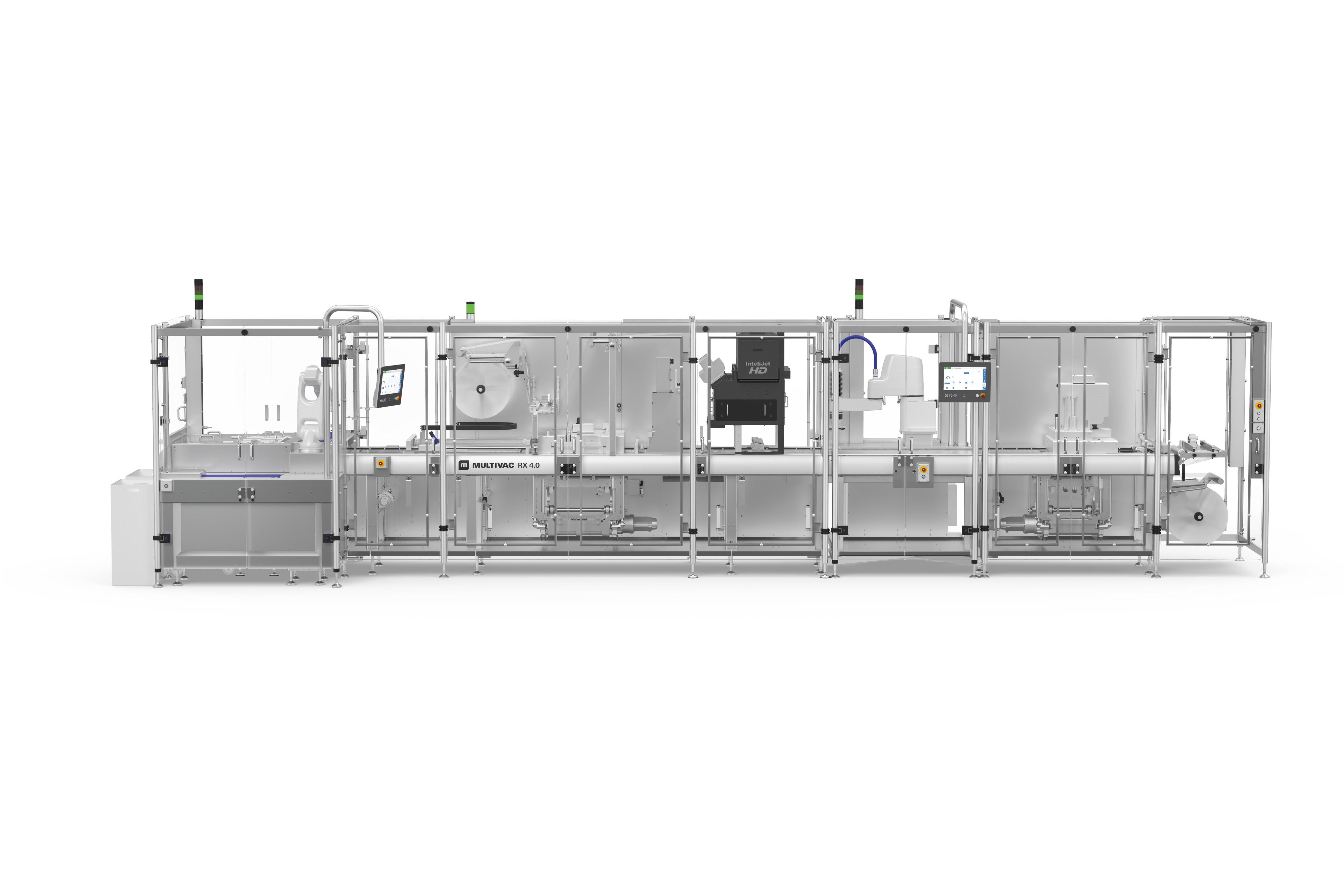

MULTIVAC Packaging Machine for Efficient Food Processing

MULTIVAC Packaging Machine for Efficient Food Processing

Business Presentation with MULTIVAC Equipment

Business Presentation with MULTIVAC Equipment

MULTIVAC Packaging Machine at Trade Show

MULTIVAC Packaging Machine at Trade Show

MULTIVAC Packaging Machine with Conveyor System

MULTIVAC Packaging Machine with Conveyor System

MULTIVAC Certification Ceremony

MULTIVAC Certification Ceremony

MULTIVAC Packaging Machine with Fresh Meat Display

MULTIVAC Packaging Machine with Fresh Meat Display

MULTIVAC T305 Packaging Machine Image

MULTIVAC T305 Packaging Machine Image

MULTIVAC Vacuum Packaging for Fresh Meat Products

MULTIVAC Vacuum Packaging for Fresh Meat Products

MULTIVAC Groundbreaking Ceremony Event

MULTIVAC Groundbreaking Ceremony Event

Groundbreaking Ceremony with Shovels

Groundbreaking Ceremony with Shovels

MULTIVAC Certificate Presentation Event

MULTIVAC Certificate Presentation Event

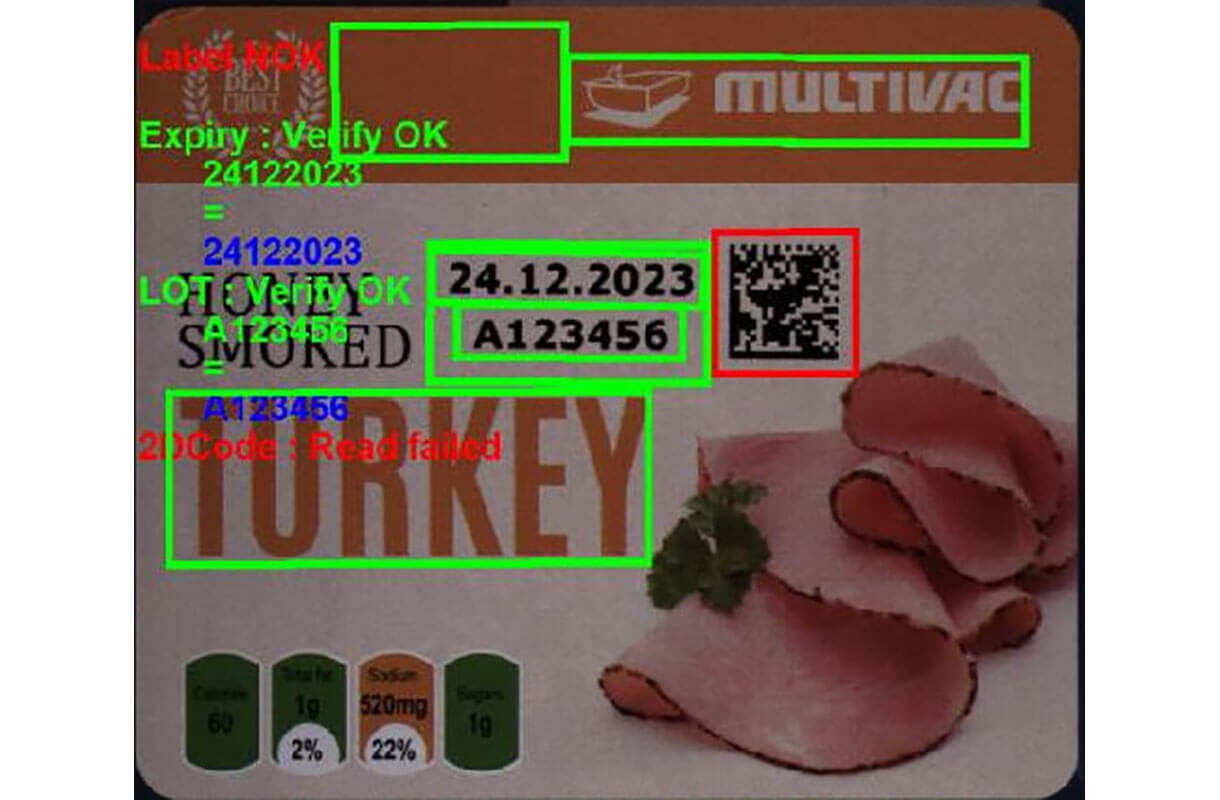

MULTIVAC Packaging Machine Label Verification

MULTIVAC Packaging Machine Label Verification

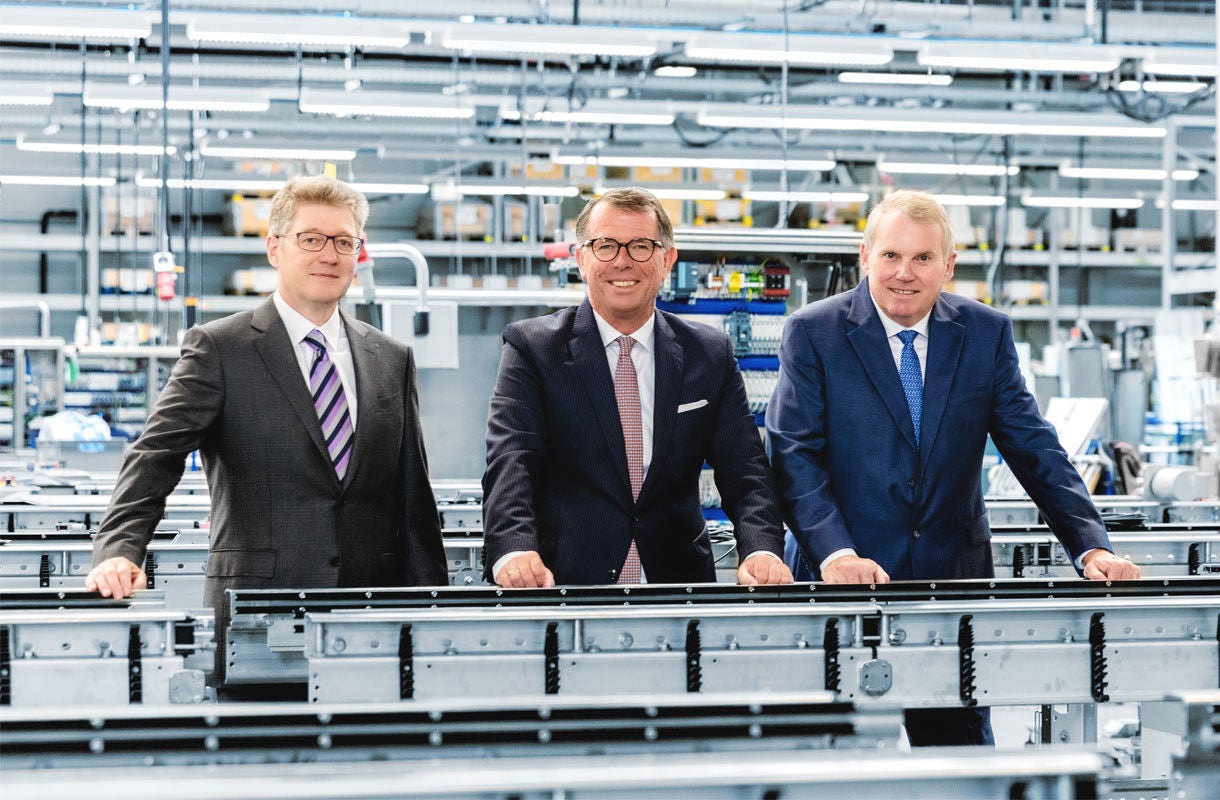

Business Professionals in Formal Attire

Business Professionals in Formal Attire

MULTIVAC TVI Facility at Sunset Landscape View

MULTIVAC TVI Facility at Sunset Landscape View

MULTIVAC Food Packaging Solutions Display

MULTIVAC Food Packaging Solutions Display

Professional Woman in Business Attire

Professional Woman in Business Attire

MULTIVAC TX 710 Packaging Machine Front View

MULTIVAC TX 710 Packaging Machine Front View

Bayerns Best 50 Award Ceremony Event

Bayerns Best 50 Award Ceremony Event

Medical Packaging Solutions by MULTIVAC

Medical Packaging Solutions by MULTIVAC

MULTIVAC Training Center Team Photo

MULTIVAC Training Center Team Photo

MULTIVAC Food Packaging Machine Demonstration

MULTIVAC Food Packaging Machine Demonstration

Business Conference Panel Discussion Event

Business Conference Panel Discussion Event

MULTIVAC Factory Exterior with German Flag

MULTIVAC Factory Exterior with German Flag

Business Professional in Brown Suit

Business Professional in Brown Suit

MULTIVAC Business Executives Portrait

MULTIVAC Business Executives Portrait

MULTIVAC Meat Packaging Solutions Display

MULTIVAC Meat Packaging Solutions Display

MULTIVAC Packaging Machine Advanced Technology

MULTIVAC Packaging Machine Advanced Technology

MULTIVAC Packaging Machine Front View

MULTIVAC Packaging Machine Front View

MULTIVAC Headquarters Modern Architectural Design

MULTIVAC Headquarters Modern Architectural Design

Recyclable Packaging Solutions by MULTIVAC

Recyclable Packaging Solutions by MULTIVAC

Team Meeting in Modern Office Space

Team Meeting in Modern Office Space

Warehouse Automation with MULTIVAC Packaging Machine

Warehouse Automation with MULTIVAC Packaging Machine

MULTIVAC B425 Packaging Machine Front View

MULTIVAC B425 Packaging Machine Front View

Business Meeting Room with Beverage Setup

Business Meeting Room with Beverage Setup

Office Meeting with Laptops and MULTIVAC Presentation

Office Meeting with Laptops and MULTIVAC Presentation

MULTIVAC Packaging Machine in Factory Setting

MULTIVAC Packaging Machine in Factory Setting

Businessman in Modern Office Corridor

Businessman in Modern Office Corridor

MULTIVAC 60th Anniversary Celebration Event

MULTIVAC 60th Anniversary Celebration Event

Award Ceremony Event at Modern Venue

Award Ceremony Event at Modern Venue

MULTIVAC Executive Portrait in Business Attire

MULTIVAC Executive Portrait in Business Attire

Cheese Slices with Tomato and Parsley on Wooden Board

Cheese Slices with Tomato and Parsley on Wooden Board

MULTIVAC Packaging Machine Celebrating 60 Years

MULTIVAC Packaging Machine Celebrating 60 Years

Smart Packaging Solutions Discussion

Smart Packaging Solutions Discussion

Business Professional in Modern Office Corridor

Business Professional in Modern Office Corridor

Business Professional in Suit and Tie

Business Professional in Suit and Tie

MULTIVAC Packaging Machine with Touchscreen Interface

MULTIVAC Packaging Machine with Touchscreen Interface

Germany Service Technician Locations Map

Germany Service Technician Locations Map

Professional Portrait Photography

Professional Portrait Photography

MULTIVAC Packaging Machine in Factory Setting

MULTIVAC Packaging Machine in Factory Setting

Eco-Friendly Packaging Solutions by MULTIVAC

Eco-Friendly Packaging Solutions by MULTIVAC

Business Meeting Award Ceremony Event

Business Meeting Award Ceremony Event

BGHM Team Event Group Photo

BGHM Team Event Group Photo

Shrimp Packaging Tray by MULTIVAC for Freshness

Shrimp Packaging Tray by MULTIVAC for Freshness

MULTIVAC Packaging Solutions for Fresh Produce

MULTIVAC Packaging Solutions for Fresh Produce

Children Playing Card Games Indoors

Children Playing Card Games Indoors

MULTIVAC Packaging Machine with Printed Labels

MULTIVAC Packaging Machine with Printed Labels

Deutschland Stipendium Event at Hochschule Kempten

Deutschland Stipendium Event at Hochschule Kempten

MULTIVAC Team Achievement Award Ceremony

MULTIVAC Team Achievement Award Ceremony

MULTIVAC Packaging Machine for Medical Devices

MULTIVAC Packaging Machine for Medical Devices

MULTIVAC TX 710 Packaging Machine at Trade Show

MULTIVAC TX 710 Packaging Machine at Trade Show

MULTIVAC Team Group Photo

MULTIVAC Team Group Photo

MULTIVAC Packaging Machine with Dual Reel System

MULTIVAC Packaging Machine with Dual Reel System

Group of Children Celebrating Outdoors

Group of Children Celebrating Outdoors

MULTIVAC Packaging Machine in Industrial Setting

MULTIVAC Packaging Machine in Industrial Setting

MULTIVAC Factory Production Line Overview

MULTIVAC Factory Production Line Overview

Group Photo at Competence Center Event

Group Photo at Competence Center Event

MULTIVAC Packaging Machine Front View

MULTIVAC Packaging Machine Front View

Construction Site Groundbreaking Ceremony

Construction Site Groundbreaking Ceremony

MULTIVAC Award Ceremony Event

MULTIVAC Award Ceremony Event

Group Photo Outside Building Entrance

Group Photo Outside Building Entrance

MULTIVAC Packaging Machine Presentation

MULTIVAC Packaging Machine Presentation

MULTIVAC Meat Packaging Solution Display

MULTIVAC Meat Packaging Solution Display

MULTIVAC TX 710 Packaging Machine Front View

MULTIVAC TX 710 Packaging Machine Front View

Open Industry 4.0 Alliance Logo Design

Open Industry 4.0 Alliance Logo Design

MULTIVAC Meat Packaging Solution Display

MULTIVAC Meat Packaging Solution Display

Fresh Salad Bowl Packaging by MULTIVAC

Fresh Salad Bowl Packaging by MULTIVAC

Vacuum Packaging Machine MULTIVAC Meat Tray

Vacuum Packaging Machine MULTIVAC Meat Tray

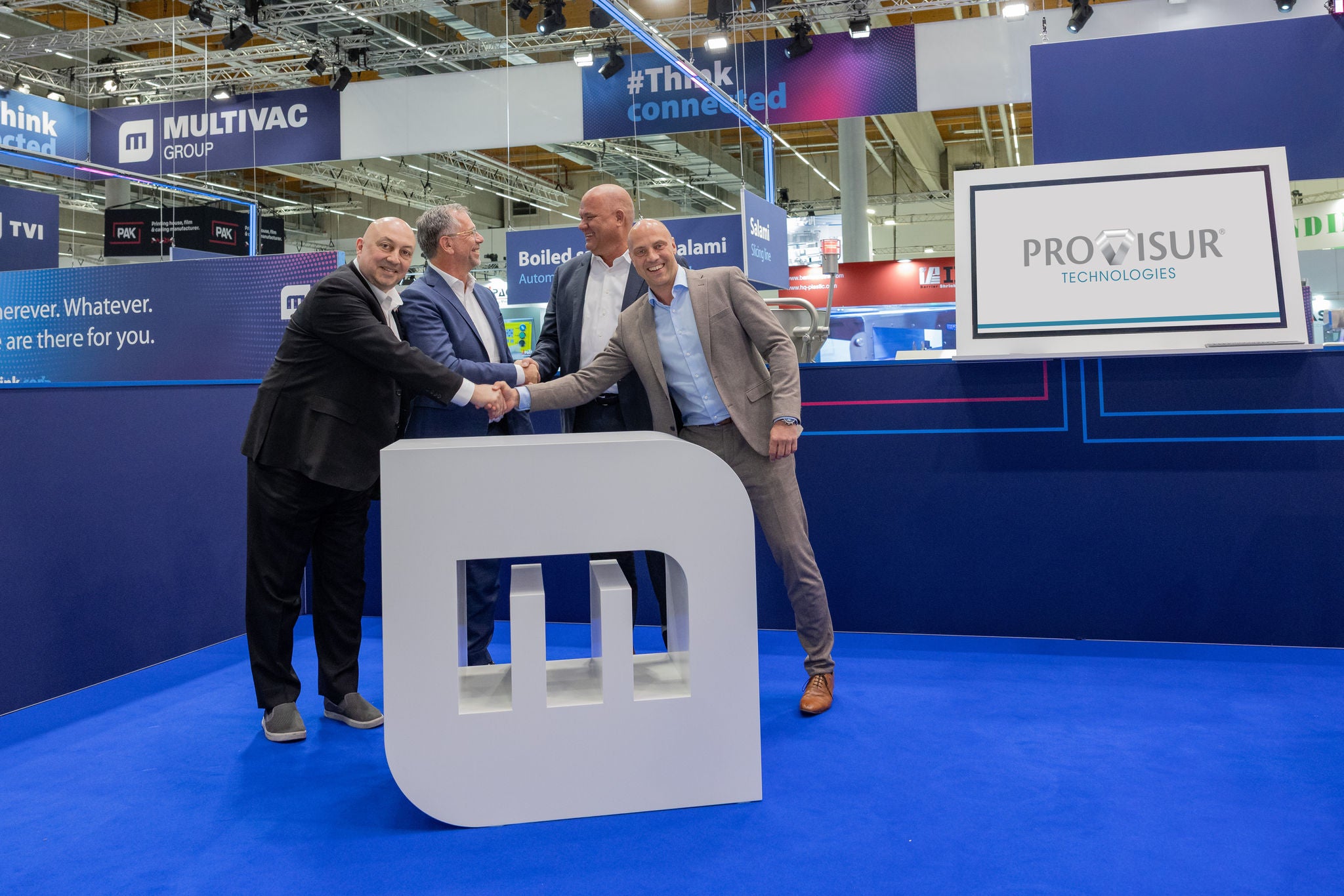

Business Networking Event Global Collaboration

Business Networking Event Global Collaboration

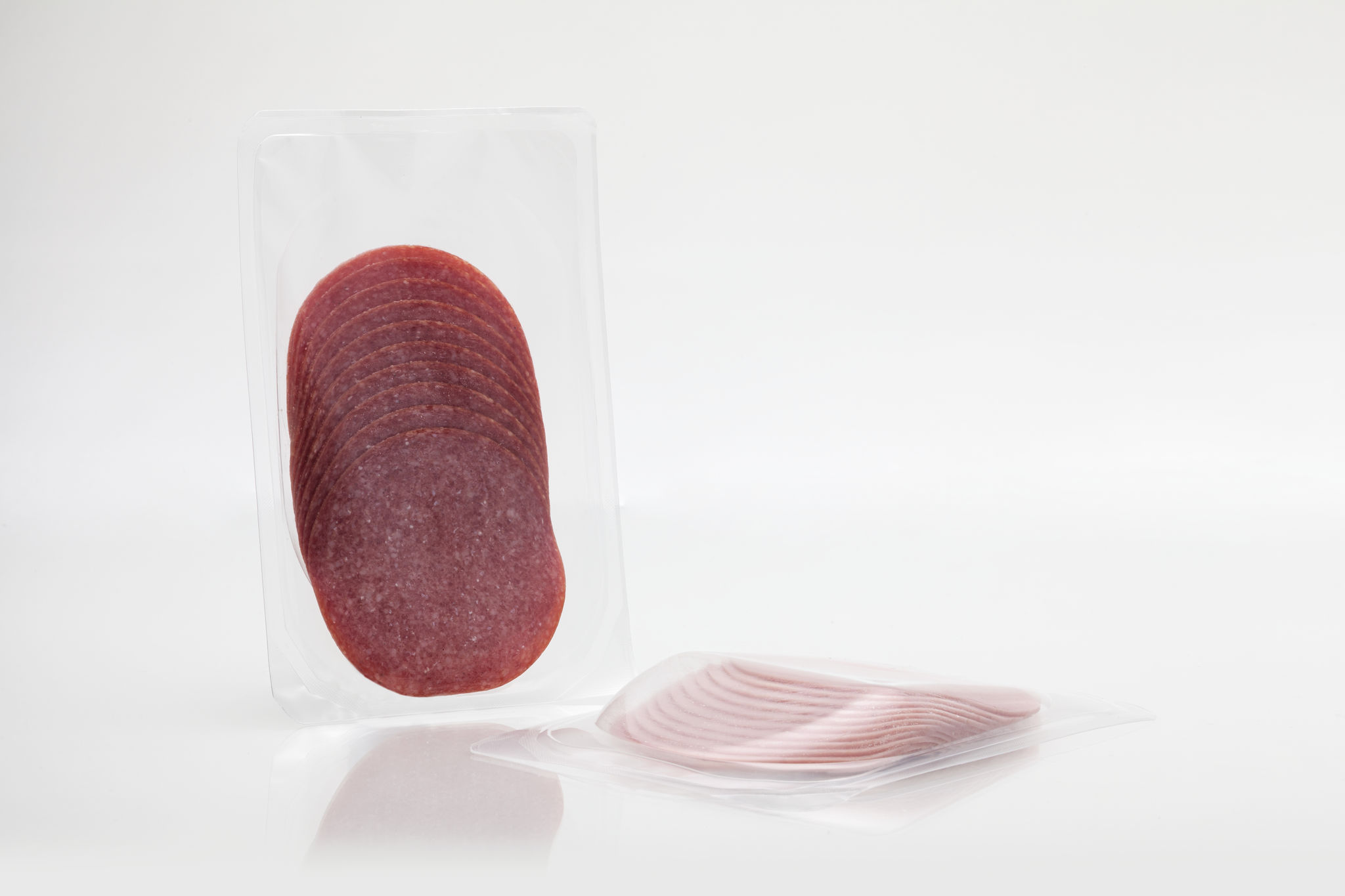

Salami Packaging by MULTIVAC: Freshness Guaranteed

Salami Packaging by MULTIVAC: Freshness Guaranteed

Pharmaceutical Blister Packaging Machine MULTIVAC

Pharmaceutical Blister Packaging Machine MULTIVAC

MULTIVAC Vacuum Sealer Control Panel Close-Up

MULTIVAC Vacuum Sealer Control Panel Close-Up

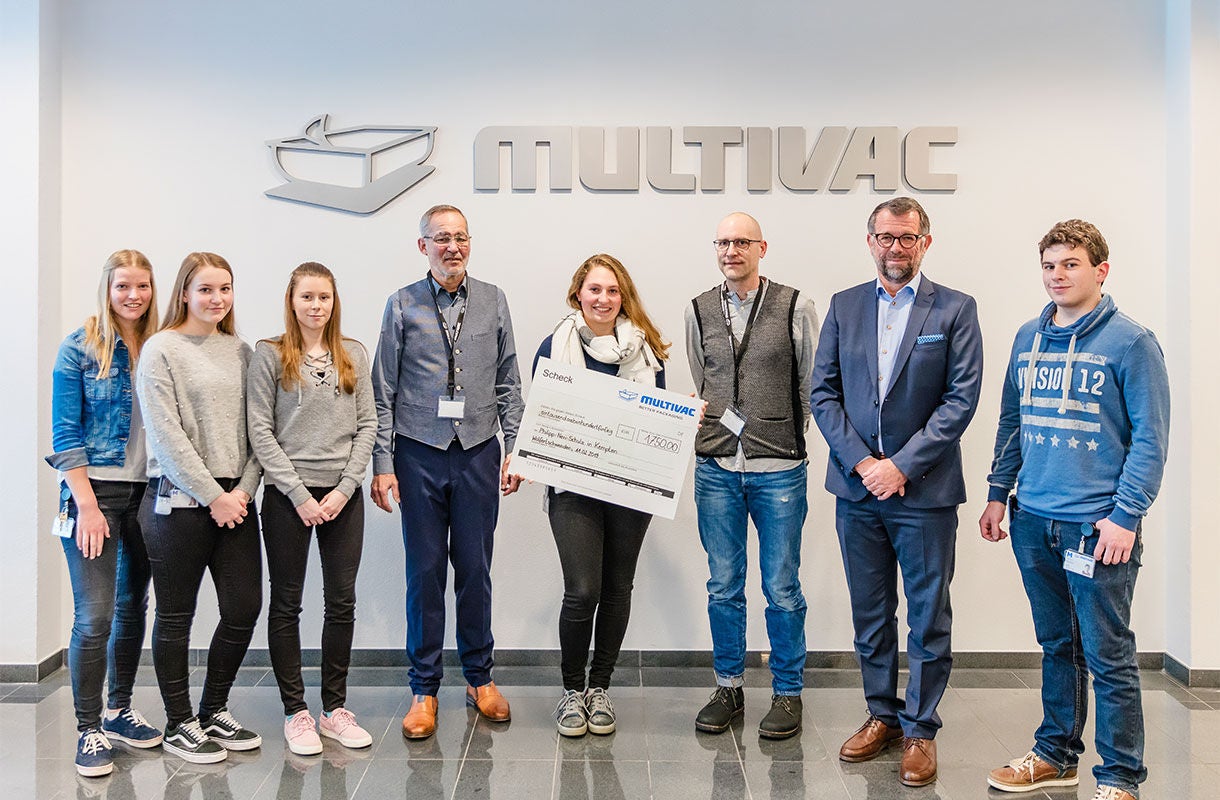

MULTIVAC Donation Ceremony Group Photo

MULTIVAC Donation Ceremony Group Photo

MULTIVAC Meat Packaging Solution Display

MULTIVAC Meat Packaging Solution Display

MULTIVAC Headquarters Modern Architectural Design

MULTIVAC Headquarters Modern Architectural Design

Tanja Böck

Public Relations Manager

Tel: +49 8334 601-0

Mail: press@multivac-group.com