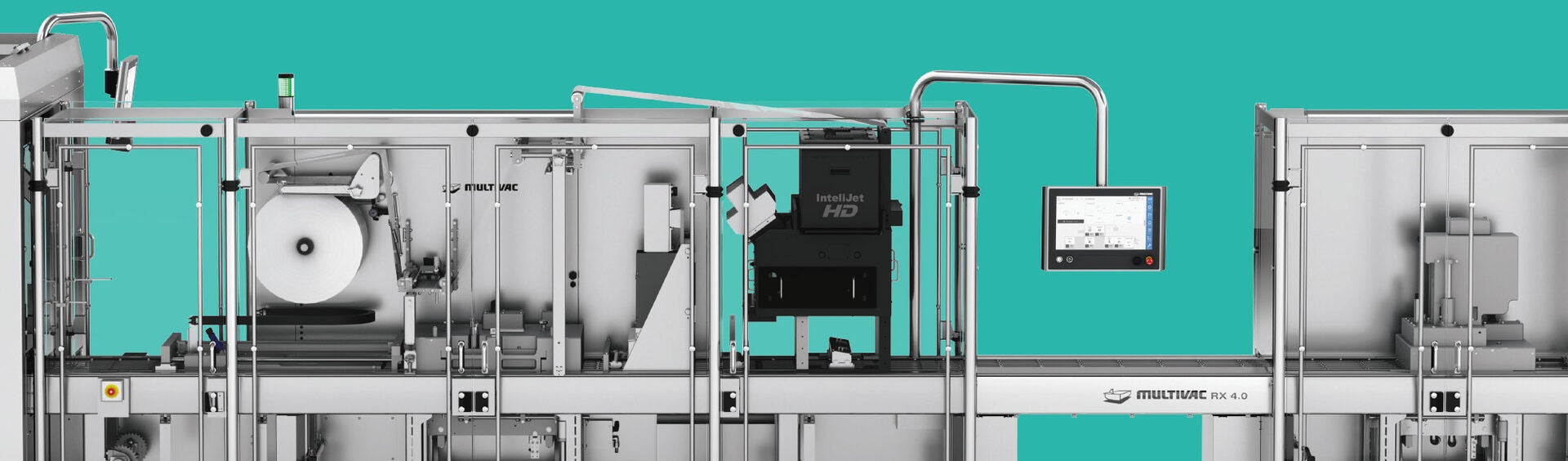

최대 효율성을 갖춘 최소한의 Change-over 시간

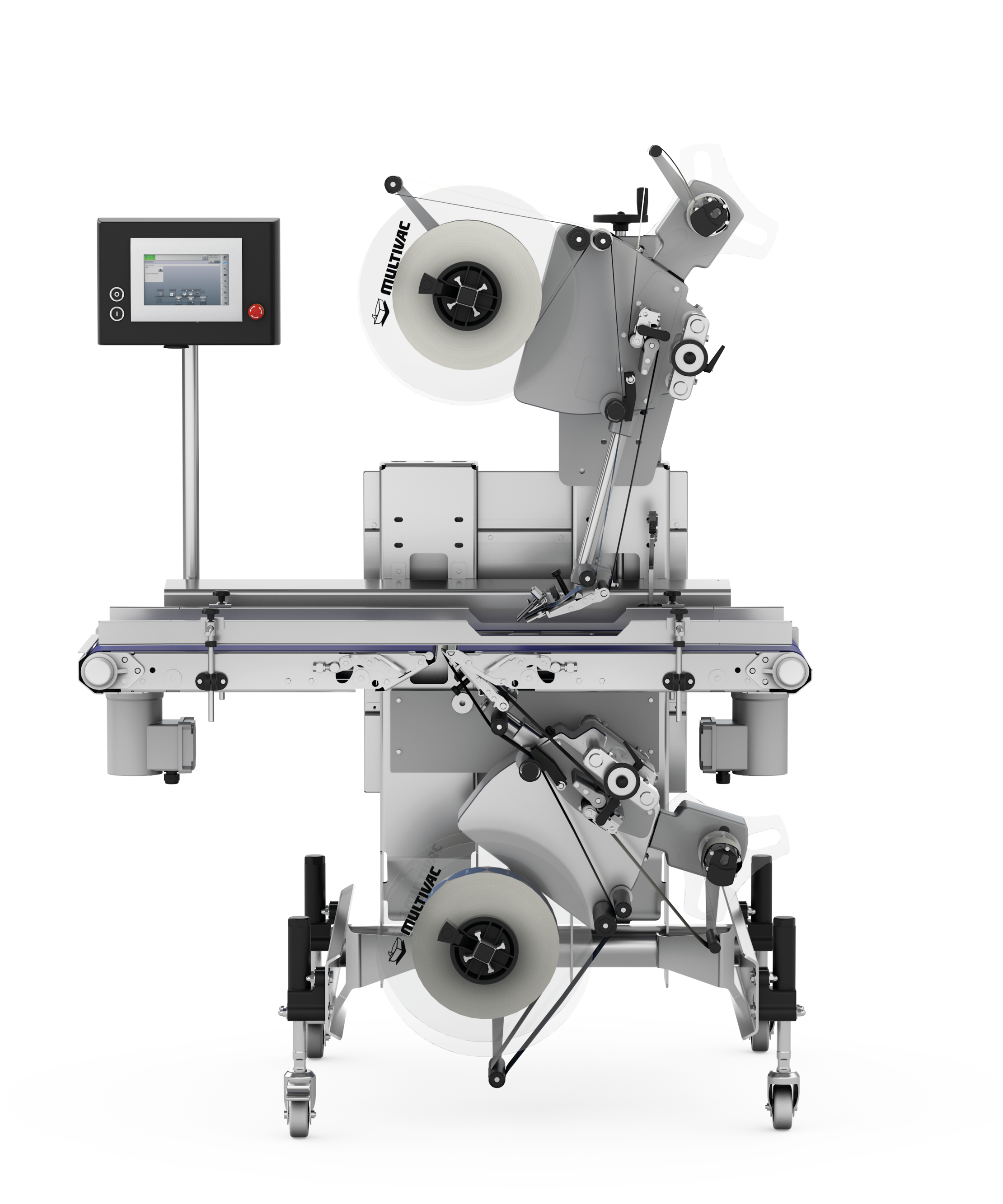

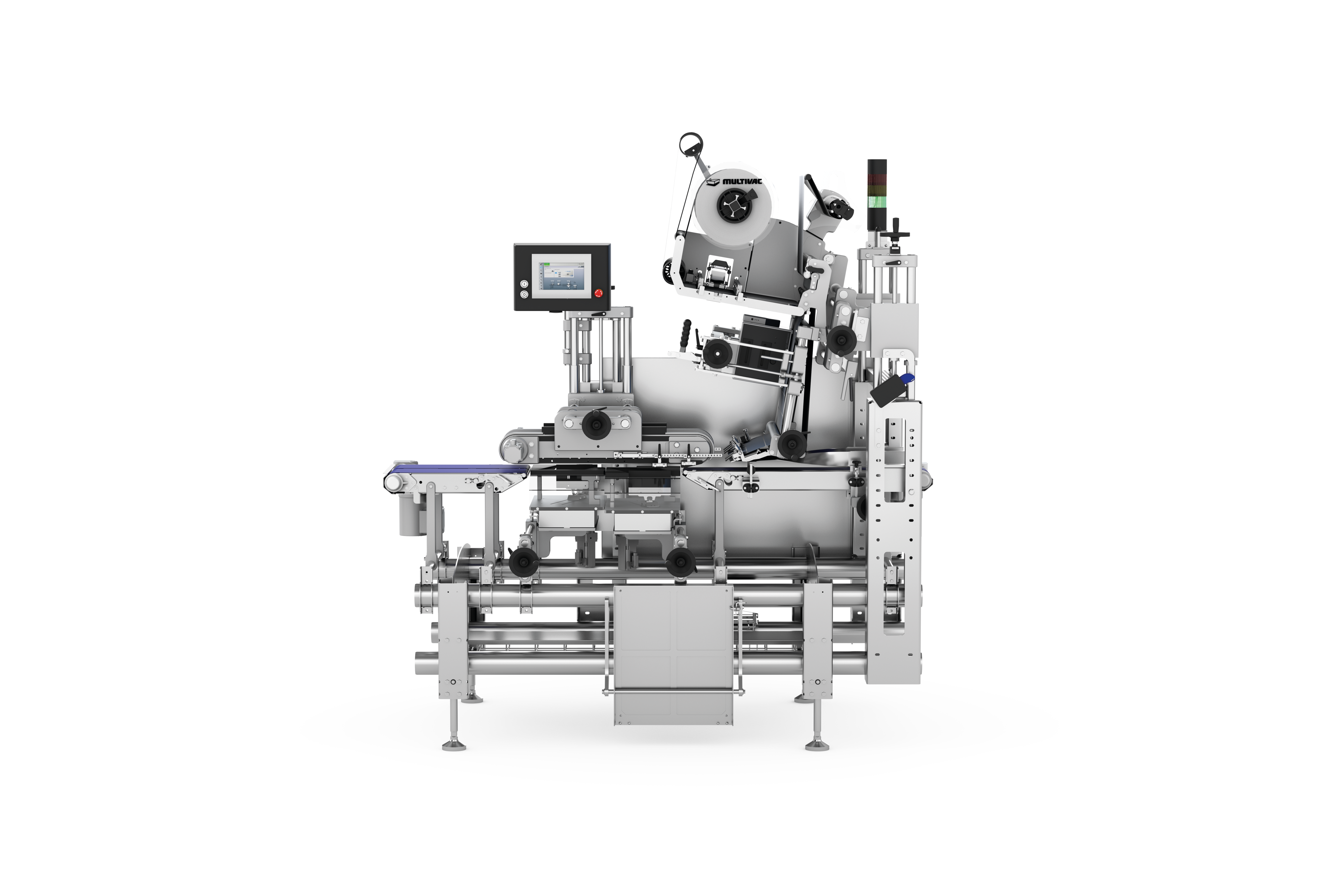

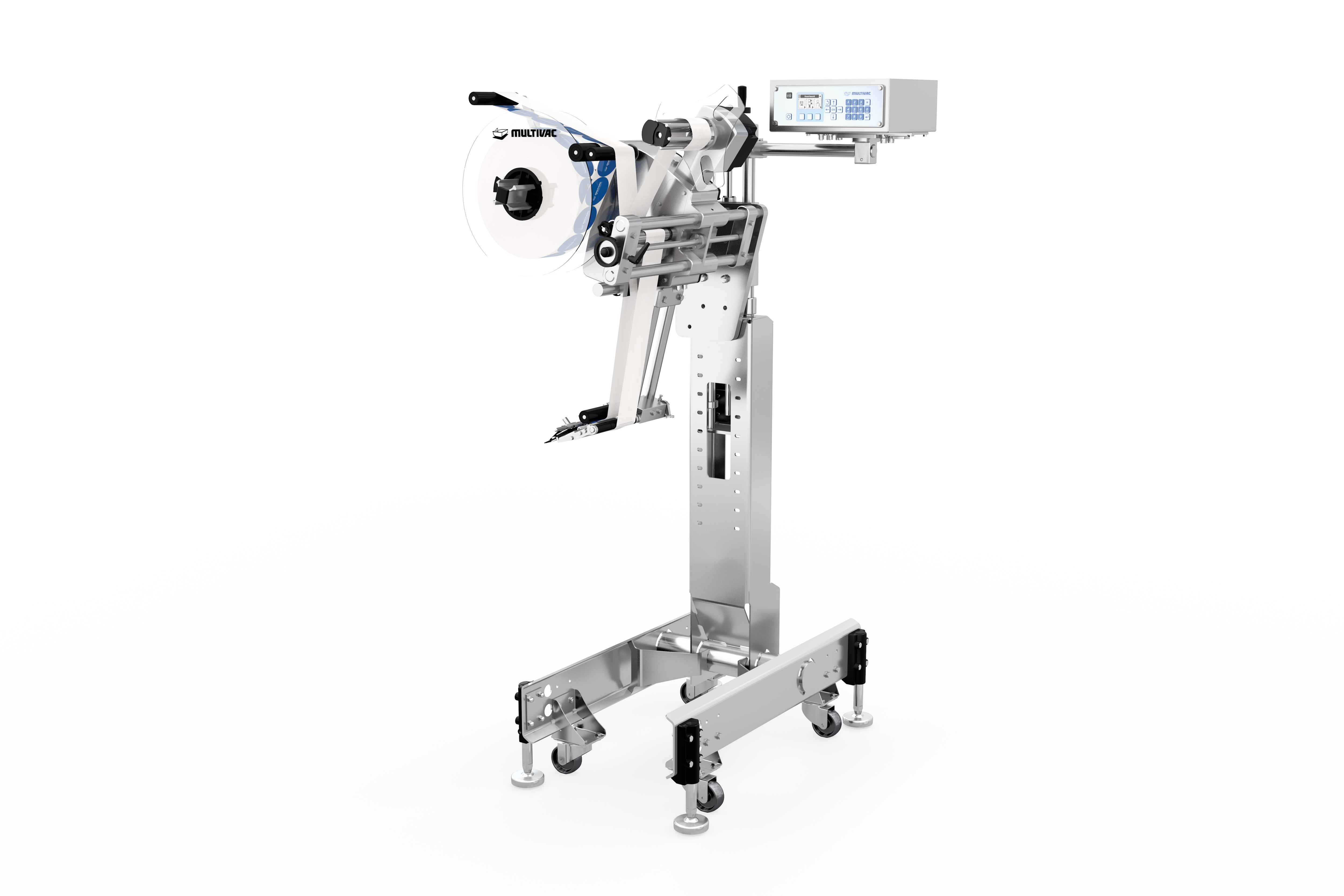

MULTIVAC 솔루션은 다양한 라벨링 공정을 지원하고 귀사 요건에 정확하게 조정할 수 있습니다.

당사의 라벨링 시스템과 프린터는 우수한 결과를 만들어 내어 판매 진열대에서 고객의 제품이 타경쟁 업체와 차별 될 수 있습니다. 짧은 제품 모델 교체 시간과 위생적인 디자인 구조, 적은 정비요소는 장비 시스템 효율성을 높일 수 있습니다. 당사의 라벨링 솔루션은 기존 생산 라인과 포장 라인을 바로 통합할 수 있습니다. HMI(유저 인터페이스)를 통해 또는 당사 포장기를 통해 직접 제어할 수 있으며, 라벨링과 관련하여 귀사는 원하는 라벨 형태와 라벨재료를 독립적으로 사용 가능합니다.

비용 절감과 신뢰성

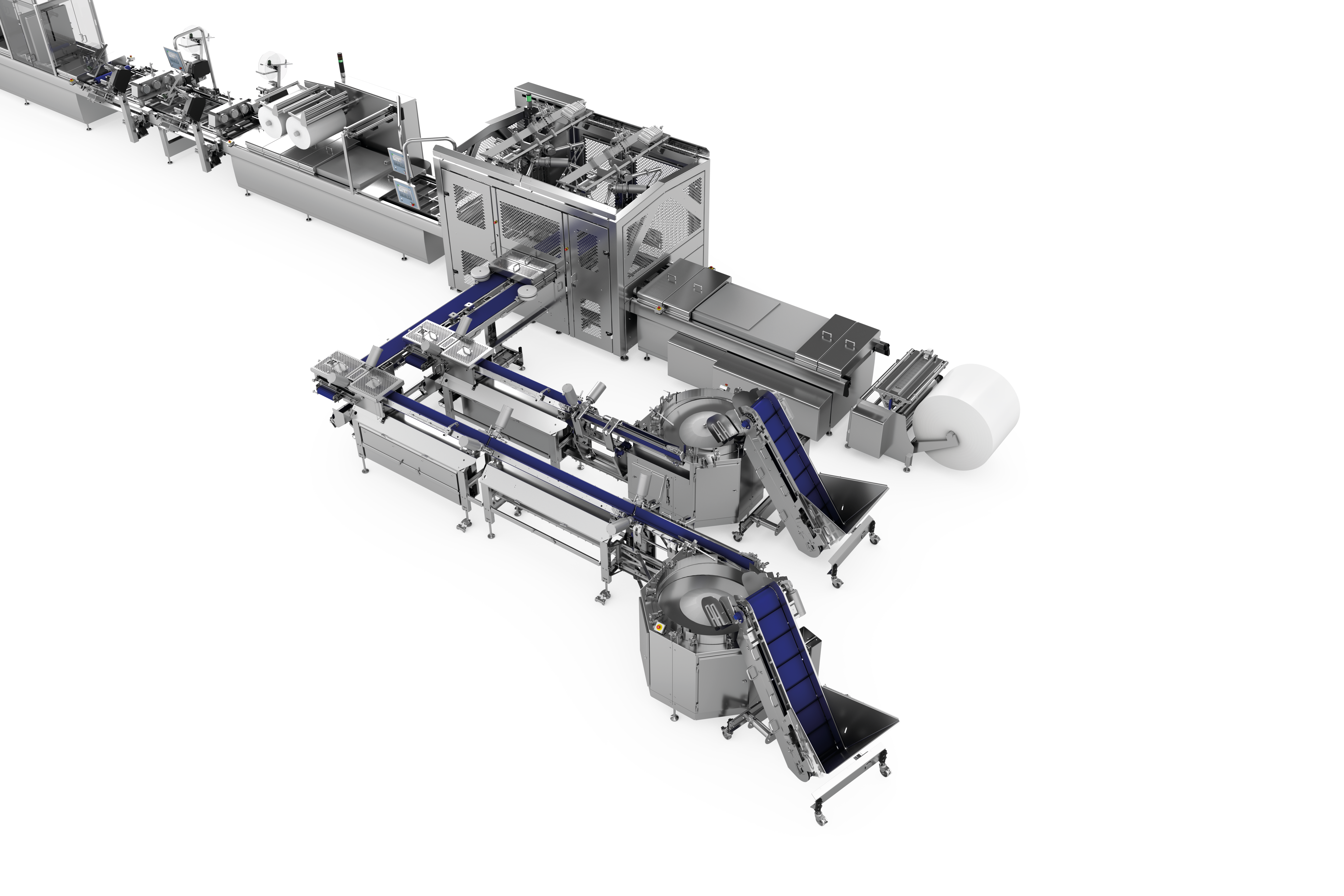

개별 프로세스, 특히 전체 프로세스에 대한 오랜 경험과 전문 지식 덕분에 당사는 요구 조건이 훨씬 복잡함에도 필요에 맞는 솔루션을 구현할 수 있습니다. 당사 포장기는 최적화된 라인 설치 면적, 적은 가동 비용 그리고 기술 및 소모품 측면에서 최고의 유연성을 특징으로 합니다. 당사 시스템은 내구성에 맞추어 설계되었고 다양한 위생 표준에 적합합니다. MULTIVAC 품질을 믿고 안전하게 투자하십시오.

추가 유연한 내용

성공 사례

Fresh Vegetables and Fruits Display

Fresh Vegetables and Fruits Display

Koninklijke Vezet places its trust in labelling solutions from MULTIVAC

Fresh food products, together with quality, convenience, and sustainability, are of increasing importance in the everyday lives of consumers. Koninklijke Vezet has developed into a fruit and vegetable specialist, which meets all these requirements. Companies which want to survive in the growing but very challenging fresh food market must also guarantee fast deliveries and the right packaging. Labelling is also an important part of the packaging procedure: labels not only have an effect on the appearance of the packs, they also contain important information for consumer protection.

Fresh food products, together with quality, convenience, and sustainability, are of increasing importance in the everyday lives of consumers. Koninklijke Vezet has developed into a fruit and vegetable specialist, which meets all these requirements. Companies which want to survive in the growing but very challenging fresh food market must also guarantee fast deliveries and the right packaging. Labelling is also an important part of the packaging procedure: labels not only have an effect on the appearance of the packs, they also contain important information for consumer protection.

추가 정보

Automated label and print inspection in the food industry

Rising demands in food labelling increase the complexity of information that has to be printed on labels. As the throughput of packaging lines continues to increase, it is no longer possible for the human eye to inspect label print thoroughly. Although present legislation does not yet stipulate the use of visual inspection systems for checking labels, investment in automatic inspection systems can be very beneficial for many reasons.

Rising demands in food labelling increase the complexity of information that has to be printed on labels. As the throughput of packaging lines continues to increase, it is no longer possible for the human eye to inspect label print thoroughly. Although present legislation does not yet stipulate the use of visual inspection systems for checking labels, investment in automatic inspection systems can be very beneficial for many reasons.

추가 정보

Cheese Platter with Grapes and Crackers

Cheese Platter with Grapes and Crackers

Cheese attractively packed

Vergeer Holland is one of the largest and most innovative cheese processors in the world. The company has grown in recent years into a flourishing business with 550 employees, and today packs around 60 million kilos of cheese per year. The company does not produce cheese, but specializes in maturing, slicing and packaging hard cheese. Its most important customers are retailing companies. When it comes to the packing and labelling of its diverse cheese products, Vergeer Holland relies on solutions from MULTIVAC: a total of 25 packaging machines and over 50 labellers from MULTIVAC are used within the company.

Vergeer Holland is one of the largest and most innovative cheese processors in the world. The company has grown in recent years into a flourishing business with 550 employees, and today packs around 60 million kilos of cheese per year. The company does not produce cheese, but specializes in maturing, slicing and packaging hard cheese. Its most important customers are retailing companies. When it comes to the packing and labelling of its diverse cheese products, Vergeer Holland relies on solutions from MULTIVAC: a total of 25 packaging machines and over 50 labellers from MULTIVAC are used within the company.

추가 정보

Potato Harvesting Machine by MULTIVAC

Potato Harvesting Machine by MULTIVAC

Potato specialities securely packed and protected

Systematic quality assurance from the growing of the product to the cooking process and right through to packing - that is the quality claim of Peka Kroef. The Dutch producer of pre-cooked potato specialities used the opportunity presented by the replacement of some of his packaging machinery to further improve the reliability and security of his overall packaging process. In conjunction with MULTIVAC, a solution was devised, which meant a major step forward in terms of productivity, efficiency, and sustainability.

Systematic quality assurance from the growing of the product to the cooking process and right through to packing - that is the quality claim of Peka Kroef. The Dutch producer of pre-cooked potato specialities used the opportunity presented by the replacement of some of his packaging machinery to further improve the reliability and security of his overall packaging process. In conjunction with MULTIVAC, a solution was devised, which meant a major step forward in terms of productivity, efficiency, and sustainability.

추가 정보

Digital printing systems fulfil challenging pack marking requirements

The UDI Directive applies to all companies, which manufacture medical products or bring these into circulation. From 25 April 2020 all products of Class III together with implants must be marked with a distinct and unique identification number, and this applies from May 2023 to products of Class IIa and IIb, as well as from 2025 to products of Class I. This distinct product identification is allocated by various bodies - these are currently GS1, HIBCC and ICCBBA. The products together with their master data and a so-called Basic UDI are registered in a new, central database (Eudamed) covering all of Europe.

The UDI Directive applies to all companies, which manufacture medical products or bring these into circulation. From 25 April 2020 all products of Class III together with implants must be marked with a distinct and unique identification number, and this applies from May 2023 to products of Class IIa and IIb, as well as from 2025 to products of Class I. This distinct product identification is allocated by various bodies - these are currently GS1, HIBCC and ICCBBA. The products together with their master data and a so-called Basic UDI are registered in a new, central database (Eudamed) covering all of Europe.

추가 정보

MULTIVAC Sausage Packaging Machine in Factory

MULTIVAC Sausage Packaging Machine in Factory

MULTIVAC Tray Sealer Machine Component

MULTIVAC Tray Sealer Machine Component

MULTIVAC Tray Carrier as a solution for packing in small series of batches

Comprehensive quality control

Comprehensive quality control

추가 정보

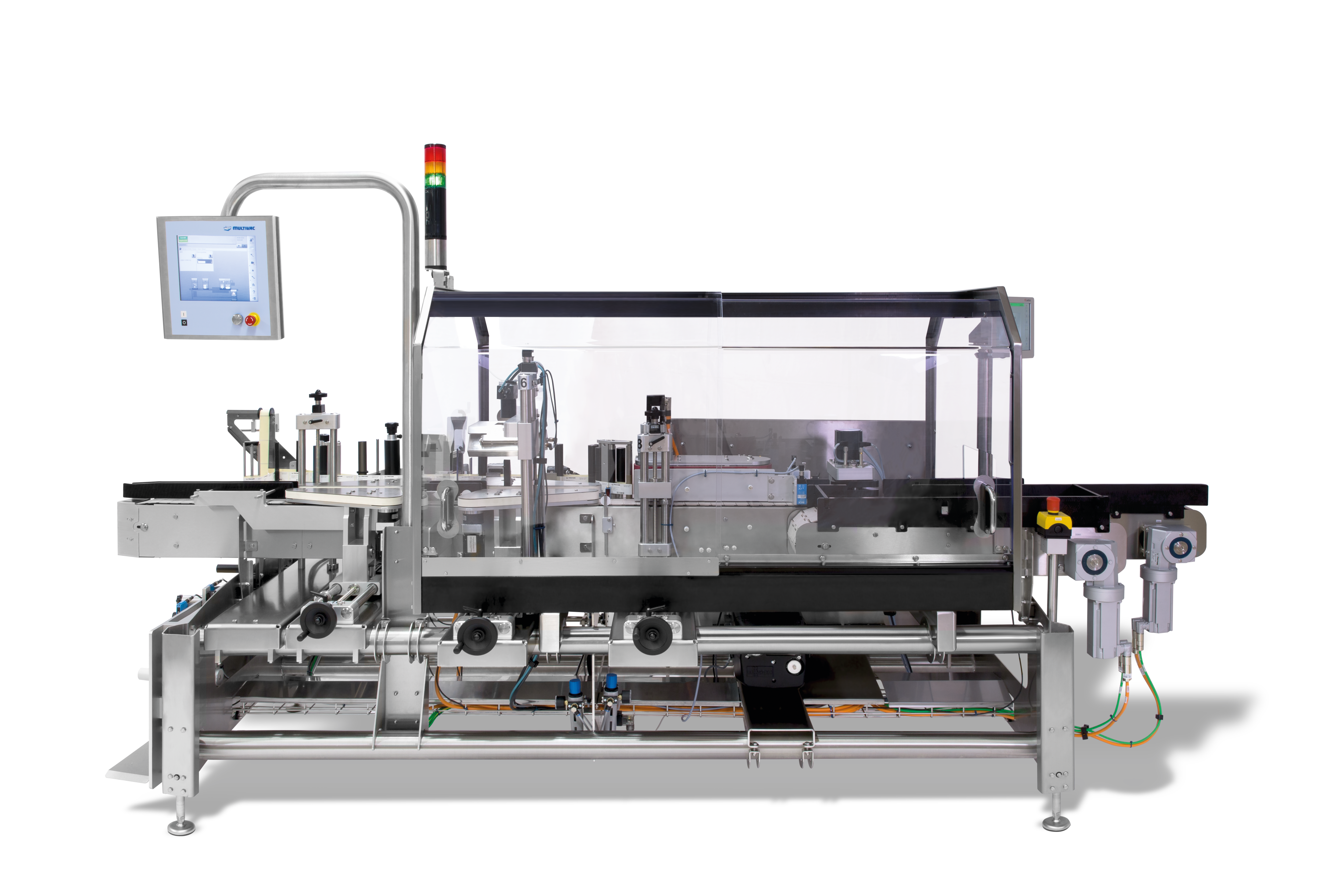

Success has a name

The modular conveyor belt labellers of the L 320 series from MULTIVAC Marking & Inspection offer the highest level of flexibility and precision in the labelling of cylindrical and oval products, shaped bottles, glasses and pots. Just such a model has recently been put into operation at Dr. August Wolff GmbH & Co. KG Arzneimittel for labelling the Linola products among others.

The modular conveyor belt labellers of the L 320 series from MULTIVAC Marking & Inspection offer the highest level of flexibility and precision in the labelling of cylindrical and oval products, shaped bottles, glasses and pots. Just such a model has recently been put into operation at Dr. August Wolff GmbH & Co. KG Arzneimittel for labelling the Linola products among others.

추가 정보

MULTIVAC Meat Skewer Packaging Machine Display

MULTIVAC Meat Skewer Packaging Machine Display

Networked, reliable and efficient: a new dimension in tray packaging

Whether it is gourmet hamburgers, filled chicken breast, beef and poultry kebabs or even veggie kebabs, pork fillets or asparagus in bacon - quality, innovation and appetizing appearance are always the first priority at Premier Custom Foods. The ethos of the food producer based in Kansas City is to transform high-quality raw materials into innovative food products, to rethink the concept of taste, and to constantly surprise consumers with new ideas.

Whether it is gourmet hamburgers, filled chicken breast, beef and poultry kebabs or even veggie kebabs, pork fillets or asparagus in bacon - quality, innovation and appetizing appearance are always the first priority at Premier Custom Foods. The ethos of the food producer based in Kansas City is to transform high-quality raw materials into innovative food products, to rethink the concept of taste, and to constantly surprise consumers with new ideas.

추가 정보

MULTIVAC Packaging Machine with Food Tray

MULTIVAC Packaging Machine with Food Tray

Sushi Mania - A bit of the Far East in Switzerland

Maximum efficiency, cost-effectiveness and pack appeal - with a big plus in terms of sustainability.

Maximum efficiency, cost-effectiveness and pack appeal - with a big plus in terms of sustainability.

추가 정보

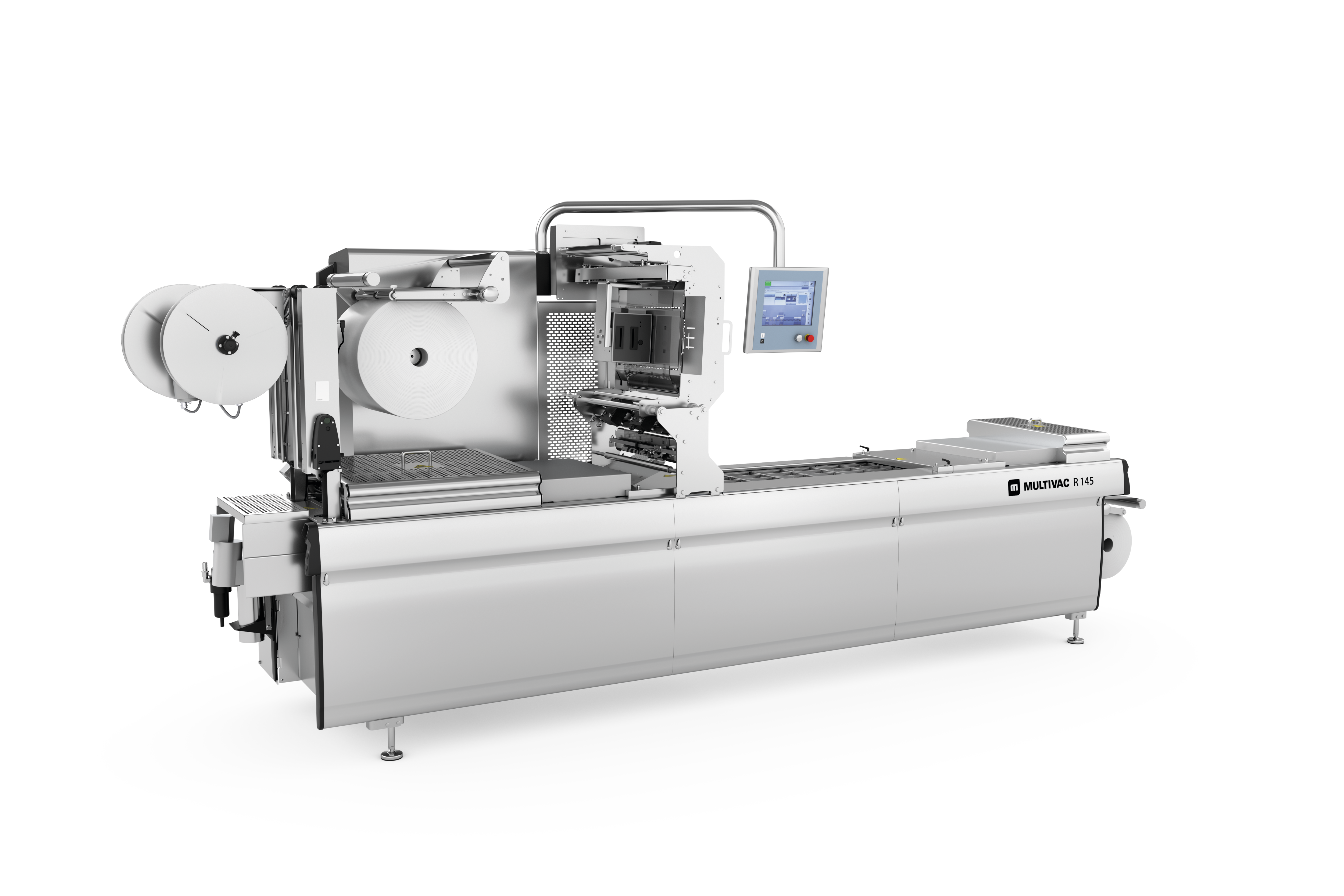

MultiFresh™ packs with full-wrap labelling increase the attractiveness at the point of sale

With its deep, clear and cold fjords, Norway is a paradise for salmon and salmon farms alike. Best conditions therefore for Seafood Farmers of Norway AS, which was founded in 1986, and its parent company the HOFSETH Group, which processes the freshly caught fish and exports most of it abroad. In order to increase the attractiveness of the fish products at the point of sale, the company in Valderøy recently invested in a thermoforming packaging machine for producing high-quality vacuum skin packs and in a labelling solution for the D labelling of the packs.

With its deep, clear and cold fjords, Norway is a paradise for salmon and salmon farms alike. Best conditions therefore for Seafood Farmers of Norway AS, which was founded in 1986, and its parent company the HOFSETH Group, which processes the freshly caught fish and exports most of it abroad. In order to increase the attractiveness of the fish products at the point of sale, the company in Valderøy recently invested in a thermoforming packaging machine for producing high-quality vacuum skin packs and in a labelling solution for the D labelling of the packs.

추가 정보

Sterile Medical Connectors by MULTIVAC

Sterile Medical Connectors by MULTIVAC

Valve sets packed efficiently and reliably

Science and technological progress, combined with inspiration and

determination - this is the basis of Boston Scientific's success.

Science and technological progress, combined with inspiration and

determination - this is the basis of Boston Scientific's success.

추가 정보

MULTIVAC Food Packaging Machine Honey Peppers

MULTIVAC Food Packaging Machine Honey Peppers

Attractive solutions for full-wrap labelling of packs

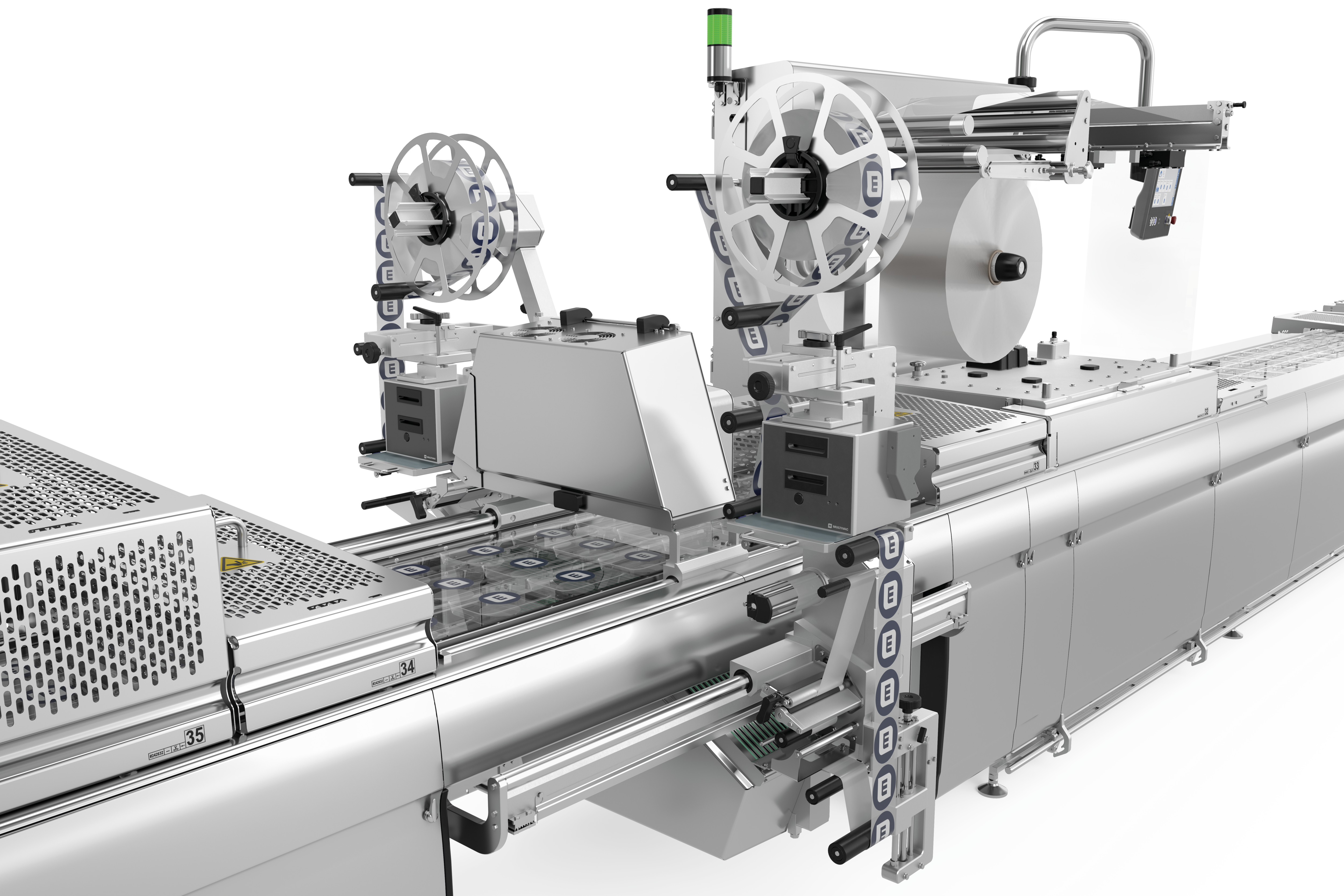

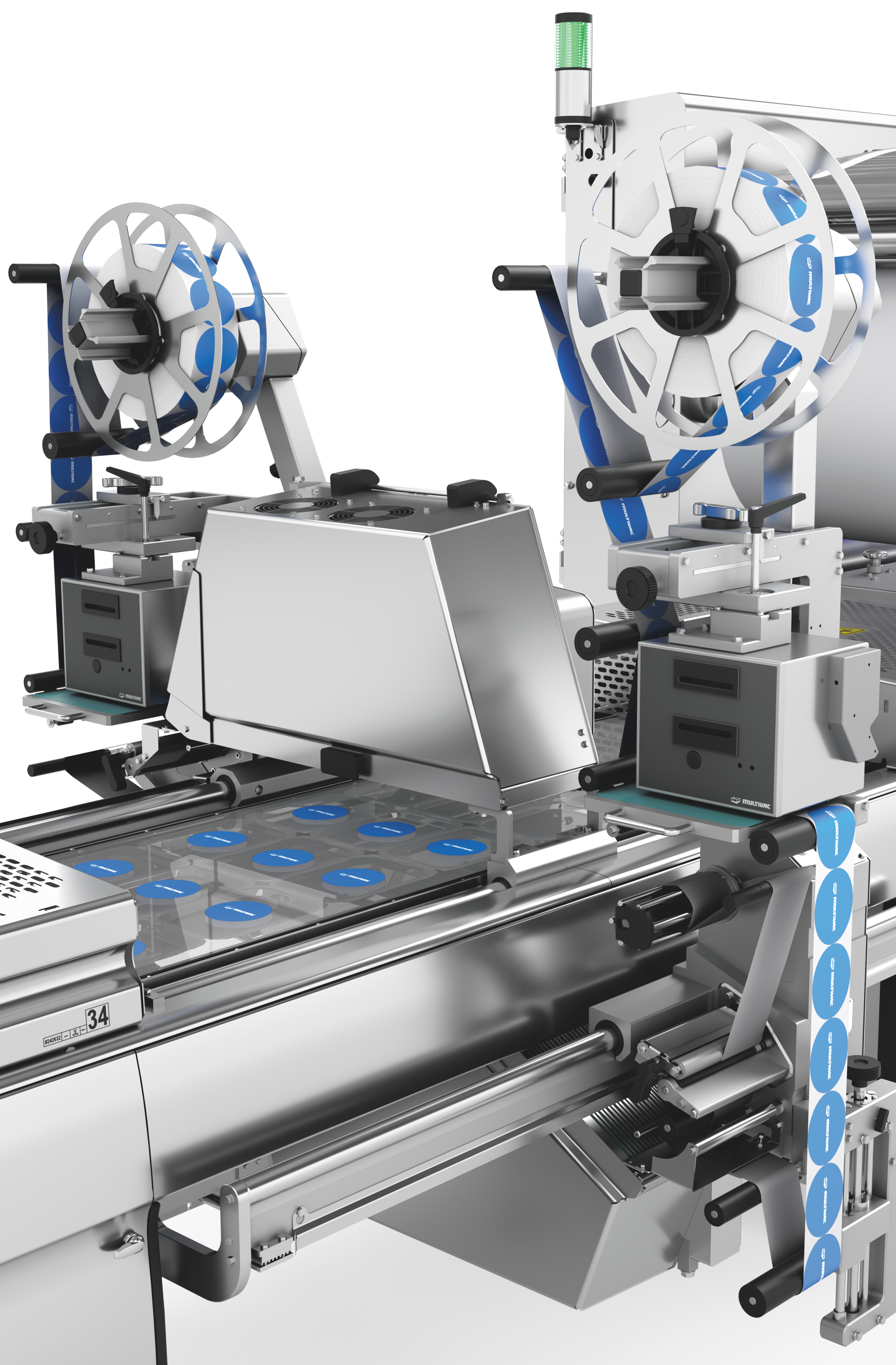

MULTIVAC Marking & Inspection has continually expanded its range of conveyor belt labellers in recent years. The spectrum now includes a wide range of solutions for many different labelling requirements and output categories – from the simple BASELINE conveyor belt labellers to 2-track labelling systems with up to ten label dispensers.

MULTIVAC Marking & Inspection has continually expanded its range of conveyor belt labellers in recent years. The spectrum now includes a wide range of solutions for many different labelling requirements and output categories – from the simple BASELINE conveyor belt labellers to 2-track labelling systems with up to ten label dispensers.

추가 정보

Healthy Salad Bowls with Fresh Ingredients

Healthy Salad Bowls with Fresh Ingredients

Vegetable Spread Packaging Design

Vegetable Spread Packaging Design

Labelling of dairy products

The range of dairy products is very large - it extends from hard cheese, semi-hard sliced cheese or soft cheese through to butter and cream cheese and right up to liquid or creamy products such as milk, whipped cream, and yogurt. In this article you will learn how the labelling process for the different product groups can be performed as reliably, efficiently, and cost-effectively as possible.

The range of dairy products is very large - it extends from hard cheese, semi-hard sliced cheese or soft cheese through to butter and cream cheese and right up to liquid or creamy products such as milk, whipped cream, and yogurt. In this article you will learn how the labelling process for the different product groups can be performed as reliably, efficiently, and cost-effectively as possible.

추가 정보

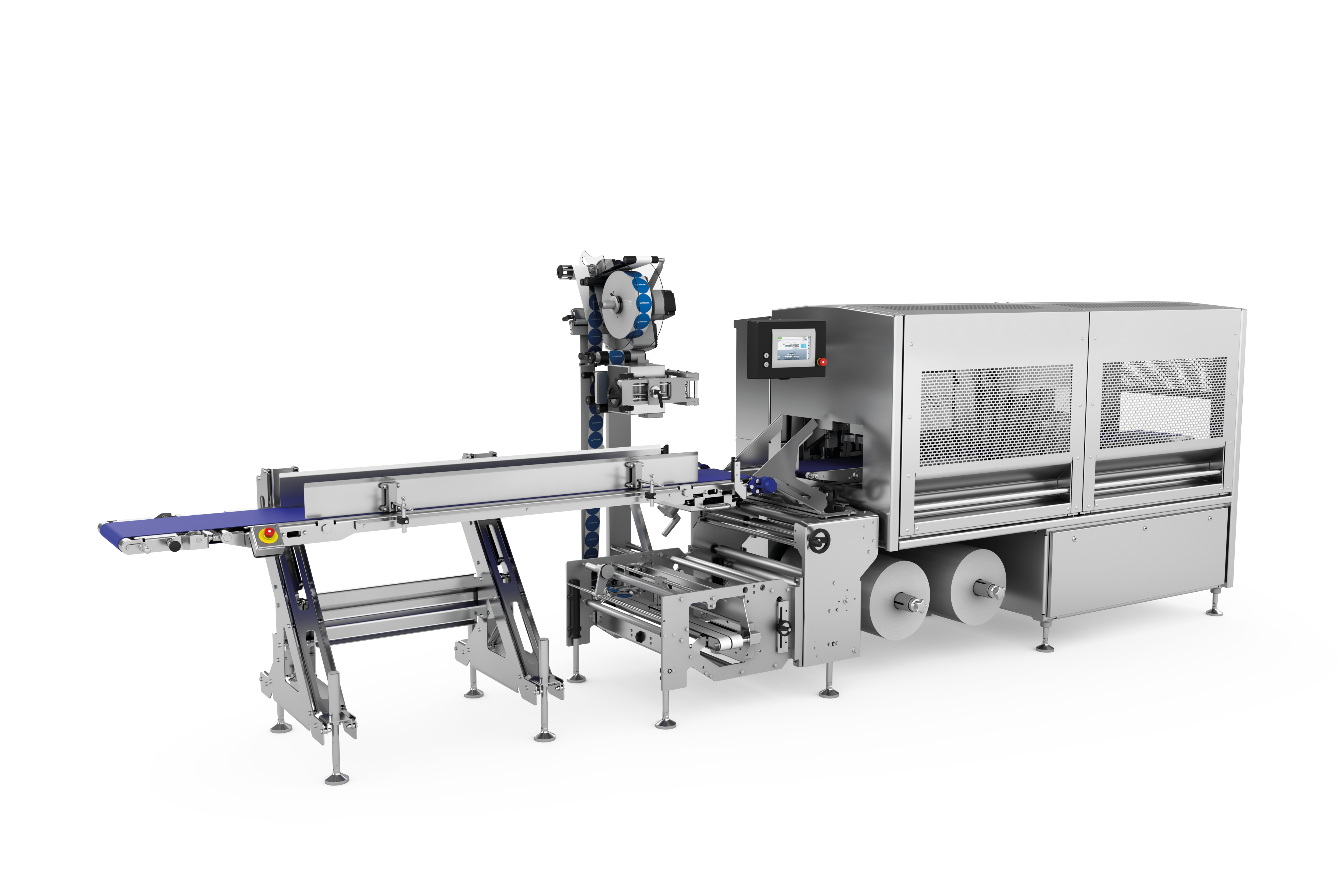

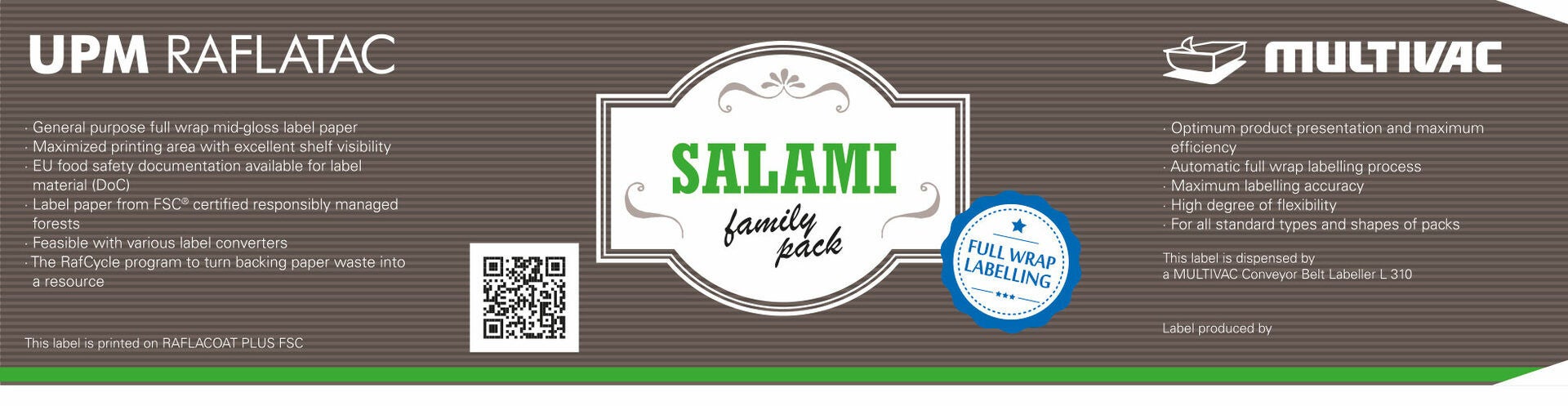

Maximum pack attractiveness with Full Wrap labelling

Full wrap labels offer a broad range of competitive advantages in comparison to other labelling solutions. In addition to their function as an information medium, they are increasingly becoming an important design element of retail packs. This way, they help the brand owners to increase the differentiation of the product at the Point of Sale and to offer further value to the consumer.

Full wrap labels offer a broad range of competitive advantages in comparison to other labelling solutions. In addition to their function as an information medium, they are increasingly becoming an important design element of retail packs. This way, they help the brand owners to increase the differentiation of the product at the Point of Sale and to offer further value to the consumer.

추가 정보

“Tradition is always based on innovation”

For more than a century Albert Spiess AG has been committed to this philosophy. In addition to classics such as "Bündnerfleisch" air-dried meat, dry-cured ham and raw sausage specialities, the company's product range also includes pioneering innovations such as "my ENERGY" snacks.

For more than a century Albert Spiess AG has been committed to this philosophy. In addition to classics such as "Bündnerfleisch" air-dried meat, dry-cured ham and raw sausage specialities, the company's product range also includes pioneering innovations such as "my ENERGY" snacks.

추가 정보

MULTIVAC Packaging Solutions for Meat Products

MULTIVAC Packaging Solutions for Meat Products

Full wrap labelling for maximum pack attractiveness at the POS

Full wrap labels, which enclose all four sides of a pack like a banderole, feature a whole range of competitive advantages over other solutions for labelling and marking. In addition to their function as information carriers, full wrap labels are today also an essential design feature for increasing the appeal of packs on the shelf. They support manufacturers in optimal presentation of their brand and offer consumers real added value.

Full wrap labels, which enclose all four sides of a pack like a banderole, feature a whole range of competitive advantages over other solutions for labelling and marking. In addition to their function as information carriers, full wrap labels are today also an essential design feature for increasing the appeal of packs on the shelf. They support manufacturers in optimal presentation of their brand and offer consumers real added value.

추가 정보